Abstract

Rare earth manganite YMnO3 and YMn0.9Cr0.06Fe0.04O3 wherein transition metal ions are co-substituted at Mn-sites, were synthesized via sol–gel auto combustion route. The present work aims to study the effect of Cr3+ and Fe3+ co-substitution at Mn-site of YMnO3, on their structural and electrical properties. The structural and morphological studies were performed using X-ray diffraction (XRD), Raman spectroscopy, and field emission scanning electron microscopy (FESEM). The XRD pattern confirmed the existence of monophasic hexagonal structure for YMnO3 while the onset of few orthorhombic peaks was observed for YMn0.9Cr0.06Fe0.04O3. The A1 Raman scattering line at ∼ 676 cm−1 was observed to be much stronger than the other Raman modes. Uniform and dense morphological structure were observed in the FESEM micrographs. Enhanced dielectric properties were observed in the substituted sample. The frequency dependence of AC conductivity was investigated using Jonscher’s law. Non-overlapping small polaron tunnelling model was predicted for the conduction model in YMnO3 and correlated barrier hopping in YMn0.9Cr0.06Fe0.04O3 to elucidate the conduction mechanism of the system. The activation energy for intrinsic charge carriers was calculated using Arrhenius equation. The impact of grains and grain boundaries on the electrical behaviour of the samples was validated by fitting the Nyquist plot.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the past few decades, advances in materials science have led to various developments in different fields such as nanotechnology, electronic materials, biomedical technology, energy storage etc. [1]. Materials science embodies different materials from ceramics to metals, semiconductors, alloys, polymers, composites, biomaterials etc. and study of their structural, mechanical, electrical, and magnetic properties to enhance their functionalities in different fields. Various nanocomposite materials have also been developed for wide application in photocatalytic and antibacterial activities, electrolytes of solid-state batteries, optoelectronics, food packaging materials etc. [2,3,4,5,6]. Another class of nanomaterials are the multiferroics, which possess at least two or more ferroic order such as ferroelectricity, (anti-) ferromagnetism and ferroelasticity. These materials have drawn considerable interest from the research community around the world. They are potential materials for applications in transducers, sensors, actuators, memory devices, spintronics and other fields [7,8,9,10,11,12,13]. Rare-earth manganite (RMnO3) forms one of the promising candidates for multiferroic materials due to their cross-coupling between the magnetic and electric order in a single phase [14]. Generally, they are crystallized into two structural phases, depending on the ionic size of the rare-earth elements as well as the doping element. Smaller ionic radii of the rare-earth (R = Ho–Lu, Y, and Sc) favours hexagonal structure while relatively larger ionic radii (R = La–Dy) favours the orthorhombic phase [15]. Among the rare-earth manganites, YMnO3 has emerged as one of the interesting lead-free multiferroic materials due to the absence of volatile elements and for its ferroelectric property at room temperature (TC ~ 900 K) [14, 16]. In YMnO3 structure, each Mn3+ ion forms MnO5 trigonal bipyramids with three in-plane (ab plane) and two apical oxygen (along c direction) ions separated by layers of Y3+ ions along the c axis. The ferroelectricity in YMnO3 arises due to buckling of MnO5 polyhedra accompanied by displacement of Y3+ layers while the origin of magnetism is attributed to anti-ferromagnetic superexchange interaction of Mn spins in the ab plane of YMnO3 structure [17].

In most of the multiferroics, high leakage current, poor dielectric features and low polarisations are major drawbacks for device applications. Hence, the need to study their electrical properties and transport mechanism [18, 19]. One of the favourable ways to improve the magnetic or electrical properties of the parent compound is by substitution at Y-site or Mn-site. The substituting element also play a crucial role in tuning the properties of the parent compound. Various research works have been done on improving the properties of YMnO3 by substituting various elements such as Cr, Ti, Zr, Os, Ni, Fe, Co, Mg etc. at Mn-site or Y-site [20,21,22,23,24,25,26,27,28]. However, detailed literature review reveals that there is limited report on the detailed study of co-substituted YMnO3.

The present work, therefore, aims to investigate pristine YMnO3 and the effect of co-substitution of transition metal ions Cr3+ and Fe3+ at the Mn-site on the properties of the system. Various synthesis techniques are available for fabrication of nanoparticles viz. co-precipitation, hydrothermal, sol–gel, sonochemical method etc. [29,30,31,32]. Among these synthesis techniques, sol–gel combustion has several advantages such as homogeneous mixing of the precursors, ease in process, more uniform morphology and micro-structures etc. The present samples are synthesized using sol–gel auto-combustion method.

As the mixed oxidation states and ionic radii of the doping element play a major role in tuning the electrical properties of the parent YMnO3, we expect an interesting change in the electrical properties of the substituted sample. Detailed study has been done on the structural and electrical properties of the materials in different frequency and temperature ranges showing improved electrical properties. The conduction mechanisms are discussed with the support of appropriate theoretical models, providing a deeper understanding on designing such compounds for practical applications. No such work has been reported before on the co-substituted system under investigation.

2 Experimental details

2.1 Synthesis

The polycrystalline YMnO3 and YMn0.9Cr0.06Fe0.04O3 are prepared by sol–gel auto-combustion technique. Stoichiometric amount of yttrium nitrate [Y(NO3)·6H2O], manganese acetate [Mn(C2H3O2)2·9H2O], chromium nitrate [Cr(NO3)3·9H2O], and iron nitrate [Fe(NO3)3·9H2O] are used as precursors for the preparation of the samples. The appropriate amounts of precursors are dissolved in deionised water (DI water) with constant stirring at 100 °C. Citric acid (CA) and ethylene glycol (EG) are added into the solution such that the molar ratio of metal ions: CA: EG is equal to 1:1:2. The resulting solution is magnetically stirred for 2 h to get a homogeneous and stable solution. The temperature of the solution is raised to 150 °C to initiate gel formation, after which it is set to 300 °C leading to auto combustion of the gel. Black powdery ash is formed on completion of the combustion process, which is further calcined at 900 °C for 2 h for complete phase formation. The calcined samples are mixed with 3 wt% polyvinyl alcohol (PVA) and pressed into circular pellets using hydraulic press by applying 100 kg/cm2 of pressure. Finally, the pellets are sintered at 1100 °C for 5 h using conventional furnace, with a heating rate of 5 °C/min in O2 atmosphere.

2.2 Characterization techniques

The crystalline structure and phase formation of the samples are studied using X-ray diffraction technique. Bruker X-ray diffractometer with CuKα (λ = 0.154 nm) radiation source is used to record the XRD data in the range of 20° ≤ 2θ ≤ 70° with step size of 0.02°. Structural parameters and crystallite size are determined from the XRD data. The Raman spectra of the samples are measured at room temperature in unpolarised geometry, using a Lab Ram HR evolution with excitation laser source of 532 nm. The surface morphology and microstructural investigation of the samples are studied by employing JOEL, JSM-100F field emission scanning electron microscope (FE SEM). The electrical properties of the samples are studied from dielectric, AC conductivity and impedance analysis using Agilent HP 4284A LCR Meter in the frequency range of 100 Hz to 1 MHz. The measurements are carried out at different temperatures in the range from room temperature to 200 °C with step size of 5 °C. The samples for electrical measurement are silver coated on both sides to act as electrodes for electrical conduction.

3 Results and discussion

3.1 Structural analysis

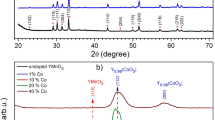

The X-ray powder diffraction pattern of the samples are depicted in Fig. 1. It is observed from the figure that pure YMnO3 crystallize in single hexagonal phase with P63cm space group without any impurity phase as confirmed with ICDD card number 00-025-1079 and the peaks are indexed to the corresponding (hkl) planes.

For the YMn0.9Cr0.06Fe0.04O3 sample, few orthorhombic peaks are observed (denoted by * mark on the XRD pattern) which signifies the onset of orthorhombic phase when YMnO3 is substituted at Mn-site by Cr3+ and Fe3+. The stability of the phase of a perovskite compound based on the ABO3 formula is determined by Goldschmidt’s tolerance factor (t) given by, \(t= \frac{({r}_{\text{A}} + {r}_{\text{O}} )}{\surd 2({r}_{\text{B}}+ {r}_{\text{O}})}\) where, rA, rB and rO represents the ionic radii of A-cation, B-cation and oxygen respectively [33]. The co-substitution at the Mn-site by ions of different size i.e., Fe3+ (\(r_{{{\text{Fe}}^{3 + } }}\) = 0.67 Å) and Cr3+ (\(r_{{{\text{Cr}}^{3 + } }}\) = 0.61 Å) replacing Mn3+-ions (\(r_{{{\text{Mn}}^{3 + } }}\) = 0.64 Å) causes small change in tolerance factor which may contribute to the orthorhombic phase. The average crystallite size of the samples is calculated by Scherrer equation [34],

where D is the crystallite size, λ the wavelength of X-ray source, β the full width at half maximum of the diffraction peak, θ the diffraction angle in radian and K the so-called Scherrer constant. The value of K depends on the crystallite shape and the size distribution, indices of the diffraction line and the actual definition used for β [35]. It can be anywhere between 0.62 and 2.08 where in the present case K = 0.9 is used. The calculated value of the crystallite size only represents the estimate value and the discussion on the accuracy of Scherrer formula can be found in the literature [36].

The lattice parameters of the samples are calculated from the standard formula

where d is the interplanar spacing, a and c the lattice parameter and h, k, l the Miller indices.

The calculated structural parameters and the crystallite size are tabulated in Table 1. The crystallites are found in the nano range and the cell volume is observed to increase slightly in the substituted sample.

The FESEM micrographs of the samples are illustrated in Fig. 2 along with the histogram for particle size distribution. Uniform distribution of particles with no micro-cracks is observed for both the samples. Significant increase in particle size with uniform and dense growth of particles is observed in YMn0.9Cr0.06Fe0.04O3 with average size of 477 nm as compared to 229 nm of YMnO3. The observed particle size from FESEM image is found to be very much larger as compared to the crystallite size calculated from the Scherrer equation (Table 1). It can be understood that particles are formed by aggregation of many crystallites during the sample synthesis process. Hence, calcination and sintering process of the nanopowders also contribute to the growth of larger particle size.

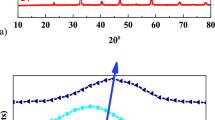

Raman spectroscopy is a versatile tool to study the lattice vibration of solids which can provide information on subtle local variations in the structure of the material. Figure 3 illustrates the room temperature Raman spectra of the samples fitted with Lorentzian function. Unit cell of hexagonal YMnO3 with space group P63cm consists of six formula units. Group theory calculation predicted a total of 60 phonon modes (Γ-point) for this structure viz. 10A1 + 5A2 + 10B1 + 5B2 + 15E1 + 15E2 [37]. Among these modes, 38 (9A1 + 14E1 + 15E2) are Raman active and 2 (A1 + 1E1) are infrared active while the remaining modes 20 (5A2 + 10B1 + 5B2) are inactive or silent modes.

For pure YMnO3, the experimentally observed Raman scattering bands at 676 cm−1 is of A1 symmetry, 401 cm−1 belongs to E1 symmetry while those at 221 cm−1 and 130 cm−1 are of E2 symmetry. These results are in good agreement with standard reported values of Iliev et al. [38] and confirms the formation of hexagonal YMnO3. In the case of YMn0.9Cr0.06Fe0.04O3 the hexagonal Raman modes are observed at 676, 397, 209, and 131 cm−1. Along with these bands, orthorhombic Raman modes are also observed at 470 and 638 cm−1 which belong to B2g Jahn–Teller symmetry in-phase oxygen stretching mode [39]. An interesting observation in the Raman spectra of both the samples is the occurrence of the most intense A1 mode at 676 cm−1. This signature mode is of substantial importance for the phonon line assignments. It can be mentioned here that a phonon mode is Raman active when its atomic displacements modulate the macroscopic polarizability. The stronger the phonon-mode-induced polarizability, the higher the intensity of the corresponding Raman line [38, 40]. This A1 mode is related to apical oxygen atoms stretching along c-axis. The observed E2 mode at ~ 221 cm−1 is associated with deformation in vibration of oxygen and Mn atoms while the band at 130 cm−1 is related to the motion of Y3+ atoms. It is observed that the E2 mode at ~ 221 cm−1 and E1 mode ~ 401 cm−1 of pure YMnO3 are red shifted in YMn0.9Cr0.06Fe0.04O3. This is attributed to the increase in cell volume, which imply elongation of average bond length. Eventually, the force constant decrease thereby decreasing the corresponding vibrational frequency or wavenumber, which manifests as red shift in the Raman modes [41]. The red shift in peak position is also known to be attributed to local heating effects, lattice strain, microstructures, structural defects, loss of stoichiometry etc. [42].

3.2 Dielectric property

The variation of room temperature dielectric constant (ε') as a function of frequency in the range 100 Hz to 1 MHz is depicted in Fig. 4a. Usual dispersive behaviour of dielectric constant is observed in both the samples where the value is much higher at lower frequencies, decreases with increasing frequency of the applied alternating field and becomes almost constant at higher frequencies. This can be explained considering the four types of polarization phenomena viz. (1) interfacial (space-charge polarization), (2) orientational or dipolar polarization, (3) ionic polarization and (4) electronic polarization. Ionic and electronic polarization becomes significant only at very high frequency (~ 1011 Hz) and hence are not relevant in the frequency range of the present study. At lower frequencies, space-charge polarization and dipolar polarization contribute to the dielectric constant. The polarization in manganites is via the electron hopping between Mn3+ and Mn4+ ions. The low frequency dispersive behaviour of dielectric constant can be well understood from Maxwell–Wagner polarization phenomena in accordance with Koop’s phenomenological theory [43,44,45]. According to this theory, the polycrystalline materials are assumed to be composed of well-defined conducting grains surrounded by poorly conducting grain boundaries. The grain boundaries, thus, act as potential barrier and block the mobile charge carriers, thereby inhibiting charge hopping. Thus, mobile charge carriers get accumulated at the boundaries due to restriction of charge hopping on application of an alternating electric field. This led to localised accumulation of charges at the boundaries leading to space charge polarization and producing a very large capacitance, and hence, a large dielectric constant. As the frequency is increased, the charge carriers reverse their orientation more frequently before reaching the grain boundary and, as a consequence polarization decreases. At higher frequencies, the charge transfer could not follow the frequency of the applied field and hence the dielectric constant drops to nearly constant values.

It is also observed that the dielectric constant significantly increases with substitution of Cr3+ and Fe3+ at Mn-site. This suggest that substitution of Cr3+ and Fe3+ may induce increased transformation of Mn3+ to Mn4+ ions increasing charge hopping and hence the dielectric constant. The increase in grain size as well as uniformity of grain size may also lead to increased dielectric constant. Other factors such as lattice distortion, oxygen vacancy and creation of defect site due to doping might also influence the dielectric constant of the material [46].

Figure 4b shows the room temperature frequency variation of dielectric loss of the samples. The dielectric loss (tan δ) is observed to be very small and decrease continuously with increasing frequency and becomes almost constant at higher frequencies signifying the usual dispersive behaviour. The decrease in tan δ with frequency can be understood in accordance with Koop’s phenomenological theory as discussed above.

The temperature dependence of dielectric constant (ε') at some selected frequencies are shown in Fig. 5a, b. It can be noticed that ε' increases with temperature for both the samples. This indicates the presence of thermally activated charge carriers whose mobility towards the grain boundaries increase with temperature, thereby increasing space-charge polarization and hence the dielectric constant. It is also observed that as a function of frequency the temperature dependence of ε' is strong at lower frequency but as the frequency increases, ε' becomes almost temperature independent which may be due to the dominance of dipolar polarization over the space charge polarization at higher frequencies [47].

The temperature variation of dielectric loss at selected frequencies are shown in Fig. 5c, d. The tan δ value is found to increase with increase in temperature for all the samples and the variation exhibits similar nature as that of the variation of dielectric constant with temperature. The observed behaviour may be attributed to the accumulation of charge carriers at the grain boundaries, due to increased mobility of the ions at higher temperature, as explained above [48]. Another factor of higher dielectric loss at high temperature may be due to conduction loss, according to which the movement of ions over large distance led to loss of electric energy as some of their energy are transferred to the lattice as heat energy. As the temperature increases, the conduction loss become more pronounced due to increase of the mobility of ions, thus increasing the dielectric loss at high temperature [49].

3.3 AC conductivity

The AC conductivity of the samples are investigated to have a deeper understanding on the conduction mechanism of the materials. AC conductivity (σAC) is calculated from the empirical relation

where εo is the absolute permittivity (8.854 × 10−12 C2 N−1 m−2), ω the angular frequency, ε' the dielectric constant and tanδ the dielectric loss. The plot of σAC versus frequency at selected temperatures is shown in Fig. 6. It is observed that in low frequency region, the AC conductivity is small due to polarization effect (charge accumulation at grain boundaries) and at high frequency region, it increases due to hopping of charge carriers.

The AC conductivity curves are fitted by using Jonscher’s Universal power law [50] which is related to the dynamics of ionic hopping transport between localised sites and is given by

where \({\sigma }_{\text{dc}}\) is the dc conductivity, A a frequency dependent parameter and n(T) a constant which gives the degree of interaction between the mobile ions and lattices. For n < 1, translational hopping of charge carriers is indicated but for n > 1, the motion is a localised one [51]. It is well known that the appropriate conduction mechanism can be assigned to the material from the trend of variation of frequency exponent n w.r.t. temperature. Several investigations suggested that if n is independent of temperature the electrical transport mechanism in the system is given by the quantum mechanical tunnelling model (QMT). If n increases with temperature the non-overlapping small polaron tunnelling (NSPT) can be expected for the conductivity mechanism. Whereas, correlated barrier hopping (CBH) model is the dominant conduction process when n decreases with temperature [52,53,54]. Figure 7 shows that the value of n for YMnO3 increases with temperature up to 400 K, implying the NSPT conduction model for that temperature range, and then slightly decreases with temperature above 400 K, indicating the possibility of another mechanism. For YMn0.9Cr0.06Fe0.04O3, the decreasing trend of n with temperature suggests that the CBH model is the most appropriate conduction model.

According to the NSPT model the frequency exponent n is given by [52,53,54]

where WH is the barrier height or polaron energy, \({\tau }_{0}\) relaxation time which is in the order of vibrational period (10−13 s) and ω is the angular frequency.

For large value of \(\frac{{W}_{\text{H}}}{{k}_{\text{B}}T}\), the frequency exponent becomes

Using this equation, the energy of polarons has been estimated to be around 0.09 eV for YMnO3.

In CBH model of conduction, the exponent n can be represented by

where Wm is the maximum barrier jump height i.e., the energy required for the electron to hop from one site to another. At high value of the reduced energy \(\frac{{W}_{\text{m}}}{{k}_{\text{B}}T}\), the equation is simplified as

The barrier height for the hopping of charge is deduced from the above equation (Eq. 8) to be around 0.56 eV for YMn0.9Cr0.06Fe0.04O3.

Figure 8 shows the variation of AC conductivity (σAC) with inverse temperature 103/T (K−1) at different frequencies for YMnO3 and YMn0.9Cr0.06Fe0.04O3. The curves are seen to consist of two regions with different slopes- region I (low temperature region) and region II (high temperature region). In region I there is strong frequency dispersion of AC conductivity for both the samples, where conductivity increases with increase in frequency. This may be attributed to hopping of charge carriers to random sites having variable barrier heights and separation [55]. While, in region II the AC conductivity curve tend to converge at high temperature, which indicates that at high temperature thermal activation of charge carriers is dominant over the frequency dependence [56].

The activation energy is calculated by using the Arrhenius equation [57]

where Ea is the activation energy for the intrinsic conduction of charge carriers, k the Boltzmann constant and T the temperature, and tabulated in Table 2 for the two temperature regions at different frequencies. A decrease is observed with increasing frequency.

In perovskite compounds charge carriers (electron) and oxygen vacancies generated during high temperature calcination and sintering process play a major role on the conduction behaviour. Rao et al. also reported that the valence change from Mn3+ to Mn4+ during heat treatment in YMnO3 is compensated by holes (oxygen vacancies) and thus yielding p-type conductivity [58]. The created oxygen vacancies may be singly or doubly ionised according to the Kröeger–Vink notation [59],

where \({V}_{\text{o}}^{\prime}\) and \({V}_{\text{o}}^{\prime\prime}\) are singly and doubly ionized oxygen vacancies, respectively. These holes are bound to Mn3+ as \({\text{Mn}}^{3+}+{V}_{\text{o}}^{\prime}\iff {\text{Mn}}^{4+}\) and thus the charge transfer takes place between these neighbouring Mn-ions.

The obtained activation energy values for YMnO3 in both the regions and for YMn0.9Cr0.06Fe0.04O3 in region I indicate that the conduction is due to short range hopping motion of oxygen vacancies [60]. The larger activation energy values (0.50–0.84 eV) at different frequencies in Region II for YMn0.9Cr0.06Fe0.04O3 suggests that the conduction mechanism may be due to the presence of long-range motion of electrons from doubly ionized oxygen vacancies and the presence of charged defects [61, 62].

3.4 Impedance analysis

Impedance spectroscopy provides insights to the electrical conductivity behaviour and contribution of grain and grain boundaries on the electrical property of the material. The complex impedance Z* is composed of real and imaginary parts as given below

where Z', Z", and ω are the real and imaginary part of the impedance, and angular frequency, respectively.

Figure 9a, b shows the frequency dependence of the real part of impedance (Z') at different temperatures of the studied samples. It is observed that Z' value decrease with increasing frequency and at very high frequencies (around 10 KHz) the Z' values merge for all temperatures. The decrease with frequency can be related to space charge polarization. It is also observed that as a function of temperature, Z' decreases with increase in temperature i.e., Z' is inversely proportional to temperature suggesting a negative temperature coefficient of resistance (NTCR) [56]. This indicates that AC conductivity increases with temperature due to enhancement of thermally activated charge conduction which is analogous to semiconductor nature. Further, the value of Z' is less in the co-substituted sample.

The variation of Z" vs frequency at different temperatures are shown in Fig. 9c–f. It is observed from the plot that Z" decreases with frequency and merged at higher frequencies (above 10 KHz) for the different temperatures. The characteristic peaks of the relaxation behaviour are observed clearly at higher temperature (~ 398 K) for both the samples which indicates the presence of relaxation phenomena. It can also be seen from the figure that the position of the peak shifts towards higher frequencies with increase in temperature which suggest that the relaxation process is temperature dependent [63].

To study the contributions of electrode interfaces, grain and grain boundary to the relaxation process of the samples, the Cole–Cole or Nyquist plot (− Z" vs Z') at various selected temperature are given in Fig. 10a–d.

The Nyquist plot show characteristic incomplete semi-circular arc at lower temperatures for both the samples which indicates the high insulating behaviour. The semi-circular arc become fuller or complete with increase in temperature while the height of the peak decreases. With further increase in temperature the radius of the semi-circular arc decreases. This indicates that the conductivity of the samples increase with temperature indicting the semiconducting behaviour of the samples [64]. It can be seen that the centre of the semi-circular arcs tends to move towards the lower resistance value with increase in temperature. Moreover, the arcs are asymmetric and the centre of the arc shifts below the real part of the impedance axis which indicates the non- Debye type of relaxation process in the studied compounds [65]. The Nyquist plot are fitted using ZSimpWin Software to represent the multi-relaxation behaviour of the compounds in terms of a series and parallel combination of resistance and capacitance i.e., RC equivalent circuit. For non-Debye-type system, constant phase element (CPE) is introduced in the circuit [66]. The fitted impedance data along with the circuit model for the samples at 473 K are shown in Fig. 11 and the obtained fitted parameters are shown in Table 3.

The term Rs denotes the series resistance, which may be attributed to the material's electrode effect. The resistance, constant phase element, and capacitance of the grain are represented by Rg, CPEg, and Cg, respectively while Rgb, CPEgb and Cgb represent the corresponding terms for grain boundary. The goodness of fitting (χ2) is in the order of 10−4 for both the samples which shows that the circuit model is fitted well with the impedance data. From the interpretation of the fitted equivalent circuit, it can be concluded that two relaxation behaviours due to grains and grain boundaries are present in both the samples. Grains boundaries are observed to be more resistive than grains in both the samples. Also, the resistance of grain and grain boundary decreases in YMn0.9Cr0.06Fe0.04O3.

4 Conclusion

Pure YMnO3 and YMn0.9Cr0.06Fe0.04O3 have been synthesised via sol–gel method. X-ray diffraction confirms the formation of single hexagonal structure for YMnO3 while few peaks of orthorhombic phase are observed for the co-substituted sample. Raman scattering line at ~ 676 cm−1 dominates the Raman spectra in both the samples. In the substituted sample, red shift of some of the Raman modes are observed which has been attributed to variation in Mn–O bond length. Significant enhancement of dielectric constant is observed in YMn0.9Cr0.06Fe0.04O3. Temperature dependence of the dielectric property predicts the thermally activated charge conduction process. The variation of the frequency exponent n with temperature in the frequency dependent AC conductivity study at different temperature indicates that the charge transport mechanism in YMnO3 and YMn0.9Cr0.06Fe0.04O3 can be taken to be governed by NSPT and CBH model, respectively. The values of activation energies of the intrinsic charge carriers indicate that the conduction process in the samples are controlled by oxygen vacancies—short range motion in YMnO3 and long range motion in co-substituted sample in the high temperature region. The impedance analysis shows non-Debye relaxation type in the studied samples. The fitting of Nyquist plot reveals the contribution of grain and grain boundary on the electrical behaviour. The grain boundaries are found to be more resistive than the grains in both the sample. The obtained results can be useful for synthesizing high dielectric multiferroics for potential application in resonators and switching devices.

Data availability

During the reviewing process, the experimental data associated with this manuscript, if needed, will be made available on request.

Code availability

Not applicable.

References

D.D.L. Chung, Applied Materials Science: Applications of Engineering Materials in Structural, Electronics, Thermal, and Other Industries (CRC Press, Washington, 2001)

S.R. Yousefi, H.A. Alshamsi, O. Amiri, M. Salavati-Niasari, J. Mol. Liq. 337, 116405 (2021)

A.M. Hezma, A. Rajeh, M.A. Mannaa, Colloids Surf. A Physicochem. Eng. Asp. 581, 123821 (2019)

A. Rajeh, H.M. Ragab, M.M. Abutalib, J. Mol. Struct. 1217, 128447 (2020)

S.R. Yousefi, M. Masjedi-Arani, M.S. Morassaei, M. Salavati-Niasari, H. Moayedi, Int. J. Hydrog. Energy 44, 24005 (2019)

Q.A. Alsulami, A. Rajeh, Opt. Mater. 11, 2021 (1820)

M. Fiebig, J. Phys. D: Appl. Phys. 38, R123 (2005)

W. Prellier, M.P. Singh, P. Murugavel, J. Phys.: Condens. Matter 17, R803 (2005)

C.-W. Nan, G. Liu, Y. Lin, H. Chen, Phys. Rev. Lett. 94, 197203 (2005)

N.A. Spaldin, MRS Bull. 42, 385 (2017)

Y. Yamasaki, S. Miyasaka, Y. Kaneko, J.-P. He, T. Arima, Y. Tokura, Phys. Rev. Lett. 96, 207204 (2006)

J. Park, S. Lee, M. Kang, K.-H. Jang, C. Lee, S.V. Streltsov, V.V. Mazurenko, M.V. Valentyuk, J.E. Medvedeva, T. Kamiyama, J.-G. Park, Phys. Rev. B 82, 054428 (2010)

D.I. Khomskii, J. Magn. Magn. Mater. 306, 1 (2006)

A.B. Van Aken, T.T.M. Palstra, A. Filippetti, N.A. Spaldin, Nat. Mater 3, 164 (2004)

H. Schmid, Ferroelectrics 162, 317 (1994)

M. Kumar, D.M. Phase, R.J. Choudhary, Heliyon 5, e01691 (2019)

P.J. Brown, T. Chatterji, J. Phys.: Condens. Matter 18, 10085 (2006)

K.F. Wang, J.-M. Liu, Z.F. Ren, Adv. Phys. 58, 321 (2009)

A.K. Pradhan, K. Zhang, D. Hunter, J.B. Dadson, G.B. Loiutts, P. Bhattacharya, R. Katiyar, J. Zhang, D.J. Sellmyer, U.N. Roy, Y. Cui, A. Burger, J. Appl. Phys. 97, 093903 (2005)

O. Polat, M. Coskun, F.M. Coskun, Z. Durmus, M. Caglar, A. Turut, J. Alloys Compd. 752, 274 (2018)

A. Durán, G. Guzmán, C.I. Ochoa-Guerrero, C. Herbert, R. Escudero, F. Morales, R. Escamilla, J. Appl. Phys. 125, 034102 (2019)

K.N. Rathod, K. Gadani, Z. Joshi, D. Dhruv, A.D. Joshi, K. Asokan, P.S. Solanki, N.A. Shah, Mater. Today: Proc. 5, 9804 (2018)

Z.L. Moreno Botello, A. Caneiro, P. Roussel, G. Gauthier, J. Alloys Compd. 690, 348 (2017)

F. Wan, X. Bai, K. Song, X. Lin, X. Han, J. Zheng, C. Cao, J. Magn. Magn. Mater. 424, 371 (2017)

F. Wan, X. Bai, K. Song, X. Han, J. Zheng, X. Lin, C. Cao, J Mater Sci: Mater Electron 28, 15819 (2017)

S. Namdeo, A.K. Sinha, M.N. Singh, A.M. Awasthi, J. Appl. Phys. 113, 104101 (2013)

O. Peña, M. Bahout, Y. Ma, T. Guizouarn, D. Gutiérrez, P. Durán, C. Moure, Mater. Sci. Eng. B 104, 126 (2003)

K. Asokan, Y.S. Chen, C.W. Pao, H.M. Tsai, C.W.O. Lee, C.H. Lin, H.C. Hsueh, D.C. Ling, W.F. Pong, J.W. Chiou, M.-H. Tsai, O. Peña, C. Moure, Appl. Phys. Lett. 95, 131901 (2009)

S.R. Yousefi, A. Sobhani, M. Salavati-Niasari, Adv. Powder Technol. 28, 1258 (2017)

Q.A. Alsulami, A. Rajeh, M.A. Mannaa, S.M. Albukhari, D.F. Baamer, Int. J. Hydrog. Energy 46, 27349 (2021)

S. Raheleh Yousefi, A. Sobhani, H. Abbas Alshamsi, M. Salavati-Niasari, RSC Adv. 11, 11500 (2021)

M.M. Abutalib, A. Rajeh, Polym. Test. 93, 107013 (2021)

V.M. Goldschmidt, Naturwissenschaften 14, 477 (1926)

P. Scherrer, Nachr. Ges. Wiss. Göttingen. Math. Phys. Klasse 2, 96–100 (1918)

J.I. Langford, A.J.C. Wilson, J. Appl. Cryst. 11, 102 (1978)

V. Uvarov, I. Popov, Mater. Charact. 85, 111 (2013)

A.L. Rousseau, R.P. Bauman, S.P.S. Porto, J. Raman Spectrosc. 10, 253 (1981)

M.N. Iliev, H.-G. Lee, V.N. Popov, M.V. Abrashev, A. Hamed, R.L. Meng, C.W. Chu, Phys. Rev. B 56, 2488 (1997)

M.N. Iliev, M.V. Abrashev, H.-G. Lee, V.N. Popov, Y.Y. Sun, C. Thomsen, R.L. Meng, C.W. Chu, Phys. Rev. B 57, 2872 (1998)

A. Varshney, P. Sharma, A. Kumar, Mater. Res. Express 2, 076102 (2015)

J. Shukla, A. Mishra, J. Supercond. Nov. Magn. 34, 451 (2021)

H. Fukumura, S. Matsui, H. Harima, K. Kisoda, T. Takahashi, T. Yoshimura, N. Fujimura, J. Phys.: Condens. Matter 19, 365239 (2007)

J.C. Maxwell, A Treatise on Electricity and Magnetism (Clarendon Press, Oxford, 1873)

A. Wagner, Arch. Elektroteeh 3, 83 (1914)

A.G. Koops, Phys. Rev. 83, 121 (1951)

S. Zheng, D. Shi, L. Liu, G. Li, Q. Wang, L. Fang, B. Elouadi, J Mater Sci: Mater Electron 25, 4058 (2014)

L.L. Hench, J.K. West, Principles of Electronic Ceramics (Wiley, New York, 1990)

P.R. Das, L. Biswal, B. Behera, R.N.P. Choudhary, Mater. Res. Bull. 44, 1214 (2009)

J.M. Stevels, Electrical Conductivity II/Elektrische Leitungsphänomene II (Springer, Berlin, 1957), p. 350

A.K. Jonscher, Nature 267, 673 (1977)

A.N. Papathanassiou, I. Sakellis, J. Grammatikakis, Appl. Phys. Lett. 91, 122911 (2007)

A. Ghosh, Phys. Rev. B 41, 1479 (1990)

S.R. Elliott, Philos. Mag. 36, 1291 (1977)

S. Nasri, A.L.B. Hafsia, M. Tabellout, M. Megdiche, RSC Adv. 6, 76659 (2016)

P. Pandit, S. Satapathy, P.K. Gupta, Phys. B: Condens. Matter 406, 2669 (2011)

T. Sahu, B. Behera, J Mater Sci: Mater Electron 29, 7412 (2018)

K.J. Laidler, J. Chem. Educ. 61, 494 (1984)

G.V.S. Rao, B.M. Wanklyn, C.N.R. Rao, Solid State Chemistry (World Scientific, Singapore, 1995), pp. 365–378

R.E. Cook, K.C. Goretta, J. Wolfenstine, P. Nash, J.L. Routbort, Acta Mater. 47, 2969 (1999)

P.R. Mandal, T.K. Nath, J. Alloys Compd. 628, 379 (2015)

M. Bourguiba, Z. Raddaoui, A. Dhahri, M. Chafra, J. Dhahri, M.A. Garcia, J Mater Sci: Mater Electron 31, 11810 (2020)

A. Rehman, J.-B. Li, J.-S. Zhang, M. Rizwan, C. Niu, H.-B. Jin, J. Appl. Phys. 118, 214101 (2015)

T. Sahu, B. Behera, J. Phys. Chem. Solids 113, 186 (2018)

M. Younas, M. Nadeem, M. Atif, R. Grossinger, J. Appl. Phys. 109, 093704 (2011)

M. Smari, H. Rahmouni, N. Elghoul, I. Walha, E. Dhahri, K. Khirouni, RSC Adv. 5, 2184 (2014)

R. Schmidt, W. Eerenstein, T. Winiecki, F.D. Morrison, P.A. Midgley, Phys. Rev. B 75, 245111 (2007)

Acknowledgements

One of the authors, Lisham Paris Chanu would like to thank DST INSPIRE for providing financial assistance in the form of INSPIRE Fellowship. The authors would also like to thank IIT Kanpur for FESEM measurement and IIT Guwahati for the facility of Raman spectroscopy.

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study conception and design. Material synthesis, data collection and original draft preparation were performed by LPC. Design of the experiment and analysis of the results was done by LPC and SP. Reviewing and editing the manuscript were done by SP. All the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All the authors approve the submission of the manuscript in its current form.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chanu, L.P., Phanjoubam, S. Study on the structural and electrical properties of YMnO3 co-substituted with transition metal ions at Mn-site and their conduction mechanism. J Mater Sci: Mater Electron 33, 6107–6120 (2022). https://doi.org/10.1007/s10854-022-07788-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-07788-8