Abstract

Microspheres have been prepared from the resorbable linear polyester of β-hydroxybutyric acid (polyhydroxybutyrate, PHB) by the solvent evaporation technique and investigated in vitro and in vivo. Biocompatibility of the microspheres has been proved in tests in the culture of mouse fibroblast cell line NIH 3T3 and in experiments on intramuscular implantation of the microspheres to Wistar rats for 3 months. Tissue response to the implantation of polymeric microspheres has been found to consist in a mild inflammatory reaction, pronounced macrophage infiltration that increases over time, involving mono- and poly-nuclear foreign body giant cells that resorb the polymeric matrix. No fibrous capsules were formed around polymeric microparticles; neither necrosis nor any other adverse morphological changes and tissue transformation in response to the implantation of the PHB microparticles were recorded. The results of the study suggest that polyhydroxybutyrate is a good candidate for fabricating prolonged-action drugs in the form of microparticles intended for intramuscular injection.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Designing of controlled-release drug delivery systems is a promising and rapidly developing line of pharmacology. The main advantage of using drug delivery systems is that drug concentration in a patient’s blood and/or tissues can be maintained at a target level for an extended time [1, 2]. The principal requirement for fabricating prolonged-action controlled-release drug delivery systems is availability of an appropriate material, which must be absolutely harmless to an organism and possess the necessary physical–mechanical and biomedical properties, including degradability in biological media. At the present time, the most widely used and actively developed bioresorbable materials are polymers of monocarboxylic acid derivatives (polylactides and polyglycolactides), which have recently been joined by linear polyesters of microbiological origin—polyhydroxyalkanoates (PHAs) [1, 3].

PHAs are good candidates for fabrication of drug delivery systems [4–6], because they possess all the properties required of materials for these systems. These polymers are biocompatible and inert towards animal tissues; in biological environments they are degraded to end products (CO2 and H2O). In contrast to other materials that are widely used in controlled drug delivery, such as gelatine, proteins, polylactide and poly(ethyleneglycol)-poly(d,l-lactide), PHAs are available in a chemically pure form [7, 8] and their degradation rate in biological media is low. By varying the chemical structure of PHAs or blending them with different materials, one can control porosity and degradation rate of the polymeric matrix and, hence, the rate of drug release.

At the present time, biodegradable carriers are used to prepare pain killers, antidepressants, contraceptives, anticancer and anti-inflammatory drugs [9–11].

The most promising drug delivery systems are biodegradable microspheres and microcapsules. Microparticles can be used as delivery systems for a very wide range of drugs; the release profile can be controlled rather easily; they can be injected into the bloodstream, subcutaneously, and intramuscularly and adapted for oral administration or inhalation [5, 12]. The currently available literature describes methods of fabricating microspheres from PHAs, mainly hydroxybutyrate and its copolymers with hydroxyvalerate, using solvent evaporation technique [13, 14], aerosol solvent extraction process [15], and monomer polymerisation [14, 16].

Microspheres are considered to be the best form for injection-delivered prolonged-action drugs. However, microspheres, though containing a small amount of biomaterial, have a large surface area and, being injected subcutaneously or intramuscularly, come in contact with extensive area inside the host organism, which can cause stronger tissue reaction [17, 18].

The biocompatibility of polyhydroxybutyrate (PHB, the most widespread and best studied PHA) has been confirmed in vitro, in cultures of cells of various origins [19–21]. Rather few results have been reported on in vivo biocompatibility of PHB, including data on local tissue reaction to polyhydroxybutyrate and poly(hydroxybutyrate/hydroxyvalerate) implants [22, 23]. However, those investigations were performed using large implants, in the form of sutures, film grafts or pins [3, 24]. It is well-known, though, that biocompatibility of biomaterials depends not only on the chemical structure and purity of the specimens but, to a large extent, on the size and shape of the implant [17].

The purpose of this study was to test biocompatibility of polyhydroxybutyrate microparticles in vitro and in vivo.

2 Materials and methods

2.1 Preparation of pure PHB polymer

The tested material was the PHB samples synthesized by the bacterium Ralstonia eutropha B5786 (Mw 340 000 Da, crystallinity 70–78%). The strain is registered in the Russian Collection of Industrial Microorganisms. The culture technique was described elsewhere [25]. P(3HB) (C4H6O2) is a homopolymer of D(-)-3-β-hydroxybutyric acid, an isotactic polyester with regular (C4H6O2) units. PHB is extractable from bacterial biomass due to its ability to dissolve in organic solvents and to be then precipitated by alcohols. PHB was extracted from bacterial biomass with chloroform and precipitated with ethanol. The extraction of PHB from biomass was conducted in several stages. In the first stage, to partially destroy the cell wall and attain a fuller extraction of lipids, the bacterial biomass was centrifuged (for 15 min at 6,000 rpm), collected, and covered with ethanol, pH 10.5-11.0 (0.5–0.7 g KOH/L ethanol). The sample was boiled using a backflow condenser for 30 min. Then the alcohol was removed, the biomass was covered with 86% ethanol and separated from alcohol by centrifuging. In the next stage the partly destroyed and defatted biomass was covered with chloroform and boiled for 30–40 min using a water bath with a backflow condenser. The sample was cooled and placed into a funnel to separate the chloroform extract of the polymer from the biomass. After separation of the phases, the polymer was precipitated by adding ethanol as a reagent. The procedure of re-dissolution and further precipitation of polymer was repeated several times to prepare specimens that would not contain organic impurities of protein, carbohydrate or lipid nature. All the organic solvents used in the procedure were preliminarily distilled to remove impurities. We have previously shown that this procedure can be used to prepare high-purity PHB specimens, which would not contain any organic impurities—components of bacterial biomass—and would exhibit excellent biocompatibility characteristics, allowing them to contact with blood [26]. The trademark of the material is BIOPLASTOTAN [27].

2.2 Preparation of microspheres

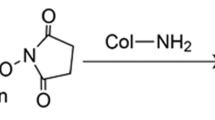

PHA-based microspheres were prepared by the solvent evaporation technique, using a triple emulsion. 600 mg of the polymer (PHB) and 200 mg of polyethylene glycol (PEG40, molecular mass 40 kDa) were dissolved in 10 mL of dichloromethane at 40 °C. Then, 1 mL of a 6% gelatin solution (40 °C) was added and the mixture was shaken vigorously. The resulting water/oil (W/O) double emulsion was allowed to cool to room temperature and, then, it was gradually poured into 150 mL of a 0.5% PVA solution, which was stirred with a three-blade propeller at 700 rpm, for 20 min, to obtain a triple (water/oil/water, W/O/W) emulsion. The emulsion was continuously mixed mechanically for 24 h, until the solvent was completely evaporated. Microspheres were collected by centrifuging (at 10,000 rpm, for 5 min), rinsed 7–8 times in distilled water, and freeze dried in an LS-500 lyophilic dryer (Russia).

Here we used the following sterilization technique: an aliquot of microspheres was suspended in physiological saline, the suspension was poured into sterile Eppendorf tubes and sterilized by autoclaving at 0.5 atm for 30 min. Then all harvested microspheres were used for the in vitro and in vivo investigations.

2.3 Microspheres characterization

The size (mean diameter) and the size distribution of microspheres were determined with an Automatic Particle Counter + Analyser system (Casy TTC, Scharle System GmbH, Germany). Approximately 2 mg of microspheres were suspended in 10 mL CASY®ton (electrolyte developed specifically for counting and aspirating particles through a precision measuring pore of defined geometry at a constant flow speed) and measured in capillary tubes with diameter of 150 μm. Each sample was measured in triplicate. The obtained size distribution was used to describe the particle size.

The structure of microspheres surfaces was analyzed by electron microscopy. The samples were placed on the microscopic stage, coated with carbon and aluminum in a JEE-4C vacuum evaporator and studied using a JEM-100C electron microscope with an EM-ASID-4 raster attachment (Japan).

2.4 In vitro cytotoxicity of microspheres

After sterilization, microspheres were tested for cytotoxicity towards the viability, growth, morphology and metabolism of fibroblasts. The cytotoxicity test was conducted according to the ISO 10993 standard. MEM Elution-Test on Extracts was conducted according to the ISO 10993-5 standard: in this study, 100 mg of the dry microspheres (equals at least 120 cm2) were extracted at 37 °C for 24 h in 20 mL of Minimum Essential Medium (MEM) supplemented with 10% fetal calf serum. As a positive control we used red technical rubber, RFSS (the Russian Federation state standard)—5496-78 [28]. This standard corresponds to the European analogue of the cytotoxic positive control—Para rubber [29]. As a negative control 60 cm2 of polystyrene “Greiner bio-one” was used. The maximum negative control was cells cultured in standard medium.

An extract was prepared from the test material, which was then placed on cell monolayers. The cells were examined for morphologic changes and cytolysis to determine a toxicity score. The objects used were cultured cells: mouse fibroblast cell line NIH 3Т3, which belongs to the least transformed cell lines and retains many features of normal diploid cells. Fibroblasts of line NIH 3Т3 were cultured in DMEM medium supplemented with 10% FCS (RPA “Vector”, Novosibirsk), 1.0 mM l-glutamine, 10 mM HEPES, and 100 μg/mL kanamycin sulfate (BDSL, UK). Cells were cultured in a humidified atmosphere at 5% CO2 at 37 °C. The duration of experiments ranged from 4 h to 3 days. The cell count increased after the cells were passed two or three times using 0.2% collagenase solution diluted with a 0.02% versene solution. All stages were conducted under sterile conditions. After exposure to the extract for 72 h at 37 °C the medium was removed, leaving a film of medium in each well, and the cells were examined and scored microscopically for cytotoxic effects: cell viability, change of cellular morphology and cell doubling time. For cytological investigations, fixed and incompletely dried cells were Giemsa stained in astandard Jurr 65500 buffer at pH 6.8 and examined under a microscope with an H190/1.30 immersion objective and a PKIOX ocular. The grades of cytotoxicity are given in Table 1 [29]. Preliminarily, cell viability was estimated by live staining with trypan blue (0.5% stain solution in 0.85% NaCl).

Cell metabolic activity was measured at 3 days using 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium bromide (MTT) assay [30]. Serum free medium of 800 μL and 80 μL MTT solution (5 mg MTT/mL in phosphate buffer saline) were quickly added to each sample and incubated for 3 h at 37 °C until formazan crystals were formed in cells. The medium and MTT were replaced by 800 μL 10% sodium dodecyl sulfate (SDS) in 0.01 M HCl to dissolve the formazan crystals. Formazan concentrations were quantitatively determined by measuring the optical density (OD) at 570 nm against SDS solution blank. Each sample was measured thrice. The number of living cells in the culture was determined from the MTT absorbance standard curve. The mean OD570 value of the positive control is standardized as 100% inhibition. The mean OD570 value of a test sample is expressed as % of inhibition, resulting in a cytotoxicity grade (Table 1).

2.5 Animal model

In vivo experiments were conducted on sexually mature female Wistar rats (200–240 g each). The rats were kept in a vivarium and fed a standard diet in accordance with the directive “Using animals in space biology and medical studies” [31]. As control, intact animals were used. Sterile microspheres (20 mg in 0.3 mL of a physiological saline) were injected intramuscularly into the femurs of the rats. At 24 h after injection and then every week, three animals were sacrificed by using an overdose of diethyl ether as volatile anesthetic. The general tissue reaction to implanted microspheres was investigated using conventional histological techniques. The microspheres were removed with excess surrounding tissue; the samples were fixed in 10% formalin and embedded in paraffin; 5–10 μm thick microtome sections were stained with hematoxylin and eosin.

To prepare semithin sections, tissue samples were fixed in 2.5% glutaraldehyde in 0.1 M cacodylate buffer at pH 7.2; then they were additionally fixed in a 1% OsO4 solution in the same buffer. The samples were dehydrated in graded series of ethanol and in acetone; then they were embedded in Epon 812-Araldite M resin (“Serva”). Semithin (1.5 μm thick) sections were cut using a Reichert Um-03 ultramicrotome (Austria) and then stained with 1% methylene blue. A Carl Zeiss Image Analysis System (Germany) was used for viewing microscopic images and analyzing morphometric characteristics of sections (ocular 10, objectives 10 and 40). The slides were evaluated for intensity and duration of inflammation, infiltration of cells at the site of microspheres injection, and the state of implanted microspheres [23]. Assessment of the activity of cell elements was based on their average number in the field of view, with 10 fields of view analyzed. The estimated parameters were: the dynamics of formation and thickness of the fibrous capsule (fc): the parameter shows the intensity of the connective tissue reaction in the area of implantation; the number of fibroblast rows (fr) in fc—an indication of the activity of production reaction at the site of implantation; the number of neutrophiles (n) in the site of injection, as a inflammatory parameter; the number of macrophages (m), as an indication of the implant biodegradation rate. Also, we counted the number of FBGCs’ (foreign body giant cells) nuclei. These parameters, too, are indicative of material biodegradation [32].

The starting quantitative data for morphometry were obtained as follows. The sample was placed into the substage of the microscope stage so that the examined portion of the capsule was in the field of vision when it was moved horizontally and vertically. The objective was moved along the zone of injection and measurements were taken. The eyepiece micrometer was used to measure the total thickness of a fc and to count the fr and the number of m, n, and fbgc nuclei in 10 fields of vision. At the same time, using an electron ruler in the monitor, we recorded the capsule thickness and the number of fr in it. Based on the obtained numerical results, we calculated the parameters. We took at least 15 measurements in different parts of fc in each of the 3–5 serial sections of one animal. As there were three animals per each observation period, at least nine sections were analyzed for every experimental point. Thus, sampling for the determination of quantitative parameters (fc, fr, n, and m) was at least 135 in each experimental point. The number of fbgc’ nuclei was counted in cells in 10 fields of view.

2.6 Statistics

Statistical analysis of the results was made using the standard software package of Microsoft Excel. Arithmetic means and standard deviations were found. Significant differences between mean values in control and treatment groups were tested using Student’s t-test (significance level: p = 0.05) by standard methods: using two sample equal variance, with two tail distribution. We used six samples per in vitro citotoxical experiment and three samples (animals) per in vivo experiment.

3 Results

3.1 Microspheres characterization

The microspheres were of regular spherical shape and had a well-developed “wrinkled” porous surface; their diameters were significantly heterogeneous (Fig. 1). The determination of the microparticle size distribution was performed as described in part 2.3. The size distribution was from 1.73 ± 0.22 to 35.57 ± 4.62 μm, with a mean microsphere diameter of 10 ± 0.23 μm.

3.2 Cytotoxity

Evaluations of growth and metabolic parameters of the fibroblast cell culture in the treatment group and in the positive and negative control groups are presented in the Table 2. Mouse fibroblast cells cultured in the presence of polymeric (PHB) microspheres extracts similarly to the negative control (polystyrene extract) retained the morphology of normal cells, like those grown in the control, on polystyrene. Cell viability test, performed by the method of live staining with trypan blue, showed that 99.8 ± 0.2% of the cultured cells did not incorporate the dye, i.e., remained highly viable, in contrast to the positive control (rubber extract), in which most of the cells died. The doubling time of fibroblasts corresponded to the generation time of the cells cultured on standard medium and experimental culture were 25.1 ± 1.8 and 25 ± 2 h; on negative and positive controls 24.9 ± 2.1 and 168 ± 21.3. The MTT test did not indicate any toxic effect of the polymer extract on the metabolic activity of fibroblasts, either. It is well-known that only active dehydrogenases of living cells will convert MTT into insoluble formazan crystals.

Having tested extracts of PHB-microspheres, we revealed no citotoxic effects, which was indicated by the absence of cell morphology changes, changes in cell viability and doubling time, and shifts in the cell proliferative activity. These parameters were virtually the same as those of the negative control—polystyrene—and standard media. Statistically proven differences were detected only for industrial red rubber—the positive control.

The biocompatibility of the polymeric microparticles was subsequently investigated in the longduration in vivo experiment.

3.3 In vivo reaction

All animals in the treatment group, which had been injected with a microspheres suspension, were healthy and ate well. Their body mass and masses of their internal organs were similar to those of the rats in the control group.

At 24 h after the injection of polymeric microparticles, the microscopic picture at the injection site was characterized by a slight tissue edema and leukocyte infiltration (Table 3). The cluster of microspheres injected intramuscularly may be considered as an open porous implant with a large overall interface. In our experiment, in 24 h after the injection of PHB microparticles, the initial inflammatory response was started as could be seen from the presence of polymorphonuclear leukocytes (up to 20–25 in the field of view). This tissue reaction was of short duration; after 1 week the intensity of polymorphonuclear leukocyte infiltration decreased significantly. The low intensity of leukocytes during that time suggests that tissue reaction to the implantation of polymeric microparticles can be described as a mild inflammatory response. After 1 week of implantation, we observed infiltration of fibroblast cell elements and formation of a thin fibrous capsule at the interface between the microspheres and the intact muscular tissue, as a foreign body reaction of the organism. Figure 2a–b shows the tissue at the microspheres implantation site at 2 weeks. One can see mononuclear secretory-phagocytic macrophages and a few FBGCs with 2–3 nuclei. Besides phagocytosis, macrophages initiate the formation of granulation tissue. The granulation tissue response is characterized by fibroblast infiltration and the development of blood capillaries [33]. If an implant is made from non-resorbable material, a thick fibrous capsule is usually formed around it. If biocompatible and biodegradable implants are used, the tissue response may not involve the formation of a thick fibrous capsule or, if the capsule is formed, it is later involuted [21].

At 2 weeks, the cluster of the injected microspheres was encapsulated with thin connective tissue (Fig. 2a). At that time, the percentage of large particles (over 10–15 μm) in the cluster of microspheres was significantly reduced and did not exceed 14% in the field of view. Active fibroblast elements were identified in the structure of the thin capsule; its mean thickness was not more than 50–60 μm; it consisted of 4–6 fibroblast layers. The reaction was almost 3 times less intensive than the reaction of muscular tissue to the implantation of sutures that we reported earlier [21]. This result is in good agreement with the data reported by Fournier et al. [34], who found that the intramuscularly injected microspheres cluster was isolated from the muscular tissue by a very thin fibrous capsule, which was much less developed than the capsule formed in the event of subcutaneous injection. At the site of injection of PHB microparticles, the newly formed tissue was significantly vascularized (Fig. 3), indicating high biocompatibility of the polymeric microspheres and favorable tissue reaction. The area of the edema at the implantation site was considerably decreased, there were no necrotic areas. There were a few leukocytes among the microspheres. We recorded an increase in the number of mature secretoryphagocytic macrophages (up to 6.36 ± 0.42 in the field of view) on the inner side of the capsule adhering to the implant and at the cluster of the microspheres (Fig. 2b). A large part of the macrophage cytoplasm was occupied with lysosomes and phagosomes. Later in the experiment we observed more intensive macrophage infiltration at the site of injection of the microspheres; the amounts of both mononuclear macrophages and FBGCs increased. At 5 weeks, the number of mono- and poly-nuclear macrophages at the site of implantation of the microspheres increased (Fig. 2d). The fraction of large particles became smaller and did not exceed 4–5% of the total amount of the particles in the field of view, suggesting that the polymeric matrix was being degraded. FBGCs with 6–8 nuclei were observed to aggregate around large (more than 10 μm in diameter) microspheres. At the interface between the intact muscular tissue and the microspheres there still was a fibrous capsule, though very thin, consisting of 2–3 layers of mature fibroblasts (Fig. 2c). The macrophage response grew more intense at 7–9 weeks; the number of FBGCs increased and so did the number of their nuclei. At the site of implantation of the microspheres we clearly saw macrophages grouped around large microparticles. In some cases we could see penetration of cell elements into the surface matrix of the microspheres and degraded (resorbed) parts around the circumference of the particles at the implant/tissue interface, which indicated that the polymeric matrix of the microparticles was being degraded. There were no fibrous capsules either at the microspheres/tissue interface or around any of the microspheres. This is a very important fact because the fibrous capsule around a polymeric particle could significantly influence the release behavior of the encapsulated drug and resorption of the polymeric matrix. At the end of the experiment (11–12 weeks), the tissue reaction remained essentially the same: we observed pronounced macrophage infiltration with a large number of poly-nuclear FBGCs, which either surrounded polymeric particles or were grouped around a cluster of smaller microparticles (Fig. 2g); there were rather large fusions of FBGCs with 10–12 and even more nuclei (Fig. 2f–g). There were no fibrous capsules at the interface between the intact muscular tissue and the cluster of the microspheres (Fig. 2e). In some parts of the microspheres cluster there was polymeric detritus, as a degradation product of larger particles. The fraction of microspheres larger than 10–15 μm in the field of view significantly decreased (to about 2–3%) and fragmented microparticles were seen (Fig. 4). For quite a long time, however, most of the microspheres persisted in the tissue undegraded, suggesting that in vivo bioresorption of microparticles must be rather a long process, which makes polyhydroxybutyrate a good candidate for fabricating a prolonged-action drug form intended for intramuscular injection.

4 Discussion

Biodegradable natural polyesters, PHAs, are being actively investigated as candidates for various biomedical applications. It has been shown that PHAs can be used to fabricate various items for medicine: surgery, transplantology, tissue engineering, and pharmacology [17, 33]. One of the main tasks facing those investigating new biomaterials is to prove that they are absolutely biocompatible with and harmless to the host organism. Some researchers investigating PHAs such as polyhydroxybutyrate (PHB) and hydroxybutyrate/hydroxyvalerate copolymers (PHB/PHV) reported their cytotoxicity in animal cell cultures in vitro [12] and slight inflammatory and pyrogenic reactions in animals during in vivo experiments [22]. In recent years in vivo studies were conducted to evaluate biocompatibility of new PHAs (incorporating hydroxyhexanoate) [24]. However, inflammation and other undesirable reactions to the tested biomaterials can also be related to their chemical composition, a particular implantation site, and the degree of chemical purity of the material.

Literature reports show that it is not uncommon to use commercially available polymers in biomedical studies of PHAs [35]. The level of endotoxins in them can reach 120 U/g [36, 37] due to the presence of microbial cell debris, which contains lipopolysaccharides and other complexes capable of causing negative reactions in cells in the in vitro systems and pyrogenic reactions in vivo [38, 39]. We have developed a procedure for synthesis, recovery and purification of PHAs to prepare polymer specimens that would not contain organic impurities of protein, carbohydrate or lipid nature. Experiments with two PHA types—polyhydroxybutyrate (PHB) and copolymers of hydroxybutyric and hydroxyvaleric acids (PHBV)—in cultures of animal cells of various origins (fibroblasts, hepatocytes, and endothelial cells) did not show any negative influence of these PHAs, which directly contacted the cultured cells, on the cells. In experiments with laboratory animals biocompatibility of these polymers was proven at the cell [40], tissue [41], and organism [42] levels.

In a number of works it was reported that variously-structured polyhydroxyalkanoate-based objects were implanted to laboratory animals for long periods of time [43, 44]. All implants, although subjected to biodegradation, fulfilled their functions throughout the observation periods (6 months to 2.5 years). The residual mass of the implants varied depending on the experiment (90–40% of the initial mass).

The biodegradability of oriented fibers made of polyhydroxybutyrate (P(3HB)) and its co-polymer with β-hydroxyvalerate (P(3HB-co-3HV)) was investigated in biological media in vivo [45]. After 180 days, the mass of P(3HB) and P(3HB-co-3HV) fibers reduced to 74% and 62% of the initial mass.

Generally speaking, in vivo polyhydroxyalkanoate biodegradation is quite a long process, lasting for months and years.

The nature and extent of the tissue reaction to the implant is known [17, 18] to be characterized by the presence of specific cell types. After injury due to surgical intervention and implantation of the material or a tested item, aseptic tissue inflammation develops at the site of implantation. It is usually divided into several phases: alteration (injury), exudation, and proliferation; the last phase is at the same time the first phase of tissue repair. The phases of exudation and proliferation are sometimes subdivided into neutrophil, macrophage, and fibroblast phases. The neutrophil phase occurs during the first few hours of implantation: polymorphonuclear leukocytes (PMNs) migrate from the vessels to the site of damage, surround it, and, after 6–12 h, form a leukocyte barrier. The lifetime of PMNs is short; within 24 h neutrophilic leukocytes stop migrating and their decomposition is started. The foreign body reaction is expressed by the amount of macrophages at the microspheres/tissue interface [17]. In this phase (the macrophage phase), macrophages penetrate into the leukocyte barrier and phagocytize cell detritus and degradation products from the tissue and implanted material. Macrophages surround the foreign body and form neutrophilmacrophage > macrophage > macrophage-fibroblast barriers, which prevents the formation of granulation tissue [46–48]. When biodegradable materials are implanted, the macrophage response, which follows the neutrophil response, increases rather than decreases. The reason for this is that macrophages and foreign body giant cells phagocytize and resorb biodegradable materials. The main contribution to the formation of foreign body giant cells (FBGCs) is made by macrophages, which phagocytize the implanted material. It is well-known that FBGCs, formed on the surface of or around the particles of the implanted material by the fusion of macrophages and by nuclear division of macrophages without cytokinesis, resorb the material [49, 50]. This has been demonstrated in numerous studies of polymeric microparticles prepared from various resorbable materials: polyethylene glycol [29], polylactides and lactide/glycolide copolymers [51], and poly(methylidene malonate 2.1.2) [35]. It has been reported that in some PHAs, including 3- and 4-polyhydroxybutyrate, in vivo resorption involves active participation of phagocytic macrophages and foreign body giant cells (FBGCs) [3]. In our recent study we investigated tissue response to polyhydroxybutyrate monofilament sutures used to close muscle-fascial wounds and found out that macrophages played an important role in the tissue repair response, phagocytizing injured cells and tissues and polymer particles and degradation products [21]. The reaction of tissues to polyhydroxybutyrate implants was comparable in intensity and length to their reaction to silk and was considerably less pronounced than their reaction to resorbable catgut.

In this work in the in vitro and in vivo experiments showed that polyhydroxybutyrate microspheres were biocompatible; they neither inhibited growth and metabolic activity of fibroblasts nor caused negative response in animals that were intramuscularly injected with them. The tissue response to the implantation of polyhydroxybutyrate microparticles was characterized by mild inflammatory reaction of short duration, pronounced and ever increasing macrophage infiltration involving foreign body giant cells that resorbed the polymeric matrix, and the granulation response, involving the formation of a highly vascularized thin fibrous capsule at the microspheres/tissue interface, which was resorbed after several weeks of implantation. No fibrous capsules were formed around polymeric microparticles; neither necrosis nor any other adverse morphological changes and tissue transformation in response to the implantation of the polymeric microparticles were recorded. The results of the study suggest that polyhydroxybutyrate is a good candidate for fabricating prolonged-action drugs in the form of microparticles intended for intramuscular injection.

References

W. AMASS, A. AMASS and B. TIGHE, Polymer Int. 47 (1998) 144

J. KOST and R. LANGER, Adv. Drug. Deliver. Rev. 46 (2001) 125

S. WILLIAMS and D. MARTIN, in “Series of Biopolymers”, edited by A. Steinbüchel, Vol 10 (Wiley-VCY Verlag GmbH, 2002) p. 91

C. W. POUTON and S. AKHTAR, Adv. Drug. Deliver. Rev. 18 (1996) 133

H. UEDA and Y. TABATA, Adv. Drug. Deliver. Rev. 55 (2003) 501

V. PIDDUBNYAK, P. KURCOK and A. MATUSZOWICZ, Biomaterials 25 (2004) 5271

S. T. HARRISON, H. A. CHASE and S. R. AMOR, Int. J. Biol. Macromol. 14 (1992) 50

I. GURSEL and V. HASIRCI, J. Microincapsulation 12 (1995) 185

I. GURSEL, F. KORKUSAZ and F. TURESIN, Biomaterials 22 (2000) 73

B. LY, Z. R. WANG and H. YANG, J. Microencapsulation 18 (2001) 55

M. A. SALMAN, A. SAHIN and M. A. ONUR, Acta. Anaestesiol. Scand. 47 (2003) 1006

S. FREIBERG and X. ZHU, Int. J. Pharm. 282 (2004) 1

G. RUAN and S. FENG, Biomaterials 24 (2003) 5037

Y. H. YUN, D. J. GOETZ and P. YELLEN, Biomaterials 25 (2004) 147

J. BREITENBACH, Eur. J. Pharm. Biopharm. 54 (2002) 107

M. SIMEONOVA, K. CHORBADJIEV and M. ANTCHEVA, Biomaterials 19 (1998) 2187

J. ANDERSON and M. SHIVE, Adv. Drug Deliv. Rev. 28 (1997) 5

V. V. SEROV and V. S. PAUKOV, in “Vospaleniye” (“Inflammation”) (Meditsina, Moscow, 1995) p. 629

T. G. VOLOVA, in “Microbial polyhydroxyalkanoates—Plastic Materials of the 21st Century (Biosynthesis, Properties, Applications)” (Nova Science Pub. Inc., New York, 2004) p. 283

B. SAAD, M. CASOTTI and T. HUBER, J. Biomater. Sci. Polymer Edn. 11 (2000) 787

E. SHISHATSKAYA, T. VOLOVA and S. EFREMOV, J. Mater. Sci. Mater. Med. 15 (2004) 719

S. GOGOLEWSKI, M. JAVANOVIC and S. PERREN, J. Biomed. Mater. Res. 27 (1993) 1135

E. SHISHATSKAYA and T. VOLOVA, J. Mater. Sci. Mater. Med. 15 (2004) 915

X. QU, Q. WU and K. ZHANHANG, Biomaterials 27 (2006) 3540

T. VOLOVA and G. KALAACHEVA, P12. RF Patent No. 2051967 (in Russian)

V. SEVASTIANOV, N. PEROVA and E. SHISHATSKAYA, J. Biomater. Sci. Polymer Edn. 14 (2003) 1029

TRADEMARK “BIOPLASTOTANTM” Registration Certificate No. 315652 of the Federal Institute for Patent Examination for Application No. 2006703271/50, Priority of 15.02.2006

RFSS (The Russian Federation state standard) 5496–78

R. DIJKHUIZEN-RADERSMA, S. HESSLING and P. KAIM, Biomaterials 23 (2002) 4719

R. I. FRESHNEY, in “Culture of Animal Cells: A Manual of Basic Technique” (Wiley, New York, 2000) p. 329

A. GENIN, A. Il`IN and A. KAPLANSKII, Aviakosmicheskaya i ekologicheskaya meditsina 35 (2001) 14 (in Russian)

G. A. PKHAKADZE, V. P. YATSENKO, A. K. KOLOMIITSEV, M. V. GRIGORIEVA and K. L. KONOPLITSKAYA, in “Biodestruktivnyye polimery” (“Biodegradable polymers”) (Naukova Dumka, Kiev, 1990) p. 143 (in Russian)

J. ANDERSON, Asaio 11 (1988) 101

E. FOURNIER, C. PASSIRANI and N. COLIN, Biomaterials 27 (2006) 4963

S. WILLIAMS, D. MARTIN and D. HOROWITZ, Int. J. Biol. Macromol. 235 (1999) 111

R. SADIN, S. HOERSTRUP and J. SPERLING, Ann. Thorac. Surg. 70 (2000) 140

V. SEVASTIANOV, I. ROZANOVA and E. TSEITLINA, Meditsinskaya tekhnika (Medical technology) 4 (1990) 26 (in Russian)

V. SEVASTIANOV, in “Iskusstvennyye organy” (“Artificial organs”), edited by V. I. Shumakov (Meditsina, Moscow, 1990) p. 216 (in Russian)

N. B. DOBROVA, T. P. NOSKOVA and S. P. NOVIKOVA, in “Sbornik metodicheskikh rekomendatsii po otsenke biosovmestimykh svoistv iskusstvennykh materialov, kontaktiruyushchikh s krovyyu” (“Collected methodological suggestions for evaluating biocompatible properties of artificial materials contacting blood”) (VNITIPRIBOR, Moscow, 1991) p. 70 (in Russian)

G. N. STASISHINA and T. G. VOLOVA, P12. RF Patent No. 2053292 (in Russian)

T. G. VOLOVA and G. S. KALAACHEVA, P12. RF Patent No. 2051967 (in Russian)

T. G. VOLOVA, G. S. KALACHEVA and V. M. KONSTANTINOVA, P12. RF Patent No. 2051968 (in Russian)

U. STOCK, M. NAGASHIMA and P. N. KHALIL, J. Thorac. Cardiovasc. Surg. 119 (2000) 732

F. KORKUSUZ, P. KORKUSAZ and F. EKSIOGLU, J. Biomed. Mater. Res. 55 (2001) 217

E. I. SHISHATSKAYA, T. G. VOLOVA, S. A. GORDEEV and A. P. PUZYR, J. Biomater. Sci. Polymer Edn. 16 (2005) 643

R. MARCHANT, A. HILTNER and C. HAMLIN, J. Biomed. Mater. Res. 17 (1983) 301

Q. ZHAO, J. ANDERSON and A. HILTHNER, J. Biomed. Mater. Res. 26 (1992) 1019

W. KAO, Q. ZHAO and A. HILTNER, J. Biomed. Mater. Res. 28 (1994) 73

R. HHEE, S. BIRGH-DEWINTER and W. DAFMS, Cell Tis. Res. 198 (1979) 355

J. M. ANDERSON, in “Encyclopedia of Materials: Science and Technology” (Elsevier Science Ltd., 2001) p. 560

F. KANG and J. SINGH, Aaps Pharm. Sci. Tech. 6 (2005) 487

Acknowledgments

This study was financially supported by the Russian Ministry of Education and the U.S. Civilian Research & Development Foundation CRDF (Grant No. P1MO002), the Program of the RAS Presidium “Fundamental Research to Medicine” (Project No. 12.5), and the Program of the President of Russia (Grant MK-4149.2006.4).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shishatskaya, E.I., Voinova, O.N., Goreva, A.V. et al. Biocompatibility of polyhydroxybutyrate microspheres: in vitro and in vivo evaluation. J Mater Sci: Mater Med 19, 2493–2502 (2008). https://doi.org/10.1007/s10856-007-3345-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-007-3345-6