Abstract

Calcium phosphate cement (CPC) is a highly promising bone substitute and an excellent carrier for delivering growth factors. Yet, the lack of macro-porosity and osteoinductive ability, limit its use. This study is aimed at developing a novel biodegradable biomaterial for bone repair with both highly osteoconductive and osteoinductive properties. RhBMP-2 loaded PLGA microspheres were incorporated into rhBMP-2/CPC for macropores for bone ingrowth. The compressive strength, crystallinity, microscopic structure, and bioactivity of the composites were investigated. The results showed that with the incorporation of rhBMP-2 loaded PLGA microspheres, the compressive strength was decreased from (29.48 ± 6.42) MPa to (8.26 ± 3.58) MPa. X-ray diffraction revealed that the crystallinity pattern of HA formed by CPC had no significant change. Inside the composite, the microspheres distributed homogeneously and contacted intimately with the HA matrix, as observed by scanning electron microscopy (SEM). When the PLGA microspheres dissolved after having been emerged in PBS for 56 days, macropores were created within the CPC. The rhBMP-2/PLGA/CPC composite, showing a 4.9% initial release of rhBMP-2 in 24 h, followed by a prolonged release for 28 days, should have a greater amount of rhBMP-2 released compared to the CPC delivery system. When rabbit marrow stromal cells were cocultured with the composite, the alkaline phosphatase (ALP) and osteocalcin (OC) showed a dose response to the rhBMP-2 released from the composite, indicating that the activity of rhBMP-2 was retained. This study shows that the new composite reveals more rhBMP-2 release and osteogenic activity. This novel BMP/PLGA/CPC composite could be a promising synthetic bone graft in craniofacial and orthopedic repairs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Calcium phosphate materials have been widely used as bone substitutes in dentistry as well as orthopedic and reconstructive surgery. This group of materials exhibits a high level of biocompatibility and osteoconductivity. Of the various calcium phosphates, calcium phosphate cement (CPC) has received considerable attention. Calcium phosphate cement (CPC) consists of a mixture of fine particles of calcium phosphate salts, such as tetracalcium phosphate [TTCP] and dicalcium phosphate anhydrous (DCPA). The CPC powder can be mixed with water to form a paste that can conform to osseous defects with complex shapes and set in vivo to form degradable hydroxyapatite [1, 2]. Thus, CPC is highly promising as a bone substitute in orthopedics and serves as a carrier material for growth factors such as BMP [3–5]. However, some problems hinder clinic use of CPC. One problem with CPC is that it consists of only micropores with pore sizes of submicrometer to a few micrometers. Lack of macropores and low porosity make its resorb rate rather slow [1, 6], one study showed about half of the CPC implant was resorbed and replaced by new bone after 9–18 months [6]. Meanwhile, when the CPC was used as the carrier of BMP, the BMP release rate was rather slow (3–13% after two weeks) [3, 4]. Prolonged retention of the entrapped proteins might result in the loss of their osteoinductive potential. So it is desirable to shorten the resorption time of CPC. Creating a high macroporosity in CPC may increase the graft surface area and biodegradable rate and facilitate cell infiltration and tissue ingrowth [7, 8]. Recent studies showed that the formation of macropores in conventional CPC, with pore forming agents, would enhance bone ingrowth and implant fixation [8]. However, one problem is that incorporating macropores into the cement has always led to a significant decrease in mechanical strength [9, 10]. Here we synthesis a novel bone substitute by incorporating rhBMP-2 loaded poly(lactide-co-glycolide) microspheres into calcium phosphate cement during the self-setting of CPC. We assumed that the PLGA microspheres will initially stabilize the graft but can then quickly degrade to leave behind macropores for bone ingrowth, the BMP release rate will be increased, and the CPC matrix could then be resorbed and replaced with new bone. The present study addresses the effects of the PLGA microspheres on mechanical properties, the in vitro rhBMP-2 release character and the bioactivity of the new composite.

Materials and methods

Preparation of rhBMP-2-loaded micropheres

Recombinant human bone morphogenetic protein-2 (rhBMP-2) was obtained from R&D Systems. The poly (lactide-co-glycolide) (PLGA) was obtained from Decon (Shichuan, China) with a lactide–glycolide molar ratio of 50:50 and an average molecular weight (Mw) of 24,000. RhBMP-2 loaded microparticles entrapping rhBMP-2 were prepared by a water-in-oil-in-water (W/O/W) double-emulsion, solvent-extraction technique [11]. Briefly, 247.5 mg PLGA was first dissolved in 1 ml of dichloromethane, and 200 μg rhBMP-2 was diluted in a buffer solution of phosphate buffered saline solution (PBS) with 0.1% bovine serum albumin (BSA) to a final concentration of 1.6 mg/ml, then the BMP was mixed with the PLGA and the entire mixture was emulsified on a vortexer for 1 min. This solution was then re-emulsified in 100 ml of 0.3% poly (vinyl alcohol) (Mw = 13,000–23,000, sigma) solution, resulting in a double emulsion. The second emulsion was added to 100 ml of a 2% aqueous isopropyl alcohol (IPA) solution and maintained on a magnetic stirrer for 1 h. The formed microspheres were finally collected by centrifugation, lyophilized and stored at −20 °C for future use. The size of the microparticles was measured with a Coulter counter multi-sizer (model 0646; Coulter Electronics, USA). The morphology of the microparticles was evaluated by scanning electron microscopy (JSM-5300; JEOL, Japan). The rhBMP-2 loading density of the microspheres was determined using a solvent-extraction technique [12]. Approximately 20 mg of microparticles were dissolved in 1 ml of dichloromethane for 6 h at 37 °C. The entrapped rhBMP-2 was extracted from the organic phase to the aqueous phase by incubation with 1 ml of PBS for an additional 24 h. The concentration of rhBMP-2 was analyzed by enzyme linked immunosorbent assay (ELISA) using an rhBMP-2 quantified kit (Boster Cor, China) [12]. Briefly, 50 μl of the sample solution was added to each well of the kit coated with anti-BMP-2 monoclonal antibody. After 3 h of incubation, the solution was decanted from the plate, rinsed several times with a buffer solution, and a secondary antibody solution was added to combine the rhBMP-2 to the base of the plate. A colorized reagent was then added and the amount of rhBMP-2 present in each sample was quantified by measuring the absorbance at 450 nm with a microplate reader (MK3, Labsystem Instruments), with a sensitivity of 10 pg/ml.

Preparation of rhBMP-2/PLGA/CPC and rhBMP-2/CPC composites

CPC was kindly supplied by Rebone Company (Shanghai, China). The cement powder consisted of an equimolar mixture of tetracalcium phosphate (TECP) and anhydrous dicalcium phosphate (DCPA). The cement liquid consisted of H2O containing 4% sodium hydrogen phosphate (Na2HPO4). The BMP loaded PLGA microspheres were mixed with the CPC powder at a weight ratio of 0/100 and 40/60 as solid phase, then the solid phase was mixed with rhBMP-2 containing liquid phase (2% Na2HPO4) at ratio of 3 (g/ml). Each mixed paste was then placed into stainless steel molds of φ 6 mm × 5 mm to make specimens. The paste in each mold was sandwiched between two glass slides, set in a humidor with 100% relative humidity at 37 °C and removed from the molds after setting. In rhBMP-2/CPC, the concentration of rhBMP-2 of the liquid was adjusted to achieve an rhBMP-2 dosage of approximately 250 μg per specimen. In rhBMP-2/PLGA/CPC, according to the result of rhBMP-2 loading density of the PLGA microspheres, the amount of rhBMP-2 in the liquid phase was reduced by the amount of rhBMP-2 in the PLGA microspheres in the specimen to ensure the same dosage. The specimens were then sterilized by epoxy ethane gas.

Characterization of rhBMP-2/PLGA/CPC and rhBMP-2/CPC composite

The physicochemical characteristics of rhBMP-2/PLGA/CPC and rhBMP-2/ CPC were evaluated by compressive test, X-ray diffraction (XRD) analysis and scanning electron microscopy (SEM). Samples for the compression test were immersed in saline solution (0.9% NaCl) at 37 °C for 4 days once they were removed from the mold, and the compression was then tested using an Universal Testing Machine (AGS-10KNG, Autograph, Japan) at a speed of 1 mm/min until failure. The mean value of compressive strength for each group was obtained from the results of at least six parallel cement samples. The analysis was performed with a Ni-filter Cu Ka radiation. The potential was 40 kV and the current was 30 mA. The step-scanning was performed with an integration time of 10 s at intervals of 0.02° (2θ). One sample for each material was collected for microscopic observations using scanning electron microscopy (SEM) (JEOL6400, Japan).

In vitro release of rhBMP-2 from rhBMP-2/PLGA/CPC and rhBMP-2/CPC composite

Release studies were conducted in Eagle’s basal medium (BME; Sigma) supplemented with 10% heat-inactivated fetal bovine serum (Sijiqin, China) and antibiotics of 100 IU/ml penicillin and 100 mg/ml streptomycin; (Sigma). This medium will be referred to as ‘complete BME’. Each rhBMP-2-loaded composite was immersed into 2 ml complete BME and incubated at 37 °C. At pre-determined time intervals (1, 3, 7, 14, up to 28 days), the supernatant was withdrawn completely and replaced with an equal volume of fresh medium. The collected supernatant was filtered and stored at −20 °C until evaluation by an rhBMP-2 sandwich enzyme-linked immunosorbent assay (ELISA) kit (Boster, China) as previously described. The amount of protein released at each time point was used to construct cumulative release profiles. The composites were continued to culture within the medium for up to 56 days, then the compressive stress and the interior microstructure of the composites (referred to as “aged” composites) were evaluated with the methodology mentioned above.

In vitro cellular response to the rhBMP-2 released from rhBMP-2/PLGA/CPC and rhBMP-2/CPC composite

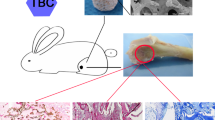

Preparation of MSCs cells

Bone marrow stromal cells were isolated from the femurs of New Zealand White rabbits. Primary cultures of bone marrow cells were established as previously described [13]. In brief, the femurs of the rabbits were aseptically excised from the hind limbs, the proximal head and distal end of the femur were clipped off, the medullary canals of the femurs were flushed with complete BME to harvest bone marrow, Samples of cell suspensions were cultured in complete BME in an incubator at 37 °C with a 100% humid atmosphere of 5% CO2. Nonadherent cells were removed on the third day by exchanging the medium. Subculturing was performed with a 2.5 g/l trypsin solution before the cells reached confluence. The medium was then exchanged every 3 days. Cells from the 3rd to 5th passages were used for in vitro testing.

Preparation of rhBMP-2 release medium (conditioned medium)

Each rhBMP-2/PLGA/CPC or rhBMP-2/CPC sample, sterilized by epoxy ethane gas, was individually poured into 2 ml of complete BME culture medium and incubated in a humid atmosphere of 5% CO2 at 37 °C. At 1 and 7 days, the 24 h rhBMP-2 release medium was collected and stored at −20 °C until used.

In vitro rhBMP-2 bioactivity testing

MSCs were seeded at 2 × 104/well in 24 well plates containing 2 ml complete BME. After cell adhesion in 24 h, the culture medium was removed and the different rhBMP-2 release mediums were added to the plates inoculating MSCs cells. The medium without released rhBMP-2 served as the control group. The plate was incubated in a humid incubator with 5% CO2 at 37 °C for 7 days, with two medium renewals per week. After completion of cell culture, the media was removed, the cells were washed once in phosphate buffered saline (PBS) and lysed with 0.5 ml 0.1% (v/v) Triton-X-100. The lysed cells were analyzed for alkaline phosphatase, protein, and osteocalcin expression.

Alkaline phosphatase activity was measured using p-nitrophenyl phosphate as substrate in 2-amino-2-methyl-1-propanol alkaline buffer solution by a modification of the protocol of Lowry [14]. Total cell protein was measured employing the Bio-Rad reagent (Bio-Rad, USA.) according to the manufacturer’s instructions using bovine serum albumin as a standard. ALP activity was normalized by the protein concentration and expressed as nmol PNP/h/ μg protein. The osteocalcin levels of the conditioned medium of four wells in each group were assayed by radioactive immunoassay (East Asia Biomedical Technologies Inc. China). The medium samples and standards were incubated with goat anti-rabbit osteocalcin antibody (100 μl) and normal goat serum (300 μl) and maintained at 4 °C for 24 h, then 125I-labeled rabbit osteocalcin solution (100 μl) was added and incubated for an additional 24 h. Finally, all the samples were incubated for 2 h with donkey anti-goat IgG solution (1 ml). Following centrifugation at 1,500 rpm at 4 °C for 20 min, the sample pellets were rinsed with ddH2O, and analyzed on a γ-irradiation counter (Gensys, USA).

Statistical analysis

All values were expressed as means ± standard deviation (SD). Statistical analyses of the data were performed using an unpaired t-test with Welch correction with the aid of the SPSS package (version 10.0), with significance assumed at P ≤ 0.05.

Results

Characteristics of the rhBMP-2/PLGA microspheres

The average sizes of the microspheres was (253 ± 64) μm. The SEM pictures showed that the microspheres were spherical and had smooth surfaces (Fig. 1). The loading density of rhBMP-2 in the microspheres was 0.52% ± 0.14%.

SEM

Representative SEM pictures of the fractured rhBMP-2/PLGA/CPC and rhBMP-2/CPC cylinders are shown in Fig. 4. The microspheres maintained their integrity, distributed homogenously and contacted intimately with the CPC matrix (Fig. 4B). Micropores, 1 μm wide at maximum, were observed in CPC matrix (Fig. 4A). Examples of macropores from the PLGA microspheres dissolution after 56 days immersion in PBS are shown in Fig. 4C. A pore at a higher magnification is shown in Fig. 4D, where arrows point to the micropore between the macropores.

Compressive strength

The mean maximum compressive strength for rhBMP-2/PLGA/CPC and rhBMP-2/CPC are shown in Fig. 2. The compressive strength for the rhBMP-2 PLGA/CPC cylinder was significantly lower (P < 0.01) than that for the rhBMP-2/CPC (29.48 ± 6.42 MPa vs. 8.26 ± 3.58 MPa), but significantly higher (P < 0.01) than that for the aged rhBMP-2 PLGA/CPC composites (4.6 ± 1.35 MPa).

XRD

Typical XRD patterns of rhBMP-2/PLGA microspheres, rhBMP-2/PLGA/CPC and rhBMP-2/CPC are shown in Fig. 3. No differences could be detected in the XRD patterns between rhBMP-2/PLGA/CPC and rhBMP-2/CPC except for the emergence of an rhBMP-2/PLGA pattern in the rhBMP-2/PLGA/CPC composite. The incorporation of PLGA microspheres was not involved in the apatite formation, as shown by the peak at 30.18 (2θ). The component protein for rhBMP-2 did not affect the crystallinity.

Scanning electron micrographs of fracture surface of rhBMP-2/CPC (A), rhBMP-2/PLGA/CPC composite (B) and the aged composite (C, D). Micropores, 1 μm wide at maximum, were observed in CPC matrix (A). In rhBMP-2/PLGA/CPC composite (B) the microspheres contacted intimately with the CPC matrix. Figure 4 C, D showed the macropores from the PLGA microspheres dissolution after 56 days immersion in PBS. Arrows point to the micropores

In vitro protein release kinetics

The release of rhBMP-2 from rhBMP-2/PLGA/CPC and rhBMP-2/CPC is shown in Fig. 5. For all cylinders tested, the release profiles comprised two phases: (a) an initial burst occurring during the first 24 h, (b) a linear slow steady release phase linear release phase for the rest of the time course (days 2–28). Except for a smaller burst effect (4.9% vs. 8.3%) observed in rhBMP-2 /PLGA/CPC, the rhBMP-2 release rate was faster in all the other evaluated time periods than that of the control. In 28 days, (32.58 ± 0.35)% of the loaded protein was released; while in the control group the release rate was (16.80 ± 0.27)%.

In vitro cellular response to the released rhBMP-2 from the composition

The bioactivity of rhBMP-2 was monitored by determining the expression of two markers of osteoblastic phenotype: ALP activity and osteocalcin production. Fig. 6 plots the ALP activity of cells cultured with the control medium and the condition medium of all time points. The ALP activity was significantly higher (P < 0.01) for the cells maintained in the conditioned medium in the presence of rhBMP-2 than those in the control medium. No difference in activity was found in the rhBMP-2 release medium on 1st day, however, on the 7th day release medium group, the ALP activity for rhBMP-2 PLGA/CPC group was significantly higher (P < 0.01) than that for rhBMP-2/CPC. Similar results were observed for osteocalcin production (Fig. 7). The cells exposed to rhBMP-2 had a significantly higher level of osteocalcin expression than those maintained in the absence of rhBMP-2. An increase in rhBMP-2 content resulted in a significant increase in level of the osteocalcin.

ALP activity of MSCs cultured with rhBMP-2 release medium. The ALP activity was higher in all the rhBMP-2 containing groups. No difference in activity was found in the rhBMP-2 release medium on 1st day, on the 7th day release medium group, the ALP activity for rhBMP-2 PLGA/CPC group was higher than that for rhBMP-2/CPC

OC expression of MSCs cultured with rhBMP-2 release medium The OC expression was higher in all the rhBMP-2 containing groups. No difference in activity was found in the rhBMP-2 release medium on 1st day, on the 7th day release medium group, the OC expression for rhBMP-2 PLGA/CPC group was higher than that for rhBMP-2/CPC

Discussion

The results suggested that a novel moldable, degradable bone substitute with more degradability and osteogenesis activity could be developed by incorporating rhBMP-2 loaded PLGA microspheres into rhBMP-2/CPC. The composite can be applied in surgery via minimally invasive techniques such as injection. The moldability and in situ self-hardening ability of the new scaffolds in the present study make them desirable materials for orthopedic repair.

Compressive and tensile strength are critical biomechanical parameters for biomaterials in bone replacement therapy. It was shown that the compressive strength of the CPC composites decreased from 29.48 ± 6.42 MPa to 8.26 ± 3.58 MPa when rhBMP-2/PLGA microspheres were added during setting, this is because the structure of interlocking CPC crystal needles, which produce the cement strength, was inhibited when the microspheres were added into cement [15]. Although the mechanical properties of the composites decreased significantly after PLGA microspheres were added, they were higher than that of the aged composites, and equivalent to the cancellous bone (10 MPa). At the present time, most of the porous materials are biologically derived HA blocks that do not have the advantage of in situ molding and setting. This makes them hard to use in defects with complicated geometry. Their compressive strength is only 2–4 MPa [16, 17]. The compressive strength for modified cements was within the range of thin trabecular bone, so it can be used as void filler in non stress-shared applications.

It is important that the initial mechanical strength of the composite is significantly higher compared with initially porous materials. A higher mechanical strength will assure defect stability in the early critical stage when little bone has yet grown into the defect site. Another advantage with this novel composite material is that the strength could be controlled by the amount of PLGA microspheres present, which makes it possible for the surgeons to modify the material to obtain an adequate strength.

SEM of the fracture surface of the aged composite showed that the shapes of the macropores from PLGA microspheres dissolution were round and neighbored each other. Pore-size distribution was found to be similar to the microparticle size distribution. This result implies that Ca–P cement macropore size was determined by PLGA microphere size and suggests that variation of pore size can be engineered by selection of the appropriate microphere size. The average sizes of the PLGA microspheres of the composite were (253 ± 64) μm. Pores of this size range have been found to be optimal for bony ingrowth [18]. Previous studies noted that the size of interconnection is the main limiting factor for vascularization and bony ingrowth rather than the size of the pores themselves [19, 20]. In the aged composition, the macropores formed by the degradation of the PLGA microspheres was interconnected by the inherent micropores. The presence of these interconnected micropores could allow water to penetrate into the CPC-PLGA to facilitate the degradation of the PLGA microspheres and the interconnectivity of the macropores.

In vitro release results show that rhBMP-2 was released from all the composites in a multiphasic fashion: an initial burst release in the first 24 h and a linear slow steady linear release phase. In 24 h, the cumulative rhBMP-2 release in the composite was lower than that in CPC, while in the following time course, the composite showed more rhBMP-2 release than CPC. In the PLGA microspheres, rhBMP-2 was enwrapped in the PLGA matrix, and the microsphere had no micropores, so the composite showed less rhBMP-2 burst release. The faster rhBMP-2 release rate in the composite may be due to its faster degradation rate, as compared to pure CPC. The mechanisms via which the rhBMP-2/PLGA/CPC composite degraded faster than BMP/CPC control can be explained as follows: (1) The PLGA microspheres degraded faster than HA. (2) The acidic condition caused by the hydrolyzation of PLGA microspheres can accelerate the degradation of CPC. (3) The macropores formed by PLGA microspheres dissolution can facilitate CPC resorption. The high affinity of HA with BMP may also account for the different release kinetics [3, 4].

The release of rhBMP-2 from PLGA/CPC composite was found to enhance marrow stromal cell differentiation. In our previous research [21], we compared the effects of release medium from PLGA/CPC or CPC on the proliferation and the differentiation of MSCs. We found that although both of them could mildly increase differentiation and proliferation, there was no significant difference between them, consistence with other’s result [22]. In the present study, compared with rhBMP-2/CPC group, the ALP activity and osteocalcin levels were significantly higher in MSCs cultured with the 7th day release medium from rhBMP-2 PLGA/CPC group, but there was no difference on the 1st day release medium. Combining with the result of the in vitro release, we found that the released rhBMP-2 enhanced the differentiation of MSCs in a dose-dependent manner. These results indicated that the growth factor retained its activity during the microspheres fabrication process and could be released not only in a controlled fashion but also in a bioactive form.

In summary, we have developed a novel degradable, injectable bone repair composite by incorporation of biodegradable rhBMP-2 loaded PLGA microspheres into calcium phosphate cement. The incorporation of the microspheres did not affect the physicochemical character of CPC. As delivery vehicles for rhBMP-2, the composite was found to be capable of releasing bioactive rhBMP-2 over 28 days. These in vitro results revealed that the rhBMP-2/PLGA/CPC composite could be a promising bone repair substitute. Further investigations are needed to elucidate the in vivo behavior of this composite.

References

C. D. FRIEDMAN, P. D. CONSTANTINO and K. JONES, Arch. Otolaryngol Head Neck Surg. 117 (1991) 385

P. D. CONSTANTINO, C. D. FRIEDMAN and R. JONES, Plast. Reconstr. Surg. 90 (1992) 174

P. Q. RUHE, H. C. KROESE, J. G. WOLKE, P. H. SPAUWEN and J. A. JANSEN, Biomaterials 25 (2004) 2123

E. J. BLOM, J. N. KLEIN, J. G. WOLKE, M. A. WAAS, F. C. DRIESSENS and E. H. BURGER, J. Biomed. Mater. Res. 59 (2002) 265

R. H. LI, M. L. BOUXSEIN, C. A. BLAKE, D. D. AUGUSTA, H. KIM, X. J. LI, J. M. WOZNEY and H. J. SEEHERMAN, J. Orthop. Res. 21 (2003) 997

M. L. SHINDO, P. D. CONTANTINO, C. D. FRIEDMAN and L. C. CHOW, Arch. Otolaryngol. Head Neck Surg. 119 (1993) 185

T. LIVINGSTON, J. DUCHEYNE and C. GARINO, J. Biomed. Mater. Res. 62 (2002) 1

S. TAKAGI and L. C. CHOW, J. Mater. Sci. Mater. Med. 12 (2001) 135

R. P. DEL REAL, J. G. WOLKE, M. VALLET-REGI and J. A. JANSEN, Biomaterials 23 (2002) 3673

R. P. DEL REAL, E. OOMS, J. WOLKE, M. VALLET-REGI and J. A. JANSEN, J. Biomed. Mater. Res. 65 (2003) 30

S. J. PETER, L. C. LU, D. J. KIM, G. N. STAMATAS and M. J. MILLER, J. Biomed. Mater. Res. 50 (2000) 452

L. C. LU, G. N. STAMATAS and A. G. MIKOS, J. Biomed. Mater. Res. 50 (2000) 440

K. G. MARRA, J. W. SZEM, P. N. KUMTA, P. A. DIMILLA and L. E. WEISS, J. Biomed. Mater. Res. 47 (1999) 324

C. M. SHEA, C. M. EDGAR, T. A. EINHORN and L. C. GERSTENFELD, J. Cell Biochem. 90 (2003) 1112

B. K. NICOLAIA, A. REINSTORFA, I. HOFINGERA, K. FLADEA, R. WENZB and W. POMPE, Biomol. Eng. 19 (2002) 227

K. A. HING, S. M. BEST, K. E. TANNER, W. BONFIELD and P. A. REVELL, J. Mater. Sci. 10 (1999) 663

M. IKENAGA, P. HARDOUIN, J. LEMARTRE, C. ANDRIANJATOVO and B. FLAUTRE, J. Biomed. Mater. Res. 40 (1998) 139

Y. KUBOKI, Q. JIN and H. TAKITA, J. Bone Joint Surg. 83A (2001) S105

N. TAMAI, A. MYOUI, T. TOMITA, T. NAKASE, J. TANAKA. T. OCHI and H. YOSHIKAWA, J. Biomed. Mater. Res. 59 (2002) 110

R. B. MARTIN, M. W. CHAPMAN, R. E. HOLMES, D. J. SARTORIS, E. C. SHORS, J. E. GORDON, D. O. HEITTER, N. A. SHARKEY and A. G. ZISSIMOS, Biomaterials 10 (1989) 481

Z. Q. FEI, Y. Y. HU, D. C. WU, H. WU, J. P. BAI and X. D. LING, Biomed. Eng. Clin. Med. 10 (2006) (in press)

C. G. SIMON, C. A. KHATRI, S. A. WIGHT, S. A. WIGHT and F. W. WANG, J. Orthop. Res. 20 (2002) 473

Acknowledgements

This work is supported by funds from the National Science foundation of China (009–0160)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fei, Z., Hu, Y., Wu, D. et al. Preparation and property of a novel bone graft composite consisting of rhBMP-2 loaded PLGA microspheres and calcium phosphate cement. J Mater Sci: Mater Med 19, 1109–1116 (2008). https://doi.org/10.1007/s10856-007-3050-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-007-3050-5