Abstract

Our prior study has shown that polyethylene glycol (PEG) played a crucial role in improving the properties of the physically crosslinked chitosan-PEG-poly(N-isopropylacrylamide) (PNIPAAm) hydrogels. In this paper, we further investigated the effect of the molecular weight (MW) of PEG on the properties of the chitosan-based physical hydrogels. Fourier Transform Infrared Spectroscopy (FTIR) study showed that the interaction between PEG and other components in the physically crosslinked hydrogels became stronger as the MW of PEG increased. The wide angle X-ray diffraction (WAXD) study indicated that the crystallinity of the physical hydrogels decreased with an increase in the MW of PEG. The thermal study using differential scanning calorimetry (DSC) revealed the crystallizability of the physical hydrogels first reduced with an increase in the MW of PEG, but slightly increased thereafter with a further increase in the MW of PEG. The swelling test showed the water uptake capability of the physical hydrogels increased with an increase in the MW of PEG. The results obtained by scanning electron microscope (SEM) found that the morphological changes of the physical hydrogels with MW of PEG were consistent with the results of swelling and thermal properties; and, contrary to pure PNIPAAm hydrogels which showed a compact and dense network structure at a temperature (37°C) above its LCST, the physical chitosan-PEG-PNIPAAm hydrogels exhibited porous network structure at 37°C instead. The mechanical property of the physical hydrogels was initially increased with an increase in PEG MW, but deteriorated with a further increase in PEG MW. Therefore, the MW of PEG played a key role in controlling the property of the chitosan-based physical hydrogels.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Hydrogels are three-dimensional crosslinked polymeric networks that can swell dramatically in the presence of an aqueous medium and retain large amounts of the medium while maintaining their structures. Highly hydrated hydrogels are biocompatible and their structures are very similar to natural tissues, hydrogels thereby found various biomedical and pharmaceutical interests and applications during the past several decades [1, 2].

Currently, a variety of novel crosslinking methods have been employed to prepare different kinds of hydrogels [3]. Crosslinking is one of the key issues for designing hydrogels. Crosslinking in the hydrogel network tie different molecules together and prevent hydrogels from being dissolved in a swelling medium. Based on the nature of crosslinking, hydrogels can fall into two broad categories: chemically or physically crosslinked. Chemically crosslinked hydrogels are the most widely studied because of their easy manipulation by controlling the crosslinking agents, initiator concentration, precursor ratio and concentration as well as the stability of covalent-bond crosslinking. Unfortunately, most crosslinking agents and initiators are toxic, and their residues must be removed or extracted after preparation [3]. Another drawback for some chemically crosslinked hydrogels, such as PNIPAAm hydrogel, is that the crosslinking bonds are non-degradable and thus the resulting hydrogels are non-degradable. Biodegradable hydrogels are desirable for certain biomedical applications, such as the release of large biologically active macromolecules like proteins.

Physically crosslinked hydrogels (referred as physical gels) have the potential to overcome these disadvantages, and they have recently received more research attention [4–7]. During the preparation of physically crosslinked hydrogels, no crosslinking agents or initiators are used, and crosslinkings are usually provided by hydrogen or ionic bonds, van der Waal’s interactions, crystal formation and/or physical entanglements [8–10]. Physically crosslinked systems, however, are not as strong and stable as covalent crosslinked systems and can eventually disintegrate, regardless of whether any hydrogel components are biodegradable or not.

Chitosan is the N-deacetylation product of chitin, a biocompatible and biodegradable polysaccharide, which has long been known for its gel forming ability and has been extensively studied as physical gels [11–14]. Chitosan has many useful properties such as mucoadhesive, antimicrobial, anticoagulation, and immunostimulation. Because of its unusual biological activity, the use of chitosan as drug carriers would have dual therapeutic effects, which makes chitosan a novel drug carrier candidate. Thereby chitosan has been intensively investigated in the biomedical [15] and pharmaceutical fields [16].

In our prior study [11], we reported the fabrication of physically crosslinked hydrogel from chitosan, PEG and PNIPAAm. These chitosan/PEG/PNIPAAm hydrogels had both temperature sensitivity and pH sensitivity. The originally prepared hydrogels from chitosan and PNIPAAm, however, were brittle and showed poor physical and mechanical properties. To improve the properties of the physically crosslinked hydrogels, we incorporated PEG. PEG was chosen to improve the properties of chitosan-based hydrogels because of its flexibility, non-toxicity and biocompatibility. The introduction of PEG significantly improved the mechanical and other properties of the hydrogels. It was found out that the chitosan/PNIPAAms had a reduced crystallinity than each individual component. However, after PEG was introduced, the chitosan/PEG/PNIPAAm gels had a much higher crystallinity. The PEG-induced crystals acted as crosslinkers and had a profound effect on the formation and properties of these physically crosslinked hydrogels.

Because PEG acted as a plasticizer in the chitosan/PEG/PNIPAAm hydrogels, PEG MW is expected to be an important factor that could affect the interactions among the three macromolecular components as well as the crystallization process. In this study, the effect of PEG on the properties of chitosan-based physical hydrogels was further investigated by changing the PEG MW. The property of these physically crosslinked hydrogels was characterized using FT-IR, differential scanning calorimetry (DSC), X-ray diffraction, scanning electron microscope (SEM), mechanical strength and swelling study.

2 Experimental procedures

2.1 Materials

Chitosan (MW 400,000) was purchased from Fluka Chemie AG (Buchs, Switzerland). Acetic acid was purchased from EM Science Industries (Gibbstown, NJ). PEG (MW 2,000, 4,000, 6,000, 8,000, 10,000 and 20,000), benzoyl peroxide (BPO) and N-isopropylacrylamide (NIPAAm) were purchased from Aldrich Chemical Company (Milwaukee, WI); NIPAAm was further purified with benzene/n-hexane by recrystallization before use. Diethyl ether and acetone were purchased from J.T. Baker (Phillipsburg, NJ).

2.2 Hydrogel fabrication

PNIPAAm precursor was first prepared by free radical polymerization in methanol according to our previous method [11, 17]. In brief, the polymerization of NIPAAm (5.65 g, 50 mmol in methanol) in a 150 ml flask under dry nitrogen atmosphere was initiated by BPO (0.242 g, 2.0 mol% based on NIPAAm) at 70°C and lasted for 24 h. After polymerization, the resulting product was precipitated in excess of diethyl ether. The product was further purified by dissolution in acetone and precipitation in diethyl ether three times. The purified product was dried in vacuum at room temperature for 24 h prior to further use. PNIPAAm of molecular weight 33,000 was thus obtained.

All physically crosslinked chitosan/PEG/PNIPAAm hydrogels were prepared by the dissolution/evaporation method as described in our previous study [11]. In that prior study, we found that the hydrogel samples at the concentration of 0.6 g/70 ml during fabrication had a higher and faster swelling, and some swollen hydrogels even fractured upon swelling. However, a lower concentration can facilitate the formation of thin gels with a more compact structure [18], which could slow down the swelling. In this study, to testify the hypothesis, the solution concentration was reduced to 0.3 g/70 ml instead of 0.6 g/70 ml. Briefly, 0.3 g of blended chitosan/PEG/PNIPAAm with different MW of PEG at the feed ratio of 70/20/10 was dissolved in 70 ml acetic acid solution (2% v/v). The solution was shaken for 2 days and was then filtered using a glass Buchner funnel to remove any undissolved materials. The hydrogels were obtained by casting this solution onto petri dishes (100 × 10 mm) and dried for 2 days in a fume hood. The resulting hydrogels were further dried in vacuum for 2 days at room temperature. A series of hydrogels with thickness from 0.1 to 0.4 mm were prepared and the obtained hydrogels were designated as fresh ones. The composition of the chitosan/PEG/PNIPAAm hydrogels was expressed as CGN#, and # was referred to the MW of PEG here. For example, the chitosan/PEG/PNIPAAm hydrogel with PEG MW 2000 was labeled as CGN2000.

2.3 FTIR analysis

FTIR (Nicolet Magna 560, Madison, WI) was used to study the interactions among the components of the fresh gels. The fresh gel samples were directly placed on the horizontal Attenuated Total Reflectance (ATR) attachment of a Nicolet Magna 560 FTIR for recording IR spectra. The pure chitosan gel was characterized by the ATR method as the control. Pure PEG or PNIPAAm powders, yet were mixed with KBr powder (1/10, w/w) and compressed into pellets for regular FTIR measurement (without ATR).

2.4 X-ray diffraction

The crystalline characteristics of the physical hydrogels were studied using a wide angle X-ray diffractometer (WAXD, Scintag, Cuttertino, CA). In this study, the WXAD patterns were obtained under the condition of 45 KV and 40 mA with a continuous scan mode at the speed of 2.5°/min from 5° to 35°. The pure chitosan and other physical hydrogels were horizontally mounted on the holder and tested.

2.5 DSC measurement

The thermal property of the physical hydrogels were measured by DSC (2920 modulated DSC, TA instruments, CA). The fresh hydrogel samples were cut into small pieces, and about 10 mg each of the hydrogel sample were placed inside an aluminum sample pan. An empty sample pan was used as the reference. The thermal analysis was performed from 30 to 300°C at the heating rate of 10°C/min under dry nitrogen atmosphere with a flow rate of 25 ml/min. TA universal analysis software was used for data acquisition and analysis. The crystallization peak was referred as the crystallization transition temperature (T c).

2.6 Swelling test

The swelling property of hydrogels was gravimetrically studied. A known weight of the hydrogel sample was immersed in distilled water at 37°C. The swollen hydrogels were removed at predetermined intervals and weighed after wiping off the excess water on the hydrogel surface with a wet filter paper. The swelling ratio is defined and calculated as below:

where W t is the weight of swollen hydrogel at time t, and W d is the weight of dry hydrogel before immersion in water.

2.7 Morphological study

The surface morphological changes of the swollen hydrogels at 37°C were studied using scanning electron microscope (SEM, Leica Cambridge Stereoscan 440, Cambridge, UK). Small pieces of the hydrogels (10 × 10 mm) were cut and immersed in distilled water for 3 h at 37°C. The swollen gels were then freeze-dried for 3 days prior to SEM observation. The specimens were mounted onto aluminum stubs with double side carbon tape and sputter-coated with gold for 30 s (JFC-1200 Fine Coater, Japan).

2.8 Mechanical properties

The tensile property of all physical hydrogels was measured by Instron (model 1122, Instron Corporation) at the condition of 22°C and 65% relative humidity. The specimens were cut into 10 mm wide, 70 mm long stripes. The width and thickness were measured three times at three different positions respectively for each sample, and the averages were then obtained. The gauge length of the Instron was set to 40 mm and the crosshead speed was 50 mm/min. The stress, strain and toughness were used to evaluate the mechanical property of the physical hydrogels.

3 Results and discussion

3.1 FTIR analysis

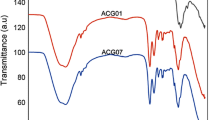

FTIR was used to investigate molecular interactions and the change of physical state of the blended chitosan/PEG/PNIPAAm gels. Figure 1 shows the spectra of individual polymer components and their physically crosslinked fresh hydrogels at the feed ratio of CGN70/20/10 with different MW of PEG. The IR peaks at 842 cm−1 (1 & 2) and 1,344 cm−1 (3 & 4) are the characteristic peaks of PEG and were from its crystalline regions [19]. The absorbance peak at 1,650 cm−1 (peak 5) is the amide I of PNIPAAm, and the peak at 1,630 cm−1 (peak 6) is amide I of chitosan. However, after blending, these two peaks shifted medially and only one peak at 1,642 cm−1 (peak 7) appeared, which suggests that PNIPAAm and chitosan have good intermolecular interactions, i.e., they are miscible and compatible [11].

The molecular structure of a plasticizer, such as chemical composition and molecular weight, plays an important role in polymer-to-polymer interactions [20]. The MW of PEG is an important factor that affects the molecular interactions of the blended chitosan/PEG/PNIPAAm and the corresponding hydrogel property. Due to a higher number of polar hydroxyl end groups, low MW PEGs could lead to a higher degree of plasticization. Higher MW PEG plasticizer, however, provides many different types of interactions with chitosan and PNIPAAm. For example, higher MW PEG would not only have more opportunity to entangle with chitosan and PNIPAAm, but also would interact with PEG chain itself. The data in Fig. 1 shows that the relative intensity of the PEG crystalline absorbance peaks at 842 (peak 2) and 1,344 cm−1 (peak 4) increased as the PEG MW increased from spectrum D (CGN2000) to spectrum G (CGN20000). PEG in CGN2000 showed no distinct crystalline peaks, which is consistent with our previous study [11], however, the PEG crystalline peaks increased dramatically when PEG MW increased to 6,000 and above. Since the intensity of these two peaks is directly proportional to the degree of the crystallinity of PEG, an increase in the relative intensity of these two peaks indicated an increase in PEG crystallinity.

As a polar plasticizer, low MW PEG interacts with both chitosan and PNIPAAm components in the chitosan/PEG/PNIPAAm blends and weakens the physical crosslinking between chitosan and PNIPAAm, thus improving the properties of the hydrogels at the expense of retarded chain mobility of PEG molecules. Such a retardation of chain mobility of low MW PEG in the chitosan/PEG/PNIPAAm blend could make PEG molecules more difficult to organize into an orderly structure, i.e., a lower level of crystallization. This is why the FTIR data did not show distinct sign of PEG crystals in CGN2000. However, PEG itself is a highly crystallizable polymer. When PEG MW is high enough, due to the relatively smaller numbers of polar hydroxyl end groups, the interaction between a higher MW PEG with chitosan and PNIPAAm macromolecules would be lesser and the free PEG chain segments could be present in the blend, which would help PEG chains to reorganize themselves relatively more freely to crystallize as evidenced by the higher PEG crystallinity in the CGN20000 blend.

3.2 X-ray diffraction

The X-ray diffraction patterns of the CGN hydrogels with different MW of PEG are shown in Fig. 2. The diffraction pattern of the physical hydrogels is a collective result of blend constituents: chitosan, PNIPAAm and PEG; and the relative intensity of the crystalline peaks in the X-ray data decreased with an increase in PEG MW from CGN2000 (spectrum A) to CGN20000 (spectrum D). Our prior study showed that pure low MW PEG (2,000) exhibited very strong and distinctive diffraction peaks at 2θ = 19.1° and 23.3°, but such characteristic PEG crystalline peaks disappeared in the blending gels [11]. In this study, similar results were also observed in both CGN2000 (spectrum A) and CGN6000 (spectrum B) hydrogels, i.e., the lack of distinctive and characteristic PEG crystalline peaks. However, CGN10000 (spectrum C) and CGN20000 (spectrum D) exhibited a very weak peak at 2θ = 23°, indicating few PEG crystalline regions formed. The presence of weak PEG crystalline peaks in a blend was also reported by Kolhe et al. [19] who studied the blending of chitosan and high MW PEG (10,000). The X-ray diffraction results in this study are consistent with the FTIR results, i.e., PEG component becomes crystallizable in a chitosan/PEG/PNIPAAm blend when PEG MW is high enough.

The physical hydrogel crystallinity highly relies on the MW of PEG. As a polar plasticizer, low MW of PEG would not only weaken the interaction between chitosan and PNIPAAm, but also could generate additional space between chitosan and PNIPAAm to facilitate their crystallization. However, as the MW of PEG increases, there are stronger interactions between PEG, chitosan and PNIPAAm, which would retard the chain mobility of PEG [19, 21], chitosan and PNIPAAm. Such retardation on chain mobility inhibited the crystal growth of each component in the hydrogels, which led to the lower crystallinity of the hydrogels. As a result, the crystallinity of the hydrogel CGN10000 and CGN20000 is much lower than CGN2000 and CGN6000.

Meanwhile, unlike low MW PEG, which completely lost its crystallinity, the high MW PEG (i.e. MW 10,000 or 20,000) has a longer chain and less interrupted PEG chain segments in the gels. Those chain segments still had some mobility and could fold and rearrange to ordered positions, thus leading to the appearance of the characteristic crystallization of PEG.

3.3 DSC measurement

The thermal properties of the physical hydrogels were measured by DSC and their results are shown in Fig. 3. It shows that the chitosan/PEG/PNIPAAm hydrogels had distinctive exothermal peaks ranging from 168 to 195°C. These exothermal peaks were attributed to crystallization of the blended hydrogels. The appearance of a crystallization peak demonstrated that the blended chitosan/PEG/PNIPAAm hydrogels are crystallizable and these data were consistent with the X-ray diffraction data shown in Fig. 2. The crystallization temperature, T c, first increased with an increase in PEG MW (from 168°C of CGN2000 to 195°C of CGN10000), but reduced to 177°C as PEG MW reached 20,000.

As discussed earlier, the polar plasticizer PEG could weaken the interactions between chitosan and PNIPAAm. Upon heating, both chitosan and PNIPAAm macromolecules that are free from mutual interactions could gain enough thermal energy to rearrange themselves to form thermally stable crystals. In the case of physically crosslinked hydrogels having low MW PEG, the intermolecular interaction between PEG, chitosan and PNIPAAm was comparatively weak; thus, chitosan and PNIPAAm were less restricted from entanglement/interaction with PEG and can migrate with relative ease and rearrange for crystallization with little external energy, i.e., lower crystallization temperature. As the MW of the PEG component in the blend increased, the interaction between PEG and chitosan and PNIPAAm would become stronger due to more molecular entanglement. As a result, a higher external energy would be required to break this interaction, i.e., higher crystallization temperatures with an increase in PEG MW as shown in Fig. 3. However, when the MW of PEG increased up to 20,000, T c of the blend decreased. It is not clear what mechanism is behind this reduction of crystallization temperature after PEG MW reached 20,000. Our guess is that when PEG MW is high enough, its chain behaves more like ideal freely jointed chain, i.e., equivalent freely jointed chain. When PEG molecular chains were long enough in the blending, though the interaction could make the segments of the equivalent freely jointed chains longer, they still could rearrange their positions to form thermally stable crystals when gaining enough energy, thus causing the T c of CGN20000 lower than some blended with middle MW PEG physical hydrogels.

3.4 Swelling tests

Figure 4 shows that the equilibrium swelling ratio of the CGN hydrogels as a function of PEG molecular weight at 37°C. The swelling ratio of the hydrogels increased as the MW of PEG increased. For instance, the equilibrium swelling ratio of CGN hydrogels increased from 145% (CGN2000) to 450% (CGN20000) when the MW of PEG increased from 2,000 to 20,000. This PEG MW effect on swelling ratio could be attributed to the decrease of the level of crystallinity of the physical gels as the MW of PEG increased. As the level of crystallinity of the CGN physical hydrogels decreased, a lesser crystalline structure would be available to provide physical crosslinking of the network structure, i.e., leading to a more open and porous network with a higher swelling ratio.

Our prior study showed the physical hydrogel CGN2000 had a much higher swelling ratio (500%) at the feed concentration of 0.6 g/70 ml at 37°C, while the swelling ratio of the CGN2000 hydrogel at the feed concentration of 0.3 g/70 ml is only 145%. This difference proved our hypothesis and also supported the statement that that the lower concentration facilitates the formation of thin gels with compact structure [19]. Under such a compact structure, the macromolecules are more tightly interacted with each other, so water molecule is hard to penetrate and diffuse into the hydrogel network, resulting in the lower equilibrium swelling ratio.

Due to the physically (not chemically) “crosslinked” hybrid hydrogel system in this study, it is not practical to conduct temperature-induced deswelling/swelling cycle study. This is because some thermoresponsive PNIPAAm components in such a physically crosslinked hybrid gels could leach out during the deswelling/swelling cycles. As a result, the thermoresponsivity of the hybrid gels would lose their temperature sensitivity due to the loss of their thermoresponsive component upon cycling, i.e., no swelling and deswelling upon temperature change.

3.5 Morphological study

Figure 5 shows the SEM images of the freeze-dried hydrogels swollen at 37°C (>LCST). The images clearly show that the gels have a very compact structure, and only CGN6000 (B) shows clear 3-D pores. CGN2000 (A) shows few pores generated during the swelling due to the shrinkage of PNIPAAm in the hydrogel, while CGN6000 (B) has much more pores formed (1.1 ± 0.6 μm); CGN10000 (C) and CGN20000 (D) had very few pores.

The different morphological appearance of the swollen hydrogels at 37°C is well consistent with the swelling behavior and thermal property. The pore-forming mechanism of the physically crosslinked gels is different from chemically crosslinked gels, and is attributed to the different swelling behaviors between PNIPAAm and other components within the blends (chitosan and PEG). Chitosan and PEG have no thermo-responsive property and swell regardless of temperatures. When temperature reaches its LCST or higher, the PNIPAAm component in the blended physical gels dehydrates and shrinks, thus phase separation happens between PNIPAAm and its adjacent chitosan and PEG materials due to different swelling ratio. Because of the PNIPAAm shrinkage and phase separation, pores were formed in the blended gels. As for CGN2000, due to its high crystalline regions, i.e., higher crosslinking level, the swelling is limited, and very few pores formed. For CGN6000, the swelling ratio of this hydrogel increased due to the reduced crystallinity of the physical hydrogel, and this increased swelling has facilitated the formation of bigger and more pores. As for CGN10000 and CGN20000 hydrogels, due to the increase of the MW of PEG, however, the interactions between PEG and PNIPAAm and chitosan become stronger, which limits the mobility of PNIPAAm molecules, PNIPAAm becomes harder to adjust its position even at a temperature >LCST, i.e., no coil-globule phase transition. So, very few pores were found in both CGN10000 and CGN20000.

The formation of pores in the blended chitosan/PEG/PNIPAAm hydrogels at 37°C (greater than the LCST of PNIPAAm) (Fig. 5) is quite different from the temperature-dependent morphology of pure PNIPAAm gels. A pure PNIPAAm gel is well known to show dense compact morphology at 37°C because of the collapsed PNIPAAm network structure at the temperature above its LCST [22–25]. Thus, the data in Fig. 5 show that we could design a new gel system having thermo-responsive PNIPAAm element but exhibit porous network structure at a temperature above the LCST of the PNIPAAm component, and the MW of PEG was a key factor in the formation of such thermo-responsive chitosan/PEG/PNIPAAm hydrogels.

3.6 Mechanical properties

The effects of the MW of PEG on the mechanical property of the physical hydrogels are shown in Figs. 6 and 7. The data in these figures show that the stress, strain and toughness of the CGN hydrogels first increased with an increase in PEG MW, then deteriorated with a further increase in the MW of PEG. For example, when PEG MW increased from 2,000 to 6,000, the stress and strain increased about 11% (36 to 40 MPa) and 86% (22 to 41 MPa), respectively. However, with the further increase of PEG MW, i.e., 6,000–20,000, the stress and strain dropped about 38% (40 to 25 MPa) and 17% (41 to 34 MPa), respectively. The toughness has a slight increase at 6,000, but dropped dramatically (13.5 to 5 MPa) with the further increase of PEG MW.

There are two factors that contribute to the mechanical property of these hydrogels: level of crystallinity and intermolecular force. In the case of hydrogel CGN2000, it has a higher crystallinity, but intermolecular forces, like van der Waals force and entanglement, between PEG and chitosan/PNIPAAm are weak because of the shorter PEG chain. As the MW of PEG increases to 6,000, intermolecular forces between PEG and other molecules are strengthened without noticeable expenses of crystalline domains, and this combined effect resulted in an increase in hydrogel mechanical property. However, with a further increase of PEG MW, the crystallinity of the physical hydrogel was largely reduced and the hydrogels had to rely on intermolecular forces to provide mechanical property, i.e., lower mechanical property as observed. There is a competition between the MW of PEG with the crystalline regions.

The strain has a similar change to stress change with an increase in PEG MW. The increase of the MW of PEG led to the decrease of crystallinity in the hydrogels. The crystalline domains acted as physical crosslinkers, which governs the elongation of crosslinked materials. CGN2000 had a higher crystallinity, thus it has relatively lower elongation. The relatively higher elongation of CGN6000 and CGN10000 may also be attributed to the reduced crystallinity. However, as the MW of PEG reached 20,000 in CGN20000 hydrogel, the intermolecular forces and molecular entanglement would reach the level that could retard the uncoiling of macromolecular conformation under force, i.e., lower elongation.

Figure 7 shows toughness drops dramatically. It’s known that toughness is inversely proportional to brittleness, and a decrease of toughness means an increase in brittleness. Figure 7 indicates the gels become brittle as the MW of PEG increases. Our previous study indicated the addition of PEG improved the toughness of the hydrogels. As the content of PEG is constant in the blending, the increase of MW of PEG means the decrease in the number of PEG end groups in the blending. The number of end groups is an important factor for polar plasticizer, and such reduction led to low plastic efficiency. Therefore, the increase of the MW of PEG caused a lower plasticization effect in the blending, i.e., the increase in brittleness.

4 Conclusion

In this study, the effect of MW of PEG on the properties of CGN hydrogels was investigated. The FTIR analysis revealed that the low MW PEG lost the crystallization ability, while the high MW PEG still had some crystallinity in the CGN hydrogels. The further X-ray diffraction study showed that crystallization of the physical hydrogels became difficult due to the retardation of the stronger intermolecular force between PEG and chitosan and PNIPAAm with the increase of the MW of PEG. DSC data also indicated that the crystallization of the physical hydrogels became difficult as the MW of PEG increased, evidenced by the increase of crystallization temperature (T c), even though T c has a drop. The crystallization change of physical gels had an immediate effect on the swelling property of the hydrogels, and the swelling ratio of the hydrogels increased due the reduction of crystal crosslinks. The SEM study found that morphology of the hydrogels changed with the increase of the MW of PEG and the result is well consistent with the results of swelling and thermal studies. The mechanical property is the results of counter balance between crystallization and the intermolecular force. In a word, the MW of PEG plays a key role in property of the hydrogels. Consequently, the choice of appropriate MW of PEG is an important in the formulation of the physical hydrogels.

References

B.D. Ratner, A.S. Hoffman, ACS Symposium Series. 31 (American Chemical Society, Washington, 1976), pp. 1–36

R. Langer, N.A. Peppas, AIChE J. 49, 2990 (2003)

W.E. Hennink, C.F. Van Nostrum, Adv. Drug Delivery Rev. 54, 13 (2002)

Y. Ikada, K. Jamshidi, H. Tsuji, S.H. Hyon, Macromolecules 20, 904 (1987)

K. Nakamae, T. Miyata, A.S. Hoffman, J. Biomater. Sci. Polym. Ed. 6, 79 (1994)

T. Inoue, G.H. Chen, A.S. Hoffman, K. Nakamae, J. Bioact. Compat. Polym. 13, 50 (1998)

B. Jeong, S.W. Kim, Y.H. Bae, Adv. Drug Delivery Rev. 54, 37 (2002)

K. Kamath, K. Park, Adv. Drug Delivery Rev. 11, 59 (1993)

D. Campoccia, P. Doherty, M. Radice, P. Bum, G. Abatangelo, D.F. Williams, Biomaterials 19, 2101 (1998)

G.D. Prestwich, D.M. Marecak, J.F. Marecak, K.P. Vercruysse, M.R. Ziebell, J. Control Rel. 53, 93 (1998)

G. Sun, X.Z. Zhang, C.C. Chu, J. Mater. Sci. Mater. Med. 18, 1563 (2007)

S.Y. Kim, S.M. Cho, Y.M. Lee, S.J. Kim, J. Appl. Polym. Sci. 78, 1381 (2000)

X.L. Yan, E. Khor, L.Y. Lim, J. Biomed. Mater. Res. 58, 358 (2001)

M.Y. Cheng, J.U. Deng, F. Yang, Y.D. Gong, N.M. Zhao, X.F. Zhang, Biomaterials 24, 2871 (2003)

V. Dodane, V.D. Vilivalam, Pharm. Sci. Technol. Today 1, 246 (1998)

D.K. Singh, A.R. Ray, J. Macromol. Sci. Rev. Macromol. Chem. Phys. C40, 69 (2000)

X.Z. Zhang, C.C. Chu, J. Appl. Polym. Sci. 89, 1935 (2003)

S. Zohrehvand, R. Cai, B. Reuvers, K.T. Nijenhuis, A.P.D. Boer, J. Coll. Int. Sci. 284, 120 (2005)

P. Kolhe, R.M. Kannan, Biomacromolecules 4, 173 (2003)

K.Y. Lim, D.H. Kim, U. Paik, S.H. Kim, Mater. Res. Bull. 38, 1021 (2003)

W. Zhao, L. Yu, X. Zhong, Y. Zhang, J. Sun, J. Macromol. Sci. Phys. B34, 231 (1995)

X.Z. Zhang, C.C. Chu, J. Mater. Chem. 13, 2457 (2003)

X.Z. Zhang, C.C. Chu, J. Polym. Sci. Polym. Phys. 41, 582 (2003)

X.Z. Zhang, C.C. Chu, Coll. Polym. Sci. 282, 589 (2004)

X.Z. Zhang, C.C. Chu, Polymer 46, 9664 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, G., Zhang, XZ. & Chu, CC. Effect of the molecular weight of polyethylene glycol (PEG) on the properties of chitosan-PEG-poly(N-isopropylacrylamide) hydrogels. J Mater Sci: Mater Med 19, 2865–2872 (2008). https://doi.org/10.1007/s10856-008-3410-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-008-3410-9