Abstract

Hydroxyapatite was modified by stearic acid (Sa) in the organic mediated solution using a reflux setup. Activation ratio was introduced to characterize the effect of organic solvents, reaction times and adding amounts of Sa. HA before and after surface modification were investigated by XRD, FTIR, particle size distribution, TEM and ICP. The optimal adding amount of Sa is about 3 wt%, and there are Sa molecules on the surface of HA with a chemical reaction between HA and Sa. Sa did not change the phases and particle size of HA. HA after modified has good bioactivity in vitro. Sa has great potential as surface modifier to improve the properties of inorganic fillers in the organic matrix.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Calcium phosphates are widely used as the inorganic fillers in the polymer matrix to produce biocomposite materials, which can improve its biological and mechanical properties [1]. The inorganic-organic composition and structure of biocomposites can simulate those of bone in the body. However, the interface of biocomposites is very poor while that of mineral and collagen in bone is considered to be an ideal composite interface. The interface is determined by the polarities of the filler and matrix. But calcium phosphates are hydrophilic and polymer is mostly hydrophobic. The main approach is to modify the surface of the filler or polymer to change the polarities (i.e. hydrophobic or hydrophilic modification). More and more attentions have been paid to surface modification of calcium phosphate fillers in the past decades [2–11], due to its more simpleness and convenience compared to that of polymer.

On the other hand, the surface modification of calcium phosphates also can change their behaviors in the physiological solution and interaction with the tissue in vivo, and adjust the release rate of Ca2+ and PO4 3− and biological properties on the surface of materials (cell adhesion and cell proliferation on the materials) [12]. Therefore, surface modification of calcium phosphates not only remodels their surface state, but also controls their biological properties.

Surface modifier of biomaterials should satisfy the following requirements, because it is implanted in the body: (i) no physiological toxicity, (ii) biocompatibility, (iii) no obvious changing the physico–chemical and biological properties of the inorganic fillers. The surface modifiers mostly used to calcium phosphates include silane coupling agent [3, 5, 6, 10, 11, 13], titanate coupling agent [7], organic phosphate [2, 14, 15] and some functional polymer [16–18], small molecular organic [19–21] and even phosphoric acid [22]. However, most of these chemicals can not satisfy the above requirements, simultaneously. For example, the free silane is biotoxic to tissue cell as reported by Dupraz et al [13]; some macromolecules such as poly(acrylic acid) retard strongly (even prevent) the deposit of apatite on the implant surface in the SBF solution, that is, depress badly the bioactivity [23]. The suitable surface modifiers are poly (ethylene glycol) and poly(lactic acid) with small molecule weight by grafting on the surface of calcium phosphate fillers.[4, 17, 24] However, the grafting reaction is complex and difficult to control the parameters and finial product.

In this paper, stearic acid (denoted as Sa) was introduced to modification of calcium phosphate fillers in order to resolve the problems as described above. Sa is widely used as surface modifier in the calcium carbonate industry and crystal modifier in the formation of calcium phosphates [25, 26]. Sa is a kind of fatty acids in the body, which is biocompatible, and can be excreted after decomposition into water and carbon dioxide by metabolism [27]. As for the effect on the bioactivity, there is not report, which will be investigated in this paper. Thus, it can be seen that Sa seems to be good potential to use as surface modifier for calcium phosphate fillers.

In this work, Sa was used to surface modify hydroxyapatite (HA)-mineral phase of bone in the different reaction media, reaction time and adding amount of Sa. Then physico-chemical properties and in vitro behaviors of the modified hydroxyapatite by Sa were examined.

Experimental procedure

Raw materials

Hydrated calcium nitrate (Ca(NO3)2·3H2O), ammonium hydrogen phosphate ((NH4)2HPO4), ammonium hydroxide (NH4OH), ethanol alcohol (C2H5OH), acetone, N,N-dimethylformamide, tetrahydrofuran, cyclohexane and stearic acid were purchased from Shanghai Chemical Co. and used without purification further.

Synthesis of HA

Hydroxyapatite (HA) was synthesized using wet chemical method followed by a heat-treatment. Calcium nitrate was dissolved in the distilled water to form 0.2 M calcium solution and ammonium hydrogen phosphate solution (0.133 M) was added dropwise into calcium solution with the initial Ca/P molar ratio of 1.67. The volumes of calcium nitrate and ammonium hydrogen phosphate solutions were 200 mL and 180 mL, respectively. The white precipitates occurred and the reaction was conducted at room temperature for 3 h, and pH was kept at 10 by adding ammonium hydroxide solution during the whole reaction. The precipitates were washed repeatedly by a large of distilled water and dried in oven at 120 °C for 24 h. The HA powders were obtained by heating the fresh calcium phosphate precipitates at 800 °C for 3 h without sieving or milling.

Modification of HA

At first, stearic acid (Sa) with a given amount (1–11 wt%, relative to the amount of HA powders) was dissolved in 100 mL organic solvent (such as ethanol alcohol, acetone, DMF and THF) to form a clear Sa solution and five grams of HA powders were added to the Sa solution and the mixture of HA/Sa/solvent system was put into a reflux setup to keep reaction for different times. The modified HA powders were collected after washed several times by hot ethanol alcohol to remove the free Sa adsorbed on the surface and dried at 80 °C for 24 h.

Activation ratio (%)

The modification effect of Sa was expressed by activation ratio (%). The activation ratio, also called floating ratio, is defined according the Chinese chemical industry standard (HG/T2567-1994, Activated Precipitated Calcium Carbonate for Industrial Use) as followed: a given amount of modified inorganic fillers (m0) are dispersed in the water, and shaken for 1 min, the sank fillers on the bottom are dried and weighted (m1) after placement for a long time to get obvious delamination. Then the activation ratio (x) is calculated as Eq. 1.

However, the calculation of activation ratio in our work was a little modified as followed: a given amount of modified inorganic fillers (m0) are dispersed in the water, and shaken for 5 min, ultrasonic for 10 min and shaken again for 5 min, the mixture was placed intact for more than 12 h to get the separately floating fillers on the surface and sinking filler on the bottom of the water, respectively. The floating fillers on the surface are collected, dried and weighted (m1). Then the modified activation ratio (x) is calculated as Eq. 2.

The modified activation ratio is more reasonable and scientific. The ultrasonic detaches the aggregation of fillers in the solution at the most extent and make the filler contact with water completely. The calculated activation ratio is lightly lower than the real value because not all of the floating fillers were collected. The activation ratio was measured three times and the average was used. The activation ratio expresses the effect of surface modification, which means the higher activation ratio, the more Sa molecule on the surface of HA powders.

Characterization

Basic characterization

The HA powders before and after surface modification were characterized by X-ray diffractometry (XRD), Fourier transform infrared spectrometry (FTIR), particle size distribution and Transmission Electron Microscopy (TEM). The XRD profiles were recorded in step-scan intervals of 0.02° 2θ at a scanning speed of 4°/min with Cu Kα radiation (λ = 1.5418 Å) using a Rigaku X-ray diffractometer operated at 36 kV and 30 mA. The FTIR (from 4000 cm−1 to 400 cm−1) was conducted using a Nicolet Avatar 360 spectrophotometer by a KBr pellet method with 2 cm−1 resolution and the scan number of 16. In order to observe the dispersion of HA powders in the non-polar solvent, they were dispersed in cyclohexane and dropt on the 300-mesh copper grid with carbon coating on the polymer film support after ultrasonic treatment for 10 min, the morphology of HA powders was observed using TEM (JEOL CX-100) operated at 200 KeV.

Biodegradation

One hundreds mg HA powders before and after surface modification were weighted precisely and put into 50 mL 0.1 M NaAc-HAc buffer solution with pH value of 5.0. The NaAc-HAc buffer solution was put in the 100 mL PP bottle with a cover. Then, the PP bottles were placed in constant temperature shaking incubator with the shaking rate of 100 time·min−1 after ultrasonic treatment for 10 min. The incubating temperature was kept at 37 °C. The PP bottle was taken out of the incubator after incubating for 6, 12, 24, 48 and 96 h and the clear solution was collected immediately after centrifuge. The Ca2+ and PO4 3− concentration in the clear solution were determined by induced coupled plasma atomic spectroscopy (ICP) with a Thermo Jarrell Ash Mark IV instrument.

Bioactivity

One hundreds mg HA powders before and after surface modification were weighted precisely and put into 50 mL simulated body fluid (SBF) solution prepared as reported by Kokubo et al [28]. The SBF solution was put in the 100 mL PP bottle with a cover. Then, the PP bottles were placed in constant temperature shaking incubators with the shaking rate of 100 time·min−1 after ultrasonic treatment for 10 min. The incubating temperature was kept at 37 °C. The PP bottle with SBF solution and HA sample was taken out of the incubator after incubating for 8, 16, 24, 48 and 96 h and the clear solution was collected immediately after centrifuge. The Ca2+ and PO4 3− concentration in the clear solution were determined by ICP. The amount of calcium precipitate was calculated as Eq. 3:

Where, [Ca2+]t is calcium concentration in SBF solution after soaking HA sample for t time, [Ca2+]SBF is calcium concentration in SBF solution before soaking HA sample, [Ca2+]SBF = 2.5 mM, Then Eq. 3 can be expressed as Eq. 4.

The amount of phosphate precipitate was calculated with similarity to that of calcium precipitate as Eq. 5:

Where, [PO4 3−]t is phosphate concentration in SBF after soaking HA sample for t time.

Results

Surface modification

HA powders were modified using different organic solvents as reaction media after refluxing for 12 h. The effect of reaction media is shown in Fig. 1. The activation ratios of HA samples modified in acetone, ethanol, DMF and THF are 94, 84, 78 and 76%, respectively. Taking the effect of modification and properties of reaction media (especially the safety of biomaterials) into account, ethanol was selected as reaction media in the following experiments.

The effect of reaction time on the activation ratios is given in Fig. 2. At the beginning, the longer reaction time used, the higher activation ratio obtained. However, the maximum of activation ratio was obtained after reflux for 12 h. The activation ratio almost became constant after refluxing for more than 12 h.

Figure 3 presents the activation ratios of the HA samples modified by adding different amounts of Sa into the ethanol. The activation ratio is very low when just adding a little Sa into the solvent. The activation ratio increased fast from 4% to 54% as the adding amount of Sa from 1 to 2 wt%, and arrived the maximum when adding 3 wt% Sa. And the activation ratio almost did not increase when adding more than 3 wt% Sa.

Characterization

XRD pattern

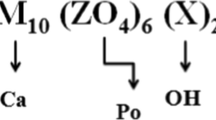

The crystalline phases of HA powders before and after surface modified by Sa are both hydroxyapatite phase (ICDD 09-432) as shown in Fig. 4. The crystalline phases of the HA fillers are same before and after modified by Sa.

FTIR spectra

FTIR spectroscopy is an effective tool to examine the interaction between active groups at the molecular level. Fig. 5 presents FTIR spectra of HA modified by different amounts of Sa in the ethanol-mediated solution. There are some very strong absorption bands at 2954, 2917, 2848 1471, 1430 and 1409 cm−1. These bands are due to CH3 and CH2 groups coming from Sa molecule [20, 29], which shows the Sa exists in the surface of HA fillers. Moreover, the intensity of these bands increased as adding more Sa in the solution, consisted with the results of activation ratio. It is worthy to note that two new bands at 1548 and 879 cm−1 appeared and their intensity increased as adding more Sa in the reaction system. The band at 1548 cm−1 is ascribed to antisymmetric stretching vibration of COOCa from the interaction between COOH and Ca2+ [29], and the one at 879 cm−1 assigned to HPO4 2− group coming from reaction of PO4 3− with H+ from COOH group. The bands at 1100–900 and 610–500 cm−1 are due to vibration of PO4 3− in crystalline calcium phosphate phase [30, 31]. The 3571 and 630 cm−1 bands are characteristics of stretching and libration vibration of OH group respectively.[30, 31] There is 1457 cm−1 band in the FTIR spectrum of unmodified HA (no stearic acid), which is ascribed to CO3 2− group (v 3), an indicator of carbonate in the hydroxyapatite structure [31].

Particle size distribution

The particle size of HA after modification is smaller than that of HA before modification when dispersed in the ethanol solution as showed in Fig. 6.

TEM observation

HA fillers before and after modification were dispersed in no-polar cyclohexane to examine the effort of the modification. Seeing Fig. 7, the representative dispersion of HA fillers after modification in the no-polar cyclohexane is obviously better than that before modification.

Biodegradation

Figure 8 gives the Ca2+ and PO4 3− release of HA before and after modification soaked in the pH 5.0 NaAc-HAc buffer solution. The ions release from HA are a little lower after modified by Sa.

Bioactivity

The amount of apatite deposited on the surface of HA after modified decreased in certain extent because the surface of HA fillers are covered by Sa. But Sa can not prevent the deposit of apatite as reported by Kamitakahara et al [23]. The amount of apatite deposited on the HA after modified by Sa soaked for 48 h is equal to that before modified soaked for 8 h. This means that Sa only delay 40 h for apatite deposit.

Discussion

HA fillers were modified by different organics or polymers. However, most of them change the properties of HA fillers after surface modification.

Surface of HA fillers were modified successfully by Sa in the organic mediated solutions. The different solvents affect the activation ratio of HA fillers as showed in Fig. 1. It is due to chemical properties of the mediated solvents and physico–chemical properties of Sa. Sa can volatilize at ∼60 °C with a very low rate. The reaction temperature was controlled by a reflux setup (actually, the boiling point of the solvents). Table 1 presents boiling points of the used solvents. There are obviously differences between the boiling points of the different solvents: only the boiling point of AT (56.2 °C) is lower than the volatilizing point of Sa (∼60 °C); those of the others are higher. Some of Sa volatilized during the reflux in the EA, DMF and THF, which results in the lower activation ratio in these three solvents, respectively.

There are two modes in the reaction of HA and organics: adsorption and chemical reaction. The absorption is not very strong, and the Sa can be removed after washed using the hot ethanol. The chemical reaction means reaction of Sa and HA and formation of chemical bond (Fig. 9).

It can be found from FTIR spectra (Fig. 5) that two new bands at 1549 and 879 cm−1 appeared in the modified HA samples. These new bands are due to vibrations of COOCa group from reaction of Ca and COOH and HPO4 2− group from reaction of PO4 3− with H+ from COOH group which means there is chemical reaction between Sa and HA as showed in Fig. 10 and there are Sa molecules staying on the surface of HA fillers.

The Sa on the surface of HA fillers can endow its hydrophobicity and the modified HA has good compatibility with cyclohexane. This makes it good dispersion of modified HA in non-polar cyclohexane (Fig. 7).

HA still can release Ca2+ and PO4 3− ions in the acetate buffer solution after surface modification as showed in Fig. 8 and apatite can deposit on the surface of modified HA in the SBF solution. According to the view of Kokubo et al, the bioactivity of HA containing materials can be verified by: (i) release of Ca2+ and PO4 3− ions and (ii) deposit of apatite in SBF solution [12, 23]. Our work presents that HA still has bioactivity even after modified by Sa in the organic solvent. This shows that Sa only delays the bioactivity of HA several hours as showed in Fig. 9.

Conclusions

Sa was used to modify HA in the organic solution to improve its surface characteristics. There are Sa molecules reacted with HA to form chemical bond, which make HA after modified have good dispersion in non-polar cyclohexane. When HA soaked in the SBF solution, Sa on the surface of HA just delay 48 h to deposit apatite, which shows that Sa does not prevent apatite deposit as reported [23].

References

M. WANG, Biomaterials 24 (2003) 2133

S. C. D’ANDREA and A. Y. FADEEV, Langmuir 19 (2003) 7904

S. M. ZHANG, S. P. LI, Y. H. YAN, T. WAN, X. JIANG, C. R. HAN and X. P. SONG, J. Wuhan Univ. Technol.-Mat. Sci. Edit. 16 (2001) 37

Q. LIU, J. R. DE WIJN, K. DE GROOT and C. A. VAN BLITTERSWIJK, Biomaterials 19 (1998) 1067

A. M. P. DUPRAZ, J. R. DEWIJN, S. A. T. VANDERMEER and K. DEGROOT, J. Biomed. Mater. Res. 30 (1996) 231

R. A. SOUSA, R. L. REIS, A. M. CUNHA and M. J. BEVIS, J. Mater. Sci.-Mater. Med. 14 (2003) 475

C. M. VAZ, R. L. REIS and A. M. CUNHA, Biomaterials 23 (2002) 629

S. DEB, M. WANG, K. E. TANNER and W. BONFIELD, J. Mater. Sci.-Mater. Med. 7 (1996) 191

A. M. P. DUPRAZ, S. A. T. MEER, J. R. WIJN and J. H. GOEDEMOED, J. Mater. Sci.-Mater. Med. 7 (1996) 731

M. WANG and W. BONFIELD, Biomaterials 22 (2001) 1311

E. LOSTE, J. FRAILE, M. A. FANOVICH, G. E. WOERLEE and C. DOMINGO, Adv. Mater. 16 (2004) 739

T. MIYAZAKI, C. OHTSUKI, H. IWASAKI, S. OGATA and M. TANIHARA, Mater. Sci. Forum. 426(4) (2003) 3201

A. M. P. DUPRAZ, S. A. T. VANDENMEER, J. R. DEWIJN and J. H. GOEDEMOED, J. Mater. Sci.-Mater. Med. 7 (1996) 731

L. M. RODRIGUEZ-LORENZO, B. VAZQUEZ and J. S. ROMAN, in “Bioceramics, Vol 17” (2005) p. 357

H. TANAKA, A. YASUKAWA, K. KANDORI and T. ISHIKAWA, Colloid Surf. A-Physicochem. Eng. Asp. 125 (1997) 53

M. B. CLAASE, D. GRIJPMA and J. FEIJEN, J. Control. Release 101 (2005) 329

Z. K. HONG, P. B. ZHANG, C. L. HE, X. Y. QIU, A. X. LIU, L. CHEN, X. S. CHEN and X. B. JING, Biomaterials 26 (2005) 6296

Q. LIU, J. R. DE WIJN and C. A. VAN BLITTERSWIJK, J. Biomed. Mater. Res. 40 (1998) 490

H. TANAKA, T. WATANABE, M. CHIKAZAWA, K. KANDORI and T. ISHIKAWA, J. Colloid Interface Sci. 214 (1999) 31

L. BORUM-NICHOLAS and O. C. WILSON, Biomaterials 24 (2003) 3671

R. MURUGAN and K. P. RAO, J. Biomater. Sci.-Polym. Ed. 14 (2003) 457

C. KUNZE, T. FREIER, E. HELWIG, B. SANDNER, D. REIF, A. WUTZLER and H. J. RADUSCH, Biomaterials 24 (2003) 967

M. KAMITAKAHARA, M. KAWASHITA, T. KOKUBO and T. NAKAMURA, ibid. 22 (2001) 3191

Q. LIU, J. R. DEWIJN, D. BAKKER and C. A. VANBLITTERSWIJK, J. Mater. Sci.-Mater. Med. 7 (1996) 551

K. J. KIM, J. L. WHITE, S. E. SHIM and S. CHOE, J. Appl. Polym. Sci. 93 (2004) 2105

H. B. LU, C. L. MA, H. CUI, L. F. ZHOU, R. Z. WANG and F. Z. CUI, J. Cryst. Growth 155 (1995) 120

Q. N. ZHANG, G. Q. YIE, Y. LI, Q. S. YANG and Y. T. NAGAI, Int. J. Pharm. 200 (2000) 153

T. KOKUBO, H. KUSHITANI, S. SAKKA, T. KITSUGI and T. YAMAMURO, J. Biomed. Mater. Res. 24 (1990) 721

F. KIMURA, J. UMEMURA and T. TAKENAKA, Langmuir 2 (1986) 96

J. C. ELLIOT, in “Structure and chemistry of the apatites and the other calcium orthophosphates”, edited by J. C. Amsterdam: Elliot Elesiver Science B.V. (1994)

S. KOUTSOPOULOS, J. Biomed. Mater. Res. 62 (2002) 600

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Weng, W. Surface modification of hydroxyapatite by stearic acid: characterization and in vitro behaviors. J Mater Sci: Mater Med 19, 19–25 (2008). https://doi.org/10.1007/s10856-007-3123-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-007-3123-5