Abstract

Organic polymer materials gain much attentions due to its high nature abundance, tuneable property with respect to functional groups, easy processing, low-cost alternate to their inorganic counter-part. The conversion of one functional group to others, building cyclic skeleton, synthesis of various heterocycles, protection of one sensitive functional group during the conversion of another one in a substituted molecule, low temperature and high pressure reactions, etc. are the part of synthetic chemistry. Especially, care is needed to synthesis electrochemically active compounds for energy storage applications. Almost, all secondary batteries decorated with the organic polymer materials as part/full of the electrodes design. This review summarizes the synthesis of electrochemically active organic redox polymers such as carbonyl, organosulfur, conducting polymers and its application in various alkali metal-ion rechargeable batteries as electrode components.

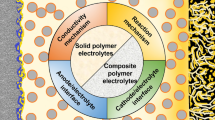

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The award of 2000 Noble prize to Heeger, MacDiarmid and Shirakawa for the discovery of conducting polymer in 1977 provoked researchers to think about usage of organic polymers in electronic applications [1]. There are many research fields such as photovoltaic devices, field-effect transistors, light-emitting diodes, batteries and sensors employing organic conducting polymers as one of the device components [2,3,4,5]. Organic polymers are easily processable, flexible and the most important argument is their redox property which can be tuned by synthesizing them with proper functional groups [6]. Also, the polymers made up of naturally abundant C, H, N, O and S while the inorganic materials need of transition metals and high precious metals. Hence, the disposal of polymer electrode is easy rather than that of the inorganic one. Even though, the organic polymers can be used to develop a clean and efficient energy storage system for electronic devices with many advantages over the inorganic materials, but still not reached the society as commercial products now. Commercial secondary batteries have primary role on the developments of those devices.

Electronically conducting polymers such as polyacetylene, polypyrrole, polyaniline and poly(p-phenylene) were proposed and tested as the electrode materials in 1987 [7]. The conducting polymer can be used either positive or negative electrode in rechargeable batteries [8]. Because, the polymer electrodes must up take or give off the ions during oxidation and reduction reactions to become neutral which increases the electronic conductivity of the polymer. At the same time, the charge could also be balanced by moving the ions in the polymer skeleton and become ionic conductor. Thus, the conducting polymers have both electronic and ionic conductivity [9]. Both are essential for making highly efficient batteries. The inorganic materials and carbon-based materials follow intercalation/de-intercalation or alloying/de-alloying mechanism during charge/discharge of batteries whereas polymers follow a doping/dedoping and binding/de-binding mechanism [10, 11].

2 Li-ion battery

Until the commercial launch by Sony in 1990, there were no awareness about lithium–ion battery (LIB) [12]. The commercial LIB are using graphite anode and transition metal oxide-based cathodes. The simple operation enables to do extensive research on alternative high capacity anodes and cathodes. One of the promising candidates is the polymers. The polymers may be different in kind, viz., conducting polymers, electrochemically active organic redox polymers such as carbonyl, nitroxide radical and organosulfur. Those polymers have been employed both as anodes and cathodes [13, 14]. The electrochemistry of organic polymer battery slightly differs from the usual LIB, the former stores the energy by binding/de-binding with shuttle ions while the latter act as intercalation/de-intercalation host. Precisely, redox-active, n-type polymers serve as the electron acceptor whereas p-type redox-active polymers serve as the electron donor [15]. During the charge process the cations from electrolyte will move to the n-type polymeric electrode while that of anions move to the p-type polymeric electrode (Fig. 1a). The discharge process releases the ions from the respective electrode to the electrolyte (Fig. 1b). The advantage of the symmetric polymer battery is that utilizes only one polymer material both as anode and cathode. The simple fabrication will lead to easy processing, low-cost and hence commercialization. Also, it doesn’t need metal foils, instead it needs only salts in the electrolyte. Since, the polymer battery utilizes the ions from the electrolyte, no need to pre-insertion and hence it will be ready to charge [16].

Electrochemical reactions of full polymer battery (Reproduced with permission from Ref. [15]. Copyright 2019 American Chemical Society)

The following section will discuss about the polymers which are used as anode and as cathode in LIBs.

2.1 Polymers as an anode material for LIBs

Many reviews have already given the primary information about the use of polymers as anode in LIBS [6, 17]. The current review updates the latest information which are essentially show their significant electrochemical performance. Poly(1,6-dihydropyrazino[2,3g]quinoxaline-2,3,8-triyl-7-(2H)-ylidene-7,8-dimethylidene) (PQL), a ladder type of nanostructured polymer (Fig. 2) synthesized by the reaction between 2,5-dihydroxy-1,4-benzoquinone and 1,2,4,5-tetraaminobenzene tetrahydrobromide in polyphosphoric acid. As anode in LIB, a maximum specific capacity of 1750 mAh/g at 0.05 C rate. The cycle stability results are surprising that capable of delivering 500 mAh/g after 1000 cycles and the current rate was 2.5 C. An added information that the cycle stability test was conducted at 50 °C. The obtained specific capacity is slightly inferior to the high theoretical capacity of 1822 mAh/g has been calculated based on 14 Li+ ion insertion in the PQL structure [18]. Another ladder type of nanostructured polymer, polybenzimidazo-benzoisoquinoline (BBL) was synthesized by similar one-pot polycondensation method. However, 1,4,5,8-naphthalenetetracarboxylic dianhydride (NTCDA) is used instead of bezoquinone derivative. The delivered discharge capacity is almost equal on 1780 mAh/g at 0.05 C rate. The cycle stability also as high as to the PQL. The BBL has delivered a discharge capacity of 496 mAh/g at 3 C after 1000 cycles [19].

FESEM images of PQL nanoparticles. a Low-resolution micrograph of the large quantity of PQL nanoparticles. b Highresolution image of PQL nanoparticles (Reproduced with permission from Ref. [18]. Copyright 2015 John Wiley and Sons)

Liang claimed that they had reported the first π-conjugated redox polymers for the energy storage application in LIB. The specific capacity is very low that 54.2 mAh/g at 50 mA/g. However, the reversible doping level of the polymer has attained to 2.0. The capacity retention of every single cycle was 99% at 10 C. Even at 500 C the capacity retention is nominal on 79%. The cycle stability of the conjugated redox polymer is relatively, i.e. after 3000 cycles the retention of capacity was 96% at 10 C [20]. Chemical oxidative polymerization of dopamine by ammonium persulfate yield polydopamine (PDA) with interesting structure, viz. it contains both catechol and o-benzoquinone functionalities. The binder-free PDA electrode displayed an initial discharge capacity of 1818 mAh/g at 50 mA/g. A reversible capacity of 1510 mAh/g at 500 mA/g maintained to 1414 mAh/g after 580 cycles and the capacity retention was calculated as 93% [21]

Nauroozi et al., synthesized a vinyl-based polymer with pendent terephthalate as redox-active functionality. The synthesis involves multiple step starting from 2-methylterephthalonitrile and finally terephthalate functional groups were lithiated. As anode, the delivered discharge capacity by the polymer was very low (58 mAh/g at 0.33 C) and it was claimed that the polymer electrode exhibited a retention capacity of 85% after 100 cycles at 0.33 C rate [22]. Polypyrrole (PPy), a simple heterocyclic conducting polymer, synthesized by vapour phase polymerization process by employing ferric tosylate as oxidizing agent. The free-standing PPy films with layered structure of pyrrolic chains not only delivering a high specific capacity of 309 mAh/g but also capable of showing high cycle stability at 10 C over 1000 cycles [23]. Numazawa et al., prepared carboxylic acid functionalised polypyrrole (PPy-COOH) and polythiophene (PT-COOH) from its respective carboxylic acid monomers in chloroform solvent and as usual oxidizing agent viz. FeCl3. The PPy-COOH and PT-COOH show excellent electrochemical behavior as anode in LIBs compared to their parent PPy and PT. For example, the PPy-COOH delivered a discharge capacity of 730 mAh/g at 20 mA/g whereas that of the parent PPy displayed only 157 mAh/g. The effect of carboxylic acid functional group played a vital role in PT which can be evidenced from its higher capacity (963 mAh/g) than that of the parent PT (44.4 mAh/g). The multistage redox reactions of the carboxylic acid functionalised polythiophene with Li in the potential range of 3 to 0 V could be seen in Fig. 3 [24]. As a consequence of the effect of substitution, benzene ring fused at 3,4-position of PT have exhibited a good impact on the electrochemical performance as anode in LIB. A low bandgap and high conducting polymer, polyisothianaphthene (PITN), have been employed as bipolar material in LIB. It was synthesized by refluxing phthalide as precursor and phosphorus pentasulfide as the source of sulfur in xylene as solvent. The PITN electrode exhibited a specific capacity of 730 mAh/g at 0.1 C rate as anode which implies that it could be promising anode. A specific capacity of 486 mAh/g still observed after 200 cycles while the coulombic efficiency was above 99.1%. A discharge capacity of 702 mAh/g was recovered at 0.1 C after finishing the rate test at 10 C. As cathode it could deliver a discharge capacity of 106 mAh/g and the all organic battery using PITN capable of providing a capacity of ~ 92 mAh/g due its acceptance of both Li+ and PF6− during n-doping and p-doping processes [25]. It should be remembered that the presence of lone pair containing heteroatom such as N, O and S in a π-conjugated polymer backbone increases the intrinsic conductivity by increase in multiple redox centers.

Electrochemical redox reactions of PTp-COOH. a Redox reaction with doping and dedoping of anions (X–) (p doping). b Redox reaction with doping and dedoping of cations, such as Li+ (n doping). The neutral state is stable in the white region between panels a and b at approximately 3 V. c Redox reactions with the charge and discharge of cations in the heteroaromatic ring and carbonyl substituent. The red balls represent the Li+ electrochemically reacted with the monomer unit during the charge–discharge reactions (Reproduced with permission from Ref. [24]. Copyright 2018 Springer Nature)

Very recently, the increase in capacity was obtained with ladder-type microporous polymers. Three types of fused arylene diimides were synthesized from dianhydrides such as pyromellitic, 1,4,5,8-naphthalenetetracarboxylic and perylene 3,4,9,10-tetracarboxylic dianhydride reacted with fused arylamine. The electrochemical performance was unusual that the capacity of perylene-based polymer (LPPTCDABAHA) gets increased from 95 to 783 mAh/g after 1000 cycles, respectively, whereas that of pyromellitic-based polymer (LPPMABAHA) increased from 44 to 737 mAh/g after 1000 cycles [26]. Some of the discussed polymers as anode in LIB are shown in Fig. 4. Nanostructured polymers would be the solution for achieving high capacity and cycle stability. It is well known that nanostructures have high surface area, short path lengths for electronic and ionic conduction and most importantly their strain tolerance during the electrochemical reactions. It can be synthesized by controlling the polymerization conditions.

2.2 Polymer cathode materials for LIB

The redox-active polymers have been tested as cathode in LIBs which are having good to excellent electrochemical behaviors. In 2008, Feng et al., synthesized polytriphenylamine (PTPAn) from its monomer, triphenylamine in chloroform solvent using FeCl3 as oxidizing agent. The PTPAn delivered nearly 94% theoretical capacity at 0.5 C. The capacity retention of the PTPAn cathode after 1000 cycles at 20 C was 95%. and the coulombic efficiency was almost as close as 100% at the extended cycles. This might be arising from the radical redox behavior and facile charge transport processes of triphenylamine unit in the polymer backbone. This showed the potential of PTPAn towards high rate capability and long life stability on LIBs [27]. Davoglio produced an interesting architecture to overcome the issue of loss of active mass from disulfides during charge/discharge processes. 2,5-dimercapto1,3,4-thiadiazole (DMcT) is known for its high theoretical capacity of 362 mAh/g as the cathode material. The researchers fabricated the poly(DMcT) on a carbon fiber (CF) and finally a nanometer thick polypyrrole (PPy) was grown on the poly(DMcT) film. On the event of this bilayer structure, the specific capacity has been reached to 320 mAh/g after 40th cycle and maintained its coulombic efficiency ~ 100%. Even after 100 cycles there was no significant loss in capacity observed [28]. As like other polymers, polyindole has also been evaluated as cathode in LIB and the polyindole was prepared by chemical oxidation of its monomer in a chloroform solution as usual with FeCl3 as the oxidizing agent. The experimental specific capacity (80 mAh/g at 10 A/m2) of polyindole closes to its theoretical capacity (84 mAh/g). Further, a careful investigation implies that after 5000 cycles it retains 98% of its specific capacity and 80% capacity retention was identified even after 30,000 cycles [29]. The life cycle stability is ultimately good and functionalization with electroactive carbonyl groups in the skeleton may provide higher specific capacity.

Vinyl polymers with redox-active phenothiazine units were suggested as cathode material for LIBs because it can be operated to 3.7 V [30]. Later, Peterson designed some linear and cross-linked polymers such as poly(N-methylphenothiazine dimethylphenylenediamine) (PT-DMPD) and poly(N-methylphenothiazine benzidine) (PT-BZ). The synthesis of those polymers were accomplished by Buchwald–Hartwig cross-coupling of 3,7-dibromo-N-methylphenothiazine with dimethylphenylenediamine or dimethylbenzidine. The polymers were insoluble in their neutral state and they claimed that the starting materials used for the synthesis of polymers are inexpensive. Also they observed that the cross-linked polymer could deliver a high capacity and high rate capability than that of the linear ones. As a cathode in LIB, the 10% cross-linked copolymer delivered a specific capacity of 150 mAh/g at the voltage between 2.8 to 4.3 V vs Li+/Li and providing high energy density. An excellent capacity retention of 82% was perceived at ultra-fast 120 C. Some of the important assumptions for their high capacity and other achievement are as follows: (a) electron-rich and redox-active aryl diamines has stable charged states, (b) stabilized quinoidal character of aryl diamines at potentials above 3.3 V against Li+/Li and (c) copolymerization at 3 and 7 positions of phenothiazine would provide conjugation which allow a fast electron transfer [31]. A hyperbranched structure of polytriphenylamine (PHTPA) was found to be appropriate for high rate performance and ultra-high cycle stability. It has been synthesized by refluxing bis(4-bromophenyl)amine and diphenylamine precursors, sodium tert-butoxide as base and toluene as solvent in the presence of bis(tri-t-butylphosphine)palladium(0) as catalyst at 100 °C for 6 h. As a cathode, the PHTPA delivered a discharge capacity of 64 mAh/g at 0.5 C but exhibited an unexpected cycle stability, i.e. more than 5000 cycles without any significant degradation. It is noteworthy to mention here that the cycle stability tests were conducted at 20 C and 100 C. They claimed that the microsphere morphology of PHTPA had contributed to the high rate performance and high cycle stability. Also confirmed that there is no elution of PHTPA in to the electrolyte [32].

Polythiophene (PT) also exhibited its anion accepting behavior in LIBs. The PT prepared by usual chemical oxidation method with ferric chloride as oxidant and thiophene as monomer. However, they have got porous morphology and the porous PT that delivered as discharge capacity of 58.4 mAh/g at 100 cycle at a current density of 100 mA/g. The PT cathode displayed a stability over 500 cycles and still could deliver 50 mAh/g at a current density of 900 mA/g [33]. Hernández designed and synthesized redox-active polyimide-polyether copolymers. Out of many substituted polymers, the naphthalene polyimides with longest poly(ethylene oxide) (PEO2000) blocks, demonstrating a superior electrochemical performance, i.e. the presented discharge capacity was 170 mAh/g. The main advantage of the present polymer is that it doesn’t need a binder [34]. The other interesting redox-active polymer designed by Häupler, who uses the vinyl-based polymer that was synthesized with pendent dithiophenedione as the redox-active functional group. The electrode fabricated with this polymer exhibited a capacity of 217 mAh/g as its maximum value and the cycle stability was not so impressed [35]. An organosulfur polymer, poly(benzoquinonyl sulphide) (PBQS), synthesized from dichlorobenzoquinone with three consecutive steps, employed as cathode for both LIB and SIBs. A relatively stable discharge capacity of 272 mAh/g at 50 mA/g was obtained. After reaching the stable value of 246 mAh/g at 500 mA/g at 140 cycle, the capacity decay was very slow that 0.04 mAh/g per cycle [36].

A new type of polymer designed for cathode in LIB, in which benzene act as the main conducting backbone while the redox-active imide with carbonyl groups form the side chain. However, the electrochemical performance was not significant to highlight as a high capacity cathode [37]. A notable performance was demonstrated by polyimide synthesized from NTCDA and sulfamide. A stable discharge capacity of 120 mAh/g after 450 cycles [38]. A different structured block copolymers were synthesized by copper azide–alkyne coupling cycloaddition of poly(3-hexylthiophene) and poly(2,2,6,6-tetramethylpiperidinyloxy-4-ylmethacrylate). The electrochemical performances of the diblock copolymers (P3HT-b-PTMA) are greater than the individual homopolymers and their simple blends. A discharge capacity of P3HT-b-PTMA is 116 mAh/g at 0.1 C rate and observed a stable cycle performance over 200 cycles [39]. Another block copolymer poly(fluorene-alt-naphthalene diimide) was proposed as cathode material for LIB by Sarang et al. [40].

Very recently, polymers were synthesized to employ as cathode from conjugated carbonyl compounds. The present material form binder-free electrode and the electrochemical performances are notable. Poly(pyrene-4,5,9,10-tetraone) (PPT) delivers a reversible capacity of 142 mAh/g at a current density of 50 mA/g while the capacity retention of 74.6% at 500 mA/g after 300 cycles. In addition to that, it displayed an excellent rate capability of 120 mAh/g at a current density of 1000 mA/g. Figure 5 displays the schematic and real arrangements of flexible half-cell and full cell with PPT cathode. It also shows the illumination of light-emitting diodes by the full cell [41]. In addition to single polymer cathodes, polythiophene and polyimides composite electrodes were prepared by Lyu in 2017. The polymer composite was synthesized by in situ chemical oxidative polymerization. The composite polyimide cathode with 30% polythiophene coating was found to be best in electrochemical performance. It delivered a specific capacity of 216 mAh/g at 0.1 C and capable of delivering 89 mAh/g at a current rate of 20 C after 1000 cycles with a notable capacity retention of 94%. The synergetic effect of conductive polythiophene and redox-active polyimide made it possible [42]. Figure 6 displays the chemical structures of polymer cathodes. However, further research on this type of polymers is essential to address any unfavorable interactions with electrolyte and to achieve a reasonably good electrochemical performance.

a Schematic representation and b discharge/charge curves of the flexible battery. c Schematic representation and d discharge/charge curves of the full cell. Digital photographs of LED lighting by the flexible battery under different conditions e and f lighting of different devices by the full cell (Reproduced with permission from Ref. [41]. Copyright 2019 American Chemical Society)

3 Sodium ion battery (SIB)

The limited abundance of Li urges the researchers to think alternate alkali- and alkaline-earth-metals such as sodium, potassium, calcium and magnesium etc. to use as in batteries. As everyone know that sodium is more abundant in the earth and also similar redox behavior as lithium ion, indicating it can be used in rechargeable batteries [43, 44]. It is more important that the price of Na is cheaper than that of Li and hence the production cost will also be very less.

3.1 Evolution of polymers as anode materials for SIB

The electrochemical binding reactions of the polymers with Na+ ions have been studied. Polypyrrole (PPy) have given promising electrochemical results when it was employed as anode in SIB. The PPy with submicrostructure synthesized displays an initial discharge capacity of 471 mAh/g and a steady discharge capacity of 183 mAh/g at 400 mA/g after 100 cycles. The superior cycle stability was measured from its delivered discharge capacity of 84 mAh/g after 500 cycles at 14,400 mA/g [45]. Polyimides were extensively investigated as anode and cathode materials in LIBs because of its redox-active carbonyl group and can be synthesized by easiest synthetic methodologies. The identical strategy was applied to SIBs also. A polyimide material (PNTCDA) synthesized by dehydration condensation reaction between NTCDA and ethylenediamine in N-methylpyrrolidone (NMP) as solvent. As an anode, it delivered a specific capacity of 140 mAh/g and a reasonably good initial coulombic efficiency of 97.6%. The excellent cyclic stability can be inferred from its 90% capacity retention over 500 cycles at 1 C rate while maintains the coulombic efficiency nearly 100% [46]. The same polyimide was published by other research group with different abbreviated name, i.e. poly-(naphthalene four formyl ethylenediamine) (PNFE) and the synthetic method also the same. The twist is that the polyimide tested in a non-aqueous electrolyte containing 1 M NaClO4 whereas PNFE anode was tested in an aqueous electrolyte containing 1 M Na2SO4. The electrochemical redox behavior arises from the carbonyl groups and displayed a specific capacity of 134 mAh/g for 1000 cycles without any distinct capacity loss at 10 C. The high cycle stability usually comes from the conjugated structure and the fast rate capability originated from the redox-active carbonyl groups [47]. Three dimensional polyimides with extended conjugation were synthesized by Li et al., The polymers were synthesized from NTCDA, pyromellitic dianhydride (PMDA), and melamine employed as an anode in SIB. The polymer (PNTCDAMA) synthesized with NTCDA demonstrated a superior performance than that of the PMDA due to extended conjugation. An excellent cycling stability of PNTCDAMA delivers 88.8 mAh/g after 1000 cycle at 5 A/g and the capacity retention was 83.1% [48]. Pyromellitic dianhydride-based polyimide anodes with flower-like morphology was synthesized by hydrothermal method from para-phenylenediamine and PMDA. The polymide anode exhibited 125 mAh/g after 100 cycles [49]. The electrochemical properties of PIs vary with different alkyl-substitutions. An effective design is necessary to solve the low-capacity and capacity fading problems.

Remarkably, Fernández designed and synthesized a redox-active polymer with Schiff bases (PSb) and polyethyleneoxide (PEO) structures. The polycondensation reaction occurs by combining p-phenylenediamine with terephthalaldehyde while polyether having amine functional groups that introduced to the increases of the flexibility and ionic conductivity. After 25 cycles, the PSb-PEO delivered a specific capacity of 178 mAh/g whereas in laminated binder-free electrode delivered that of 185 mAh/g, respectively [50]. Schiff base compounds (R1CH=NR2) found to be active as electrodes in SIB. Especially, the polymer was synthesized from a monomer that contains two Schiff base functional groups on the central benzene ring. This simple condensation reaction between aliphatic/aromatic diamines and terephthalaldehyde as the benzene ring source with aldehyde functional groups produce the polymeric Schiff base. The polymeric Schiff bases with aromatic amine linkers found to be more stable electrochemical activity due to their conductivity. A reversible capacity of 350 mAh/g at 0.1 C rate was exhibited by poly[N,N’-p(benzylidene)phenylenediamine] (PBPDA) and the capacity was accounted from more than one sodium atom per azomethine C=N– unit [51]. PDA has also been tested as anode in SIB and the results were impressive. An attained discharge capacity PDA delivered 508 mAh/g after five cycles at a current density of 50 mA/g and become stable until 1024 cycles on a nearly 100% coulombic efficiency [21]. Figure 7 represents chemical structures of some of discussed polymer anode materials. It might be challenging to design excellent electrode materials with all beneficial aspects such as capacity, stability and suitable electrolytes. The knowledge can be borrowed from LIB to bring forward the SIB in people hands.

3.2 SIB cathode materials design from polymers

The function of cathode is considered as very significant since it is related to the potential of the battery. The potential could also be tuned by doping of the polymer. PPy has also been employed a cathode in SIB. A redox-active ferricycanide ions–doped PPy exhibited a reversible capacity of 135 mAh/g at 50 mA/g. For the high rate performance, it demonstrated a specific capacity to 75 mAh/g at a current density of 1600 mA/g. In addition, the 85% capacity retention over 100 cycles at 50 A/g enlightened its cycle stability [52]. As a continuation of the external doping, self-doped PPy was synthesized from pyrrole and sodium sulfonate-containing pyrrole monomers. The claim of the work was that self-doping strategy would be helpful to host sodium insertion and extraction reaction. A steady capacity of 85 mAh/g was obtained after a few cycles and found to be stable over 100 cycles [53]. Yet another article published with PPy as cathode in SIB. Diphenylamine-4-sulfonate was used as the dopant and an initial discharge capacity of 115 mAh/g is shown [54]. The same research group synthesized the polymer of diphenylaminesulfonic acid sodium (previously used as dopant) and employed as cathode. The poly(diphenylaminesulfonic acid sodium) delivered a reversible capacity of 100 mAh/g owing to one sodium ion insertion/extraction reaction [55]. The concept of self-doping with electron withdrawing sulfonate groups adapted by the same researchers, i.e. an aniline containing sulfonate group in ortho position was polymerized to get polyaniline with self-doping sulfonate groups. The capacity has also been increased from 100 to 133 mAh/g. A capacity retention of 96.7% over 200 cycles at a constant current density of 100 mA/g showed its excellent cycling stability [56]. Remarkably, a copolymer synthesized from mixture of aniline and nitroaniline proficient of delivering a reversible capacity of 180 mAh/g at 50 mA/g and get a stable capacity of 173 mAh/g after 50 cycles [57].

Poly(benzoquinonyl sulfide) (PBQS) has also been introduced as cathode material for SIBs. The PBQS electrode delivered a maximum discharge capacity of 268 mAh/g. The cycle stability of the PBQS cathode in SIB was not impressive to that of LIB [36]. Followed by the above research entry, Tang proposed that the electrochemical performance can be improved by tailoring π-conjugated system in monomers which will led to the solve solubility problem, enhancing the π–π interaction and the layer-by-layer π–π stacking on the charge transport and ionic diffusion of the electrode. They prepared a series of polymers such as poly(benzoquinone sulfide) (PBQS), poly(anthraquinone sulfide) (PAQS) and poly(pentacenetetrone sulfide) (PPTS) with the idea of extension of π-conjugation. The synthesis was started from chlorobenzene and pyromellitic dianhydride in the presence of an Lewis acid catalyst which form an intermediate viz. 2,5-bis(4-chlorobenzoyl)terephthalic acid. The intermediate was converted to 2,9-dichloropentacene-5,7,12,14-tetrone by trifluoromethanesulfonic acid. Finally, the PPTS was obtained by reaction of the above chloro-derivative of pentacenetetrone with sodium sulfide in N-methyl pyrrolidone as medium. The highly conjugated polymer, PPTS showed a reversible capacity of 290 mAh/g with nearly 100% coulombic efficiency at 100 mA/g. PPTS has also proved their ability for the long cycle-life, delivering a reversible capacity of 160 mAh/g even after 5000 cycles at 10 A/g. All such high capacity and cycle stability under fast charge/discharge processes could be endorsed by the extended conjugation with rigid structure and layer-by-layer arrangement like graphene [58]. Very recently, poly(hexaazatrinaphthalene) (PHATN) tested as cathode material in a SIB and a superior electrochemical performance was demonstrated by Mao et al. The polymerization occurs through carbon–carbon bond between two phenyl rings and it was synthesized by simple condensation reaction between cyclohexanehexone and amines. As a cathode, it showed a discharge capacity of 236 mAh/g at 50 mA/g. In addition, the excellent cycle stability at 25 C delivers 100 mAh/g after 50,000 cycles can be shown in Fig. 8. The energy density exhibited by PHATN was 210 Wh/kg at a high power density 20,000 W/g [59].

a Discharge–charge curves and b cyclic voltammograms of PHATN for the first three cycles at 50 mA/g and at 0.5 mV/s, respectively. c and d show the long-term cycling performance of PHATN under 5C for 10,000 and 25C for 50,000 cycles (Reproduced with permission from Ref. [59]. Copyright 2019 John Wiley and Sons)

Polyimides with effect of conjugation was analyzed by Wang et al. In which a series of polyimides were synthesized by reacting dianhydrides such as pyromellitic dianhydride (PMDA), 1,4,5,8-naphthalenetetracarboxylic dianhydride (NTCDA) and perylene 3,4,9,10-tetracarboxylic dianhydride (PTCDA) with alkyl diamines. PTCDA-based polyimide showed a superior electrochemical performance that retained reversible capacity of 137 mAh/g after 400 cycles with nearly 100% coulombic efficiency. Unbelievable cycle stability, a capacity retention of 87.5% at 0.8 C rate was demonstrated 5000 cycles [60]. Polyimides prepared with redox-active anthraquinone as linking unit were synthesized by the reaction of PMDA/NTCDA with 2,6-diaminoanthraquinone. A highly reversible capacity of 192 mAh/g was obtained from the above product and a 95% capacity retention after 150 cycles accounts its cycle stability [61]. Poly(anthraquinonyl imides) (PAQI), a series of polymers were synthesized from various combinations of PMDA/NTCDA with 1,4-diaminoanthraquinone/ 1,5-diaminoanthraquinone. They concluded that the PAQI displayed a high reversible capacity of 190 mAh/g. The cycle stability was also good to light, i.e. a 93% capacity retention was demonstrated over 150 cycles at the current density of 50 mA/g [62]. The last two articles reported the electrochemical performances of polyimides with different positional isomers. However, the obtained results almost the same with capacity and cycle stability. The researchers (Zhijiang et al.) who tested the polyindole as a cathode in SIB. The substituted polyindole, poly(5-cyanoindole) was used with electrospun nanofiber structure. The obtained highest discharge capacity of 106 mAh/g at 0.2 C rate was retained with only a small decay speed of 0.0159 mAh/g to attain a capacity retention of 85% after 1000 cycles [63]. A recent literature that claims the first report on the use of highly porous azo-linked polymer to employ as cathode for SIB. The 1,1,2,2-tetrakis(4-aminophenyl)ethane uses as a precursor while copper (I) salts are employed as a catalyst. The first discharge capacity of 315 mAh/g at 0.3 C led to a reversible capacity of 194 mAh/g at the second cycle. It was found to be stable over 150 cycles with a capacity retention of 95% at 0.3 C [64]. Poly(N-vinyl carbazole) is a redox-active polymer contains electron-rich carbazole moiety. As a cathode in SIB, it exhibits a highly stable discharge capacity, which is around 62 mAh/g for 900 cycles at a current density of 500 mA/g. An average discharge capacity of approximately 110 mAh/g could be realized for 100 charge/discharge cycles at 50 mA/g [65]. Polymers, known as cathodes for SIB are shown in Fig. 9. Tertiary nitrogen containing polymer have shown their high potential while organosulfur polymers have shown their excellent cyclic stability. In order to get a high capacity, the content of tertiary nitrogen in a monomer should be increased. But, the sulfur should also be presented in the conducting chain not in the side chain.

4 Potassium ion battery (PIB)

The successful commercialization and advancements in LIB motivate the researchers to think about high abundance element with similar redox potential of lithium. In this case, potassium is considered due to its very close redox potential (− 2.93 V vs E°) compares with lithium (− 3.04 V vs E°). Publications are getting increased in PIB to understand the electrochemistry, develop the electrochemical performance by designing materials, electrode/electrolyte interface, and battery configuration [66, 67]. However, the PIB is in infancy state. In the way of achieving high energy density and high cycle stability, the polymer materials are discussed here.

4.1 Active polymer anodes for PIB

The storage of potassium ion is exemplified in an imine-rich poly(o-phenylenediamine) (PoPD). As usual, the PoPD was synthesized by chemical oxidation method using ammonium persulfate as oxidizing agent. However, an optimum content of quinoid imine dominates the oxidation of monomer which was in good relation with the electrochemical performance, viz. as the oxidant amount increases the content of imine also increases. It was concluded that the monomer to oxidant ratio of 1:1 resulted in optimized electrochemical performance with optimized content of imine. The content of imine played an important role in conductivity of the polymer and also presents an unstable state at highly oxidation. After activation process, it could deliver a discharge capacity of 450 mAh/g at 50 mA/g until 205 cycles [68]. Some combined theoretical and experimental studies provided the basic understanding of structure–property relationship between the conjugated microporous polymers and their electrochemical performance in PIBs. They have selected benzene and benzothiadiazole containing microporous polymers for this study. These polymers have high delocalization of LUMO energy which is favorable for high degree of n-doping activity. Not only the low LUMO energy level but also the low bandgap provided the high electron affinity and conductivity. Further, the porous structure and high surface area cause facilitated electrochemical storage of potassium ions. All polymers were synthesized by Suzuki coupling reaction. Out of all polymers, the polymer (PyBT) synthesized by pyrene and benzothiadiazole units showed excellent performance, i.e. a reversible capacity of 428 mAh/g at 30 mA/g. The cycle stability of the porous polymer could be understood from its capacity retention of 272 mAh/g after 500 cycles at 50 mA/g [69]. The chemical structures of two polymers are shown in Fig. 10. The PIB needs more research to attain the commercial status.

4.2 Designed PIB cathode materials

Since the redox properties of cathodes almost the same, the polymers which are tested as cathodes in LIB and SIB are tried once again in PIB. Poly(anthraquinonyl sulfide) (PAQS) has already shown its promising electrochemical property in SIB. However, it is necessary to test the capability of potassium ion storage property. It was synthesized from the mixture of 1,5-dichloroanthraquinone and sodium sulfide nonahydrate in methylpyrrolidone under argon atmosphere. The cathode delivered a specific capacity of 200 mAh/g in a 0.5 M potassium bis(trifluoromethane sulfonyl) imide (KTFSI) in mixed dimethoxyethane and dioxolane solution (1:1 by volume) as an electrolyte. However, the cycle stability is not good enough to show as promising cathode material. This is attributed from the reason that the PAQS partially soluble in the electrolyte [70]. The electrochemical behavior of PAQS cathode and the mechanism behind the capacity contribution could be understood from Fig. 11. As a continuation of the excellent electrochemical performance of PPTS cathode in SIB, it was employed as cathode here by Wang et al. A testing in PIB was adopted that a high reversible capacity of 260 mAh/g at 0.1 A/g is obtained. A delivered capacity greater of 190 mAh/g over 3000 cycles at 5 A/g is also studied [71]. It seems that the anthraquinone molecule is a good skeleton for energy storage applications. Polydiaminoanthraquinones having cyano functional groups (PDAAQ-CN) are linked by aniline show a reversible capacity of 184 mAh/g while the polymer without cyano functional groups (PDAAQ) displays a cycle stability for 200 cycles with a capacity retention of 91% at 250 mA/g [72].

a Charge/discharge profiles of PAQS/K cells in KPF6/EC + DMC for the initial three cycles between 1.5 and 3.4 V at a current density of 20 mA/g, b charge/discharge profiles of PAQS/K cells in KTFSI/DOL + DME for the initial three cycles between 1.5 and 3.4 V at a current density of 20 mA/g, c charge/discharge profiles of PAQS/K cells in KTFSI/DOL + DME for the initial three cycles between 1.2 and 3.4 V at a current density of 20 mA/g, d CV curves of PAQS in KTFSI/DOL + DME for the initial three cycles between 1.2 and 3.4 V at a scan rate of 0.1 mV/s, e A possible redox mechanism of potassium storage in PAQS (Reproduced with permission from Ref. [70]. Copyright 2016 Elsevier)

Tian designed and synthesized three polymers in terms of the carbonyl-based polyimide, polyquinoneimide, and 2D conjugated microporous polymer (PI-CMP). The polymer with high content of carbonyl groups (polyquinoneimide) displayed a high capacity (221 mAh/g) than that of the other polymers. While the polymer with conjugation (PINTCDABTCA) exhibited a high cycle stability (1000 cycles) at a current density of 1 A/g. They concluded that the high number of carbonyl groups is the reason for high specific capacity while the extended conjugation helps for best cycling stability and high rate performance [73]. A usual polyimide structure has been reported for their electrochemical performance as cathode in SIB. Off course, this polyimide (PNTCDA) was synthesized with usual precursors such as NTCDA and ethylenediamine. The researchers made the cathodes with different carbon additives and found the graphite nanosheets as the suitable one (Fig. 12a). With the optimized experimental conditions, a high reversible capacity of 142 mAh/g was delivered and a capacity retention of 83% was demonstrated after 500 cycles (Fig. 12c) [74].

a Electrochemical cycling performance of PI with different carbon-based additives. b CV curves of PI@graphite nanosheets at sweep scan of 0.01 mV/s. c Long-term cycling performance of PI@ graphite nanosheets for 500 cycles at 100 mA/g (Reproduced with permission from Ref. [74]. Copyright 2019 American Chemical Society)

Very recently, poly(N-phenyl-5,10-dihydrophenazine) (p-DPPZ) proposed as efficient cathode for PIB by Obrezkov. The p-DPPZ was synthesized by Buchwald–Hartwig condensation of 5,10-dihydrophenazine with 1,4-dibromobenzene. The electrochemical performance of p-DPPZ cathode was tested in an electrolyte containing 2.2 M KPF6 dissolved in diglyme. They debate that the obtained capacity of 162 mAh/g at the current density of 200 mA/g is superior than that of LiFePO4 in LIBs. The capacity retention of 79% after 1000 cycles at a current density of 2 A/g explicates its suitability to use as a cathode [75]. The same p-DPPZ was published by another researcher group at the same time. However, they have synthesized one more polymer for the investigation and also used Na/K alloy as anode instead of single metal anodes. Both poly(N-phenyl-5,10-dihydrophenazine) and poly(hexaazatrinaphthylene) exhibited a superior performance in the new design than that of the reported literatures for PIBs. Poly(N-phenyl-5,10-dihydrophenazine) delivered a high specific energy up to 631 Wh/kg at 0.2 A/g and an energy density of 169 Wh/kg was grasped at a specific power of 141 kW/kg. Poly(hexaazatrinaphthylene) cathodes showed a comparable performance with a specific energy of 169 Wh/kg that achieved at a power of 85 kW/kg. The capacity retention of 69% was noted for poly(N-phenyl-5,10-dihydrophenazine) after 1500 cycles whereas that of 89% was observed for cells made with poly(hexaazatrinaphthylene) cathode over 10,000 cycles [76].

As an extension of the PVK cathode in SIB, PVK was employed as cathode in PIB as well. Interestingly, a higher discharge capacity of 117 mAh/g was obtained at 20 mA/g. An excellent cycling stability could be realized at the highest current density of 2000 mA/g i.e. an average specific capacity of 61 mAh/g still could be obtained even after 500 cycles [77]. Figure 13 screens few good polymer cathodes for their reasonable electrochemical performances. Composites of polymers could be an alternative choice to overcome some issues caused by single polymers. The complementary properties of the composites would be beneficial to obtain both high capacity and cycle stability.

In order to get an overview of the active polymers in the alkali metal-ion rechargeable batteries, the polymers are given in the table form. Table 1 gives an overview of the polymer anodes in LIB, SIB and PIBs. Only very few polymers exhibited the specific capacity more than 1000 mAh/g, which are PQL, BBL, PDA and PNTCDAMA. A high capacity and stability polymer electrodes should be designed by combining the merits of those polymers. The polymer cathodes couldn’t be classified as similar to anodes. Instead it can be divided into low and relatively high-voltage polymers based on their electrochemical performances in the respective potential window. As may be noted from Table 2, most of the polymers really come under the low voltage classification (below 4 V) and only some polymers such as PTPAn, PHTPA, PT, P3HT-b-PTMA, PBQS and PVK are working around 4 V. Based on the applications, the polymer with appropriate functional groups should be selected, because there is no limitation to design such molecules.

5 All organic polymer rechargeable battery

The current-state-of art in rechargeable batteries adopt several high-cost metals to the electrode material fabrications. It suffers a high cost and also the resource restrictions. In order to commercialize the batteries, the new electrode materials should meet the following requirements apart from the conductivity, redox centers, chemical and electrochemical stability. (1) it should be obtained from simple raw materials, (2) simple synthetic methodologies for large scale production, (3) the electrochemical performance should be not less than the currently obtaining parameters, and (4) it is preferable to have light-weight. All polymer battery may use to satisfy those criterions. The first type is that a single polymer capable of acting as both anode and cathode (symmetric) viz. bipolar mode. The other is that one polymer works as an anode while other polymer will serve as a cathode (un-symmetric) [78]. There are two type of categories in polymers regarding the bipolar mode. One of them is electroactive redox polymers having wide potentials which also have redox centers for both n and p-type redox reactions [79] and the other one is conducting polymers that can be p-doped at higher voltage and n-doped at lower potential to act as cathode and anode, respectively [80].

Even though many researchers claiming their findings in alkali metal-ion batteries, only some of polymers entered in to the full polymer or plastic battery which are discussed in the section. Polyparaphenylene (PPP), a conducting polymer was synthesized by polymerization of benzene which was used as the bipolar electrode in a full organic battery. The bipolar reactions of PPP were taken as an example for all the polymer based bipolar electrodes. During charge reaction, PPP anode is n-doped while the PPP cathode is p-doped. In total, Li+ ion is inserted in the anode while PF6− ion is inserted in the cathode as counter ions. The external electron comes from the PPP cathode, because it underwent p-doping by donating its electron. At discharge process, the external electron comes from anode to cathode while Li+ ion and PF6− ions are de-doped to electrolyte. Zhu et al., also claimed that the reported discharge capacity of approximately 153 mAh/g at a current rate of 40 mA/g is the highest value. The symmetric organic battery could be operated in a high voltage of 3 V [80]. A polymer battery capable of producing 1 V with a capacity of 16 mAh/g and energy density of 15 Wh/kg was produced by Sen et al. Self-doped PPy by covalently attached viologen (derivatives of 4,4′-bipyridine)- was employed as cathode (derivatives of 4,4′-bipyridine) while 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) doped PPy used as cathode to construct full polymer battery. Acetonitrile containing 0.2 M LiClO4 was engaged as electrolyte. The full polymer battery adept of retaining 70% of its original capacity after 100 cycles [81]. Advancements made in coating technology to fabricate SIB. Screen printing on poly (3,4-ethylenedioxythiophene): poly (styrene sulfonate sodium) (PEDOT:PSS, a commercial and highly conducting polymer ink) was taken. The PEDOT:PSS electrode would act as anode and cathode, This all polymer SIB delivers a specific capacity of 5.5 mAh/g [82]. Recently, the sulphur containing polymer, PITN has been reported to act as bipolar electrode in LIB. PITN in the full cell configuration displayed a reversible capacity of 92 mAh/g at 0.1 C rate in the potential window between 0 to 4 V [25]. A ladder-type heterocyclic dithioether containing polyquinone, poly(2,3-dithiino-1,4-benzoquinone) (PDB) was employed as both anode and cathode in a symmetric full organic battery. The initial capacity of the symmetrical battery was 249 mAh/g at 20 mA/g and it was found to be stable for 250 cycles at 500 mA/g in between 3.2 and 0.005 V with 70% capacity retention. The charge/discharge profile, rate performance and cycle stability studies of full cell with PDB could be seen in Fig. 14 [83]. Conducting polymers exhibited their bipolar activities towards the rechargeable batteries are shown in Fig. 15.

Prototype and electrochemical performance of the all-plastic-electrode symmetric full-battery. a Prototype of the all-PDB-electrode battery. b Representative charge and discharge profiles between 2.9 and 0.005 V at 20 mA/g. c Energy density versus power density plot for the all-PDB battery (inset table shows the detailed values). The values are obtained based on the weight of the cathode-active PDB loading. Energy density values are calculated by the integration area under the charge–discharge profile. Correspondingly, power density values are calculated by energy density/discharge time (in h). d Cycling and rate stability at different current densities. e Long-term cycling and corresponding CE for 250 cycles at 500 mA/g between 3.2 and 0.005 V (Reproduced with permission from Ref. [83]. Copyright 2018 John Wiley and Sons)

The second type of all polymer battery (un-symmetric) fabricated with PTPAn as cathode and PAQS as anode. The reported discharge potential of the un-symmetric organic battery was 1.8 V. The full cell delivered a discharge capacity of 220 mAh/g and the 85% capacity retention with 99% coulombic efficiency at 8 C rate over 500 cycles invariably enlightening the superior cycle stability [84]. In addition to the all polymer battery, all solid-state SIB was reported with PAQS anode and poly(aniline/o-nitroaniline) cathode while NaClO4 dissolved in succinonitrile served as the solid-state electrolyte. The open-circuit voltage of the un-symmetric all solid-state SIB was 2.4 V and the reversible capacity at 50 mA/g was 200 mAh/g. After 50 charge/discharge cycles the battery capable of delivering a specific capacity corresponds to 80% capacity retention [85]. An unsymmetrical battery was reported by assembling poly(2-methacrylamide-tetracyanoanthraquinone) anode and poly(2-vinylthianthrene) cathode with a discharge potential of 1.35 V. The initial capacity of 105 mAh/g was found to be slightly decreased to 99 mAh/g after 250 cycles at 1 C rate [79]. A copolymer, perylene polyimide-polyether anode material was synthesized by polycondensation reaction between PTCDA and Jeffamine (PEO2000). The biopolymer cathode material, PEDOT:lignin was synthesized by chemical oxidative polymerization of EDOT with alkali lignin. The conducting silver coated poly(ethylene naphthalate) was used as substrate and current collector while plain carbon cloth utilized as current collector for cathode and anode, respectively. Nitrogen purged aqueous solution containing 1 M Na2SO4 and 0.1 M HClO4 was employed as the electrolyte. Even though, the full-cell operated between 0 and 1.1 V, it delivered 1 V. The discharge capacity also notable that 53 mAh/g was delivered at 10 C. When the cycle stability test was conducted at 100 C, the discharge capacity decreased from 41 to 35 mAh/g only after 800 cycles [86].

If the new battery is developed with naturally abundant resources with low-cost production it would be the encouraging choice. It is somewhat difficult to make full-cell batteries since it need careful calculation in pairing the anode and cathode. The challenging fact for the commercialization of polymer batteries is achieving both high energy density and cycle stability in a simultaneous approach. In order to get those electrochemical parameters, the molecules, and electrolyte system of a battery should be designed or extended to other dual ions. The deeper understanding of the ion binding and transport mechanism will be helpful to achieve the best performance in the near future.

6 Conclusion and scope for the future

The review charts the polymers used in rechargeable batteries such as Li, Na and K ion batteries. A large number of polymers have been utilized as electrode materials with relatively reasonable electrochemical performances. However, it still needs more efforts to overcome across the requirements of commercialization. This could be attained by advanced design in the monomer structure to get a desired polymer with expected redox properties. The chemical structures presented in this review will motivate the researches to design the monomers with required electrochemical properties. Based on the literatures, it is suggested that the anode material should contain (i) N or S containing heterocyclics (ii) multiple C=O groups with conjugation (iii) C=N functional group with conjugation (iv) both C=O and C=N functional groups. Functional groups rule the specific capacity while the π-conjugation is essential for high rate and high cycle stability. The necessary points need to take care when the researchers design polymers for cathode are (i) polymers should have tertiary N or secondary imine (ii) high number of N=N functional groups with conjugation (iii) sulphides with conjugated C=O or C=C functional groups. An addition to the above criteria, a common suggestion for both anode and cathode material is alkyl chains in the redox-active units should be minimized or avoided to get high theoretical capacity. The further understanding and optimizing the electrochemical reactions of polymers with many electrolytes system will provide a large opening to get high capacity and stable battery. The other parameters such as choice of solvents, concentration of electrolyte salt and potential window should be carefully selected based on reproducible experiments. So, the polymers with appropriate functional groups having high voltage should be tested with many electrolytes system rather than the usual electrolytes like frog in the well.

Abbreviations

- ALP:

-

Azo-linked polymer from 1,1,2,2-tetrakis(4-aminophenyl)ethane

- BBL:

-

Polybenzimidazo-benzoisoquinoline

- CF:

-

Carbon fiber

- DMcT:

-

2,5-Dimercapto1,3,4-thiadiazole

- LIB:

-

Lithium-ion battery

- LPPMABAHA:

-

Ladder polymer from pyromellitic anhydride and 9,10-dihydro-9,10-[1,2]benzenoanthracene-2,3,6,7,14,15-hexaamine

- LPPTCDABAHA:

-

Ladder polymer from perylene 3,4,9,10-tetracarboxylic dianhydride and 9,10-dihydro-9,10-[1,2]benzenoanthracene-2,3,6,7,14,15-hexaamine

- NMP:

-

N-methylpyrrolidone

- NTCDA:

-

1,4,5,8-Naphthalenetetracarboxylic dianhydride

- P(NDI2OD-T2):

-

Poly{[N,N′-bis(2-octyldodecyl)-1,4,5,8-naphthalenedicarboximide-2,6-diyl]-alt-5,5′-(2,2′-bithiophene)}

- P3HT-b-PTMA:

-

Diblock copolymer of poly(3-hexylthiophene) and poly(2,2,6,6-tetramethylpiperidinyloxy-4-yl methacrylate)

- PANS:

-

Poly(aniline-co-aminobenzenesulfonic sodium)

- PAQI:

-

Poly(anthraquinonyl imide) derived from 1,4,5,8-naphthalenetetracarboxylic dianhydride and 1,4-diaminoanthraquinone

- PAQS:

-

Poly(anthraquinonyl sulphide)

- PBPDA:

-

Poly[N,N′-p(benzylidene)phenylenediamine]

- PBQS:

-

Poly(benzoquinone sulfide)

- PBQS:

-

Poly(benzoquinonyl sulphide)

- PDA:

-

Poly(dopamine)

- PDAAQ:

-

Polydiaminoanthraquinone

- PDAAQ-CN:

-

Polydiaminoanthraquinone with cyano groups

- PDB:

-

Poly(2,3-dithiino-1,4-benzoquinone)

- PDPAS:

-

Poly(diphenylaminesulfonic acid sodium)

- p-DPPZ:

-

Poly(N-phenyl-5,10-dihydrophenazine)

- PEO:

-

Polyethyleneoxide

- PHATN:

-

Poly(hexaazatrinaphthalene)

- PHTPA:

-

Hyperbranched polytriphenylamine

- PIB:

-

Potassium-ion battery

- PINTCDABTCA:

-

Polyimide from 1,4,5,8-naphthalenetetracarboxylic dianhydride and benzene-1,3,5-tricarboxaldehyde

- PINTCDABTCA:

-

Polyimide from 1,4,5,8-naphthalenetetracarboxylic dianhydride and benzene-1,3,5-tricarboxaldehyde

- PIPTCDA:

-

Polyimide from perylene 3,4,9,10-tetracarboxylic dianhydride

- PIPTCDADAAQ:

-

Polyimide from perylene 3,4,9,10-tetracarboxylic dianhydride and 2,6-diaminoanthraquinone

- PITN:

-

Poly(isothianaphthene)

- PMDA:

-

Pyromellitic dianhydride

- PNFE:

-

Poly-(naphthalene four formyl ethylenediamine)

- PNTCDA:

-

Polyimide from 1,4,5,8-naphthalenetetracarboxylic dianhydride and ethylenediamine

- PNTCDAMA:

-

Polyimide derived from 1,4,5,8-naphthalenetetracarboxylic dianhydride and melamine

- PoPD:

-

Poly(o-phenylenediamine)

- PPP:

-

Poly(para-phenylene)

- PPT:

-

Poly(pyrene-4,5,9,10-tetraone)

- PPTS:

-

Poly(pentacenetetrone sulfide)

- PPy:

-

Polypyrrole

- PPy-COOH:

-

Carboxylic acid functionalized polypyrrole

- PQL:

-

Poly(1,6-dihydropyrazino[2,3g]quinoxaline-2,3,8-triyl-7-(2H)-ylidene-7,8-dimethylidene)

- PSb:

-

Polymeric Schiff base

- PT:

-

Polythiophene

- PT-BZ:

-

Poly(N-methylphenothiazine benzidine)

- PT-COOH:

-

Carboxylic acid functionalized polythiophene

- PT-DMPD:

-

Poly(N-methylphenothiazine dimethylphenylenediamine)

- PTPAn:

-

Polytriphenylamine

- PVK:

-

Poly(N-vinyl carbazole)

- PyBT:

-

Polymer from pyrene and benzothiadiazole

- SIB:

-

Sodium-ion battery

References

H. Shirakawa, E.J. Louis, A.G. MacDiarmid, C.K. Chiang, A.J. Heeger, J. Chem. Soc., Chem. Commun. 578–580 (1977)

H. Dong, W. Hu, Conducting Polymers: Applications in Electronics and Photovoltaics, in Encyclopedia of Radicals in Chemistry, Biology and Materials, ed. by C. Chatgilialoglu, A. Studer (2012), https://doi.org/10.1002/9781119953678.rad064

A.R. Brown et al. Conjugated Polymer Light-emitting Diodes, in Intrinsically Conducting Polymers: An Emerging Technology, ed. By M. Aldissi, NATO ASI Series (Series E: Applied Sciences), vol 246. (Springer, Dordrecht, 1993). https://doi.org/https://doi.org/10.1007/978-94-017-1952-0_9

J. Xie, P. Gu, Q. Zhang, ACS Energy Lett. 2, 1985–1996 (2017)

S.B. Kondawar, P.T. Patil, Conducting Polymer Nanocomposites for Sensor Applications, in Conducting Polymer Hybrids, ed. By V. Kumar, S. Kalia, H. Swart, Springer Series on Polymer and Composite Materials) Springer, Cham, 2017). https://doi.org/10.1007/978-3-319-46458-9_8

R. Gracia, D. Mecerreyes, Polym. Chem. 4, 2206–2214 (2013)

P. Passiniemi, J.-E. Österholm, Synth. Met. 18, 637–644 (1987)

M.E. Abdelhamid, A.P. O’Mullaneb, G.A. Snook, RSC Adv. 5, 11611–11626 (2015)

J. Owen, Polymers with Both Ionic and Electronic Conductivity, in Conducting Polymers, ed. by L. Alcácer (Springer, Dordrecht, 1987). https://doi.org/10.1007/978-94-009-3907-3_8

B. Wu, S. Wang, W.J. Evans IV., D.Z. Deng, J. Yang, J. Xiao, J. Mater. Chem. A 4, 15266–15280 (2016)

N. Levy, M.D. Levi, D. Aurbach, R. Demadrille, A. Pron, J. Phys. Chem. C 114, 16823–16831 (2010)

T. Nagaura, K. Tozawa, Progress in Batteries and Solar Cells (JEC Press Inc., Brunswick, 1990)

M.E. Abdelhamid, A.P. O’Mullane, G.A. Snook, RSC Adv. 5, 11611–11626 (2015)

D. Mecerreyes, L. Porcarelli, N. Casado, Macromol. Chem. Phys. 221, 1900490 (2020)

S. Muench, A. Wild, C. Friebe, B. Häupler, T. Janoschka, U.S. Schubert, Chem. Rev. 116, 9438–9484 (2016)

T. Suga, H. Nishide, in Polymers for Energy Storage and Delivery: Polyelectrolytes for Batteries and Fuel Cells, ed. by K.A. Page, C.L. Soles, J. Runt, (American Chemical Society, Washington, DC, 2012) vol. 1096, pp. 45−53

P. Novák, K. Müller, K.S.V. Santhanam, O. Haas, Chem. Rev. 97, 207–281 (1997)

J. Wu, X. Rui, G. Long, W. Chen, Q. Yan, Q. Zhang, Angew. Chem. Int. Ed. 54, 7354–7358 (2015)

J. Wu, X. Rui, C. Wang, W.-B. Pei, R. Lau, Q. Yan, Q. Zhang, Adv. Energy Mater. 5, 1402189 (2015)

Y. Liang, Z. Chen, Y. Jing, Y. Rong, A. Facchetti, Y. Yao, J. Am. Chem. Soc. 137, 4956–4959 (2015)

T. Sun, Z. Li, H. Wang, D. Bao, F. Meng, X. Zhang, Angew. Chem. Int. Ed. 55, 10662–10666 (2016)

D. Nauroozi, M. Pejic, P.O. Schwartz, M. Wachtler, P. Bäurle, RSC Adv. 6, 111350–111357 (2016)

T. Yuan, J. Ruan, W. Zhang, Z. Tan, J. Yang, Z.-F. Ma, S. Zheng, ACS Appl. Mater. Interfaces 8, 35114–35122 (2016)

H. Numazawa, K. Sato, H. Imai, Y. Oaki, NPG Asia Mater. 10, 397–405 (2018)

B.A. Kahsay, A. Ramar, F.-M. Wang, N.-H. Yeh, P.-L. Lin, Z.-J. Luo, T.-S. Chan, C.-H. Su, J. Power Sources 428, 115–123 (2019)

T.B. Schon, S.Y. An, A.J. Tilley, D.S. Seferos, ACS Appl. Mater. Interfaces 11, 1739–1747 (2019)

J.K. Feng, Y.L. Cao, X.P. Ai, H.X. Yang, J. Power Sources 177, 199–204 (2008)

R.A. Davoglio, S.R. Biaggio, R.C. Rocha-Filho, N. Bocchi, J. Power Sources 195, 2924–2927 (2010)

C. Zhijiang, Y. Guang, Synth. Met. 160, 1902–1905 (2010)

A.A. Golriz, T. Suga, H. Nishide, R. Berger, J.S. Gutmann, RSC Adv. 5, 22947–22950 (2015)

B.M. Peterson, D. Ren, L. Shen, Y.-C.M. Wu, B. Ulgut, G.W. Coates, H.D. Abruña, B.P. Fors, ACS Appl. Energy Mater. 1, 3560–3564 (2018)

K. Yamamoto, D. Suemasa, K. Masuda, K. Aita, T. Endo, ACS Appl. Mater. Interfaces 10, 6346–6353 (2018)

L. Liu, F. Tian, X. Wang, Z. Yang, M. Zhou, X. Wang, React. Funct. Polym. 72, 45–49 (2012)

G. Hernández, N. Casado, R. Coste, D. Shanmukaraj, L. Rubatat, M. Armand, D. Mecerreyes, RSC Adv. 5, 17096–17103 (2015)

B. Häupler, T. Hagemann, C. Friebe, A. Wild, U.S. Schubert, ACS Appl. Mater. Interfaces 7, 3473–3479 (2015)

Z. Song, Y. Qian, T. Zhang, M. Otani, H. Zhou, Adv. Sci. 2, 1500124 (2015)

N. Zindy, J.T. Blaskovits, C. Beaumont, J. Michaud-Valcourt, H. Saneifar, P.A. Johnson, D. Bélanger, M. Leclerc, Chem. Mater. 30, 6821–6830 (2018)

F. Xu, J. Xia, W. Shi, S. Cao, Mater. Chem. Phys. 169, 192–197 (2016)

N. Hergué, B. Ernould, A. Minoia, J.D. Winter, P. Gerbaux, R. Lazzaroni, J.F. Gohy, P. Dubois, O. Coulembier, Polym. Chem. 10, 2570–2578 (2019)

K.T. Sarang, A. Miranda, H. An, E.S. Oh, R. Verduzco, J.L. Lutkenhaus, ACS Appl. Polym. Mater. 1, 1155–1164 (2019)

Q. Li, D. Li, H. Wang, H.G. Wang, Y. Li, Z. Si, Q. Duan, ACS Appl. Mater. Interfaces 11, 28801–28808 (2019)

H. Lyu, J. Liu, S. Mahurin, S. Dai, Z. Guo, X.-G. Sun, J. Mater. Chem. A 5, 24083–24090 (2017)

X. Yang, A.L. Rogach, Adv. Energy Mater. 10, 2000288 (2020)

T. Perveen, M. Siddiq, N. Shahzad, R. Ishan, A. Ahmad, M.I. Shahzad, Renew. Sust. Energy Rev. 119, 109549 (2020)

X. Chen, L. Liu, Z. Yan, Z. Huang, Q. Zhou, G. Guo, X. Wang, RSC Adv. 6, 2345–2351 (2016)

L. Chen, W. Li, Y. Wang, C. Wang, Y. Xia, RSC Adv. 4, 25369–25373 (2014)

W. Deng, Y. Shen, J. Qian, H. Yang, Chem. Commun. 51, 5097–5099 (2015)

Z. Li, J. Zhou, R. Xu, S. Liu, Y. Wang, P. Li, W. Wu, M. Wu, Chem. Eng. 287, 516–522 (2016)

Q. Zhao, R.R. Gaddam, D. Yang, E. Strounina, A.K. Whittaker, X.S. Zhao, Electrochim. Acta 265, 702–708 (2018)

N. Fernández, P. Sánchez-Fontecoba, E. Castillo-Martínez, J. Carretero-González, T. Rojo, M. Armand, Chemsuschem 11, 311–319 (2018)

E. Castillo-Martínez, J. Carretero-González, M. Armand, Angew. Chem. Int. Ed. 53, 5341–5345 (2014)

M. Zhou, L. Zhu, Y. Cao, R. Zhao, J. Qian, X. Ai, H. Yang, RSC Adv. 2, 5495–5498 (2012)

L. Zhu, Y. Shen, M. Sun, J. Qian, Y. Cao, X. Ai, H. Yang, Chem. Commun. 49, 11370–11372 (2013)

M. Zhou, Y. Xiong, Y. Cao, X. Ai, H. Yang, J. Polym. Sci. Pol. Phys. 51, 114–118 (2013)

Y.F. Shen, D.D. Yuan, X.P. Ai, H.X. Yang, M. Zhou, Electrochem. Commun. 49, 5–8 (2014)

M. Zhou, W. Li, T. Gu, K. Wang, S. Cheng, K. Jiang, Chem. Commun. 51, 14354–14356 (2015)

R. Zhao, L. Zhu, Y. Cao, X. Ai, H.X. Yang, Electrochem. Commun. 21, 36–38 (2012)

M. Tang, S. Zhu, E. Wang, J. Ma, Z. Liu, C. Jiang, C. Wang, Chem 4, 2600–2614 (2018)

M. Mao, C. Luo, T.P. Pollard, S. Hou, T. Gao, X. Fan, C. Cui, J. Yue, Y. Tong, G. Yang, T. Deng, M. Zhang, J. Ma, L. Suo, O. Borodin, C. Wang, Angew. Chem. 131, 17984–17990 (2019)

H. Wang, S. Yuan, D. Ma, X. Huang, F. Meng, X. Zhang, Adv. Energy Mater. 4, 1301651 (2014)

F. Xu, J. Xia, W. Shi, Electrochem. Commun. 60, 117–120 (2015)

F. Xu, H. Wang, J. Lin, X. Luo, S. Cao, H. Yang, J. Mater. Chem. A 4, 11491–11497 (2016)

C. Zhijiang, Z. Qing, Z. Cong, S. Xianyou, L. Yuanpei, Synth. Met. 231, 15–18 (2017)

K.S. Weeraratne, A.A. Alzharani, H.M. El-Kaderi, ACS Appl. Mater. Interfaces 11, 23520–23526 (2019)

W. Tang, H. Hea, J. Shi, B. Cao, C. Yang, C. Fan, Org. Electron. 75, 105386 (2019)

C. Zhang, H. Zhao, Y. Lei, Energy Environ. Mater. 3, 105–120 (2020)

W. Zhang, Y. Liu, Z. Guo, Sci. Adv. 5, EAAV7412 (2019)

T. Sun, Z.-J. Li, X. Yang, S. Wang, Y.-H. Zhu, X.-B. Zhang, CCS Chem. 1, 365–372 (2019)

C. Zhang, Y. Qiao, P. Xiong, W. Ma, P. Bai, X. Wang, Q. Li, J. Zhao, Y. Xu, Y. Chen, J.H. Zeng, F. Wang, Y. Xu, J.-X. Jiang, ACS Nano 13, 745–754 (2019)

Z. Jian, Y. Liang, I.A. Rodríguez-Pérez, Y. Yao, X. Ji, Electrochem. Commun. 71, 5–8 (2016)

M. Tang, Y. Wu, Y. Chen, C. Jiang, S. Zhu, S. Zhuo, C. Wang, J. Mater. Chem. A 7, 486–492 (2019)

M. Zhou, M. Liu, J. Wang, T. Gu, B. Huang, W. Wang, K. Wang, S. Cheng, K. Jiang, Chem. Commun. 55, 6054–6057 (2019)

B. Tian, W. Tang, X. Li, J. Zheng, C. Zhao, G.-H. Ning, J. Mater. Chem. A 7, 9997–10003 (2019)

Y. Hu, H. Ding, Y. Bai, Z. Liu, S. Chen, Y. Wu, X. Yu, L. Fan, B. Lu, ACS Appl Mater. Interfaces 11, 42078–42085 (2019)

F.A. Obrezkov, V. Ramezankhani, I. Zhidkov, V.F. Traven, E.Z. Kurmaev, K.J. Stevenson, P.A. Troshin, J. Phys. Chem. Lett. 10, 5440–5445 (2019)

R.R. Kapaev, F.A. Obrezkov, K.J. Stevenson, P.A. Troshin, Chem. Commun. 55, 11758–11761 (2019)

C. Li, J. Xue, A. Huang, J. Ma, F. Qing, A. Zhou, Z. Wang, Y. Wang, J. Li, Electrochim. Acta 297, 850–855 (2019)

G. Dai, Y. He, Z. Niu, P. He, C. Zhang, Y. Zhao, X. Zhang, H. Zhou, Angew. Chem. Int. Ed. 58, 9902–9906 (2019)

A. Wild, M. Strumpf, B. Häupler, M.D. Hager, U.S. Schubert, Adv. Energy Mater. 7, 1601415 (2017)

L.M. Zhu, A.W. Lei, Y.L. Cao, X.P. Ai, H.X. Yang, Chem. Commun. 49, 567–569 (2013)

S. Sen, J. Saraidaridis, S.Y. Kim, G.T.R. Palmore, ACS Appl. Mater. Interfaces 5, 7825–7830 (2013)

Z. Tehrani, T. Korochkina, S. Govindarajan, D.J. Thomas, J. O’Mahony, J. Kettle, T.C. Claypole, D.T. Gethin, Org. Electron. 26, 386–394 (2015)

J. Xie, Z. Wang, Z.J. Xu, Q. Zhang, Adv. Energy Mater. 8, 1703509 (2018)

W. Deng, X. Liang, X. Wu, J. Qian, Y. Cao, X. Ai, J. Feng, Sci. Rep. 3, 2671 (2013)

X. Zhua, R. Zhao, W. Deng, X. Ai, H. Yang, Y. Cao, Electrochim. Acta 178, 55–59 (2015)

G. Hernández, N. Casado, A.M. Zamarayeva, J.K. Duey, M. Armand, A.C. Arias, D. Mecerreyes, ACS Appl. Energy Mater. 1, 7199–7205 (2018)

Acknowledgements

The author is grateful for the financial support from the Ministry of Science and Technology (MOST) of Taiwan, R.O.C., under Grant Numbers 107-2119-M-002-033, 107-2811-E-011-505, 107-2923-E-007-001, 107-2911-E-011-503, 108-2221-E-011-111, 108-2811-E-011-511, 108-3116-F-011-004, and 108-2923-E-007-001.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramar, A., Wang, FM. Advances in polymer electrode materials for alkali metals (lithium, sodium and potassium)-ion rechargeable batteries. J Mater Sci: Mater Electron 31, 21832–21855 (2020). https://doi.org/10.1007/s10854-020-04805-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04805-6