Abstract

Amorphous calcium phosphates (ACP) were synthesized utilizing poly(ethylene glycol) as stabilizing additive at low temperature. Effects of aging time, pH value, reactant and initial Ca/P atomic ratio on the phase and chemical composition of calcium phosphate precipitates were investigated by powder X-ray diffraction and induced coupled plasma atomic spectroscopy. It was found that ACP could be stabilized by poly(ethylene glycol) in the mother solution for more than 18 h at 5 °C, and Ca/P atomic ratios of ACP precipitates could be adjusted from 1.33 to 1.50 by controlling pH values and initial Ca/P atomic ratios. ACP precipitates were characterized by thermal gravity analysis, Fourier transform infrared spectroscopy, scanning electron microscopy and energy dispersive spectrum. The results show that there is 4 wt% poly(ethylene glycol) in ACP powders without any contaminated ions, and the spherical particle size of ACP powders is 60∼70 nm in the diameter with uniform size distribution which endows it as a potential precursor to prepare crystalline calcium phosphate phases. ACP has potential to be used as biodegradable and/or bioresorbable biomaterials and tissue engineering scaffold.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Amorphous calcium phosphates (ACP) are widely distributed in the bone of the vertebrate animals and some non-vertebrate organisms during the biomineralization process [1–7]. It is reported that the amount of biogenic ACP present in the early stages of tissue mineralization is higher than that of adult tissue after biological maturation [3, 5, 6, 8], showing that ACP plays a critical role in the process of the tissue mineralization.

However, in the biomineralization process, ACP fulfils three roles. Firstly, it is a precursor phase during the formation of other crystalline phases. Amorphous phase always appears in the early stage of tissue mineralization [6]. Secondly, ACP is employed as a temporary storage for bone apatite as Ca and P sources, some stable biogenic ACP exists in the mineralized tissue, and ACP also exists in the milk [9, 10]. Thirdly, the amorphous phase can also be found in the stabilized form for the mechanical purposes as the biomineral itself, due to its isotropic characteristic compared with the anisotropy of the crystalline phases. Moreover, ACP is one of the best third-generation biomaterials due to its excellent bioactivity and good biodegradation [7, 11, 12], so that it can be used as precursors to prepare the crystalline phases such as hydroxyapatites, tricalcium phosphates and calcium pyrophosphates in the form of powders, coatings and fillers [13–16].

The amorphous phase can stay stable in the organism or in the dried state, but it transforms into apatite by dissolution and recrystallization in the solution and in wet condition [7]. Biogenic ACP is only available in a small amount and always coexists with an organic matrix. The kinetic stabilization of biogenic ACP is due to the content of Mg2+, P2O7 4−, CO3 2− and F− and biological macromolecules [7, 9, 17]. Synthetic ACP is first identified by Posner group in the process of hydroxyapatite synthesis and recognized as intermediated phase [18]. Many attempts have been explored to synthesize the amorphous phase in vitro, including adding inorganic substance such as Mg2+, P2O7 4−, CO3 2− and F−, ZrOCl2 and Si [9, 16, 17, 19], and biogenic macromolecule such as adenosine triphosphate, casein phosphopeptide and poly-L-lysine [7, 9, 19, 20].

Recently, poly(ethylene glycol) was employed to stabilize ACP and stable ACP was obtained successfully from the mother solution at 5 °C in our previous paper [21]. In this paper, effects of aging time, pH value, initial reactant and initial Ca/P atomic ratio on the phase and chemical composition of calcium phosphate precipitates were investigated by powder X-ray diffraction and induced coupled plasma atomic spectroscopy. And ACP precipitates were characterized by thermal gravity analysis, Fourier transform infrared spectroscopy scanning electron microscopy and energy dispersive spectrum.

Experimental procedure

Synthesis

Reagent grade sodium phosphate (Na3PO4·12H2O), ammonium hydrogen phosphate ((NH4)2HPO4), phosphate acid (H3PO4), hydrated calcium nitrate (Ca(NO3)2·4H2O), calcium hydroxide (Ca(OH)2) , hydrated calcium chloride (CaCl2·6H2O) and poly(ethylene glycol) (PEG, M W = 10,000) were used as starting materials without further purification. Ca containing chemical and PEG were dissolved in distilled water to form 0.10 M PEG-Ca2+ solution with PEG/Ca weight ratio of 1:1. The chemical containing PO4 3− was first dissolved to form 0.133 M phosphate solution and then added into the PEG-Ca2+ solutions by droplet with different Ca/P atomic ratios. The experiments were conducted at 5 °C. The white suspension occurred when adding the phosphate solution, and the reaction was kept at 5 °C under vigorous stirring for different aged times. Calcium phosphate precipitates were separated and washed repeatedly by distilled water and absolute ethanol to remove the contaminated ions (Na+, NH4 +, Cl− and NO3 −). Finally, the precipitates were freeze-dried until the weight did not change and was kept in the P2O5 desiccator to use.

Characterization

The samples were characterized by powder X-ray diffractometry (XRD), induced coupled plasma atomic spectroscopy (ICP), thermal gravity analysis (TGA), Fourier transform infrared spectroscopy (FTIR) and scanning electron microscopy (SEM). The XRD profiles of the powder samples were conducted in the step-scan intervals of 0.02° 2θ at a scanning speed of 4°/min with CuKα radiation (λ = 1.54 Å) using a Rigaku X-ray diffractometer operated at 36 kV and 30 mA. The chemical composition (i.e. Ca/P atomic ratio) of calcium phosphate precipitates was measured using ICP with a Thermo Jarrell Ash Mark IV instrument in order to calculate the Ca/P atomic ratio of the precipitates. The calcium phosphate samples were dissolved in nitric acid to prepare the ICP samples. The FTIR spectra (from 4,000 cm−1 to 400 cm−1) were recorded using a Nicolet Avatar 360 spectrophotometer by a KBr pellet method with 2 cm−1 resolution. TGA (TGA7, TA Instruments) measurements were used to determine the content of PEG in the precipitates. The scan range was from 30 °C to 900 °C with heating rate of 10 K min−1 under 20 mL min−1 nitrogen flow. For scanning electronic microscopy (SEM) observation, calcium phosphate powders were dispersed in the absolute ethanol and dropt on the copper holder. After carbon coating, the morphology of ACP powders was observed in a field emission SEM (FEI SIRION) using 5 KeV.

Results and discussion

Synthesis of ACP

Several parameters affect the formation and/or stabilization of the fresh ACP precipitates in the mother solution, including aging time, reactants, pH and initial Ca/P [4, 7, 21]. Effects of these parameters on calcium phosphate precipitates were investigated in detail by XRD.

Figure 1 shows that the XRD patterns of calcium phosphate precipitates synthesized in the presence of PEG at 5 °C for different aged times with the initial Ca/P atomic ratio of 1.50. Amorphous phase with the characteristics of halo at 2θ = 30° could stay stable in the mother solution for 18 h and diffraction peaks at 2θ = 25.8, 31.7, 39.6, 46.7, 49.6 and 53.2°, assigned to apatite (JCPDS 9-432), began to appear if aging for more than 18 h (see Fig. 1d). Calcium phosphate precipitates synthesized without PEG on the same experimental condition was used as a control, which was poor crystalline apatite [21]. This implies that PEG is an effective stabilizer for ACP through the PEG-Ca2+ complex [22]. The Ca/P atomic ratios of ACP were examined by ICP. All of the samples synthesized for different aged times were around 1.50, equal to that of ideal Ca3(PO4)2 clusters, the ACP structure unit suggested by Posner and Betts [7].

Effects of different reactants on calcium phosphate precipitates are shown in Fig. 2. Amorphous phase with the characteristics of halo at 2θ = 30° were obviously seen in the patterns of the samples using water soluble reactants (Na3PO4 and CaCl2, (NH4)2HPO4 and Ca(NO3)2), but several diffraction peaks at 2θ = 25.8, 31.7 and 39.6°, assigned to apatite (JCPDS 9-432), appeared in that of the sample employing soluble (H3PO4) and slightly soluble Ca(OH)2 as reactants. It is known that C–O–C group in PEG can interact with Ca2+ and PEG-Ca2+ complex form [23], which stabilizes ACP in the mother solution [22]. All of the calcium ions are almost combined on the chain of PEG through the C–O–C group in the solution with the soluble calcium reagents (called bound calcium). The ACP precipitates were produced through the bound calcium, and then the fresh ACP precipitates were stabilized by this complex [22]. While some of Ca(OH)2 particles still did not dissolve in the distilled water and some small Ca(OH)2 particles were suspended in the solution and therefore these calcium ions could not be stabilized by PEG. When the phosphate solution was added, calcium and phosphate reacts directly and pure calcium phosphate precipitates without PEG were produced, which were very easy to transform into apatite in the short time by the process of dissolution and recrystallization [4, 7, 24]. ICP results show that all ACP samples synthesized using different reagents had the Ca/P atomic ratio of about 1.50. So, ACP can be obtained using the soluble stating materials.

XRD patterns of calcium phosphate precipitates synthesized using different starting materials. Ca/P = 1.5, pH = 10 and PEG:Ca2+ = 1:1 at 5 °C aged 0.5 h. (a) Sodium phosphate and calcium chloride, (b) ammonium hydrogen phosphate and calcium nitrate, (c) phosphate acid and calcium hydroxide. ■: apatite (JCPDS 9-432)

pH value is a determinant parameter in solution-chemistry. It also affects the transformation process of ACP in the mother solution [3, 7]. An increasing alkalinity in the mother solution can improve the stabilization of amorphous state [4]. Amorphous phase could be achieved until pH was no less than 7. A crystalline peak at = 11.6, 20.9, 29.2, 30.4, 34.0°, ascribed to hydrated calcium hydrogen phosphate (CaHPO4·2H2O, JCPDS 72-1240), appeared in the sample synthesized at the initial pH 6 (see Fig. 3c). The transformation of ACP into crystalline apatite in the aqueous solution can be described as follows [3]: when pH > 9.25, ACP converts into apatite directly by rearrangement of the atomics [25]; on the other hand, when pH < 9.25, ACP converts into OCP firstly and then OCP converts into apatite. The conversion of ACP into OCP is shown by Eq. 1. Acid is consumed in the conversion and acid (H+) accelerates this process. But no OCP was obtained in our experiments because the reaction in Eq. 1 did not take place due to stabilization of PEG and high pH value (pH 10). But some of phosphate group was protonated in the low pH, which depressed the Ca/P atomic ratio (see Table 1).

XRD patterns of calcium phosphate precipitates synthesized at different pH values. Ca/P = 1.5 and PEG:Ca2+ = 1:1 at 5 °C aged 0.5 h. (a) pH = 12, (b) pH = 7 and (c) pH = 6. ●: hydrated calcium hydrogen phosphate (CaHPO4·2H2O JCPDS 72-1240). The starting materials were ammonium hydrogen phosphate and calcium nitrate

However, the hydrated calcium hydrogen phosphate appeared when pH value was 6, because of two reasons. On the one hand, the phosphates were almost protonated completely in low pH solution; on the other hand, the interaction between C–O–C group and Ca2+ was very weak due to low pH [23] and then Ca2+ cannot be stabilized by PEG. Therefore, ACP cannot be formed in this condition.

Ca/P atomic ratios of the amorphous precipitates synthesized at different pH values are listed in Table 1. Ca/P atomic ratios decreased with drop of initial pH value. Ca/P atomic ratios of the samples synthesized at high pH (no less than 8) are around 1.50, while OCP-like composition, whose Ca/P atomic ratio equals to 1.33, was obtained when the initial pH value was 7. pH value not only affect the phase, but also change the chemical composition (Table 2).

Effect of the initial Ca/P atomic ratio also was studied as shown in Fig. 4. Amorphous phase could be synthesized using different initial Ca/P atomic ratios. But the Ca/P atomic ratio of the amorphous precipitates with the initial Ca/P atomic ratio of 1.25 is 1.40 ± 0.01, and those of the other samples are about 1.50, similar to chemical composition of ideal Ca3(PO4)2 clusters. It need to be investigated further to find out why the Ca/P atomic ratio of the ACP precipitates synthesized in the Ca/P atomic ratio of 1.25 is 1.40.

Characterization of ACP

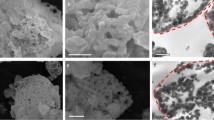

The typical ACP precipitates were characterized by TGA, FTIR and SEM/EDS, respectively, as shown in Fig. 5. There is a large weight loss (ca. 15 wt%) before 300 °C, assigned to the adsorbed water and structural water in the ACP clusters, which is consisted with the other’s results [7]. There exits about 4 wt% weight loss between 300 °C and 600 °C. PEG burned in this temperature range. This indicates that there still exists about 4 wt% PEG in the ACP precipitates even after washing repeatedly. The absorption band at 3,450 cm−1 is ascribed to molecular water. The absorption band at 2,890 cm−1 is assigned to CH2 stretching vibration, which is a group in the chain of PEG. It implies existence of PEG in ACP, consistent with TGA result. There are two obviously broad absorption peaks at 900–1,100 cm−1 and 500–600 cm−1 in the FTIR spectrum (see Fig. 5b). These non-split peaks result from the isotropic structure of amorphous materials and are the characteristics of ACP [7, 26], conformed by the XRD results. The classical spherical amorphous particles with the diameter of 60∼70 nm are seen in Fig. 5c and the particle size is uniform. There are only calcium, oxygen and phosphorus elements in the EDS spectrum (see inlet in Fig. 5c), except the copper element from the holder. It indicates that the ACP precipitates synthesized in our work are pure calcium phosphates without any contaminated elements, superior to the other work [16].

ACP is the intermediated phase of apatite and converts into the crystalline phase in the mother and/or secondary aqueous solution, through the process of dissolution and recrystallization, which is very similar to that of apatite deposit on the bioactive surface [3, 7]. It endows ACP with good bioactivity and better osteoconductivity than HA in vivo [27]. ACP with different chemical compositions (i.e. Ca/P ratio), can be used to prepare different crystalline calcium phosphate phases such as tricalcium phosphate and hydroxyapatite at the low temperature [13–15]. It is noteworthy that ACP synthesized in our work has 4 wt% PEG (Fig 5c), burning out during the heat-treatment to prepare the crystalline phases, which bring the crystalline powders smaller size and uniform size distribution [28, 29].

ACP also can retard the acid reaction of biodegradable polyester due to its high dissolution if filling the biopolymers in vitro [11]. The PEG adsorbed on the surface of ACP particles which give it potential to meliorate the interface of the ACP-based composites. ACP can be used as inorganic filler to enforce mechanical properties of the composites. Although many methods including chemical modification are developed to obtain a good surface of inorganic filler to be compatible to organic matrix, the additives are harmful to tissue [30]. It is necessary to select a biocompatible compound. Then, PEG can provide a biocompatible and hydrophobic surface of inorganic filler to get excellent mechanical properties. Therefore, ACP has potential to be used as biomaterials and tissue engineering scaffold.

Conclusion

Pure ACP without any contaminated elements were synthesized using poly(ethylene glycol) as stabilizing additive. ACP can be stabilized by PEG in the mother solution for more than 18 h, using any soluble starting materials with any initial Ca/P atomic ratio. However, amorphous phase can only be obtained in the basic or alkaline aqueous solution (>pH 6). The Ca/P atomic ratio of ACP can be controlled using adjusting the initial pH value and initial Ca/P atomic ratio from 1.33 to 1.50. The novel amorphous precipitates have uniform particle size in the diameter of 60∼70 nm, which endows it as potential precursors to prepare crystalline calcium phosphate phases.

References

A. BECKER, A. ZIEGLER and M. EPPLE, Dalton Trans. (2005) 1814

C. GUNTHER, A. BECKER, G. WOLF and M. EPPLE, Anorg. Allg. Chem. 631 (2005) 2830

E. D. EANES, In edited by L. C. CHOW and E. D. EANES, Octacalcium Phosphate (Basel: Karger, 2001) P. 130

A. L. BOSKEY and A. S. POSNER, J. Phys. Chem. 77 (1973) 2313

J. D. TERMINE and A. S. POSNER, Calcif. Tissue Res. 1 (1967) 8

J. D. TERMINE, R. E. WUTHIER and A. S. POSNER, Proc. Soc. Exp. Biol. Med. 125 (1967) 4

A. S. POSNER and F. BETTS, Acc. Chem. Res. 8 (1975) 273

P. J. TANNENBA, H. SCHRAER and A. S. POSNER, Calcif. Tissue Res. 14 (1974) 83

K. J. CROSS, N. L. HUQ, J. E. PALAMARA, J. W. PERICH and E. C. REYNOLDS, J. Biol. Chem. 280 (2005) 15362

T. C. A. MCGANN, R. D. KEARNEY, W. BUCHHEIM, A. S. POSNER, F. BETTS and N. C. BLUMENTHAL, 35 (1983) 821

W. LINHART, F. PETERS, W. LEHMANN, K. SCHWARZ, A. F. SCHILLING, M. AMLING, J. M. RUEGER and M. EPPLE, J. Biomed. Mater. Res. 54 (2001) 162

L. L. HENCH and J. M. POLAK, Science 295 (2002) 1014

P. LAYROLLE and A. LEBUGLE, Chem. Mater. 8 (1996) 134

P. LAYROLLE, A. ITO and T. TATEISHI, J. Am. Ceram. Soc. 81 (1998) 1421

T. TOYAMA, K. NAKASHIMA and T. YASUE, J. Ceram. Soc. Jpn. 110 (2002) 716

D. SKRTIC J. M. ANTONUCCI, E. D. EANES and R. T. BRUNWORTH, J. Biomed. Mater. Res. 59 (2002) 597

A. S. POSNER, F. BETTS and N. C. BLUMENTHAL, Progr. Cryst. Growth. Char. Mater. 3 (1980) 49

E. D. EANES, I. H. GILLESSE and A. S. GOSNER, Nature. 208 (1965) 365

K. J. CROSS, N. L. HUQ, D. P. STANTON, M. SUM and E. C. REYNOLDS, Biomaterials. 25 (2004) 5061

P. B. Y. OFIR, R. GOVRIN-LIPPMAN, N. GARTI and H. FUREDI-MILHOFER, Cryst. Growth Des. 4 (2004) 177

Y. B. LI, W. J. WENG, K. CHENG, P. Y. DU, G. SHEN, J. X. WANG and G. R. HAN, J. Mater. Sci. Lett. 22 (2003) 1015

Y. B. LI, W. J. WENG, K. CHENG, P. Y. DU G. SHEN and G. R. HAN, Mater. Sci. Technol. 20 (2004) 1075

K. HORIKOSHI, K. HATA, N. KAWABATA, S.-I. IKAWA and S. KONAKA, J. Mol. Struct. 239 (1990) 33

J. CHRISTOFFERSEN, M. R. CHRISTOFFERSEN, W. KIBALCZYC and F. A. ANDERSEN, J. Cryst. Growth 94 (1989) 767

F. ABBONA and A. BARONNET, J. Cryst. Growth 165 (1996) 98

L. ADDADI, S. RAZ and S. WEINER, Adv. Mater. 15 (2003) 959

M. NAGANO, T. NAKAMURA, T. KOKUBO, M. TANAHASHI and M. OGAWA, Biomaterials 17 (1996) 1771

S. BOSE and S. K. SAHA, J. Am. Ceram. Soc. 86 (2003) 1055

Y. B. LI, W. J. WENG and K. C. TAM, Acta Biomat. 3 (2007) 251

A. M. P. DUPRAZ, S. A. T. MEER J. R. WIJN and J. H. GOEDEMOED, J. Mater. Sci.: Mater. Med. 7 (1996) 731

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Weng, W. In vitro synthesis and characterization of amorphous calcium phosphates with various Ca/P atomic ratios. J Mater Sci: Mater Med 18, 2303–2308 (2007). https://doi.org/10.1007/s10856-007-3132-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-007-3132-4