Abstract

In this work, the optical and optoelectrical characterizations of the quaternary kesterite Cu2CoSnS4 (CCTS4) thin films were studied. The polycrystalline CCTS4 films have prepared by the spray pyrolysis method at four different thicknesses (160 nm, 230 nm, 297 nm and 345 nm). The X-ray diffraction charts demonstrated that the as-prepared CCTS4 films have a polycrystalline nature with tetragonal single phase. The linear optical parameters of the CCTS4 films were computed by finding the transmission and reflection data. The magnitudes of the absorption coefficient for the CCTS4 films were high in the order of 105 cm−1 while the energy gap of the CCTS4 films has been reduced from 1.41 to 1.12 eV by raising the film thickness. The optical conductivity and the Urbach energy of the CCTS4 films were computed from the absorption coefficient data. In addition, the nonlinear optical parameters represented in the nonlinear refractive index n2 and the third-order nonlinear optical susceptibility χ(3) of the CCTS4 films were boosted with rising up the film thickness.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

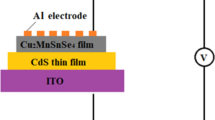

In recent years, kesterite materials are gaining importance in the different articles due to its stable, earth-abundant, nontoxic and have excellent electrical and optical properties. All of these properties make the kesterite materials capable of being good compotators to conventional materials like CdTe, GaAs materials [1,2,3]. The privilege of the kesterite materials is by virtue of their stability after the preparation for a long time without revealing any mark for degradation. Such characteristics make these materials as good candidates for different applications like optical devices and photovoltaic devices [4, 5]. Recently, the articles concentrated on a different kesterite materials like Cu2ZnSnS4, Cu2NiSnS4, Cu2CoSnS4, and Cu2FeSnS4 due to they displayed a high absorption coefficient, p-type conductivity and narrow bandgap. So these materials act as good absorber layers in thin-film solar cells [6, 7]. These kesterite thin films demonstrated high solar efficiency in various articles. The efficiency of the CZTS solar cell is 5.1% by the spray pyrolysis technique [8] and reaches to 9.6% via the thermal evaporation process [9]. Moreover, the Cu2NiSnS4 thin films display excellent electrical properties in the Ag/n-Si/Cu2NiSnS4/Au heterojunction which demonstrate a solar efficiency of about 11.34% [10]. The previous articles displayed that the Cu2CoSnS4 (CCTS4) thin films demonstrate p-type conductivity, and narrow energy gap so they suitable to be a good absorber layer for thin-film solar cells [11]. The CCTS4 films have been prepared by various processes like spin coating [12], spray pyrolysis technique [13] and electrodeposition [14]. The previous studies on the Cu2CoSnS4 films were concentrated on the structural, current–voltage and energy gap studies. Beraich et.al present the X-ray diffraction, Raman spectroscopy and energy gap studies of the Cu2CoSnS4 films [14]. El Radaf et.al present the electrical and photovoltaic properties of the Al/n-Si/ Cu2CoSnS4/Au heterojunction which demonstrates a solar efficiency of 6.17% [15]. The previous studies displayed that, there are no articles reported the optoelectrical, dispersion and nonlinear optical properties of the CCTS4 films. So this work focused on studying the optoelectrical, linear/nonlinear optical properties of CCTS4 films that are deposited by utilizing the spray pyrolysis technique.

2 Experimental details

CCTS4 thin films were fabricated successfully using an inexpensive spray pyrolysis technique via the reaction between high purity copper chloride, cobalt chloride, tin chloride and thiourea according to the present molarity 0.1 M copper chloride, 0.05 M cobalt chloride, 0.05 M tin chloride and 0.2 M thiourea SC(NH2)2. A double distilled water was used for solution preparation. The CCTS4 solution was magnetically stirred at 50 °C for 1 h to get a uniform brown solution. The CCTS4 solution was sprayed above the glass substrate via the spray pyrolysis technique according to the following conditions: the solution flow rate equal 20 ml/min, the substrate temperature equal 300 °C, the pressure of air equal 3 at and the distance between the nozzle and substrate adjusted to be 30 cm. CCTS4 thin-film thickness was measured via an alpha step D 500 stylus profilometer. Finally, thickness magnitudes of CCTS4 films were (160 nm, 230 nm, 297 nm and 345 nm).

In this work, the structural and surface morphology characterizations of the CCTS4 films were researched via Philips X' pert diffractometer, and the field emission scanning electron microscope (FE-SEM, Quanta FEG 250, and FEI, USA), respectively. The optical investigations like the optoelectrical, linear/nonlinear optical calculations of the CCTS4 films have been investigated by collecting the transmittance and reflectance data of the CCTS4 films using a spectrophotometer (kind JASCO Corp., V-570).

3 Results and discussions

3.1 Structural study

The crystal structure of the CCTS4 thin films was checked by the X-ray diffraction instrument (kind X’Pert) with CuKα radiation. The results of the XRD for CCTS4 thin films were presented in Fig. 1. The analysis of this figure displayed that the sprayed CCTS4 films are polycrystalline and the indexed planes of the polycrystalline CCTS4 films were matched with the standard data JCPDS No. 26-0513 which belong to the tetragonal crystal system. In addition, the diffraction peaks of this pattern were positioned at 28.49°, 48.36° and 57.31° according to (112), (204) and (312) planes, respectively. Moreover, the structure constants of the polycrystalline CCTS4 films represented in the strain function (ε), the crystallite size (D), the number of crystallites per unit surface area \({N}_{\text{C}}\) and the dislocation density (δ) were computed according to the below Scherer formulas [16,17,18,19]:

where \(\beta ,\theta\), \(\varepsilon\), t denote the experimental full width at the half maximum (FWHM), the Bragg diffraction angle, the lattice strain and the film thickness, respectively.

Table 1 presented the computed values of \(D\), \(\delta\), \({N}_{\text{C}}\), and \({\varepsilon }_{\text{s}}\) for the CCTS4 thin films. The results in Table1 demonstrated that the raising of film thickness for the CCTS4 thin films accompanied with a rise in the crystallites size (D). This behavior related to increasing the film thickness leads to coalesce of the crystallites with each other and hence improving the crystallinity of films which led to an increase in the crystallite size D.

Also, the raising of film thickness for the CCTS4 thin films accompanied with a reduction in the magnitudes of the dislocation density \(\delta\), number of crystallites per unit surface area \({N}_{\text{C}}\) and the strain function (ε) of the CCTS4 thin films. This behavior due to the \(\delta\), \({N}_{C}\), and \({\varepsilon }_{\text{s}}\) is inversely proportional to the crystallite size. So, when the crystalline state of a material depends on crystallite sizes, D; where if D has increased the crystallinity of the material increases. Thus, \(\delta\), \({N}_{\text{C}}\), and \({\varepsilon }_{\text{s}}\) in the material decreases.

Figure 2 depicted the variation of the crystallites size (\(D\)) and the number of crystallites per unit surface area \({N}_{\text{C}}\) with the thickness of the CCTS4 films. The analysis of this figure displayed that the rise of the film thickness leads to the rise of the values of crystallites size (D) and reduces the magnitudes of the number of crystallites per unit surface area \({N}_{\text{C}}.\) The EDAX analysis of the CCTS4 thin film synthesized at 345 nm was given in Fig. 3 as a representative example.

The high-resolution SEM micrograph of the CCTS4 thin film synthesized at different thicknesses (160 nm, 230 nm, 297 nm and 345 nm) were illustrated in Fig. 3 and displayed that the CCTS4 films have a uniform and homogeneous surface. Moreover, the EDAX data of the CCTS4 films have been presented in Table 2 which presents the constituents’ ratio of the elements forming the studied films. The EDAX analysis and the EDAX graph confirm the existence of copper, cobalt, tin and sulfur in the as-deposited CCTS4 thin films. In addition, the atomic percentage of Cu, Co, Sn and S in the as-deposited CCTS4 films is close to 2:1:1:4 so the CCTS4 films are nearly stoichiometric.

3.2 Linear optical properties

3.2.1 Transmittance and reflectance spectra

In this study, the optical properties of the sprayed CCTS4 films with different thicknesses (160 nm, 230 nm, 297 nm and 345 nm) were investigated via recording optical transmittance and reflectance data in view of incident wavelength λ alteration in the domain of (400–2500 nm). Figure 4a, b present the transmittance and reflectance spectra of the CCTS4 films. It is observed from these curves that the values of reflection for the CCTS4 films were boosted by enlarging the film thickness while the transmittance magnitudes have a reverse manner.

3.2.2 Absorption coefficient and absorption index

The recording of both transmittance and reflectance data of the CCTS4 films helped us in estimating the magnitudes of the absorption coefficient α according to the relation [20, 21]:

Here d presents the thickness value.

Figure 5a depicts the variation of the absorption coefficient for the CCTS4 films with wavelength. From this plot, it can be seen that the absorption coefficient of the CCTS4 films was increased with the rise of the film thickness. Also, all films revealed high values of the absorption coefficient.

The absorption index (k) of the CCTS4 thin films synthesized at different thicknesses (160 nm, 230 nm, 297 nm and 345 nm) was calculated via the formula [22, 23]:

The absorption index dependence on wavelength for the CCTS4 films is given in Fig. 5b. It is seen from this plot that the magnitude of \(k\) rises up with increasing the film thickness.

3.2.3 Energy gap and Urbach energy evaluation

The energy gap values for the CCTS4 films were determined using Tauc's equation [24, 25]:

In this equation, p is an important factor that detects the kind of the optical transition where the p value may be equal 1/2, 2 for direct allowed, indirect allowed transitions, respectively. Also, B denotes a band tailing parameter.

The fits for different values of p factor have been examined and the best fit was obtained at p equal 1/2. Figure 6 implies the alteration of (αhν)2 due to the variation in photon energy (hν) for the CCTS4 films. This plot illustrated the direct energy gap for the CCTS4 thin films and the bandgap values were evaluated by extending this straight line of the curve to intercept x-axis at zero (αhν)2. Table 3 presented the direct energy gap values for the CCTS4 thin films and these values were lowered from 1.41 to 1.12 eV by enlarging the film thickness. The redshift in the absorption edge with the increase of the thickness comes out from the increase in the grain size that accompanied by boosting the disorders and defects, number localized states in the gap which leads to extending the band tail and thus increasing the Urbach's energy [26, 27]. In addition, Table 4 presents the Eg values for different kesterite thin films like Cu2CoSnS4, Cu2ZnSnS4, Cu2CdSnS4, Cu2NiSnS4, Cu2FeSnS4 thin films [28,29,30,31]. It is noted from this table that, our results in a good agreement with the values recorded by Banavoth, et.al [32]. Moreover, the Urbach's energy Eu of the CCTS4 films was computed via studding the relation between ln (α) and the photon energy (hν) according to the Urbach formula [33, 34]:

Figure 7a illustrates the plotting ln (α) against hν for the CCTS4 films with different thicknesses (160 nm, 230 nm, 297 nm and 345 nm). It is observed from this plot that the magnitude of Urbach energy Eu of the CCTS4 thin films increased with the rise of the film thickness. The computed values of the Eu for the CCTS4 films were recorded in Table 3.

3.2.4 Refractive index and dispersion analysis

The refractive index, n of the sprayed CCTS4 films synthesized at various thicknesses (160 nm, 230 nm, 297 nm and 345 nm) can be evaluated by exploiting the magnitudes of the reflectance (R) and absorption index (k) according to Fresnel formula [35, 36]:

Figure 7b depicts the impact of film thickness on the refractive of the sprayed CCTS4 films. It is observed that by boosting the film thickness, the refractive index rises up. This behavior related to the rising of the free carrier concentration with rising the film thickness [37].

The dispersion parameters of the CCTS4 films were discussed in view of Wemple–DiDomenico model according to the equation [38]:

Here \(\hslash \upsilon\) displays photon energy.

The Eo and Ed values for the CCTS4 films were extracted from slopes (EoEd)−1 and intercepts (Eo/Ed) of the plot \(({n}^{2}-1{)}^{-1}\) against the \(({\hslash }\upsilon {)}^{2}\) as shown in Fig. 8a. By utilizing Eo and Ed, the oscillation strength parameter has been calculated using the expression, \(f={E}_{0}{E}_{\text{d}}\). The values of the oscillation strength have been reduced by rising up the film thickness.

The dependences of dispersion energy, as well as the oscillation energy on the variation of film thickness, are displayed in Fig. 8b. It is noted that Eo decreases while Ed increases with enlarging film thickness. This behavior is related to the change in the Atoms diffusion rate in the CCTS4 films, showing an increase in the number of atoms at interstitial cited [39]. The other oscillator parameters for the CCTS4 thin films like the static refractive index, no (0), Wemple-DiDomenico energy gap \({E}_{\text{g}}^{\text{wmp}}\) and the static dielectric constant, \({\varepsilon }_{\text{s}}(={n}_{o}^{2})\) have been evaluated according to the presented relations [40,41,42]:

Table 3 displayed the oscillator parameters for the CCTS4 films. It is noticed that \({E}_{\text{d}}\), \({n}_{0}\), \({\varepsilon }_{\text{s}}\) values boost. Moreover, the values of \({E}_{\text{g}}\), \({E}_{\text{o}}, f\), \({E}_{\text{g}}^{\text{wmp}}\) were decreased with the increase in film thickness due to the reduction in the energy of the bonds formed between the film elements [43]. It was found that the relation between Eo and Eg follows by this formula Eo≈ 1.8 Eg which coincides with the anticipation of a single oscillator model.

3.2.5 Optical and electrical conductivities

The optical and electrical conductivities of the CCTS4 films obtained at different thicknesses (160 nm, 230 nm, 297 nm and 345 nm) were determined via the expressions [44, 45]:

Here \({\sigma }_\text{opt}\) denotes the optical conductivity, c presents the speed of light, \({\sigma }_{\text{e}}\) denotes the electrical conductivity and α implies the absorption coefficient and n refers to the refractive index.

The subordination of optical conductivity on the variation in photon energy for CCTS4 films is presented in Fig. 9a. The analysis of this curve displayed that the optical conductivity of the CCTS4 films boosts with enlarging the film thickness and rising up photon energy. This behavior related to boosting electrons excitation via rising up the incident photon energy, and due to the increase in film absorption coefficients [46]. Figure 9b reveals the reliance of the electrical conductivity on the increase in both photon energy and film thickness for the sprayed CCTS4 thin films. It is clearly seen that electrical conductivity values increase with enlarging film thickness and reduce with the excess in photon energy.

3.2.6 Optical dielectric constants

The magnitudes of the dielectric constants of the CCTS4 films synthesized at different thicknesses (160 nm, 230 nm, 297 nm and 345 nm) were evaluated via the relations [47, 48]:

Here ε2 denotes the imaginary part of the dielectric constant and the ε1 implies the real part of dielectric constant for the CCTS4 thin films.

For the CCTS4 films, the subordination of the real and imaginary parts of dielectric constant on the wavelength and the film thickness is presented in Fig.10a, b. It is noted from these plots that the ε1 and ε2 were increased with increasing film thickness. This is expected as both refractive indices and absorption indices values increase with the increase in film thickness and both \({\varepsilon }_{1}\) and \({\varepsilon }_{2}\) boost as well. Furthermore, the \({\varepsilon }_{1}\) trend follows the behavior of films refractive index and \({\varepsilon }_{2}\) ensues the trend of film absorption index.

3.3 Nonlinear optical characterization

Investigation of material's nonlinear characteristics is very important where it paves the way for detecting the possibility of exploiting studied materials in various applications such as high capacity communication systems, optical circuits, and photonic applications. The third-order nonlinear optical susceptibility \({\chi }^{(3)}\) of the CCTS4 films was computed via Miller's principles according to the present formula [49, 50]:

Here B is a constant factor equal \(1.7\times {10}^{-10}\) esu and \({n}_{0}\) denotes the values of the static refractive index.

The nonlinear refractive index \({n}_{2}\) of the CCTS4 films is estimated by the expression [51, 52]

Table. 5 displayed the magnitudes of both \({\chi }^{\left(3\right)}\) and \({n}_{2}\) for the CCTS4 thin films. Figure 11 depicted the dependence of the \({\chi }^{\left(3\right)}\) and \({n}_{2}\) on the film thickness. It can be noticed that the \({\chi }^{\left(3\right)}\) and \({n}_{2}\) were raised via increasing the film thickness. This refers to the increase in nonlinear optical properties with the rise in film thickness. This could be referred to the excess of free carriers in the material. The large magnitudes of the obtained nonlinear constants could make our studied material as a good applicant in the fabrication of low power devices for telecommunication applications.

4 Conclusion

In this work, Cu2CoSnS4 thin-film samples were fabricated by using the spray pyrolysis method at four various thicknesses (160 nm, 230 nm, 297 nm and 345 nm). The XRD charts of the CCTS4 films depicted that the CCTS4 films are polycrystalline with tetragonal single phase. The EDAX technique displayed that the compositional element ratio was near to 2:1:1:4. The linear optical results displayed that the absorption coefficient of the CCTS4 films was boosted with raising the film thickness while the energy gap has a reverse manner. In addition, the values of the Urbach energy and the optical dielectric constants of the CCTS4 films were computed. Moreover, the nonlinear refractive index n2, and optical conductivity, of the CCTS4 thin films were raised with increasing film thickness. The increase in nonlinear parameters of CCTS4 films with boosting the film thickness highlights the opportunity of exploiting the studied material in many of interesting optoelectronic devices.

References

X. Liu, Y. Feng, H. Cui, F. Liu, X. Hao, G. Conibeer, D.B. Mitzi, M. Green, Prog. Photovolt. Res. Appl. 24, 879 (2016)

S. Siebentritt, S. Schorr, Prog. Photovolt. Res. Appl. 20, 512 (2012)

D.B. Mitzi, O. Gunawan, T.K. Todorov, K. Wang, S. Guha, Sol. Energy Mater. Sol. Cells 95, 1421 (2011)

R. Schurr, A. Hölzing, S. Jost, R. Hock, T. Voß, J. Schulze, A. Kirbs, A. Ennaoui, M. Lux-Steiner, A. Weber, I. Kötschau, H.W. Schock, Thin Solid Films 517, 2511 (2009)

S. Chen, A. Walsh, Y. Luo, J.-H. Yang, X.G. Gong, S.-H. Wei, Phys. Rev. B 82, 195203 (2010)

A. Fischereder, T. Rath, W. Haas, H. Amenitsch, J. Albering, D. Meischler, S. Larissegger, M. Edler, R. Saf, F. Hofer, G. Trimmel, Chem. Mater. 22, 3399 (2010)

A. Ziti, B. Hartiti, H. Labrim, S. Fadili, H.J. Tchognia Nkuissi, A. Ridah, M. Tahri, P. Thevenin, Appl. Phys. A: Mater. Sci. Process. 125, 218 (2019)

X. Zeng, K.F. Tai, T. Zhang, C.W.J. Ho, X. Chen, A. Huan, T.C. Sum, L.H. Wong, Sol. Energy Mater. Sol. Cells 124, 55 (2014)

M.S. Kumar, S.P. Madhusudanan, S.K. Batabyal, Sol. Energy Mater. Sol. Cells 185, 287 (2018)

H.I. Elsaeedy, J. Mater. Sci.: Mater. Electron. 30, 12545 (2019)

P.S. Maldar, A.A. Mane, S.S. Nikam, S.D. Giri, A. Sarkar, A.V. Moholkar, J. Mater. Sci.: Mater. Electron. 28, 18891 (2017)

M. Krishnaiah, R.K. Mishra, S.G. Seo, S.H. Jin, J.T. Park, Ceram. Int. 45, 12399 (2019)

P.S. Maldar, M.A. Gaikwad, A.A. Mane, S.S. Nikam, S.P. Desai, S.D. Giri, A. Sarkar, A.V. Moholkar, Sol. Energy 158, 89 (2017)

M. Beraich, M. Taibi, A. Guenbour, A. Zarrouk, M. Boudalia, A. Bellaouchou, M. Tabyaoui, S. Mansouri, Z. Sekkat, M. Fahoume, Optik 193, 162996 (2019)

I.M.H.I. EI RadafElsaeedy, H.A. Yakout, M.T. El Sayed, J. Electron. Mater. 48, 6480 (2019)

A. Sawaby, M.S. Selim, S.Y. Marzouk, M.A. Mostafa, A. Hosny, Phys. B 405, 3412 (2010)

E.R. Shaaban, N. Afify, A. El-Taher, J. Alloys Compd. 482, 400 (2009)

I.M.S.S. El RadafFouad, A.M. Ismail, G.B. Sakr, Mater. Res. Express. 5, 46406 (2018)

C.-J. Kim, I.-S. Ahn, K.-K. Cho, S.-G. Lee, J.-K. Chung, J. Alloys Compd. 449, 335 (2008)

A.S. Hassanien, I. Sharma, J. Alloys Compd. 798, 750 (2019)

T.A. Hameed, I.M. El Radaf, H.E. Elsayed-Ali, J. Mater. Sci.: Mater. Electron. 29, 12584 (2018)

A.S. Hassanien, I. Sharma, Optik 200, 163415 (2020)

I.M. El Radaf, Appl. Phys. A: Mater. Sci. Process. 125 (2019)

J. Tauc, R. Grigorovici, A. Vancu, Phys. Status Solidi (B) 15, 627 (1966)

A.S. Hassanien, A.A. Akl, Appl. Phys. A 124, 752 (2018)

A.J. Jebathew, M. Karunakaran, K.D.A. Kumar, S. Valanarasu, V. Ganesh, M. Shkir, I.S. Yahia, H.Y. Zahran, A. Kathalingam, Phys. B 574, 411674 (2019)

I.S. Yahia, I.M.A.M. El RadafSalem, G.B. Sakr, J. Alloys Compd. 776, 1056 (2019)

B. Murali, M. Madhuri, S.B. Krupanidhi, Cryst. Growth Des. 14, 3685 (2014)

L. Nie, S. Liu, Y. Chai, R. Yuan, J. Anal. Appl. Pyrol. 112, 363 (2015)

N. Bitri, S. Dridi, F. Chaabouni, M. Abaab, Mater. Lett. 213, 31 (2018)

S.G. Nilange, N.M. Patil, A.A. Yadav, Phys. B 560, 103 (2019)

Y.B.K. Kumar, G.S. Babu, P.U. Bhaskar, V.S. Raja, Sol. Energy Mater. Sol. Cells 93, 1230 (2009)

T.A. Hameed, A.R. Wassel, I.M. El Radaf, J. Alloys Compd. 805, 1 (2019)

I.M. El Radaf, J. Mater. Sci.: Mater. Electron. 31, 3228 (2020)

T. Wada, T. Maeda, Phys. Status Solidi C 14, 1600196 (2017)

A.S. Hassanien, I.M. El Radaf, Phys. B 585, 412110 (2020)

H.M. Hosni, S.A. Fayek, S.M. El-Sayed, M. Roushdy, M.A. Soliman, Vacuum 81, 54 (2006)

S.H. Wemple, Phys. Rev. B 7, 3767 (1973)

H. Ticha, L. Tichy, J. Optoelectron. Adv. Mater 4, 381 (2002)

A.S. Hassanien, A.A. Akl, Superlattices Microstruct. 89, 153 (2016)

M.M. El-Nahass, A.A.M. Farag, Opt. Laser Technol. 44, 497 (2012)

M. Mohamed, E.R. Shaaban, M.N. Abd-el Salam, A.Y. Abd-elLatief, S.A. Mahmoud, M.A. Abd-elRahim, Optik 178, 1302–1312 (2019)

A.S. Hassanien, A.A. Akl, J. Alloys Compd. 648, 280 (2015)

S.S. Fouad, E.A.A. El-Shazly, M.R. Balboul, S.A. Fayek, M.S. El-Bana, J. Mater. Sci.: Mater. Electron. 17, 193 (2006)

I.M.R.M. El RadafAbdelhameed, J. Alloys Compd. 765, 1174 (2018)

S. Fouad, I.P. El RadafSharma, M. El-Bana, J. Alloys Compd. 757, 124 (2018)

M.S. AlKhalifah, I.M.M.S. El RadafEl-Bana, J. Alloys Compd. 813, 152169 (2020)

S. Hamrouni, M.S. AlKhalifah, M.S. El-Bana, S.K. Zobaidi, S. Belgacem, Appl. Phys. A 124, 555 (2018)

R.M. Abdelhameed, I.M. El Radaf, Mater. Res. Express. 5(6), 066402 (2018)

I.M. El Radaf, T.A. Hameed, G.M. EI komy, T.M. Dahy, Ceram. Int. 45, 3072–3080 (2019)

A.A.A. Darwish, M. Rashad, A.E. Bekheet, M.M. El-Nahass, J. Alloys Compd. 709, 640 (2017)

V. Ganesh, I.S. Yahia, S. AlFaify, M. Shkir, J. Phys. Chem. Solids 100, 115 (2017)

Acknowledgements

This work was funded by the Deanship of Scientific Research (DSR) at King Abdulaziz University, Jeddah, under Grant No. J: 91-665-1441. The authors, therefore, acknowledge with thanks DSR for technical and financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Al-Zahrani, H.Y.S. Synthesis, optical and optoelectrical analysis of the Cu2CoSnS4 thin films as absorber layer for thin-film solar cells. J Mater Sci: Mater Electron 31, 6900–6909 (2020). https://doi.org/10.1007/s10854-020-03252-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03252-7