Abstract

For the first time, protein fibers with excellent mechanical properties and water stability have been produced from gliadin for potential use in tissue culture and other medical applications. Biomaterials developed from plant proteins such as zein and soyproteins are preferred for several medical applications over synthetic polymers such as polylactic acid. However, the plant protein based biomaterials developed so far have poor mechanical properties and hydrolytic stability even after crosslinking. This study aims to develop biomaterials from gliadin with excellent mechanical properties and water stability without using any crosslinking agents. A novel gliadin fiber production method was used to self crosslink the fibers and obtain high strength and water stability. Gliadin fibers have high strength (120 MPa) and elongation (25%) compared to similar collagen fibers that were crosslinked with glutaraldehyde (strength of about 44 MPa and elongation of 14%). The fibers show 100% strength retention after being in pH 7 water at 50 °C for 40 days and also have better water stability than PLA in acidic conditions at high temperatures. Gliadin fibers are suitable for cell growth and promote the attachment and proliferation of bovine turbinate fibroblasts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Novel 100% protein fibers with excellent mechanical properties and water stability for potential use in tissue culture and other medical applications have been developed from gliadin without using any additional crosslinking agents. Currently, collagen and elastin are the two most common proteins used for tissue culture, controlled drug delivery and other medical applications. However, poor mechanical properties and risk of carrying diseases are the two major limitations of using collagen for medical applications [1]. Crosslinking or blending collagen with various synthetic polymers have been the most common approaches used to improve the mechanical properties of collagen to make them suitable for various medical applications. Gluteraldehyde is the common chemical used to crosslink protein materials [2]. However, gluteraldehyde is said to be cytotoxic and therefore gluteraldehyde crosslinked materials are not suitable for tissue culture [3]. Blending collagen with synthetic polymers is another approach of improving the mechanical properties of collagen based materials but the synthetic polymers are said to release toxic substances upon degradation and may also cause inflammatory reactions in the body [4].

As an alternative to collagen, plant proteins such as zein and soyproteins have been considered for tissue culture, drug delivery and other medical applications [1, 5, 6]. Zein and soyprotein have been made into films or electrospun nanofiber scaffolds for use in biomedical applications. These proteins have been shown to have biodegradability, biological stability, easy processability to the required shapes, good adhesion to various substrates and surface active properties, properties that are desirable for biomaterials. However, the mechanical properties and hydrolytic stability of plant protein based biomaterials need to be improved to make them practically useable for biomedical applications [1].

Although wheat based proteins, mainly gluten and gliadin, have been used for industrial applications such as fibers and films similar to soyproteins and zein, very few studies have been conducted on understanding the suitability of wheat proteins for medical applications [7–13]. Gliadin films were made into soft capsules and chewable gums for controlled drug release and it was reported that gliadin proteins showed high promise to be bioacceptable proteins with controlled release potency [14]. Similarly, gliadin nanoparticles have been shown to be suitable for controlled release of hydrophobic and amphiphilic drugs [15]. However, gliadin materials such as films previously developed have poor water stability even after crosslinking and they disintegrate in water immediately [7–9]. It will be necessary to make gliadin water stable for use in medical applications.

To the best of our knowledge, no reports are available on studying the suitability of gliadin proteins as tissue culture substrates. In this research, we have developed gliadin fibers with good mechanical properties and excellent water stability for potential use in tissue culture and other medical applications. Fibers are more preferable than films for medical applications especially vascular tissue engineering since arteries are composed of fiber reinforced structures [3]. The properties of the gliadin fibers developed are compared to fibers from other plant proteins and also wool and the suitability of the fibers for tissue culture have been studied.

2 Experimental section

2.1 Materials

Gliadin was extracted from commercially available wheat gluten (Whetpro 80, supplied by Archer Daniels Midlands Company, Decatur, IL) using aqueous ethanol as described earlier [8, 9].

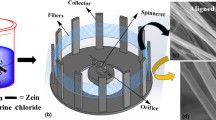

2.2 Producing fibers

Two methods, dry and wet spinning were used to produce gliadin fibers. Dry spinning was selected since the solvent can be removed by evaporation, is cheaper and easier than wet spinning. In the dry spinning process, a 40% gliadin solution was prepared using 70% (v/v) ethanol. The solution was allowed to age for 24 h and then extruded as fibers using a syringe and needle.

Wet spun gliadin fibers were produced by dissolving gliadin in 8 M urea solution with about 1% sodium sulfite (based on the weight of the solution) as a reducing agent at room temperature. The solution was aged for different times and extruded as fibers into a coagulation bath consisting of 10% (w/w) sodium sulfate. The precipitated fibers were washed in water and air dried.

2.3 Drawing and annealing

The wet spun gliadin fibers were drawn in water to about 200–300% of their original length. The fibers were then dried at 85 °C for about 90 min and later annealed (dry heated) in an oven at 125 °C for about 120 min to improve the mechanical properties of the fibers.

2.4 Tensile properties and moisture regain

All tensile tests were conducted after conditioning the samples for at least 24 h in a standard testing atmosphere of 21 °C and 65% relative humidity. Tensile properties of the gliadin fibers were tested using an Instron (Model 4000) tensile tester with 1 inch gauge length and a crosshead speed of 18 mm/min. Three groups of about 30 fibers each were tested for each condition and the average and standard error of the means is reported. Moisture regain of the fibers was determined according to ASTM standard D2654.

2.5 Physical structure

The diffraction patterns of the protein crystals in the drawn and undrawn gliadin fibers were observed in a Bruker D8 Discover model diffractometer equipped with an area detector and GAADS software. Fibers were mounted in a specially designed sample holder with the axis of the fibers being perpendicular to the X-ray beam. A voltage of 40 kV and 30 mA was used.

2.6 Atomic force microscopy

Atomic force microscopy (AFM) images of gliadin fiber surfaces were obtained on a Dimension 3100 scanning probe microscope in contact mode using silicon cantilevers with a spring constant of 30 N/m and resonant frequency of 300 kHz. Fibers were taped on silica and observed under the AFM. Five each of the drawn and undrawn fibers were randomly selected and used to collect the AFM images. The AFM images of the five fibers were similar for both the drawn and undrawn fibers.

2.7 Stability in water

The water stability of gliadin and PLA fibers was tested at 50 and 90 °C. The fibers were allowed to stay in pH 7 50 °C water for several days. Fibers were taken out after being in water for 1, 3, 20 and 40 days and tested for their strength retention compared to the respective untreated fibers. Similarly, the fibers were treated at 90 °C for 1 h at various pH conditions and the strength retention was determined. The strength retention tests were performed after conditioning the fibers in a standard atmosphere for at least 24 h.

2.8 SDS PAGE electrophoresis

The gliadin powder and fibers were used to determine the molecular weights of the proteins. One point zero (1.0) milligram of the powdered fibers were mixed with 1000 μl of SDS-PAGE 1 × sample buffer (4.1 mM Tris–HCl, 2% SDS, 2% β-mercaptoethanol, 10% glycerol, double distilled water) and left standing at room temperature for 2 h. 10 μl of the clear top layer of each sample was loaded into each slot in the gel. After electrophoresis, the gel was stained with Coomassie Brilliant Blue G-250. After standing for one night, the gel was flushed with deionized water and put in de-stain liquid until a clear background was formed. The molecular weights of the protein standard mixture ranged from 10 to 250 kDa and were obtained from Bio-Rad Chemical Co.

2.9 Cell culture

Bovine turbinate fibroblast (BT) cells were used to test the suitability of the gliadin fibers as substrates for cell growth. Autoclaved gliadin fibers were placed at the bottom of a 24 well corning microplate. The fibroblasts were seeded at a rate of 4 × 104 cells /ml on the fibers using Dulbecco’s modified eagle medium with 10% fetal bovine serum (FBS). The culture plate was incubated at 37 °C in a 5% CO2 humidified incubator for 5 days. After this, the media was pipetted out and cells were fixed with 2 ml of 2.5% gluteraldehyde in 0.1 M sodium phosphate buffer (pH 7.2–7.4). The fibers were then incubated at room temperature for 1 h and later at 4 °C over night. The fibers were then successively washed in ethanol solution of 30, 50, 70, 90 and 95% concentration. Finally, the fibers were subject to critical point drying in CO2 before observing the fibers in an SEM. The samples were sputter coated with gold palladium and observed in a Hitachi S3000N variable pressure SEM at a voltage of 15 kV.

3 Results and discussion

3.1 Alcohol and urea dissolution

Gliadin dissolved in alcohol and aged for about 24 h had the viscosity required for spinning fibers. Although relatively fine fibers were extruded from the alcohol dissolved gliadin solution, the fibers were brittle and could not be mounted on the tensile testing machine. The fibers also disintegrated in water immediately. Therefore, these fibers were not used for further testing and analysis.

Gliadin dissolved using urea and sodium sulfite produced fibers that were stable in water. However, the viscosity of the spinning dope and the properties of the fibers were dependent on the concentration of the proteins in the spinning dope and the time and temperature of aging. Spinning dopes with protein concentrations between 27 and 32% had the required viscosities for extrusion. Solutions with protein concentration lower than 27% had high viscosities and solutions with protein concentration higher than 32% were too thick and unextrudable. It was found that a solution aging time of about 24 h was necessary to have a spinnable dope and to obtain fibers with good breaking tenacity. Short aging times did not form solutions with the required viscosity and long aging times degraded the proteins resulting in fibers with low breaking tenacity of about 70 MPa.

Gliadins are reported to predominantly have intramolecular disulfide bonds [16]. The disulfide bonds in gliadin can be reduced and reoxidized accompanied by changes in the conformation of the protein molecules and intermolecular crosslinking [16]. The intermolecular crosslinking increases the molecular weight of the urea dissolved gliadin fibers as seen from the electrophoresis gel (lane 2) in Fig. 1 compared to the gliadin powder (lane 3).

3.2 Effect of drawing and annealing

Drawing and annealing plays a vital role in the orientation of the proteins and in improving the properties of the fibers produced. As shown in Fig. 2, heating without drawing (B) did not increase the strength of the fibers compared to the undrawn and unheated fibers (A) whereas heating after drawing (D) improved the strength of the fibers by about 94%. Drawing improved the elongation of the unheated fibers by about 250% (C) and that of the annealed fibers even higher, by about 317%.

Generally, dry heat improves the interactions between the protein molecules leading to higher strength and drawing improves the orientation of the polymers along the axis of the fiber and increases the strength and elongation of the fibers. The undrawn fibers have low elongations since the protein molecules are not stretched leading to poor orientation of the molecules along the axis of the fiber. We observed the gliadin fibers in an atomic force microscope (AFM) before and after drawing to understand the effect of drawing on the molecular orientation. The AFM image of an undrawn fiber (Fig. 3a) shows that the proteins have formed clusters and are in relatively large circular form. The proteins in the drawn fibers seen in Fig. 3b show more even distribution and are better oriented compared to the proteins in the undrawn fibers. The bright spots on the drawn fibers are the proteins on the surface of the fiber and are oriented parallel to the line seen in Fig. 3b. The even distribution and better orientation of the proteins in the drawn fibers gives better strength and elongation to the fibers. Although drawing improved the elongation of the fibers, there was no appreciable change in the orientation of the protein crystals along the fiber axis as seen from the diffraction patterns of the undrawn and drawn fibers shown in Fig. 4a and b, respectively. The low crystallinity of the protein fibers could be the reason for not detecting any improvement in the orientation of the protein crystals after drawing.

3.3 Mechanical properties

Gliadin fibers are finer but have similar mechanical properties as wheat gluten fibers as seen from Table 1. Both the wheat gluten and gliadin fibers have mechanical properties similar to that of wool and better than the properties of zein and soyprotein fibers reported earlier [12, 17]. Although the wheat protein fibers have lower breaking tenacity than wool, the tenacity of the gluten and gliadin fibers can be improved by methods such as crosslinking and by using solution spinning equipment with better controls. The gliadin fibers have modulus similar to that of wool and wheat gluten fibers. Moisture regain of gliadin fibers is similar to that of wool and lower than that of gluten fibers.

The excellent strength of gliadin fibers even without crosslinking become apparent when compared to the strength of collagen fibers that are most commonly used for tissue culture. Collagen fibers without crosslinking had strength of about 2.4 MPa and those crosslinked with cyanamide and glutaraldehyde had highest strength of 17 and 44 MPa, respectively [2]. In another report, collagen threads with deniers ranging from 80 to 300 have been reported to have tensile strength of about 224 MPa [18]. Compared to this, gliadin fibers have low deniers of about 25 and strength of about 120 MPa and high elongation of about 25%. This indicates that gliadin fibers have the mechanical properties required for tissue culture applications.

3.4 Water stability

Gliadin fibers retain 100% of their original strength even after being in water for 40 days. The PLA fibers lost most of their strength and could not be tested after being in water for 20 days as seen from Fig. 5a. Gliadin fibers also have better stability in water than PLA fibers under acidic conditions as seen from Fig. 5b. In fact, treating gliadin fibers in water under weak acidic conditions increases the breaking tenacity of the fibers compared to the untreated fibers. Gliadin fibers lost about 10% of their strength when treated at pH 3 but have about 10 and 5% increase in strength when heated in pH 5 and 7 water, respectively. Gliadin fibers have relatively poor stability in water under alkaline conditions and lose about 50% of their strength when heated in pH 11 water at 90 °C for 1 h.

The loss in the tenacity of the gliadin fibers at low acidic and alkaline conditions should mainly be due to the hydrolysis of the protein polymers. Although the reasons for the increase in the tenacity of gliadin fibers heated in weak acidic and neutral pH is unclear at this time, we assume that it is most probably due to the better arrangement and orientation of the protein molecules in hot water leading to higher tenacity retention.

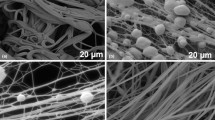

3.5 Cell culture

Gliadin fibers support the attachment, growth and division of cells as shown in the SEM images in Fig. 6. The cells attached to the fibers show growth of filaments and later division of the filaments occurs (Fig. 6b and c). The cells have good confluence on the fibers and start to spread. This indicates that gliadin protein surface is a good substrate for cell adhesion and proliferation. The better stability of the gliadin fibers in acidic and neutral conditions and their ability to support cell growth make them potential candidates for use in medical applications. In addition, protein fibers may have good compatibility with the body than synthetic fibers such as PLA.

4 Conclusions

Protein fibers made from gliadin have excellent mechanical properties, water stability and are suitable for tissue culture. Self-crosslinked fibers developed from gliadin have mechanical properties similar to that of wool and wheat gluten fibers and better than the properties of zein, soyprotein and collagen fibers. Gliadin fibers retain 100% of their strength even after being in 50 °C water for 40 days and also have better stability than PLA fibers in water at acidic conditions and high temperatures. Gliadin fibers are conducive to cell attachment, growth and proliferation. Gliadin fibers could be novel protein based materials for use in tissue culture and other medical applications.

References

C. M. VAZ, M. FOSSEN, R. F. TUIL, L. A. GRAAF, R. L. REIS, A. M. CUNHA, J. Biomed. Mater. Res., 65A (2003) 60

Y. P. KATO and F. H. SILVER, Proceedings of the annual international conference of IEEE engineering, November 9–12, Seattle, WA, 1989

L. BUTTAFOCO, N. G. KOLKMAN, P. E. BUIJTENHUIJS, A. A. POOT, P. J. DIJKSTRA, I. VERMES, J. FEIJEN, Biomaterials, 27 (2006) 724

Q. LU, K. GANESAN, D. T. SIMIONESU, N. R. YVAVAHARE, Biomaterials, 25 (2004) 5227.

J. DONG, Q. SUN, J. WANG, Biomaterials, 25 (2004) 4691

S. GONG, H. WANG, Q. SUN, S. XUE, J. WANG, Biomaterials, 27 (2006) 3793

P. H. MUNOZ, A. KANAVOURAS, R. VILLALOBOS, A. CHIRALT, J. Agric. Food. Chem., 52 (2005) 7897.

P. H. MUNOZ, A. RUBIO, J. M. LAGARON, R. GAVARA, Biomacromolecules, 5 (2004) 415

P. H. MUNOZ, A. KANAVOURAS, J. M. LAGARON, R. GAVARA, J. Agric. Food Chem., 53 (2005) 8216

N. REDDY, Y. YANG, Biomacromolecules, 8 (2007) 638

A. GENNADIOS, C. L. WELLER, Food Techn., 44(10) (1990) 63

H. C. HUANG, E. G. HAMMNOND, C. A. REITMEIER, D. J. MYERS, JOACS, 72 (1995) 1453

R. A. BOYER, Indl. Engg. Chem., 32 (1940) 1549

V. STELLA, P. VALLEE, P. ALBRECHT, E. POSTAIRE, Int. J. Pharm., 121 (1995) 117

C. DUCLAIROIR, A. M. ORECCHIONI, P. DEPRAETERE, F. OSTERSTOCK, E. NAKACHE, Int. J. Pharm., 253 (2004) 133

A. C. BECKWITH, J. S. WALL, R. W. JORDAN, Arch. Biochem. Biophys., 112 (1965) 16

Y. YANG, L. WANG, S. LI, J. Appl. Polym. Sci., 59 (1996) 433

J. F. CAVALLARO, P. D. KEMP, K. H. KRAUS, Biotechnol. Bioeng., 46 (1994) 781

Acknowledgements

This research was partially supported with funds from Nebraska Wheat Board, The Consortium for Plant Biotechnology Research, Inc by DOE prime agreement No. DE-FG36-02G012026, Archer Daniel Midland Company, USDA Hatch Act, the Agricultural Research Division at the University of Nebraska-Lincoln and by Multi State Research Project S-1026. The financial sponsors do not endorse the views expressed in this publication. We also thank Dr. Liping Xie at the Veterinary Diagnostic Center for her help in the cell culture experiments and Ying Li for her help in the electrophoresis and water stability studies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Reddy, N., Yang, Y. Self-crosslinked gliadin fibers with high strength and water stability for potential medical applications . J Mater Sci: Mater Med 19, 2055–2061 (2008). https://doi.org/10.1007/s10856-007-3294-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-007-3294-0