Abstract

In this paper, La0.8−xNdxSr0.2MnO3 (x = 0.03, 0.04, 0.05, and 0.06) ceramics were synthesized by a sol–gel method. The structure, surface morphology, electrical transport, and magnetoresistive properties of these materials were studied. X-ray diffraction (XRD) revealed samples to be single-phase with a distorted perovskite structure belonged to the (\({\text{R}}\bar 3{\text{c}}\)) space group. Scanning electron microscopy (SEM) revealed the samples to contain compact grains, with the grain size increasing slightly with the amount of doping Nd3+. The standard four-probe method was used to test the electrical resistivity of the samples as a function of temperature (ρ–T). The metal–insulator transition temperature (Tp) shifted to lower temperatures and the resistivity (ρ) increased with the content of Nd3+. Peak temperature coefficient of resistance (TCR) and magnetoresistance (MR) were both affected by the Nd3+ substitution. At x = 0.05, peak TCR and MR reached 5.12% K−1 and 19.78%, respectively. The mechanism responsible for both electrical and magnetoresistive properties of these materials was discussed in the frame of double-exchange (DE) interaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the 1950s, Zener proposed the double exchange (DE) mechanism to explain the coexistence of ferromagnetic and metallic states in doped perovskite manganites [1]. This mechanism involves two electrons on the adjacent Mn3+ and Mn4+ ions to simultaneously hop through the bridge O2− ion such that the system had minimum energy only when the spin of the itinerant electron was oriented with the core spin of the Mn ion. In the 1960s, Nagaev predicted a potential phase separation mechanism in magnetic semiconductors by which transporting electrons can be separated from the anti-ferromagnetic background, with the ferromagnetic region being stabilized via localization effect of the itinerant electrons. In 1975, this prediction was proved in a ferromagnetic semiconductor. In 1995, Millis carried out a systematic study on La1−xSrxMnO3 [2], and the results revealed that the DE model failed to explain the ferroelectric properties of manganites. The electron–phonon Jahn–Teller effect and the influence of magnetic polarization were considered later, and this was very important to interpret the electrical and magnetic transport properties involve in the magnetoresistive behavior of manganites. Despite these advances, many experimental results still remain unexplained namely, the appearance of paramagnetic metal and ferromagnetic insulating phases after Mn-site ions doping and the Curie temperature (Tc) being much higher than the metal–insulator transition temperature (Tp). These experimental results can be well explained by the phase separation theory [3].

Doped-perovskite manganites with the general formula T1−xDxMnO3 (T: trivalent rare earth elements such as La3+, Nd3+, Sm3+; D: divalent alkali earth element such as Ca2+, Sr2+, Ba2+) have been extensively studied in the past decades owing to their unique electrical and magnetic behavior including the existence of phase separation, charge/orbital ordering, colossal magnetoresistance (CMR), ferromagnetic–paramagnetic (FM–PM) transition, and metal–insulator (M–I) transition [4,5,6,7,8,9,10,11,12]. This behavior can be explained based on a DE interaction and the Jahn–Teller effect [13,14,15].

The microstructure, grain size, chemical uniformity, and preparation method of ceramics has a significant influence on their electromagnetic properties [16]. The most common way to prepare polycrystalline ceramic samples is by the conventional solid-state reaction. This method requires long sintering times, high temperatures, and several intermediate grinding steps to obtain the desired compound with homogenous composition. Co-precipitation requires solutions to be pH adjusted and aged for long times. Therefore, these methods are costly and complex. Comparatively, the sol–gel method has attracted significant attention in last decade owing to its unique advantages including short preparation times and good doping uniformity [17,18,19,20,21].

Doping A-site ions with different valent ions changes the Mn3+/Mn4+ ratio and the length and angle of the Mn–O–Mn bond, thus altering DE interaction and physical properties of manganites. According to the previous results [22,23,24], doping Mg2+, Ca2+, Ba2+, Nd3+, Bi3+ and other metallic elements changed some physical properties of LaxSr1−xMnO3 (LSMO) and LaxCa1−xMnO3 (LCMO) such as Tp and temperature coefficient of resistance (TCR) [25]. Remarkably, doping with Nd3+ resulted in LSMO with lower Tp and higher TCR values. The replacement of La3+ with Nd3+ decreases the A-site average cationic radius < rA > and the tolerance factor , thus suppressing the DE interaction. As a result, Tp is reduced and TCR is increased, as in the case of Ca2+ substituting for Sr2+ in LSMO. In addition, since Nd has good magnetic conductivity, it is interesting to study Nd-doped LSMO in terms of magnetic properties. In this paper, the electrical and magnetic properties of La0.8−xNdxSr0.2MnO3 (LNSMO) ceramics prepared by a sol–gel method were systematically studied. These characteristics changed significantly with the amount of doping Nd3+. The results revealed all the ceramics to be single-phase (hexagonal), with the grain size increasing with the Nd3+ content. The resistivity of the ceramic samples showed the same behavior under an external magnetic field of 1T, and these resistivity values were lower than those obtained in the absence of magnetic field. TCR and MR showed maximum values for a Nd3+ doping loading of 0.05. The electromagnetic transmission characteristics of the LNSMO ceramics can shed light to better understand the CMR mechanism of these materials. These properties can provide these materials with a wide range of technological applications in the field of magnetic recording media, magnetic sensors, magneto-electric devices, random access memory, and hard disk read heads [26].

2 Experiments

A series of La0.8−xNdxSr0.2MnO3 (x = 0.03, 0.04, 0.05, and 0.06) ceramic samples were prepared by a sol–gel method. First, the desired stoichiometric amounts of the precursors (La(NO3)3·nH2O, Ca(NO3)2·4H2O, Mn(NO3)2·4H2O, and SrCl2·6H2O) were weighted and dissolved in methyl alcohol. Citric acid (molar ratio to metal ions of 4:1) and ethylene glycol (ca. 40 mL) were added to the mixed solution as chelating and gelification agents, respectively. The resulting solution was magnetically stirred on a hot plate at 80 °C for about 30 min and then it turned into faint yellow. The solution was slowly evaporated to become highly viscous, after which an orange transparent gel was formed. A xerogel was formed by drying the gel in an oven at 140 °C for 12 h. Second, the xerogel was ground into powder and calcined in air at 500 °C for 8 h. Finally, the calcined powders were ground again, pressed into pellets, and then sintered at 1450 °C for 12 h to obtain the bulk polycrystalline ceramic samples.

The structure and crystallinity of the LNSMO ceramic samples were examined by powder X-ray diffraction (XRD) on a device with Cu Kα radiation at room temperature. The surface morphologies and microstructures of the ceramic samples were characterized and analyzed by scanning electron microscopy (SEM). The resistivity of the ceramic samples were measured with the standard four probe method within a temperature range of 250–350 K. MR was measured under a magnetic field of 1 T using an ET9000 electrical transport property test system (ET9000, East Changing Technologies, Inc).

3 Results and discussion

3.1 Crystal structure and surface morphology

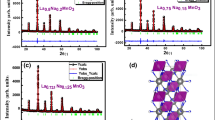

Figure 1a shows the XRD patterns of La0.8−xNdxSr0.2MnO3 (x = 0.03, 0.04, 0.05, and 0.06) from 20º to 80º. As shown in Fig. 1a, the room-temperature patterns of the ceramic samples contained sharp diffraction peaks, and no other heterogeneous phases were detected within the sensitivity of the instrument. Thus, the polycrystalline ceramic samples showed good crystallinity. All samples showed patterns typical of perovskite structure (PDF card 51-0409) that belonged to the hexagonal crystal system and the space group (\({\text{R}}\bar 3{\text{c}}\)). The inset in Fig. 1a represents a magnified view of the diffraction peaks corresponding to the planes (110) and (104). The most intense peaks did not shift significantly with the amount of doping Nd, which might be due to the little change of cell volume [27].

The XRD Rietveld results are illustrated in Fig. 1b–e. The solid spheres are the diffraction data and the red line represents the fitting result. The short vertical line is the fitting diffraction peak position, while the bottom solid line is the difference between the measured and the fitting values. The experimental diffraction peaks were consistent with those of the XRD Rietveld, further proving that all samples were single-phase crystallized.

Table 1 displays the structural parameters and refinement parameters of all samples. The samples showed a hexagonal perovskite structure and (\({\text{R}}\bar 3{\text{c}}\)) space group. All samples showed goodness of fitting (χ) values close to 1, revealing the feasibility of the fitted model. The length and angle of the Mn–O bond decreased with the amount of Nd3+ doped such that DE interaction between Mn3+/Mn4+ in the MnO6 octahedron [28,29,30,31] decreased, showing a great impact on the electrical performance of the polycrystalline ceramic samples. Considering the ionic radii of La3+ (1.216 Å) and Nd3+ (1.163 Å), the total ionic radius and the cell volume both decreased upon substitution of La3+ with Nd3+. However, due to the close ionic radius of La3+ and Nd3+ and the low doping amount, the volume of the unit cell only decreased slightly.

Figure 2a–d shows the surface morphology of the La0.8−xNdxSr0.2MnO3 (x = 0.03, 0.04, 0.05, and 0.06) polycrystalline ceramic samples as observed by SEM. Pores were hardly observed because of the low amount of grain boundaries and other internal defects of the ceramic samples, which essentially reflects the intrinsic behavior of the electric properties. With the aim to further analyze the microstructure of LNSMO polycrystalline ceramics, Nano Measurer 1.2 was used to determine the grain size of the samples. As shown in Fig. 2e, the grain size increased slightly with the Nd3+ content, although this variation was very limited.

3.2 Electrical properties

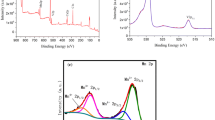

Figure 3a and b shows the electrical resistivity as a function of temperature (ρ-T) within 250–350 K for La0.8−xNdxSr0.2MnO3 (x = 0.03, 0.04, 0.05, and 0.06) ceramics for magnetic fields of 0 and 1 T, respectively. As can be seen in Fig. 3a, b, as the temperature increased, all samples underwent metal–insulator transformation at TP within the temperature range studied herein. Insulators conduct electricity at high temperatures, while metals conduct electricity at low temperatures. TP shifted towards lower temperatures and the electrical resistivity increased continuously with the loading of Nd3+.

Tp decreased from 340.55 K to 329.42 K at 0 T (from 343.61 K to 336.28 K at 1 T) as the amount of Nd3+ increased from 0.03 to 0.06. The decrease of Tp with the amount of Nd3+ can be explained as follows. The Mn–O bond distance and angle both decreased with the amount of Nd3+, thereby weakening the DE interaction between Mn3+/Mn4+ in MnO6 octahedron. As a result, the electron bandwidth decreased, which had a great impact on the electrical performance of the polycrystalline ceramic samples.

TCR can be defined by Eq. (1) as follows:

where ρ and T are the resistivity and temperature, respectively.

Figure 4 shows the dependence of TCR with temperature (295–335 K) for the LNSMO ceramics. The inset in Fig. 4 shows the variation of peak TCR temperature (Tk) with the amount of dopant. Tk varied with the amount of dopant as Tp did. The substitution of larger La3+ with Nd3+ reduced the ionic radius, thus decreasing the Mn–O–Mn bond angle and weakening the DE interaction between Mn3+/Mn4+, which in turn resulted in lower Tk values. As the amount of Nd3+ increased, peak TCR showed a maximum at a certain Nd loading and decreased thereafter. When x = 0.05, peak TCR reached 5.12% K−1. This value was higher than previous TCR values reported for La0.845Sr0.155MnO3 and La0.7Sr0.3MnO3 (2.33% K−1 [32] and 1.8% K−1 [33], respectively). Equation (1) reveals that the resistivity affects peak TCR value. The preparation method, sintering time, sintering temperature, sintering sample density, ionic radius, and other factors can also affect TCR [34, 35]. The resistivity and ionic radius are the most important factors affecting peak TCR. At low Nd3+ loadings, peak TCR is mainly affected by the ionic radius, while the resistivity has little influence on peak TCR. However, when the doping amount reaches a certain level, the resistivity prevails and the ionic radius has little impact on peak TCR. At this point, the resistivity increases and peak TCR decreases with the amount of Nd3+.

3.3 Magnetic properties

By comparing Fig. 3a and b, it can be seen that the samples showed lower resistivity when exposed to a magnetic field of 1 T. The magnetic field generated carrier delocalization, which inhibited the resistivity and increased the metal phase fraction as a result [36].

Figure 5 shows the variation of MR with temperature (290–340 K) for the LNSMO (x = 0.03, 0.04, 0.05, and 0.06) ceramics. The inset in Fig. 5 describes the change of peak MR temperature (Tm) and peak MR, with MR being defined by Eq. (2) as follows:

Peak MR temperature (Tm) changed similarly with temperature than Tp and Tk. La3+ was replaced by Nd3+, and the ionic radius decreased, thus reducing the Mn–O–Mn bond angle and the DE interaction between Mn3+/Mn4+, which in turn resulted in lower Tm values. MR showed a maximum at a certain Nd3+ loading and decreased thereafter, which is basically consistent with the trend of TCR. At x = 0.05, peak MR reached the maximum value (19.78%), with this value being higher than peak MR of La0.8Sr0.2MnO3 (17.2%) [37]. Although Eq. (2) indicates that the resistivity affects MR, Nd has a good permeability, which improved the order of the grain magnetic domains. At low Nd3+ contents, peak MR increased as the order degree of the magnetic domains was higher. At high Nd3+ contents, the resistivity dominated. At this point, peak MR decreased slightly with the amount of Nd3+.

4 Conclusions

LNSMO polycrystalline ceramics were prepared by a sol–gel method. The effects of the Nd3+ content on the structure, surface morphology, and electromagnetic transmission characteristics were studied and discussed. The XRD results revealed all the ceramics to be single-phased (hexagonal). SEM revealed that the grain size increased with the Nd3+ content. Tp, Tk, Tm, and the resistivity of the ceramic samples gradually decreased with the Nd3+ content. The resistivity of the ceramic samples behaved similarly under an external magnetic field of 1 T, although lower values were obtained compared to those obtained at 0 T. When the Nd3+ doping amount was 0.05, TCR and MR reached a maxima of 5.12% K−1 and 19.78%, respectively. Peak TCR and MR values obtained herein were slightly higher than those reported in the literature. Although the promotion effect was limited, the results indicated that a small amount of Nd3+ had a positive effect on the electrical transport and magnetoresistive properties of La0.8Sr0.2MnO3 ceramics. These properties could be explained in terms of a DE interaction.

References

C. Zener, Interaction between the d-Shells in the transition metals ferromagnetic compounds of manganese with perovskite structure. J. Phys. Rev. 82, 403–405 (1951)

A.J. Millis, P.B. Littlewood, B.I. Shraiman, Double exchange alone does not explain the resistivity of La1−xSrxMnO3. Phys. Rev. Lett. 74, 5144–5147 (1995)

J. Goodenough, Colossal magnetoresistance in Ln1-xAxMnO3 perovskites. Aust. J. Phys. 52, 155–186 (1999)

A.M. Haghirigosnet, J.P. Renard, CMR manganites: physics, thin films and devices. J. Phys. D 36, R127 (2003)

J.B. Goodenough, Electronic structure of CMR manganites (invited). J. Appl. Phys. 81, 5330–5335 (1997)

T.V. Ramakrishnan, Modelling colossal magnetoresistance manganites. J. Phys. 19, 497–503 (2007)

R. Tripathi, V.P.S. Awana, H. Kishan, G.L. Bhalla, Search for room temperature high-TCR manganite/silver composites. J. Magn. Magn. Mater. 320, L89–L92 (2008)

G.D. Tang, Z.Z. Li, L. Ma, W.H. Qi, L.Q. Wu, X.S. Ge, G.H. Wu, F.X. Hu, Three models of magnetic ordering in typical magnetic materials. Phys. Rep. 758, 1–56 (2018)

J.J. Qian, W.H. Qi, Z.Z. Li, L. Ma, G.D. Tang, Y.N. Du, M.Y. Chen, G.H. Wu, F.X. Hu, Spin-dependent and spin-independent channels of electrical transport in perovskite manganites. RSC Adv. 8, 4417–4425 (2018)

J.J. Qian, Z.Z. Li, W.H. Qi, L. Ma, G.D. Tang, Y.N. Du, M.Y. Chen, Study of magnetic structure and electrical-transport properties of La1-yBayMn1-xFexO3 (y = 0.15, 0.40) perovskite manganites. J. Alloys Compd. 764, 239–249 (2018)

D.G. Li, Y.T. Mai, J. Xiong, Y.H. Xiong, Z.L. Liu, C.S. Xiong, Studies on low-field and room-temperature magnetoresistance in La2/3(Ca1-xSrx)1/3MnO3 perovskites. J. Supercond. Novel Magn. 26, 719–723 (2012)

T.D. Thanh, L.H. Nguyen, D.H. Manh, N.V. Chien, P.T. Phong, N.V. Khiem, L.V. Hong, N.X. Phuc, Structural, magnetic and magnetotransport behavior of La0.7SrxCa0.3−xMnO3 compounds. Physica B 407, 145–152 (2012)

C. Zener, Interaction between the d-shells in the transition metals. Phys. Rev. 81, 440–444 (1951)

D.Y. Cao, Y.Y. Zhang, W.X. Dong, Structure, magnetic and transport properties of La0.7Ca0.3-xSrxMnO3 thin films by sol-gel method. Ceram Int 41, S381–S386 (2015)

H. Baaziz, A. Tozri, E. Dhahri, Effect of particle size reduction on the structural, magnetic properties and the spin excitations in ferromagnetic insulator La0.9Sr0.1MnO3 nanoparticles. Ceram Int 41, 2955–2962 (2015)

J. Ma, Y. Cai, W. Wang, Q. Cui, M. Theingi, H. Zhang, Q. Chen, Enhancement of temperature coefficient of resistivity in La0.67Ca0.33MnO3 polycrystalline ceramics. Ceram. Int. 40, 4963–4968 (2014)

F. Jin, H. Zhang, X. Chen, X. Liu, Q. Chen, Improvement in electronic and magnetic transport of La0.67Ca0.33MnO3 manganites by optimizing sintering temperature. J. Sol-Gel Sci. Technol. 81, 1–8 (2016)

T. Sun, S. Zhao, F. Jin, X. Liu, Enhanced room-temperature MR and TCR in polycrystalline La0.67 (Ca0.33−xSrx)MnO3 ceramics by oxygen assisted sintering. Ceram Int 44, 2400–2406 (2018)

T. Sun, J. Jiang, Q. Chen, X. Liu, Improvement of room-temperature TCR and MR in polycrystalline La0.67(Ca0.27Sr0.06)MnO3 ceramics by Ag2O doping. Ceram. Int. 44, 9865–9874 (2018)

I. Matos, S. Se´rio, Effect of the sintering temperature on the properties of nanocrystalline Ca1-xSmxMnO3 (0 ≤ x≤0.4) powders. J. Alloys Compd. 509, 9617–9626 (2011)

X. Yin, X. Liu, Y. Yan, Q. Chen, Preparation of La0.67Ca0.33MnO3:Agx polycrystalline by sol-gel method. J. Sol-gel Sci. Technol. 70, 361–365 (2014)

M.D. Daivajna, A. Rao, G.S. Okram, Electrical, thermal and magnetic studies on Bi-substituted LSMO manganites. J. Magn. Magn. Mater 388, 90–95 (2015)

A. Sendil Kumar, K.R. Reddy, A.K. Bhatnagar, Magnetization and ESR studies of La0.67(Ca1-xMgx)0.33MnO3 systems. J. Alloys Compd. 639, 139–144 (2015)

B. Munirathinam, M. Krishnaiah, S. Arumugam, M. ManivelRaja, Electronic transport and magnetic studies of La1-xCax-0.08Sr0.04Ba0.04MnO3. J. Phys. Chem. Solids 71, 1763–1767 (2010)

X. Chen, H. Zhang, F. Jin, X. Liu, Q.M. Chen, Fabrication of polycrystalline ceramics by sol-gel method. J. Sol-Gel Sci. Technol. 80, 168–173 (2016)

P.M. Woodward, T. Vogt, D.E. Cox, Influence of cation size on the structural features of Ln1/2A1/2MnO3 perovskites at room temperature. Chem. Mater. 10, 3652–3665 (1998)

S. Zhao, X. Yue, X. Liu, Tuning room temperature T p and MR of La1-y(Cay-xSrx)MnO3 polycrystalline ceramics by Sr doping. Ceram. Int. 43, 4594–4598 (2017)

D.S. Fan, Q. Li, Y.M. Xuan, H. Tan, J.F. Fang, Temperature-dependent infrared properties of Ca doped (La, Sr) MnO3 compositions with potential thermal control application. Appl. Therm. Eng. 51, 255–261 (2013)

K.L. Yanapu, S.S. Samatham, D. Kumar, V. Ganesan, P.V. Reddy, Effect of bismuth doping on the physical properties of La-Li-Mn-O manganite. Appl. Phys. A 122, 199 (2016)

J. Fontcuberta, B. Martínez, A. Seffar, S. Piñol, J.L. García-Muñoz, X. Obradors, Colossal magnetoresistance of ferromagnetic manganites: structural tuning and mechanisms. Phys. Rev. Lett. 76, 1122–1125 (1996)

D.Y. Cao, Y.Y. Zhang, W.X. Dong, J. Yang, W. Bai, Y. Chen, G.S. Wang, X.L. Dong, X.D. Tang, Structure, magnetic and transport properties of thin films by sol-gel method. Ceram. Int. 41, S381–S386 (2015)

G. Dong, T. Sun, F.Q. Ji, Y. Liu, S. Zhang, H. Zhang, X. Liu, Polycrystalline La0.845Sr0.155MnO3:Agx ceramics (0 ≤ x ≤ 0.5) with roomtemperature TCR and MR for improved uncooling photoelectric and magnetic devices. Ceram. Int. 45, 12162–12168 (2019)

R. Tripathi, V.P.S. Awana, H. Kishan, G.L. Bhall, Search for room temperature high-TCR manganite/silver composites. J. Magn. Magn. Mater. 320, L89–L92 (2008)

S. Das, T.K. Dey, Electrical conductivity and low field magnetoresistance in polycrystalline La1−xKxMnO3 pellets prepared by pyrophoric method. Solid State Commun. 134, 837–842 (2005)

G. Venkataiah, V. Prasad, P. Venugopal Reddy, Influence of A-site cation mismatch on structural, magnetic and electrical properties of lanthanum manganites. J Alloy Compd 429, 1–9 (2007)

L. Li, H. Zhang, X. Liu, P. Sun, C.Y. Wang, X.J. Wang, B.B. Li, G.W. Liang, Q.M. Chen, Structure and electromagnetic properties of La0.7Ca0.3-xKxMnO3 polycrystalline ceramics. J. Ceram. Int. 45, 10558–10564 (2019)

X.H. Yu, T. Sun, Q.M. Chen, Y.B. Duan, X. Liu, Modulation of room temperature TCR and MR in La1-xSrxMnO3 polycrystalline ceramics via Sr doping. J. Sol-Gel. Sci. Technol. 90, 221–229 (2019)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 11564021), the Analysis and Testing Foundation of Kunming University of Science and Technology, and the Innovation Training Program for College Students (Grant No. 201710674053).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Chen, Q., Li, L. et al. Electrical transport and magnetoresistive properties of Nd-doped La0.8Sr0.2MnO3 ceramics. J Mater Sci: Mater Electron 30, 19035–19042 (2019). https://doi.org/10.1007/s10854-019-02261-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02261-5