Abstract

Lead-free relaxor ferroelectric ceramics with high recoverable energy storage density and energy storage efficiency over a broad temperature and frequency range are attractive for pulsed power capacitor applications. In this work, novel barium zirconate titanate-based lead-free relaxor ferroelectric ceramics are designed via introduction of Bi(Zn0.5Sn0.5)O3 with heterovalent ion substitution at both A- and B-sites which could disrupt long-range order, induce polar nanoregions (PNRs), and reduce remnant polarization (Pr). The (1 − x)Ba(Zr0.15Ti0.85)O3–xBi(Zn0.5Sn0.5)O3 ((1 − x)BZT–xBZS) (x = 0.02, 0.06, 0.10, and 0.14) ceramics were prepared using a conventional solid-state reaction method. In addition, the structure, dielectric, ferroelectric, and energy storage properties of (1 − x)BZT–xBZS ceramics were systematically studied. All (1 − x)BZT–xBZS ceramics exhibited pure perovskite structure. With the increase of BZS content, the relaxor ferroelectric feature of (1 − x)BZT–xBZS ceramics tended to increase gradually, and slim linear P–E loops were obtained in x = 0.10–0.14. A high recoverable energy storage density Wrec of 2.16 J/cm3 and a high energy storage efficiency η of 90.3% were simultaneously achieved in x = 0.10 at 250 kV/cm, together with excellent temperature and frequency stability, which were superior to those of the reported barium zirconate titanate-based ceramics. Our work provides an effective strategy to optimize the energy storage performance of lead-free barium zirconate titanate-based ceramics toward practical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the high power density, high charge–discharge rate, and long cycling lifetime, ceramic capacitors are considered to be suitable for advanced pulsed power applications such as femtosecond lasers, medical defibrillators, and kinetic energy weapons [1,2,3,4]. For pulsed power applications, the ceramic capacitors are also expected to possess high energy storage performance with high recoverable energy storage density and energy storage efficiency towards miniaturization and integration of pulsed power systems [5].

At present, typical energy storage ceramic materials including normal ferroelectric, antiferroelectric, and relaxor ferroelectric materials have been extensively investigated for energy storage applications [3, 6, 7]. Although the normal ferroelectric ceramics have higher maximum polarization Pmax, the higher remnant polarization Pr caused by the existence of large-sized ferroelectric domains results in a low energy storage efficiency. Antiferroelectric ceramics (AFE) usually experience a antiferroelectric to ferroelectric phase transition under a relatively high electric field, which is accompanied by a mechanical strain and high current density in the process of charge–discharge cycle, which may lead to fatigue phenomenon and even crack [8]. Due to the existence of polar nanodomains (PNRs), low Pr, and slim polarization–electric field (P–E) loops, the relaxor ferroelectric ceramics provide a splendid material solution for energy storage applications. Owing to the environmental concerns, the energy storage properties of lead-free relaxor ferroelectric ceramics with environmental friendliness have attracted considerable research attention in recent years.

Up to now, the lead-free ABO3 perovskite structure BaTiO3 [9,10,11,12]-, Bi0.5Na0.5TiO3 [4, 13,14,15,16,17]-, BiFeO3 [18,19,20,21]-based ferroelectric materials have been extensively studied for energy storage applications. Among these ABO3-based ferroelectrics, barium zirconate titanate (BZT), as a widely studied BT-based relaxor ferroelectric ceramic, shows a great application potential in energy storage capacitors due to its excellent dielectric properties and mature fabrication processes [22]. However, the energy storage performance of pure BZT ceramics needs to be improved. It was reported that the Wrec values of Ba(ZrxTi1−x)O3 (x = 0.1, 0.2, and 0.3) were only 0.5, 0.71 , and 0.51 J/cm3, respectively, and the Pmax values were 16.72, 14.6, and 8.2 μC/cm2 [23,24,25]. Doping metallic ions can reduce Pr and improve η of BZT ceramics, and the Wrec values of (Ba1−xGd2x/3)(Zr0.3Ti0.7)O3 [26], Ba1−xSm2x/3Zr0.15Ti0.85O3 [27], and Ba1−x(Bi0.5K0.5)xTi0.85Zr0.15O3 [28] ceramics are around 1 J/cm3. Although significant improvements have been made, the energy storage performance of BZT-based ceramics still could not meet the requirements from practical pulsed power devices. Therefore, it is urgent to develop new methods to further optimize the energy storage properties of BZT-based ceramics.

In this work, (1 − x)Ba(Zr0.15Ti0.85)O3–xBi(Zn0.5Sn0.5)O3(x = 0.02, 0.06, 0.10, and 0.14) ((1 − x)BZT–xBZS) ceramics were designed and prepared using a solid-state reaction method. The introduction of Bi3+ ion at A-site for perovskite Ba(Zr0.15Ti0.85) O3 could improve the polarity of the A-site resulting from the hybridization between Bi 6p and O 2p orbitals, thus leading to a large Pmax under high fields. On the other hand, the introduction of heterovalent ions at both A- and B-sites (Bi3+ for Ba2+, (Zn0.5Sn0.5)3+ for (Zr0.15Ti0.85)4+) could disrupt the long-range ferroelectric order with macro-domains and produce polar nanoregions (PNRs), thus resulting in significantly reduced Pr and slim P–E loops. Additionally, the formation of weakly coupled PNRs is always accompanied by the reduction in dielectric constant and improvement in temperature stability of dielectric constant, which could boost the breakdown strength (BDS) and temperature stability of energy storage properties. Consequently, high recoverable energy density and energy efficiency with improved temperature stability are expected to be achieved in (1 − x)BZT–xBZS ceramics. We systematically investigated the structure, dielectric, ferroelectric, and energy storage properties of (1 − x)BZT–xBZS (x = 0.02, 0.06, 0.10, and 0.14) ceramics. It was found that the relaxor ferroelectric behavior of (1 − x)BZT–xBZS ceramics became stronger with the increase in BZS content. In particular, a high Wrec of 2.16 J/cm3 and a high η of 90.3% at 250 kV/cm were simultaneously obtained for the composition with x = 0.10, which were superior to those obtained in the reported BZT-based lead-free ceramics. Moreover, excellent temperature and frequency stability of Wrec and η were also observed for x = 0.10. All these properties demonstrate that the lead-free (1 − x)BZT–xBZS ceramics are promising candidate for pulsed power capacitor applications.

2 Methods and materials

(1 − x)Ba(Zr0.15Ti0.85)O3–xBi(Zn0.5Sn0.5)O3 (x = 0.02, 0.06, 0.10 and 0.14) ceramics were prepared using a solid-state reaction method. The starting materials are BaCO3 (Aladdin, 99%), ZrO2 (Aladdin, 99.99%), TiO2 (Aladdin, 99.9%), Bi2O3 (Aladdin, 99.9%), ZnO (Aladdin, 99.99%), and SnO2 (Aladdin, 99.99%) powders. All these materials were dried at 80 °C for 2 h, batches were weighed, and mixed according to the stoichiometry using ball milling in alcohol for 12 h. After drying, the powders were calcined at 950 °C for 2 h. Then the calcined powders were ground using ball milling in alcohol for 24 h. After drying, the powders were mixed with 5 wt% organic binder (PVB) in an agate mortar, pellets (12 mm in diameter) were pressed using a tablet press machine under a pressure of 4 MPa. Then the removal of the organic binder was performed at 600 °C for 2 h. The pellets were sintered at 1250–1350 °C for 4 h to obtain dense bulk ceramics. The densities of the sintered ceramics were examined by the Archimedes method.

X-ray diffraction (XRD) measurement (Rigaku Ultima-IV) ranging from 20 to 70 degree was pursued at room temperature. The scanning speed was fixed at 5 degree/min. The scanning electron microscope (SEM) (Hitachi S-3400N) was used to analyze the morphologies of the sintered ceramics and measure the grain size by software Image J (≥ 50 grains). Gold electrodes were sputtered on both sides of the pellets for the following electric characterization. The dielectric constant and loss tangent were procured (Agilent 4284) upon heating with a heating rate of 0.5 °C/min from − 50 to 300 °C at different frequencies (1, 10, 100 kHz and 1 MHz). The P–E loops were recorded by using a Sawyer–Tower circuit (Radiant Trek model 609B Multiferroic Test System) with sinusoidal voltage source. In order to estimate energy storage performance using P–E loops, the thicknesses of test samples with x = 0.02, 0.06, 0.10, and 0.14 were polished to 200 μm, 205 μm, 195 μm, and 210 μm, respectively.

As shown in Fig. 1, the total energy storage density (W) can be obtained by integrating the charging curve in the direction of polarization axis, Wrec is caused by the domain reorientation and obtained by integrating the area between the discharge curve and polarization axis. The energy storage efficiency (η) means the ratio of Wrec and W. All the parameters are obtained using Eqs. (1)–(3) derived from the P–E loops, respectively, where E is the applied electric field and P is the polarization, and Pmax is the maximum polarization concerning the maximum test electric field.

3 Results and discussion

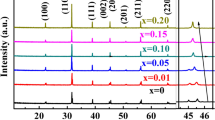

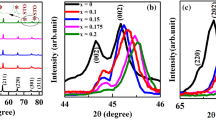

Figure 2a presents the room temperature XRD patterns of (1 − x)BZT–xBZS (x = 0.02, 0.06, 0.10, and 0.14) ceramics. According to the XRD patterns, a single phase of perovskite structure without any impurity phases is revealed for all compositions, which indicates that Bi(Zn0.5Sn0.5)O3 has completely diffused into the host lattice of Ba(Zr0.15Ti0.85)O3. Figure 2b shows the magnified XRD patterns over 44°–46° for the (1 − x)BZT–xBZS ceramics. There is only one diffraction peak shown near 45° for x = 0.02, 0.06, and 0.10, implying a pseudo-cubic phase. Interestingly, a slight split for the diffraction peak is observed for x = 0.14, which demonstrates that weak tetragonal phase is induced in the pseudo-cubic matrix with further increase in BZS content. In addition, the (200) diffraction peak has a slight shift towards lower angles as the BZS content is increased, implying that the unit cell volume tends to expand with a raise in lattice constant. Generally, Bi3+(134 pm) will replace Ba2+(135 pm) at A-site, while Zn2+(74 pm) and Sn4+(71 pm) will occupy B-site with a substitution for (Zr0.2Ti0.8)4+ (70.2 pm) [29,30,31,32,33]. Therefore, the increase in lattice volume may be mainly due to the substitution of B-site ions. Additionally, XRD Rietveld refinements are further conducted to determine the crystal structure for various compositions, as shown in Fig. S1 (see Supplementary Information). The Rietveld refinements are tried using the tetragonal phase (space group P4mm) for all the samples, the obtained key parameters are listed in Table S1 (see Supplementary Information). According to the refinement results, the c/a ratios for x = 0.02, 0.06, 0.10, and 0.14 are 1.0001, 1.0005, 1.0011, and 1.0019, respectively. It can be concluded that tetragonal structure becomes more obvious with the increase in BZS content. Actually, the phase structures for x = 0.02, 0.06, and 0.10 are pseudo-cubic due to the low c/a ratios close to 1. For x = 0.14 with a relatively high c/a ratio of 1.0019, weak tetragonal phase structure is identified, which is also confirmed by the slight split of the diffraction peak((002)/(200)) near 45°.

Figure 3a–d show the SEM images of the natural surface for the sintered (1 − x)BZT–xBZS (x = 0.02, 0.06, 0.10 and 0.14) ceramics. Dense microstructure without any remarkable pores can be observed for all compositions. Actually, high relative densities of 95.5%, 96.5%, 96.2%, and 98.6% are obtained for x = 0.02, 0.06, 0.10, and 0.14, respectively. The grain size is determined using software Image J based on the SEM images. The grain size distribution of different ceramic samples was analyzed by fitting with the Gauss function, as shown in the insets of Fig. 3a–d. It can be seen that the average grain size (Ga) tends to slightly rise from 1.82 μm (x = 0.02) to 2.31 μm (x = 0.10) or 2.30 μm (x = 0.14) with the increase in BZT content. However, the Ga is less than 2.40 μm for all compositions, demonstrating relatively fine grains with a high grain boundary density. As the resistivity of grain boundary is much higher than that of the grain [34], high grain boundary density is in favor of the improvement of breakdown strength, and subsequent enhancement of energy storage properties.

Figure 4a–d present the temperature dependences of dielectric constant and loss tangent for (1 − x)BZT–xBZS (x = 0.02, 0.06, 0.10 and 0.14) ceramics measured at various frequencies from 1 kHz to 1 MHz upon heating with a heating rate of 0.5 °C/min from − 50 to 300 °C. For x = 0.02, the maximum temperature Tm corresponding to the dielectric constant peak εm nearly remains constant with increasing frequency, indicating a normal ferroelectric. For x = 0.06, 0.10, and 0.14, relaxor ferroelectric characteristic with remarkable frequency dispersion of dielectric properties is demonstrated due to the increase of Tm and decrease of εm with the increment in measurement frequency [35,36,37,38]. It is believed that this relaxor ferroelectric behavior is caused by the ion substitution with different valences at A- and B-sites. The disorder of ion charge and size at A- and B-sites contributes to the local random fields, weakening the long-range correlation and inducing the PNRs [35, 37, 39, 40]. To quantitatively describe the relaxor ferroelectric behavior of the (1 − x)BZT–xBZS ceramics, the value of γ denoting the diffuseness degree is procured here. Generally, the modified Curie–Weiss law can be described by the following equation [41]:

where εr is the dielectric constant, T is the absolute temperature, εm is the maximum dielectric constant, Tm is the temperature corresponding to the εm, and C is the Curie constant. When γ = 1, the system is a normal ferroelectric. When γ = 2, the system is considered as an ideal relaxor ferroelectric. The linear fitting curves for ln(1/εr − 1/εm) as a function of ln(T − Tm) are shown in Fig. 5b. According to Fig. 5a, the γ value tends to gradually rise from 1.011(x = 0.02) to 1.507(x = 0.14) with increasing BZS content. For x = 0.02 with γ = 1.011, the feature is closer to a normal ferroelectric which is consistent with above analyses. Except for this composition, the γ values for x = 0.06, 0.10, and 0.14 further confirm the relaxor ferroelectric features. Additionally, it can be concluded that the relaxor ferroelectric characteristic becomes stronger with the increase in BZS content. The degree of frequency dispersion ΔTm(= Tm(1 MHz) − Tm(1 kHz)) is also calculated to estimate the degree of relaxation for all the compositions, where Tm(1 kHz) and Tm(1 MHz) are the temperatures corresponding to εm measured at 1 kHz and 1 MHz, respectively. The ΔTm value of the (1 − x)BZT–xBZS ceramics tends to gradually increase from 0 °C (x = 0.02) to 32 °C (x = 0.14) with increasing BZS content, as shown in Fig. 5a. The change trend of ΔTm is consistent with γ, indicating that the relaxor ferroelectricity of (1 − x)BZT–xBZS ceramics gradually increases with increasing BZS content.

The P–E loops measured at room temperature with a frequency of 10 Hz for (1 − x)BZT–xBZS (x = 0.02, 0.06,0.10 and 0.14) ceramics are shown in Fig. 6a–d. It can be observed that the P–E loops become slimmer with the increase of BZS content, simultaneously accompanying a transition from a normal ferroelectric to a relaxor ferroelectric, which is conducive to obtaining excellent Wrec and η. It can be seen from Fig. 7a that both the Pmax and Pr at various electric fields decrease monotonously with the increase in BZS content, and the Pr declines to almost zero as x ≥ 0.10. Therefore, high energy storage efficiencies are expected to be obtained for x = 0.10 and 0.14. On the other hand, higher Pmax is obtained for x = 0.10 in comparison with x = 0.14, which can result in a higher Wrec at the same field. Consequently, x = 0.10 is the optimum composition for energy storage applications. To further understand the excellent energy storage performance of x = 0.10 composition, the unipolar P–E loops at various electric fields ranging from 90 to 250 kV/cm (10 Hz) are shown in Fig. 7b. With the increase of the electric field, the slender P–E loops gradually extend outward, and the values of Pmax increase from 0.79 to 18.56 μC/cm2, while the change of Pr remains small (0.037–0.89 μC/cm2). Because the size of PNRs is much smaller than that of ordinary ferroelectric domains or macroscopic domains, the PNRs manifest more apt to aligning and back-switching at the applied electric field, which leads to slim P–E loops along with neglectable hysteresis characteristic and ultra-low Pr [35]. The composition with x = 0.10 presents ultra-slim P–E loops and small Pr indicating that less energy loss is generated in the course of charging and discharging. According to Fig. 7c, the Wrec increases correspondingly with the increase of applied electric field. When the applied electric field increases to 250 kV/cm, the x = 0.10 composition exhibits the highest energy storage performance with a W of 2.40 J/cm3 and a Wrec of 2.16 J/cm3. Moreover, a very high η of 90.3% is obtained when the electric field reaches the maximum value. Such a high η value signifies very low hysteretic energy dissipation and negligible joule heat produced during charging and discharging, which would be beneficial to raise the electric breakdown arising from the local accumulation of thermal energy [8, 24]. Based on the Weibull distribution analysis, as shown in Fig. S2 and S3 (see Supplementary Information), the composition with x = 0.10 also possesses the highest average BDS value of 262 kV/cm which contributes to the high energy density. The related fitting line of the BDS values based on the Weibull distribution is revealed in Fig. 7d.

a Variation of Pmax and Pr as a function of electric field for (1 − x)BZT–xBZS (x = 0.02, 0.06, 0.10 and 0.14) ceramics; b Unipolar P–E loops (10 Hz); c Calculated Wrec, W, and η under different electric fields derived from unipolar P–E loops for the composition with x = 0.10; and d Fitting line of the BDS data using the Weibull distribution function for x = 0.10

According to the XRD results, the crystal structure for x = 0.10 is pseudo-cubic, which also provides a clue that the composition possesses PNRs in cubic matrix without large-sized polar structures (macro-domains). Consequently, slim P–E loop with high energy storage efficiency is realized in x = 0.10. Additionally, the dense microstructure with high relative density and minimal porosity is also conducive to obtaining high breakdown strength for x = 0.10. Moreover, because the electric resistivity of grain boundary is much higher than that of grain, the relatively small grain size (Ga = 2.31 μm) with high grain boundary density for x = 0.10 is also beneficial to achieve high breakdown strength. These characteristics added together provide structure origin for obtaining high energy storage performance in x = 0.10.

In general, temperature and frequency stability of energy storage performance are also critical for practical applications. Figure 8a displays the unipolar P–E loops of the x = 0.10 composition at 10 Hz and various test temperatures ranging from 25 to 150 °C. It is obvious that ultra-slim P–E loops with minimal Pr is revealed in the whole test temperature range. According to Fig. 8b, the variations of Wrec and η are less than 10% and 2% from 25 to 150 °C, respectively, indicating excellent temperature stability of energy storage performance ascribed to the improvement in temperature stability of dielectric constant and existence of temperature-insensitive PNRs far below Burns temperature (TB) [42, 43]. Figure 8c and d depict the frequency dependences of unipolar P–E loops and energy storage properties for x = 0.10 measured at room temperature, respectively. It is obvious that the ceramic possesses frequency insensitive characteristics. In the frequency range of measurement, the Wrec values range from 0.80 to 0.74 J/cm3 with a variation below 7%, and the corresponding η values remain above 95% with a variation below 3%. This frequency stability should be attributed to the frequency insensitive response of PNRs under the external electric field below TB. Table 1 summarizes the energy storage properties of the composition with x = 0.10 and other reported BZT-based ceramics. It can be found that the x = 0.10 composition in this study simultaneously enjoys a high dielectric breakdown strength, a large Wrec, and a high η, which are significantly superior to other BZT-based ceramics.

a Unipolar P–E loops of 0.9BZT–0.1BZS ceramic at different temperatures with a fixed frequency of 10 Hz and under the electric field of 150 kV/cm; b calculated Wrec and η from (a); c Unipolar P–E loops of 0.9BZT–0.1BZS ceramic at room temperature (25 °C) under different frequencies; d the calculated Wrec and η from (c)

4 Conclusion

In conclusion, novel lead-free(1 − x)BZT–xBZS (x = 0.02, 0.06, 0.10 and 0.14) bulk ceramics were prepared using a solid-state reaction method. The single-phase perovskite structure for all compositions was identified by the X-ray diffraction analyses. Based on the dielectric analyses, it was observed that the relaxor ferroelectric behavior became stronger with the increase in BZT content. Moreover, a high Wrec of 2.16 J/cm3and a high η of 90.3% were simultaneously obtained at a relatively high test field of 250 kV/cm in the composition with x = 0.10, which were superior to other BZT-based ceramics. Our work demonstrates that the introduction of Bi-based perovskite end member is effective to induce relaxor ferroelectric behavior with PNRs and improve the energy storage performance of BZT-based ceramics.

References

F. Yan, H. Yang, Y. Lin et al., Dielectric and ferroelectric properties of SrTiO3-Bi0.5Na0.5TiO3-BaAl0.5Nb0.5O3 lead-free ceramics for high-energy-storage applications. Inorg. Chem. 56, 13510–13516 (2017)

L. Yang, X. Kong, Z. Cheng et al., Ultra-high energy storage performance with mitigated polarization saturation in lead-free relaxors. J. Mater. Chem. A 7, 8573–8580 (2019)

L. Yang, X. Kong, F. Li et al., Perovskite lead-free dielectrics for energy storage applications. Prog. Mater Sci. 102, 72–108 (2019)

C. Zhu, Z. Cai, B. Luo et al., High temperature lead-free BNT-based ceramics with stable energy storage and dielectric properties. J. Mater. Chem. A 8, 683–692 (2020)

F. Pang, X. Chen, C. Sun et al., Ultrahigh energy storage characteristics of sodium niobate-based ceramics by introducing a local random field. ACS Sustain. Chem. Eng. 8, 14985–14995 (2020)

X. Hao, A review on the dielectric materials for high energy-storage application. JAD 3, 1330001 (2013)

H. Pan, F. Li, Y. Liu et al., Ultrahigh–energy density lead-free dielectric films via polymorphic nanodomain design. Science 365, 578–582 (2019)

Q. Wang, M. Gong, M. Wang, High recoverable energy storage density and large energy efficiency simultaneously achieved in BaTiO3-Bi(Zn1/2Zr1/2)O3 relaxor ferroelectrics. Ceram. Int. 46, 22452–22459 (2020)

I. Burn, D. Smyth, Energy storage in ceramic dielectrics. J. Mater. Sci. 7, 339–343 (1972)

P. Kim, N. Doss, J. Tillotson et al., High energy density nanocomposites based on surface-modified BaTiO3 and a ferroelectric polymer. ACS Nano 3, 2581–2592 (2009)

H. Ogihara, C. Randall, K. Trolier et al., High‐energy density capacitors utilizing 0.7BaTiO3–0.3BiScO3 ceramics. J. Am. Cream. Soc. 92, 1719–1724 (2009)

P. Zhao, H. Wang, L. Wu et al., High-performance relaxor ferroelectric materials for energy storage applications. Adv. Energy Mater. 9, 1803048 (2019)

J. Yin, Y. Zhang, X. Lv et al., Ultrahigh energy-storage potential under low electric field in bismuth sodium titanate-based perovskite ferroelectrics. J. Mater. Chem. A 6, 9823–9832 (2018)

H. Qi, R. Zuo, Linear-like lead-free relaxor antiferroelectric (Bi0.5Na0.5)TiO3-NaNbO3 with giant energy-storage density/efficiency and super stability against temperature and frequency. J. Mater. Chem. A 7, 3971–3978 (2019)

C. Yang, P. Lv, J. Qian et al., Fatigue‐free and bending‐endurable flexible Mn‐doped Na0.5Bi0.5TiO3-BaTiO3‐BiFeO3 film capacitor with an ultrahigh energy storage performance. Adv. Energy Mater. 9, 1803949 (2019)

A.K. Yadav, H. Fan, B. Yan et al., High energy storage density and stable fatigue resistance of Na0.46Bi0.46Ba0.05La0.02Zr0.03Ti0.97-xSnxO3 ceramics. Ceram. Int. 46, 5681–5688 (2020)

B. Yan, H. Fan, C. Wang et al., Giant electro-strain and enhanced energy storage performance of (Y0.5Ta0.5)4+ co-doped 0.94(Bi0.5Na0.5)TiO3-0.06BaTiO3 lead-free ceramics. Ceram. Int. 46, 281–288 (2020)

D. Zheng, R. Zuo, D. Zhang et al., Novel BiFeO3-BaTiO3-Ba(Mg1/3Nb2/3)O3 lead-free relaxor ferroelectric ceramics for energy-storage capacitors. J. Am. Cream. Soc. 98, 2692–2695 (2015)

H. Pan, J. Ma, J. Ma et al., Giant energy density and high efficiency achieved in bismuth ferrite-based film capacitors via domain engineering. Nat. Commun. 9, 1–8 (2018)

H. Yang, H. Qi, R. Zuo, Enhanced breakdown strength and energy storage density in a new BiFeO3-based ternary lead-free relaxor ferroelectric ceramic. J. Eur. Ceram. Soc. 39, 2673–2679 (2019)

H. Qi, A. Xie, A. Tian et al., Superior energy-storage capacitors with simultaneously giant energy density and efficiency using nanodomain engineered BiFeO3-BaTiO3-NaNbO3 lead-free bulk ferroelectrics. Adv. Energy Mater. 10, 1903338 (2020)

Y. Zhang, Y. Li, H. Zhu et al., Low dielectric loss of Bi-doped BaZr0.15Ti0.85O3 ceramics for high-voltage capacitor applications. Ceram. Int. 43, 12186–12190 (2017)

V. Puli, D. Pradhan, B. Riggs et al., Structure, ferroelectric, dielectric and energy storage studies of Ba0.70Ca0.30TiO3, Ba(Zr0.20Ti0.80)O3 ceramic capacitors. Integr. Ferroelectr. 157, 139–146 (2014)

Y. Zhang, Y. Li, H. Zhu et al., Sintering temperature dependence of dielectric properties and energy-storage properties in (Ba, Zr) TiO3 ceramics. J. Mater. Sci.: Mater. Electron. 28, 514–518 (2017)

B. Liu, Y. Wu, Y. Huang et al., Enhanced dielectric strength and energy storage density in BaTi0.7Zr0.3O3 ceramics via spark plasma sintering. J. Mater. Sci. 54, 4511–4517 (2019)

S. Ghosh, S. Saha, T. Sinha et al., Large electrostrictive effect in (Ba1-xGd2x/3)Zr0.3Ti0.7O3 relaxor towards moderate field actuator and energy storage applications. J. Appl. Phys. 120, (2016)

Z. Sun, L. Li, S. Yu et al., Energy storage properties and relaxor behavior of lead-free Ba1−xSm2x/3Zr0.15Ti0.85O3 ceramics. Dalton Trans. 46, 14341–14347 (2017)

X. Wang, B. Zhang, L. Shi et al., Dielectric relaxation behavior and energy storage properties in Ba1−x(Bi0.5K0.5)xTi0.85Zr0.15O3 ceramics. J. Alloys Compd. 789, 983–990 (2019)

R. Shannon, Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. A 32, 751–767 (1976)

C. Huang, D. Cann, Phase transitions and dielectric properties in Bi (Zn1/2Ti1/2) O 3-BaTiO3 perovskite solid solutions. J. Appl. Phys. 104, (2008)

X. Fu, W. Cai, G. Cheng et al., Effects of Sn doping on the microstructure and dielectric and ferroelectric properties of Ba(Zr0.2Ti0.8)O3 ceramics. J. Mater. Sci.: Mater. Electron. 28, 8177–8185 (2017)

P. Ren, Z. Liu, X. Wang et al., Dielectric and energy storage properties of SrTiO3 and SrZrO3 modified Bi0.5Na0.5TiO3-Sr0.8Bi0.1-0.1TiO3 based ceramics. J. Alloys Compd. 742, 683–689 (2018)

G. Liu, Y. Li, Z. Wang et al., Dielectric, ferroelectric and energy storage properties of lead-free (1 − x)Ba0.9Sr0.1TiO3-xBi(Zn0.5Zr0.5)O3 ferroelectric ceramics sintered at lower temperature. Ceram. Int. 45, 15556–15565 (2019)

A. Xie, H. Qi, R. Zuo, Achieving remarkable amplification of energy-storage density in two-step sintered NaNbO3-SrTiO3 antiferroelectric capacitors through dual adjustment of local heterogeneity and grain scale. ACS Appl. Mater. Interfaces 12, 19467–19475 (2020)

Q. Yuan, F. Yao, Y. Wang et al., Relaxor ferroelectric 0.9BaTiO3-0.1Bi(Zn0.5Zr0.5)O3 ceramic capacitors with high energy density and temperature stable energy storage properties. J. Mater. Chem. C 5, 9552–9558 (2017)

C. Cui, Y. Pu, R. Shi, High-energy storage performance in lead-free (0.8 − x)SrTiO3-0.2Na0.5Bi0.5TiO3-xBaTiO3 relaxor ferroelectric ceramics. J. Alloys Compd. 740, 1180–1187 (2018)

M. Zhou, R. Liang, Z. Zhou et al., Superior energy storage properties and excellent stability of novel NaNbO3-based lead-free ceramics with A-site vacancy obtained via a Bi2O3 substitution strategy. J. Mater. Chem. A 6, 17896–17904 (2018)

J. Ye, G. Wang, M. Zhou et al., Excellent comprehensive energy storage properties of novel lead-free NaNbO3-based ceramics for dielectric capacitor applications. J. Mater. Chem. C 7, 5639–5645 (2019)

X. Zhao, Z. Zhou, R. Liang et al., High-energy storage performance in lead-free (1 − x)BaTiO3-xBi(Zn0.5Ti0.5)O3 relaxor ceramics for temperature stability applications. Ceram. Int. 43, 9060–9066 (2017)

T. Wang, Y. Wang, H. Yang et al., Structure, dielectric properties of low-temperature-sintering BaTiO3-based glass–ceramics for energy storage. JAD 8, 1850041 (2018)

Y. Pu, L. Zhang, Y. Cui et al., High energy storage density and optical transparency of microwave sintered homogeneous (Na0.5Bi0.5)(1–x)BaxTi(1–y)SnyO3-Ceramics. ACS Sustain. Chem. Eng. 6, 6102–6109 (2018)

K. Axelsson, G. Le, M. Valant et al., Electrocaloric effect in lead-free Aurivillius relaxor ferroelectric ceramics. Acta Mater. 124, 120–126 (2017)

T. Li, X. Liu, S. Shi et al., Large electrocaloric efficiency over a broad temperature span in lead-free BaTiO3-based ceramics near room temperature. Appl. Phys. Lett. 111, 202902 (2017)

W. Ping, W. Liu, S. Li, Enhanced energy storage property in glass-added Ba(Zr0.2Ti0.8)O3-0.15(Ba0.7Ca0.3)TiO3 ceramics and the charge relaxation. Ceram. Int. 45, 11388–11394 (2019)

A. Jayakrishnan, K. Alex, A. Thomas et al., Composition-dependent xBa (Zr0.2Ti0.8)O3-(1 − x)(Ba0.7Ca0.3)TiO3 bulk ceramics for high energy storage applications. Ceram. Int. 45, 5808–5818 (2019)

R. Sumang, N. Thongmee, T. Bongkarn et al., Structural, optical and electrical properties of the microcrystalline structure of (Ba1−xY2x/3)(Zr0.20Ti0.80)O3 ceramics. Radiat. Phys. Chem. 172, (2020)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51372042, 51872053), the NSFC-Guangdong Joint Fund (Grant No. U1501246), the Guangdong Provincial Natural Science Foundation (2015A030308004), the Dongguan City Frontier Research Project (2019622101006), and the Advanced Energy Science and Technology Guangdong Provincial Laboratory Foshan Branch-Foshan Xianhu Laboratory Open Fund - Key Project (Grant No. XHT2020-011).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lin, X., Zhao, X., Zhou, L. et al. Novel barium zirconate titanate-based lead-free ceramics with stably high energy storage performance over a broad temperature and frequency range. J Mater Sci: Mater Electron 32, 11845–11856 (2021). https://doi.org/10.1007/s10854-021-05814-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05814-9