Abstract

Barium strontium titanate (BaxSr1–xTiO3, BST) thin films have large dielectric constant, low dielectric loss, especially the high dielectric tunability, which make them prospective candidates for microwave tunable applications. Resent developments in BST thin films by doping modification are reviewed. The A-site doping, B-site doping, and both sites codoping modifications are summarized and analyzed, respectively. The comparison of dielectric properties and microstructure of the BST thin films with different sites doping modifications is critically analyzed. The single A-site or B-site doping modification cannot obtain the BST thin films with balanced enhancement of the dielectric properties. However, the different elements codoping in both A-site and B-site of BST thin films is demonstrated to be an effective method to achieve balanced dielectric property optimization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Barium strontium titanate (Ba1–xSrxTiO3, BST) ferroelectric materials have been studied for many years due to their high permittivity, good chemical stability, and especially the sensitivity of permittivity to electric field. Due to this unique properties, BST materials have many various tunable electronic applications, such as voltage-tunable capacitors, phase shifters, tunable filters, switching matching networks, oscillators, etc. [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15]. The tunable devices based on BST thin films usually have large flexibility, low cost, and small size, which even superior to semiconductor analogs at high frequency (above 10 GHz) [16,17,18,19,20]. The matching networks in antenna and amplifiers with BST thin films tunable capacitors can handle power efficiently. Electronically steerable systems used BST thin films may save space and weight in satellite communications and radar systems. Besides, BST thin films have many promising applications in microwave tunable systems.

The dielectric properties of BST materials are closely related to their structure. BST materials can be deemed as barium titanate (BaTiO3) and strontium titanate (SrTiO3) are both crystallined in perovskite (ABO3) structure, which use TiO6 octahedron as the skeleton as shown in Fig. 1. Ba2+ and Sr2+ ions randomly take the cube apex angle of A-site in perovskite structure, besides which can be replaced by arbitrary proportion without any changes of the crystal structure. The skeleton is related to B-site, which is occupied by Ti4+ ions. The six sides of cube are concerned with O-site. The O2− ions form an octahedral structure and centered on the Ti4+ ions. The entire crystal structure can be described as an oxygen octahedron connecting the vertices, and A-site is the space between the octahedron. The number of ions in A-site is 12, while B-site is 6.

The structure of BST thin film contributes to its large permittivity and dielectric tunability, which are expected in the miniaturization of tunable microwave devices [21,22,23]. The dielectric tunability is the electric field dependent dielectric permittivity, which is defined as the ratio of the dielectric permittivity at zero electric field bias to the permittivity under electric field bias E (\(n = (\varepsilon (0) - \varepsilon (E))/\varepsilon (0)\)). Many factors would greatly affect the dielectric properties of BST thin films, such as thin film deposited methods, microstructure, film thickness, oxygen content, film homogeneity, and etc. [24,25,26,27,28]. However, ferroelectric materials usually have a large dielectric loss, which arises from the motion of charged defects in a time-dependent electromagnetic field and their local polar nanoregions induced by structural imperfections and non-stoichiometry. Many efforts have been made to optimize the dielectric properties of BST thin films, such as doping modification, using multi-layer composites, and different post treatments after thin film growth [29,30,31,32,33,34,35,36,37,38]. Doping modification is one of the most popular modification methods, which is an effective way to enhance the dielectric properties of BST materials. The dopant addition can make considerable effect on the polarizability in the studied systems, besides even controlling the stress and orientation of thin films, which in turn increasing the tunability and decreasing dielectric loss.

The A-site and B-site of BST materials can be replaced by different ions with the following relationship:

where rA is the radius of ions on the A-site, rB is the radius on the B-site, rO is the radius of O2− ion, t is the allowance tolerance factors. The atoms of dopants can replace the atoms on the A-site or B-site to form continuous solid solution if the tolerance factors of dopants are located in the range of 0.77–1.10. The crystal lattice parameter, performance, and capability of BST thin film are varied with the doping ions. Many studies have confirmed that BST thin films with doping modification can effectively increase dielectric constant and tunability, while reduce their dielectric loss [39,40,41,42,43,44].

In this paper, we summed up the researches on the BST thin films doping modification, especially the improvement of their dielectric properties. The doping modification is including A-site doping, B-site doping, and multi-element codoping. The effects of doping modification on the structure and dielectric properties of BST thin film are discussed. It also provides the data to the predictability of dielectric properties and opens avenues to the new application of BST materials.

2 Doping modification

According to the previous studies, the dielectric properties of BST thin films are greatly affected by their microstructure, component, grain size, electrode, interface properties, and film thickness [45,46,47,48,49,50,51,52]. Table 1 lists the dielectric properties of pristine BST thin films prepared by different deposition methods. BST thin films with the stoichiometry of Ba0.6Sr0.4TiO3 thin films prepared by sol–gel, PLD, MOSD, and rf sputtering methods show the dielectric constant of 130–300, tunability of 33–48.5% and dielectric loss of 0.0153–0.028. The Ba0.5Sr0.5TiO3 thin films prepared by PLD and CSD methods have dielectric constant of 380–420, tunability of 16.7–46%, and dielectric loss of 0.025–0.17. Ba0.7Sr0.3TiO3 thin films prepared by sol–gel methods present a dielectric constant of 280, tunability of 37% and dielectric loss of 0.045. Especially, the BST thin films with the stoichiometry of Ba0.8Sr0.2TiO3 prepared by sol–gel methods show the superior dielectric properties, which have the dielectric constant of 460, tunability of 27.5% and dielectric loss of 0.118. The above results concluded that the pristine BST thin films prepared by different deposition methods have various dielectric properties, which showed a maximum tunability of 48.5% and a minimum dielectric loss of 0.0153. The dielectric properties of BST thin films are greatly enhanced by doping ions, such as the Y-doped BST thin films. Qin et al. [53] reported the Y-doped BST thin films (BSTY) prepared on LaAlO3 substrate by PLD presented the superior dielectric properties to the pristine BST thin films, which have a large dielectric constant of 785 at 10 kHz, besides the enhanced dielectric tunability of 82.7% at the electric field of 300 kV/cm. Many studies also demonstrated the BST thin films by doping modification show the enhanced dielectric properties, especially the improved dielectric tunability and dielectric constant. This review will discuss the effects of doping modification on structure and dielectric properties of BST thin films by doing various ions on A-site, B-site, and both these two sites.

2.1 A-site doping

A-site of BST materials can be substituted by various ions according to the electro neutrality principle and tolerance factor of doping modification. The ions such as Rb+ [39], K+ [40,41,42,43,44], Ag+ [57, 58], Ce3+ [59,60,61,62], Pb2+ [63, 64], Ca2+ [54, 65], La3+ [66,67,68,69,70,71,72] are good candidates for A-site doping modification.

Rb+ ions (1.52 Å) has a similar ionic radius with Ba2+ (1.34 Å) ions that can enter into the A-site in BST structure. Luo et al. [39] reported that the effect of Rb-doping on the dielectric properties of Ba0.6Sr0.4TiO3 thin films prepared by sol–gel method. The Rb-doped BST thin films show a perovskite structure with the strong (110) peak. There are no secondary phases detected in all the studied thin films, which indicates that Rb+ ions enter the unit cell and maintain the perovskite structure of the solid solution. Figure 2 shows the dielectric properties of the Rb-doped BST thin films with different Rb contents. The results exhibit that Rb-doped BST thin films with 4 mol% Rb content have the good dielectric properties with the dielectric constant of 486, dielectric loss of 0.02, and tunability of 63.37% at 2 MHz. The studies demonstrate that Rb-doping can effectively increase the dielectric constant and tunability of BST thin films as compared with that of pristine BST thin films. Moreover, Rb-doping can modify the grain morphology and grain size of the BST thin films. The increased grain size benefits the polarization, and thus increasing the dielectric constant and tunability of BST thin films. However, the Rb-doping would reduce the densification of BST thin films, which results in the high dielectric loss.

The frequency dependence of a dielectric constant and b dielectric loss of BST (Ba0.6Sr0.4)1–xRbxTiO3 (BSTRbx, x = 0,2,4,6,8) thin films at room temperature; c dielectric constant and dielectric loss of BSTRbx thin films as a function of Rb content at 2 MHz [34]

According to the doping mechanism, K+ (1.33 Å) has a similar radius to Ba2+ (1.35 Å), which can substitute Ba2+ ions on the A-site of the BST structure. Moreover, K+ (0.82) have smaller electro negativity than Ba2+ (0.89), which may improve the dielectric properties of BST thin films. The dielectric properties of K-doped BST thin films are greatly affected by the K contents and deposition methods. Liao et al. [40] prepared K-doped Ba0.6Sr0.4TiO3 thin films by the sol–gel method. The K-doped Ba0.6Sr0.4TiO3 thin films with 5% K content showed the good structural characteristics and enhanced dielectric properties, which have dielectric constant of 603, dielectric loss of 0.0083, and tunability of 49.0% at 275 kV/cm. The decrease of dielectric constant and tunability of K-doped Ba0.6Sr0.4TiO3 thin films are resulted from the loose structure of BST materials by the sol–gel method. The K-doped Ba0.6Sr0.4TiO3 prepared by rf sputtering method can obviously increase the dielectric constant and decrease the dielectric loss as compared with that of the pristine BST thin films [41]. The study results showed that 5 mol% K-doped BST thin films have the best dielectric properties with the dielectric constant of 460, dielectric loss of 0.024 and tunability of 62.3% at 1 MHz. The dielectric constant and dielectric loss exhibit significantly difference between these two studies. Liao et al. [40] explained this difference is related to the effects of different status of BST thin films by different prepared methods. There are also other deposition methods to prepare K-doped BST thin films. Upadhyay et al. [42] have successfully prepared K-doped Ba0.6Sr0.4TiO3 by metal organic solution deposition (MOSD) method. The prepared K-doped Ba0.6Sr0.4TiO3 thin films showed the enhanced dielectric properties, especially the 2 mol% K-doped BST thin films presented the dielectric constant of 144, dielectric loss of 0.0065, and tunability of 46% at 1 MHz. Sekhar et al. [43, 44] prepared (Ba0.5Sr0.5)0.925K0.075TiO3 thin films by pulsed laser deposition (PLD). The BST thin films with 7.5 mol% K-doping showed the enhanced dielectric properties, which have the dielectric constant of 560, dielectric loss of 0.017, and tunability of 77% at 400 kV/cm.

Gao et al. [54] reported that Ca-doped Ba0.7Sr0.3TiO3 thin films have been prepared on Pt/Ti/SiO2/Si (100) substrates by sol–gel technique. The dielectric properties of BST films are closely connect with Ca doping content. The dielectric loss of the Ca-doped BST thin films decreased with the increase of Ca dopant concentration, but the dielectric constant and tunability also decreased with Ca doping, as shown in Fig. 3. The decreased grain size by Ca2+ ions doping in BST thin films could increase the grain boundaries, which hindered polarization in BST materials, and thus in turn decreasing their dielectric constant and tunability.

a The dielectric constant and dielectric loss of Ca-doped BST thin films with different Ca contents; b the tunability and FOM of Ca-doped BST thin films with different Ca contents [49]

The Ag+ ions (1.14 Å) have a similar radius and electronegativity with Sr2+ ions (1.18 Å), which is the promising candidate for BST thin films doping modification. Ag-doped BST thin films prepared by sol–gel method can decrease the microwave dielectric loss [57]. The 1 mol% Ag-doped BST thin films showed the best dielectric property among the studied Ag-doped (Ba0.6Sr0.4)TiO3 thin films, which have the dielectric constant of 269.3, dielectric loss of 0.02, and tunability of 41.2% at 100 kV/cm.

Ce3+ ions (1.03 Å) have a similar radius and electronegativity with Sr2+ (1.18 Å) and Ba2+ (1.35 Å) ions, which can enter the structure of BST materials and take on the A-site. Kim et al. [59] reported the Ce-doped BST thin films on Pt/Ti/SiO2/Si substrates were prepared by sol–gel preparation method. The results indicated that the dielectric properties of BST films are greatly affected by the Ce content. The dielectric loss decreased while the tunability increased with the increase of Ce content. The Ce-doped Ba0.6Sr0.4TiO3 thin films with 1 mol% Ce content doping present the dielectric constant of 320, dielectric loss of 0.011, and tunability of 46.3% at 500 kV/cm.

Zeng et al. [63] reported the Pb-doping served to increase the BST grain size, lower the diffusion phase transition, and narrower the diffuse phase region of BST thin films, which in turn enhancing the dielectric properties of BST thin films. The Pb-doped (Ba0.8Sr0.2)TiO3 thin films were prepared on Pt/Ti/SiO2/Si substrates by sol–gel technique. The 5 mol% Pb-doped BST thin films showed a strong (110) preferential orientation, and which also exhibited good dielectric properties among all the studied Pb-doped BST thin films with dielectric constant of 402 and dielectric loss of 0.011.

La3+ ion can substitute on the A-site of the ABO3-type perovskite BST materials. The La-doped BST thin films have been deposited by a metal organic solution deposition (MOSD) technique [66]. The Ba0.6Sr0.4TiO3 thin films with 1 mol% La-doping content showed the enhanced dielectric properties, which have the decreased dielectric loss of 0.019% at 100 kHz. The La-doped BST thin films possessed an enhanced insulating behavior as demonstrated by the large film resistivity values, which were over two orders of magnitude larger than that of pristine BST thin films. However, the La-doping would decrease the dielectric constant and tunability of the BST thin films due to the worse crystalline and the poor quality of the film-substrate interface. Hao et al. [68] also studied the La-doped BST powders, whose dielectric constant and dielectric loss also increased with increasing La content.

The A-site doping modifications contribute to optimize the dielectric properties of BST thin films mentioned above are summed up in Table 2. The appropriate doping ion and doping amounts are the important factors to obtain good dielectric properties of BST thin films by A-site doping modification. Certain doping elements can remarkably enhance the tunability and dielectric constant of BST thin films, meanwhile decreasing their dielectric loss, such as K-doping and Rb-doping. However, although some A-site doping modification can decrease the dielectric loss of BST thin films, but which also decrease their dielectric constant and tunability such as Ca-doping and La-doping.

2.2 B-site doping

B-site of BST materials can be also substituted by various ions, which have similar radiuses to Ti4+ ions and satisfy the electro neutrality principle and tolerance factor of doping modification. The promising doping ions such as Cu2+ [73,74,75], Mg2+ [76,77,78,79], Ni2+ [80,81,82,83,84,85], Y3+ [53, 86, 87], Co2+ [55, 56, 88,89,90], Sn4+ [91,92,93,94], Fe3+ [95,96,97,98], Mn4+ [99,100,101,102,103], Mn2+ [104], Ta5+ [105], Cr3+ [106,107,108], W6+ [109, 110], Al3+ [111] and Li+ [112].

The Y-doped BST thin films show the enhanced dielectric properties, which can be the potential candidate applying in tunable microwave devices. Qin et al. [53] reported that Y-doped Ba0.6Sr0.4TiO3 thin films on LaAlO3 substrate were prepared by PLD. The Y-BST thin films showed the enhanced crystallization and dielectric properties. The results indicated that the addition of Y ions work as an acceptor, which obviously increased dielectric tunability and reduce the leakage current of BST thin films. Y-doped BST thin films with 1.5 mol% Y content exhibited the enhanced dielectric properties as compared with the pristine BST thin films. The tunability increased from 48.5% (pristine BST) to 82.7% (1.5 mol% Y-doped BST) at 300 kV/cm, and the dielectric constant increased from 225 (pristine BST) to 785 (1.5 mol% Y-doped BST) at 10 kHz.

The ionic radius of Cu2+ (0.73 Å) is similar to Ti4+ (0. 68 Å) make it possible to diffuse into the lattice and substitute the B-site atom of the ABO3 perovskite system. Ha et al. [73] studied the Cu-doped BST thin film on Pt(111)/Ti/SiO2/Si-(100) substrates by sol–gel technique. The coated films were annealed at 750 °C by rapid thermal annealing (RAT) processes in oxygen, air and nitrogen, separately. The Cu-doped BST thin films annealed in oxygen exhibit the tunability of 48.6% at 250 kV/cm, and the dielectric constant of 923 with leakage current density of 1.82 × 10−5 A/cm2 at 150 kV/cm.

The suitable ionic radii of Mg2+ (0.72 Å) make it easy to diffuse into the lattice of BST thin films to substitute the Ti4+ ions on the B-site of the BST materials. Mg-doping modification has a positive effect on the dielectric properties of BST materials. Liu et al. [78] studied the Mg-doped Ba0.67Sr0.33TiO3 thin films grown on (110) SrRuO3/(001) SrTiO3 substrates by PLD deposition. The Mg-doped BST thin films showed a high crystalline quality but a distorted lattice with a high degree of tetragonality, which is resulted from the larger Mg2+ ions distort the crystal structure. Mg2+ ions mainly act as an acceptor-type dopant to replace Ti4+ ions on the B-site of ABO3 perovskite structure. The Mg-doped BST thin films present the dielectric constant of 385 with dielectric loss of 0.038 at 1 kHz as shown in Fig. 4a. Moreover, the Mg-doping would enhance the ferroelectric property of BST thin films as shown in Fig. 4b.

a Effects of frequency on dielectric properties of Ba0.67Sr0.33TiO3·1 wt% Mg; b P–E hysteresis loops of the Mg-doped BST films [73]

Ni2+ ions (0.69 Å) have a very similar radius to Ti4+ ions (0.68 Å) make it easy to substitute Ti ions on the B-site of BST materials. Many studies demonstrated Ni-doping could enhance the dielectric properties of BST thin films. Lim et al. [80] reported that the Ni-doped BST thin films were prepared by PLD method. The results indicated that the crystallinity of Ni-doped BST films decreased with the increase of Ni content, which attributes to the incorporation of divalent Ni2+ ions needs higher solution energies to form compensating point defects. Figure 5a presents the 1 mol% Ni-doped Ba0.6Sr0.4TiO3 thin films on MgO substrate have a large tunability of 68.7 at 133 kV/cm, the figure of merit (FOM) of 2896 and quality factor (Q) of 45 at 10 GHz. Moreover, Ding et al. [82] prepared Ni-doped BST films by sol–gel method. The results showed that dielectric constant and dielectric loss of Ni-doped BST thin films decreased with the increase of Ni content as shown in Fig. 5b. The 10 mol% Ni-doped BST thin films showed the dielectric constant of 230.25, dielectric loss of 0.015, and tunability of 30.8%. Ni-doping can decrease the dielectric loss of BST thin films as compared with the pristine BST thin films, but it also reduced their dielectric constant and tunability. It can be attributed to the small grain size increasing amounts of the grain boundaries after Ni-doping.

Co-doped BST thin films have received much attention due to its superior dielectric properties [55, 56, 88,89,90]. Xiao et al. [55] reported that Co-doped Ba0.5Sr0.5TiO3 thin films were deposited on sapphire substrates by the chemical solution deposition (CSD) method. The dielectric loss of BST thin film decreased effectively from 0.17 to 0.036 by Co-doping. However, the Co-doping also decreased Curie temperature of BST thin films and leaded to the smaller dielectric constant and tunability. Co-doped BST thin films with 5 mol% Co content have the dielectric constant of 170, tunability of 12.6%, and dielectric loss 0.0036 at 12 GHz, as shown in Fig. 6. Chen et al. [56] also studied the Co-doped Ba0.8Sr0.2TiO3 thin films with different Co contents of 0–10 mol% by sol–gel method. The Co-doped BST thin films with 5 mol% Co content have the dielectric constant of 450, tunability of 27.2%, and dielectric loss of 0.099. The densification and the grain size of the Co-doped BST thin films decreased with the increase of Co content, which contributed to the decrease of dielectric loss. The crystal structure of BST thin films was distorted and the unit cell volume was enlarged by the larger Co3+ ions (0.745 Å) substituting the smaller Ti4+ ions (0.605 Å), which would result in the decrease of dielectric constant and tunability. Although Co-doped BST thin films show a smaller dielectric loss but also smaller dielectric constant and tunability of BST thin films, which limited there application in microwave tunable devices.

The Co content dependence of a dielectric constant, b dielectric loss and c tunability of BST thin films [50]

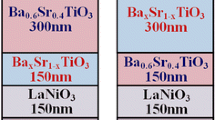

The ionic radius of Sn4+ (0.69 Å) is also very similar to Ti4+ (0.68 Å), which indicates that Sn4+ ions can easily diffuses into the lattice on the B-site of the ABO3 perovskite system. Hu et al. [91] prepared Sn-doped BST thin films on highly (200)-oriented LaNiO3 (LNO) substrates by sol–gel method. The results showed that Sn-doping can decrease the dielectric loss of the BST thin films but also reducing their dielectric constant, as shown in Fig. 7. The dielectric loss is mainly controlled by mobile electron. The Sn4+ ions will transform into Sn3+ or Sn2+ ions when doping in BST, which would lead to the reduce of oxygen vacancy and thus decreasing the dielectric loss. Moreover, the decrease of dielectric constant of Sn-doped BST thin films is attributed to the separation of Sn ions hinders the grain growth.

The frequency dependence of a dielectric constant and b dielectric loss of the Sn-doped BST thin films [86]

The suitable ionic radii of Fe3+ (0.64 Å) make it a promising candidate for BST doping modification. Ye et al. [96] prepared Fe-doped BST thin films on Pt/Ti/SiO2/Si substrate by sol–gel method. Fe-doped BST thin films with 2 mol% Fe content possessed the dielectric constant of 177, dielectric loss of 0.0159 at 10 kHz, and tunability of 45.5% at 400 kV/cm, as shown in Fig. 8. The dielectric constant of Fe-doped BST thin films decreased with the increase of Fe content is due to the smaller grain size by Fe-doping. However, Fe dopants could pin oxygen vacancies and thus decreasing the dielectric loss of BST thin films. In addition, it is worth to point out that the tunability of BST thin films is also improved by Fe-doing.

The frequency dependence of a dielectric constant and b dielectric loss of Fe-doped BST thin films; c the tunability of Fe-doped BST thin films [91]

Mn4+ ions (0.53 Å) have a small ionic radius, which make it easy to enter the lattice of BST materials and substitute the Ti4+ (0.68 Å) ions. Wang et al. [101] prepared the Mn-doped BST films on (111) Pt/Ti/SiO2/Si substrate by the metalorganic deposition (MOD) method. The dielectric properties of Mn-doped BST thin films are shown in Fig. 9. Mn-doping decreased the dielectric constant and dielectric loss of the BST films, which is due to the smaller grain size caused the reduction of the oxygen vacancy. However, the Mn-doped BST thin films do not show the dielectric tunable property, which is due to the Mn4+ ions depress the polarization of the mobile charge carriers to the applied field. Regardless, the Mn-doped BST thin films can be used for energy storage. Diao et al. also prepared the Mn-doped BST thin films by spin-coating technique [103]. The effect of Mn-doping on the ferroelectric properties and energy storage performance of the samples was investigated. The optimized energy storage performance was obtained in 3 mol% Mn-doped BST thin films with the energy storage density of 8.48 J/cm3 and energy storage efficiency of 42.4% at 1.63 MV/cm, electrical resistivity of 4.19 × 1010 Ω cm and leakage current density of 7.77 × 10−6 A/cm2 at 163 kV/cm.

The frequency dependence of a dielectric constant and loss at room temperature for the pure and Mn-doped BST films from 1 kHz to 1 MHz; b the room temperature tunability of the pure BST and Mn-doped BST films [96]

Ta5+ ions (0.64 Å) have the similar radius to Ti4+ ions (0.68 Å), which makes it is a good candidate to substitute on B-site of the BST materials. Ma et al. [105] reported the Ta-doped BST thin films deposited on Pt/SiO2/Si (100) substrates by sol–gel method. Ta-doping can effectively decreased the dielectric loss of the BST thin films. Ta-doped BST thin films with 2.7 mol% Ta content exhibited the lowest dielectric loss value of 0.072. Howevern, the dielectric constant of BST thin films was also decreased by Ta-doping, which attributed to the Ta-doping reduced the accumulation of the oxygen vacancies at the interface of the Ta-doped BST thin films and Pt electrode.

Kim et al. [106] reported that Cr-doped BST thin films showed the optimized dielectric properties. Cr-doped BST thin films were prepared by sol–gel method. The BST thin films with 5 mol% Cr-doping showed the dielectric constant of 426, dielectric loss of 0.0065, and tunability of 47.7%, as shown in Fig. 10. Hu et al. [107] reported that Cr-doped Ba0.6Sr0.4TiO3 thin films on Pt/Ti/SiO2/Si substrates by rf magnetron sputtering showed the decreased dielectric loss and increased tunability. The Cr-doped thin films with 5 mol% Cr have the best dielectric properties among the studied Cr-doped BST thin films, which have the dielectric constant of 426, tunability of 38.9%, and dielectric loss of 0.0183 at 200 kHz.

The frequency dependence of a dielectric constant and b dielectric loss of Cr-doped BST thin films; c the tunability and FOM of Cr-doped BST thin films as a function of the Cr content; d the tunability of 5 mol% Cr-doped BST thin films as a function of applied electric field [100]

W-doped BST thin films usually show a smoother surface and smaller grain size as comparison with the pristine BST thin films. However, the dielectric constant, tenability and dissipation factor decreased with increasing W content, only the figure of merit (FOM) increased after W-doping. Liang et al. [109] reported the dielectric properties of W-doped Ba0.5Sr0.5TiO3 (BST) thin films on LaNiO3 (LNO) electrode by rf magnetron sputtering. The W-doped BST films with 1 mol% W content have the dielectric constant of 239, dielectric loss of 0.0066 and tunability of 30% at 200 kV/cm, as shown in Fig. 11.

The frequency dependence of a dielectric constant of W-doped BST thin films; b loss tangent and c tunability of W-doped BST thin films as a function of applied electric field [103]

Al3+ ions (0.54 Å) have similar radius to Ti4+ ions (0.68 Å), which can be easily substituted onto the B-site of the ABO3-type perovskite BST material. Chong et al. [111] demonstrated that the Al2O3 doping played a significant role in the enhancement of dielectric properties of BST thin films, as shown in Fig. 12. Al-doping can reduce the dielectric loss of BST thin films from 0.03 to 0.011 as compared with the pristine BST thin films. However, it also reduced the dielectric constant and dielectric tunability of BST thin films. The tunability of BSTA4 (40%-Al2O3-BST) thin films was only 15.9% at 8.1 kV/cm.

The applied electric field dependence of a dielectric constant and b loss tangent of the Al2O3-doped BST films on LaAlO3 substrates [105]

Li-doped BST films through tape-casting method are studied by Zhang et al. [112]. Lithium additives can effectively decrease the sintering temperature of BaTiO3-based dielectrics. It is usually deemed as that the high sintering temperature will induce large amounts of oxygen vacancies and porosities, which may be harmful to the dielectric properties of BST materials. The substitution of Li+ for high valence Ti4+ leads to the creation of oxygen vacancies due to the ionic charge compensation, which is favorable for the mass transport during sintering and greatly promotes grain growth and densification sintering. The effects of various amounts of Li2O addition on dielectric properties of BST ceramics are firstly investigated, which demonstrates the 0.4 wt% Li2O addition is the optimum content [113, 114]. The BST films with 0.4 wt% Li2O addition presents the superior dielectric constant of 3050, dielectric loss of 0.15% at 10 kHz, FOM of 580, and a tunability of 88% at 200 kV/cm.

All of the B-site doping modifications of BST thin films mentioned above are summed up in Table 3. The appropriate ion and doping amounts are the important factors to obtain good dielectric properties. Certain doping elements can remarkably enhance the tunability and dielectric constant, meanwhile decreasing the dielectric loss of BST thin films, such as Ni, Y, and Cr doping. Especially, the Y-doped Ba0.6Sr0.4TiO3 thin films showed the best dielectric properties prepared by PLD methods among all the B-site doping modification mentioned above, which have dielectric constant of 785, tunability of 82.7% and dielectric loss of 0.032.

2.3 Multi-elements codoping

Recently, multi-elements codoping modification has attracted much attention, which may contribute to the superior dielectric properties, which cannot be obtained by single A-site or B-site doping. The codoping modifications can be divided into two kinds: one is the different doping elements in the A-site and B-site, respectively; the other is the different doping elements in the same site of BST thin films.

Firstly, we summed up the recent progress of different elements codoped separately in the A-site and B-site of BST thin films. La3+ ions and Mn3+/Mn2+ions codoped modification methods utilized to optimize the dielectric properties of BST thin films are investigated [115]. La3+ ions mainly substitute on the A-site, while Mn3+ ions substitute on the B-site. Figure 13 shows the XRD patterns of La3+ ions and Mn3+/Mn2+ ions codoped Ba0.63Sr0.37TiO3 thin films. All the studied films exhibit a pure polycrystalline perovskite structure of BST materials. Mn-doping on the B-site is beneficial to the (110) orientation. La3+ (1.36 Å) substituted Ba2+ (1.35 Å) or Sr2+ (1.13 Å) ions on the A-site of BST thin films would expand its perovskite lattice. The lattice parameters of BST-LM1 (0.6 mol% La plus 0.5 mol% Mn codoped Ba0.6Sr0.4TiO3) and BST-LM2 (0.6 mol% La plus 1.0 mol% Mn codoped Ba0.6Sr0.4TiO3) films are nearly the same, which have smaller values than that of the single La-doped BST thin films.

The XRD patterns of the pure Ba0.6Sr0.4TiO3 (pure BST), 0.6 mol% La-doped Ba0.6Sr0.4TiO3 (BST-L), 0.6 mol% La plus 0.5 mol% Mn codoped Ba0.6Sr0.4TiO3 (BST-LM1), and 0.6 mol% La plus 1.0 mol% Mn codoped Ba0.6Sr0.4TiO3 (BST-LM2) on LNO/Si substrates [106]

La-doping can significantly increase the dielectric constant of BST thin films, meanwhile which also increase their dielectric loss [71]. However, Mn-doping can optimize the dielectric loss of BST thin films [27]. Mn2+ (0.8 Å) ions have a larger ionic radius while Mn3+ (0.58 Å) ions have a smaller ionic radius, which could co-exist and substitute into the lattice position of Ti4+ (0.68 Å). La/Mn codoping could be an effective method to obtain BST thin films with high tunability and low dielectric loss. Moreover, Song et al. [115] prepared La/Mn co-doped Ba0.63Sr0.37TiO3 (BST) films on LaNiO3-coated Si substrates by rf magnetron sputtering. La/Mn codoped BST thin films showed the improved dielectric tunability (59.6%) as compared to that of the pure BST (28.2%) at 700 kV/cm. Besides the La/Mn codoped BST thin films also have the lower dielectric loss of 0.017, as shown in Fig. 14. Moreover, La/Mn co-doped BST thin films have higher FOM of 35.06 as compared with La-doped BST (tanδ = 0.0242, FOM = 26.32). It demonstrates that La/Mn codoping could be an effective method to optimize the tunability and dielectric loss of the BST thin films.

The frequency dependence of a dielectric constant and loss tangent of La/Mn codoped BST thin films; b dielectric constant and loss tangent as a function of applied electric field for the pure BST, BST-L, BST-LM1 and BST-LM2 thin films on LNO/Si at room temperature [106]

K+/Mg2+ codoped BST thin films have the better dielectric properties than that of the single K-doping or Mg-doping BST thin films, which show the higher tunability and the lower dielectric loss. Huang et al. [116] prepared K/Mg codoped Ba0.6Sr0.4TiO3 thin film by sol–gel method. K+ ions mainly substitute Sr2+ ions on the A-site, while Mg2+ ions substitute Ti4+ ions on the B-site. The K/Mg codoped BST thin films exhibit the good dielectric properties with dielectric loss of 1.17%, tunability of 32.5% at 20 V, and FOM of 23.1 at 100 kHz, as shown in Fig. 15.

The applied electric field dependence of a capacitance, b tunability, c dielectric loss and d FOM of K/Mg codoped BST thin films at 100 kHz [108]

Ce3+ and Mn2+ ions codoped BST thin films are also investigated. Ce3+ ions are apt to substitute A-site ions, which act as donor doping and make the lattice parameters decrease. Mn2+ ions incline to replace B-site ions and act as acceptor doping, which increase the lattice parameters [117,118,119]. Liao et al. [120] reported that Ce/Mn-BST thin films with various thicknesses have been prepared by improved sol–gel method. The results indicated that Ce/Mn codoped BST thin films show the decreased dielectric constant and dielectric loss as compared with pristine BST thin films, as shown in Fig. 16. The Ce/Mn codoped BST thin films show the better dielectric properties, which have dielectric loss of 0.007, permittivity of 1300, and tunability of 58%.

The applied voltage dependence of a permittivity and b dielectric loss for Ce and Mn codoped Ba0.6Sr0.4TiO3 [112]

The medium radius of Ce3+ (1.03 Å) makes it suitable to substitute the Sr2+ (1.13 Å) or Ba2+ (1.35 Å) ions on A-site, while Ni2+ (0.69 Å) ions are apt to substitute the Ti4+ (0.68 Å) ions on B-site. Ce3+ ions act as donor would decrease the lattice parameters, while Ni2+ ions act as acceptor would increase the lattice parameters. As a result, the Ce3+ and Ni2+ codoping could keep the lattice parameters of BST thin films. Kim et al. [121] reported that Ni/Ce codoped (Ba0.6Sr0.4)TiO3 on the LSCO/Pt/SiO2/Si substrates by pulsed laser deposition method, which have the dielectric constant of 298, tunability of 9.3% and the dielectric loss of 1.8%. The tunability and dielectric constant of Ni/Ce codoped BST thin films reduced sharply, which was due to the decrease of crystallization and rough surface morphologies. The decreased dielectric loss of Ni/Ce codoped BST thin films was attributed to the Ni dopant at the grain boundary.

La3+/Mg2+ codoping modification was reported by Chen et al. [122]. The La3+ ions mainly substitute Sr2+ ions and act as a donor, while Mg2+ ions substitute Ti4+ ions and act as an acceptor. The dielectric constant and leakage current of La3+/Mg2+ codoped BST thin films both decreased with the increase of the La content. The increased grain boundaries of La3+/Mg2+ codoped BST resulted in their decreased dielectric constant.

Chen et al. [123] also reported that Mg and Nb codoped on the B-site of BST thin films could keep their perovskite structure. The dielectric constant of 5% Mg-doped BST film decreased with the increase of Nb5+ content. The more Nb5+ ions entered into the structure of BST thin films would reduce the grain size of Mg-doped BST thin films, and thus in turn decrease their dielectric constant.

La and Co codoped Ba0.6Sr0.4TiO3 thin films have been investigated. La3+ ions occupy the A-site while Co3+ ions occupy the B-site, which keeps the perovskite structure of BST. Zhang et al. [123] prepared La/Co codoped Ba0.6Sr0.4TiO3 thin films by metalorganic solution deposition technique. La3+/Co3+ codoped BST thin films showed the dielectric constant of 630, dielectric loss of 0.025 and tunability of 38.4% at 12.5 kV/mm. The results indicated that La3+/Co3+ codoping have a positive effect on the dielectric properties of BST thin films, which exhibit the improved dielectric constant and tunability combined with the decrease of the dielectric loss. The uniform surface morphology and enhanced crystallinity contribute to the enhancement of their dielectric properties.

Al and W codoped on the B-site of BST thin films also can keep the perovskite structure of BST. Al3+ ions (0.535 Å) doping would decrease the lattice parameter of BST, while W6+ ions (0.62 Å) doping would increase its lattice parameter. Therefore, proportionally atomic percentage of Al3+/W6+ codoping can keep the structure and enhance the dielectric properties of BST [109]. The Al3+/W6+ codoped Ba0.5Sr0.5TiO3 were polycrystalline, which showed the decreased dielectric loss of 0.03 (0.055, the pristine BST thin films) and tunability of 19% at 40 kV/cm (33%, the pristine BST thin films) [124].

Mg and W codoped on the B-site BST thin films are studied. The Mg2+ ions can occupy both the A-site and B-site at the same times, besides which are combined with the change in oxygen vacancy behavior contributes to the enhancement of the dielectric properties of BST thin films [125, 126]. The Mg2+/W6+ codoped Ba0.5Sr0.5TiO3 thin films are polycrystalline, which show a dielectric loss of 0.03 with 25% tunability at 40 kV/cm. The BST thin films with Mg2+/W6+ and Al3+/W6+ codoping would decrease their dielectric loss, but also decrease their dielectric constant at the same time [126].

Mn2+ ions and Y3+ ions have similar radius with Ti4+ ions which prone to enter the B-site of BST materials to form acceptor doping. The studies of Mn2+/Y3+ codoping would reduce the crystal grain size of BST thin films, and in turn decreasing their dielectric loss [127,128,129,130]. Liao et al. [127] reported that 6-layer Mn2+/Y3+-BST films showed a good structure and combined with the enhanced dielectric properties, which presented the dielectric loss of 1.18%, tunability of 38%, and figure of merit (FOM) of 32.2 at 100 kHz. Wang et al. [128] also reported Mn2+/Y3+ alternately doped BST films prepared by a novel preheating process, which exhibited the dielectric loss of 0.0057, and tunability of 60.94% at 25.6 kV/mm.

Table 4 sums up and compares all the codoping modifications contribute to optimize the dielectric properties of BST thin films mentioned above. It concluded that the appropriate doping ions and doping amounts are the important factors to enhance the dielectric properties of BST thin films. The BST thin films with different ions codoping modification could obtain a large dielectric tunability, large dielectric constant and low dielectric loss at the same times, such as Mn/Y codoping and Mn/Ce codoping. The multi-elements codoped BST thin films with certain elements in appropriate amount may develop new promising ABO3 perovskite structure materials with outstanding dielectric properties.

3 Summary and outlook for future research

This paper reviewed the resent research progresses in enhancing the dielectric properties of BST thin films by doping modification and presented a summary of innovative materials design. The A-site doping modifications show a significant advantage in increasing tunability and dielectric constant of BST thin films, but which also increases their dielectric loss. The B-site doping modifications of BST thin films would obtain the decreased dielectric loss, but their dielectric constants and tunabilities are also decreased. As an improvement, the multi-elements codoping modifications combine advantages of these two kinds of single doping, which are demonstrated to effectively enhance the dielectric properties of BST thin films. The different elements codoped BST thin films with appropriate doping amounts can achieve good dielectric properties, which may develop a new type of ABO3 perovskite structure material. In other words, it may obtain the promising dielectric tunable materials with good dielectric properties to meet different microwave device applications.

As one of the most promising dielectric materials for tunable microwave applications, BST thin films must possess the balanced properties optimization such as large permittivity, high tunability, low dielectric loss, reduced leakage characteristics, and good temperature stability. It is critical to continue material research solutions to optimize the properties of BST thin films meet the development of the next generation RF-microwave devices/systems. Additionally, the enhanced film growth techniques, large area low cost relevant substrates, and the stable electrode metallization are also the important factors for the development of the BST thin film based RF-microwave devices/systems.

References

P. Bao, T. Jackson, X. Wang, M. Lancaster, Barium strontium titanate thin film varactors for room-temperature microwave device applications. J. Phys. D Appl. Phys. 41, 63001–63002 (2008)

S. Bin-Omran, Phase-transition character in (Ba0.5Sr0.5)TiO3 nanodots from first principles. J. Alloy. Comp. 674, 82–88 (2016)

C. Carlson, T. Rivkin, P. Parilla, J. Perkins, D. Ginley, A. Kozyrev, V. Oshadchy, A. Pavlov, Large dielectric constant (ε/ε0 > 6000) BaO4SrO6TiO3 thin films for high-performan cemicrowave phase shifters. Appl. Phys. Lett. 76, 1920–1922 (2000)

F. Zimmermann, M. Voigts, C. Weil, R. Jakoby, P. Wang, W. Menesklou, E. IversTiffee, Investigation of barium strontium titanate thick films for tunable phase shifters. J. Eur. Ceram. Soc. 21, 2019–2023 (2001)

A. Ahmed, I. Goldthorpe, A. Khandani, Electrically tunable materials for microwave applications. Appl. Phys. Rev. 2(1), 1–18 (2015)

G. Saddik, J. Son, S. Stemmer, R. York, Improvement of barium strontium titanate solidly mounted resonator quality factor by reduction in electrode surface roughness. J. Appl. Phys. 109(9), 91606–91609 (2011)

Y. Hui, L. Li, W. Zhang, D. Xu, H. Dong, Investigation on tunable performance of BMN/BST multilayer and BMN–BST composite thin films. J. Am. Cerem. Soc. 98(3), 819–823 (2015)

L. Sengupta, J. Synowcyznski, L. Chiu, Investigation of the effect of particle size on the optical and electronic properties of Ba1–xSrxTiO3 composite ceramics. Integrated Ferroelectrics 17(1–4), 287–296 (1997)

M. Lancaster, J. Powell, A. Porch, Thin-film ferroelectric microwave devices. Super. Sci. Technol. 11(11), 1323–1334 (1999)

O. Vendik, E. Hollmann, A. Kozyrev, A. Prudan, Ferroelectric tuning of planar and bulk microwave devices. J. Super. 12(2), 325–338 (1999)

X. Xi, H. Li, W. Si, A. Sirenko, I. Akimov, J. Fox, A. Clark, J. Hao, Oxide thin films for tunable microwave devices. J. Electroceramics 4(2–3), 393–405 (2000)

F. Miranda, F. Wankeuls, R. Romanofsky, C. Mueller, S. Alterovitz, G. Subramanyam, Ferroelectric thin films-based technology for frequency and phase-agile microwave communication applications. Integrated Ferroelectrics 42(1), 131–149 (2002)

S. Baik, N. Setter, Auciello, Science of ferroelectric thin films and application to devices. J. Appl. Phys. 100(5), 270–284 (2006)

D. Korn, H. Wu, A comprehensive review of microwave system requirements on thin-film ferroelectrics. Integrated Ferroelectrics 24(1–4), 215–237 (1999)

A. Tagantsev, V. Sherman, K. Astafiev, J. Venkatesh, N. Setter, Ferroelectric materials for microwave tunable applications. J. Electroceramics 14(3), 199–203 (2005)

A. Vorobiev, P. Rundqvist, K. Khamchane, S. Gevorgian, Silicon substrate integrated high Q-factor parallel-plate ferroelectric varactors for microwave/millimeterwave applications. Appl. Phys. Lett. 83, 3144–3146 (2003)

C.J.G. Meyers, C.R. Freeze, S. Stemmer, R.A. York, Effect of BST film thickness on the performance of tunable interdigital capacitors grown by MBE. Appl. Phys. Lett. 111, 262903 (2017)

R.D. Paolis, F. Coccetti, G. Guegan, S. Payan, M. Maglione, Characterization of ferroelectric BST MIM capacitors up to 65 GHz for a compact phase shifter at 60 GHz, Proc. Eur. Mic. Conf. (2014) 492–495

K.K. Karnati, Y. Shen, M.E. Trampler, S. Ebadi, P.F. Wahid, X. Gong, A BST-integrated capacitively loaded patch for Ka- and X-band beam steerable reflect array antennas in satellite communications. IEEE Trans. Antennas Propagation. 63(4), 1324–1333 (2015)

M. Sazegar, Y. Zheng, H. Maune, C. Damm, X. Zhou, R. Jakoby, Compact tunable phase shifters on screen-printed BST for balanced phased arrays. IEEE Trans. Micro. Theory Technol. 59(12), 3331–3337 (2011)

M. Kang, K. Cho, S. Oh, Y. Do, C. Kang, Low-temperature crystallization and electrical properties of BST thin films using excimer laser annealing. C. App. Phy. 11, S66–S69 (2011)

D. Levasseur, H. El-Shaarawi, S. Pacchini, A. Rousseau, S. Payan, G. Guegan, M. Maglione, Systematic investigation of the annealing temperature and composition effects on the dielectric properties of sol–gel BaxSr1−xTiO3 thin films. J. Eur. Cer. Soc. 33, 139–146 (2013)

X. Zhou, M. Sazegar, F. Stemme, J. Haußelt, R. Jakoby, J. Binder, Correlation of the microstructure and microwave properties of Ba0.6Sr0.4TiO3 thick-films. J. Eur. Cer. Soc. 32, 4311–4318 (2012)

S. Ezhilvalavan, T. Tseng, Progress in the developments of (Ba, Sr)TiO3 (BST) thin films for Gigabit era DRAMs. Mater. Chem. Phys. 65(3), 227–248 (2000)

K. Ahn, S. Baik, S. Sang, Significant suppression of leakage current in (Ba, Sr)TiO3 thin films by Ni or Mn doping. J. Appl. Phys. 92(5), 2651–2654 (2002)

M. Cole, C. Hubbard, E. Ngo, M. Ervin, M. Wood, R. Geyer, Structure–property relationships in pure and acceptor-doped Ba1−xSrxTiO3 thin films for tunable microwave device applications. J. Appl. Phys. 92(1), 475–483 (2002)

M. Jain, S. Majumder, R. Katiyar, F. Miranda, F. Keuls, Improvement in electrical characteristics of graded manganese doped barium strontium titanate thin films. Appl. Phys. Lett. 82(12), 1911–1913 (2003)

W. Lee, H. Kim, Electrical properties of barium strontium titanate (BST) thin films deposited on various PT-base electrodes. Integrated Ferroelectrics 11(1), 111–119 (1995)

J. Juuti, Multilayer BST-COC composite with enhanced high frequency dielectric properties. Ferroelectrics 387(1), 210–215 (2009)

W. Hu, C. Yang, W. Zhang, Y. Qiu, Dielectric characteristics of sol–gel-derived BST/BSLaT/BST multilayer. J. S-G. Sci. Technol. 36(3), 249–255 (2005)

K. Jim, D. Wang, C. Leung, C. Choy, H. Chan, One-dimensional tunable ferroelectric photonic crystals based on Ba0.7Sr0.3TiO3/MgO multilayer thin films. J. Appl. Phys. 103(8), 83107–83113 (2008)

H. Tian, Y. Wang, D. Wang, J. Miao, J. Qi, H. Chan, C. Choy, Dielectric properties and abnormal C–V characteristics of Ba05Sr05TiO3–Bi15ZnNb15O7 composite thin films grown on MgO (001) substrates by pulsed laser deposition. Appl. Phys. Lett. 89(14), 1–3 (2006)

E. Cukauskas, S. Kirchoefer, J. Pond, Low-loss Ba0.5Sr0.5TiO3 thin films by inverted cylindrical magnetron sputtering. J. Appl. Phys. 88(5), 2830–2835 (2000)

S. Halder, T. Schneller, R. Meyer, R. Waser, Effect of ozone treatment on the electrical properties of (Ba0.7Sr0.3)TiO3 thin films. J. Appl. Phys. 97(11), 114904–114909 (2005)

S. Manavalan, Structural and electrical properties of barium strontium titanate thin films for tunable microwave applications (University of South Florida, New York, 2005), pp. 4–9

M. Chiu, H. Yao, C. Huang, F. Shieu, Improvement of dielectric properties of Ba0.6Sr0.4TiO3 thin films by MgO doping. J. Appl. Phys. 102(1), 935–1010 (2007)

H. Kim, M. Lim, H. Kim, I. Kim, Characterization of Ni-doped BST thin films on LSCO buffer layers prepared by pulsed laser deposition. Elect. Sol-State. Lett. 7(2), J1–J3 (2004)

X. Li, K. Choy, I. Harrison, Co-doped BST thin films for tunable microwave applications. Surf. Coat. Technol. 205(8), 2989–2993 (2011)

X. Luo, J. Chen, Y. Fan, Z. Hu, Q. Zheng, Effect of Rb-doping on the dielectric and tunable properties of Ba0.6Sr0.4TiO3 thin films prepared by sol–gel. Ceram. Inter. 42, 17229–17236 (2016)

J. Liao, X. Wei, Z. Xu, P. Wang, Effect of potassium-doped concentration on structures and dielectric performance of barium–strontium–titaniumfilms. Vacuum 107(3), 29–296 (2014)

S. Wang, M. Guo, T. Liu, S. Guo, M. Li, X. Zhao, Effect of K-doping on the dielectric and tunable properties of Ba0.6Sr0.4TiO3 thin films prepared by RF magnetron sputtering. J. Crystal. Grow. 306, 22–26 (2007)

R. Upadhyay, S. Annam, M. Patel, U. Joshi, Influence of aliovalent doping on dielectric properties of Ba0.6Sr0.4TiO3 thin film for voltage tunable applications. Integrated Ferroelectrics 167, 184–191 (2015)

K. Sekhar, S. Key, K. Hong, S. Chan, M. Jong, S. Dong, C. Jun, C. Jong, S. Yong, Thickness-dependent tunable characteristics of (Ba0.5Sr0.5)0.925K0.075TiO3 thin films prepared by pulsed laser deposition. Curr. Appl. Phys. 12, 654–658 (2012)

K. Sekhar, S. Key, K. Hong, S. Chan, M. Jong, S. Dong, C. Jun, C. Jong, S. Yong, Enhanced dielectric and tunable characteristics of K-doped Ba0.5Sr0.5TiO3 thin films prepared by pulsed laser deposition. Thin. Sold. Film. 527, 267–272 (2013)

J. Li, D. Jin, L. Zhou, J. Cheng, Dielectric properties of Barium Strontium Titanate (BST) ceramics synthesized by using mixed-phase powders calcined at varied temperatures. Mater. Lett. 76, 100–102 (2012)

L. Zhang, J. Zhai, X. Yao, Dielectric properties of barium strontium titanate thick films prepared by electrophoretic deposition. Mater. Res. Bull. 44, 1058–1061 (2009)

J. Qiu, G. Liu, J. Wolfman, C. Autret-Lambert, S. Roger, J. Gao, Structure and dielectric characteristics of continuous composition spread Ba1–xSrxTiO3 thin films by combinatorial pulsed laser deposition. Ceram. Integrated 142, 6408–6412 (2016)

C. Mao, S. Yan, S. Cao, C. Yao, F. Cao, G. Wang, X. Dong, X. Hu, C. Yang, Effect of grain size on phase transition, dielectric and pyroelectric properties of BST ceramics. J. Eur. Ceram. Soc. 34, 2933–2939 (2014)

R. Upadhyay, K. Jalaja, U. Joshi, Structural and electrical properties of Ba06 Sr04 TiO3 thin film on LNO/Pt bottom electrode. AIP. Con. Pro. 1837(1), 1–5 (2017)

C. Lee, Y. Oh, D. Lee, D. Choi, Influence of annealing temperature on the dielectric properties of BaSrTiO3 thin films deposited on various substrates. J. Kor. Phys. Soc. 69(10), 1571–1574 (2016)

J. Wang, T. Zhang, R. Pan, J. Jiang, Z. Ma, C. Xiang, Investigation on the dielectric properties of (Ba, Sr)TiO3 thin films on hybrid electrodes. Mater. Chem. Phys. 121, 28–31 (2010)

S. Fuentes, E. Chávez, L. Padilla-Campos, D. Diaz, Influence of reactant type on the Sr incorporation grade and structural characteristics of Ba1−xSrxTiO3 (x = 0−1) grown by sol–gel–hydrothermal synthesis. Ceram. Inter. 39, 8823–8831 (2013)

W. Qin, J. Zhu, J. Xiong, J. Tang, W. Jie, X. Wei, Y. Zhang, Y. Li, Electrical behavior of Y-doped Ba0.6Sr0.4TiO3 thin films. J. Mater. Sci: Mater. Electr. 18, 1217–1220 (2007)

L. Gao, X. Yang, L. Zhang, X. Yao, Structure and dielectric properties of Ca-doped (Ba0.7Sr0.3) TiO3 thin films fabricated by sol–gel method. J. Electr. 21, 645–648 (2008)

L. Xiao, K. Choy, I. Harrison, Co-doped BST thin films for tunable microwave applications. Sur. Coat. Technol. 205, 2989–2993 (2008)

C. Chen, A. Wei, Y. Li, K. Zhou, D. Zhang, Improved tunable properties of Co doped Ba0.8Sr0.2TiO3 thin films prepared by sol–gel method. J. Alloy Comp. 692, 204–211 (2017)

K. Kim, C. Kim, D. Senior, D. Kim, Y. Yoon, Microwave characteristics of sol–gel based Ag-doped (Ba0.6Sr0.4)TiO3 thin films. Thin Solid Film 565, 172–178 (2014)

I. Reddy, C. Reddy, M. Cho, J. Shim, Morphological and chemical structure of silver doped barium strontium titanate thin films fabricated via pulsed laser deposition. Mater. Res. Exp. 4(7), 076406 (2017)

K. Kim, C. Kim, Electrical and dielectric properties of Ce-doped Ba0.6Sr0.4TiO3 thin films. Sur. Coa. Technol. 200, 4708–4712 (2006)

S. Wang, B. Cheng, C. Wang, S. Redfern, S. Dai, K. Jin, H. Lu, Y. Zhou, Z. Chen, G. Yang, Influence of Ce doping on leakage current in Ba0.5Sr0.5TiO3 films. J. Phys. D: Appl. Phys. 38, 2253–2257 (2005)

M. Sedlar, M. Sayer, L. Weaver, Sol–gel processing and properties of cerium doped Barium Strontium Titanate thin films. J. Sol-Gel. Sci. Technol. 5(3), 201–210 (1995)

S. Basu, A. Verma, D. Agrawal, Y. Mohapatra, R. Katiyar, Effect of uniform and periodic doping by Ce on the properties of barium strontium titanate thin films. J. Electr. 19(2), 229–236 (2007)

Y. Zeng, H. Zhang, S. Jiang, M. Shi, W. Lu, Fabrication and characteristics of Pb doped BST ferroelectric thin films for uncooled infrared focal plane arrays. Integrated Ferroelectrics 82, 91–99 (2006)

V. Mudinepalli, S. Song, B. Murty, Microwave sintering effect on structural and dielectrical properties of Ba1–x(Sr/Pb)xTiO3 (x = 02 for Sr and Pb) ceramics. J. Mater. Sci: Mater. Elect. 24, 2141–2150 (2013)

S. Yun, X. Wang, B. Li, D. Xu, Dielectric properties Ca-substituted barium strontium titanate ferroelectric ceramics. Sol. Stat. Commun. 143, 461–465 (2007)

M. Cole, P. Joshi, M. Ervin, La doped Ba1−xSrxTiO3 thin films for tunable device applications. J. Appl. Phys. 89(11), 6336–6340 (2001)

J. Chen, La doping effect on the dielectric property of barium strontium titanate glasse ceramics. J. Mater. Sci. Technol. 30(3), 95–298 (2014)

S. Hao, C. Wang, D. Fu, J. Zhang, Y. Wei, W. Wang, Preparation and characterization of La-doped Ba(1−x)SrxTiO3 powders and thin films. Thin Solid Films 518, 5645–5648 (2010)

W. Hu, C. Yang, W. Zhang, Fabrication and characteristics of La, Cd and Sn doped BST thin films by sol–gel method. J. Mater. Sci: Mater. Electr. 19(12), 1197–1201 (2008)

R. Liang, X. Dong, Y. Chen, F. Cao, Y. Wang, Effect of La2O3 doping on the tunable and dielectric properties of BST/MgO composite for microwave tunable application. Mater. Chem. Phys. 95(2), 222–228 (2006)

S. Hao, C. Wang, D. Fu, J. Zhang, Y. Wei, W. Wang, Preparation and characterization of La-doped Ba1–xSrxTiO3 powders and thin films. Thin Sold Film 518(20), 645–5648 (2010)

M. Cole, P. Joshi, M. Ervin, La doped (Ba1-xSrx)TiO3 thin films for tunable device application. J. Appl. Phys. 89, 6336–6340 (2001)

T. Ha, J. Kim, S. Kim, W. Kim, Enhanced tenability and electrical properties of Ba0.7Sr0.3TiO3 thin films by Cu-doping. Integrated Ferroelectrics 86(1), 77–84 (2006)

S. Yun, S. Koo, J. Ha, J. Koh, Influence of CuO addition to (Ba0.5, Sr0.5)TiO3 ceramics on sintering behavior and dielectric properties. Ferroelectrics 403(1), 19–25 (2010)

Y. Lee, Y. Huang, Effects of CuO doping on the microstructural and dielectric properties of Ba0.6Sr0.4TiO3 ceramics. J. Am. Cerem. Soc. 92(11), 2661–2667 (2009)

R. Laishram, K. Singh, C. Prakash, Enhanced dielectric loss of Mg doped Ba0.7Sr0.3TiO3 ceramics. Cerem. Integrated 42, 14970–14975 (2016)

Y. Huang, Y. Wu, W. Qiu, J. Li, X. Chen, Enhanced energy storage density of Ba0.4Sr0.6TiO3-MgO composite prepared by spark plasma sintering. J. Eur. Cerem. Soc. 35, 1469–1476 (2015)

H. Liu, J. Zhu, Q. Chen, P. Yu, D. Xiao, Enhanced ferroelectric properties of Mg doped (Ba,Sr)TiO3 thick films grown on (001) SrTiO3 substrates. Thin Solid Film. 520(9), 3429–3432 (2012)

K. Yoon, J. Lee, D. Kang, C. Song, Y. Seo, Electrical properties of Mg doped (Ba0.5Sr0.5)TiO3 thin films. Jpn. J. Appl. Phys. 40(9B), 5497–5500 (2014)

M. Lim, H. Kim, N. Kim, H. Kim, I. Kim, S. Moon, M. Kwak, H. Ryu, S. Lee, frequency and voltage dependent dielectric properties of Ni-doped Ba0.6Sr0.4TiO3 thin films. J. Electr. 13, 239–243 (2004)

A. Kakumani, B. Ruthramurthy, H. Wong, Microstructure and dielectric properties of nickel-doped Ba0.7Sr0.3TiO3 ceramics fabricated by sol–gel method. Integrated J. Appl. Cerem. Technol. 13(1), 177–184 (2016)

S. Ding, X. Yang, X. Yao, The influence of Ni doping on the properties of BST ferroelectric thin film. Ferroelectrics 385(1), 135–140 (2009)

Y. Oh, E. Choi, S. Yoon, Microwave tunable properties of Ni-doped (BaSr)TiO3 thin films grown by pulsed laser deposition. Integrated Ferroelectrics 55(1), 877–885 (2003)

H. Seo, Y. Kim, G. Lucovsky, I. Kim, K. Chung, H. Kobayashi, D. Choi, Enhanced leakage current properties of Ni-doped Ba0.6Sr0.4TiO3 thin films driven by modified band edge state. J. Appl. Phys. 107, 24109–24116 (2010)

Y. Kim, J. Kim, D. Choi, J. Hong, I. Kim, Electrically stable low voltage operating ZnO thin film transistors with low leakage current Ni-doped Ba0.6Sr0.4TiO3 gate insulator. J. Elect. 23(1), 76–79 (2009)

X. Liao, H. Wang, X. Pan, J. Xiang, J. Zhang, Z. Tian, Surface structures and dielectric properties of yttrium-doped barium strontium titanate films by improved sol–gel method. J. Inorg. Mater. 24(2), 387–391 (2009)

J. Xu, H. Liu, B. He, H. Hao, Y. Li, M. Cao, Z. Yu, Dielectric properties of Y-doped Ba1–xSrxTiO3 ceramics. Opt. Appl. 40(1), 255–264 (2010)

S. Wang, B. Cheng, W. Can, H. Lu, Y. Zhou, Z. Chen, G. Yang, Dielectric properties of Co-doped Ba0.5Sr0.5TiO3 thin films fabricated by pulsed laser deposition. J. Cry. Gro. 259(1–2), 137–143 (2003)

L. Gao, J. Zhai, X. Yao, The influence of Co doping on the dielectric, ferroelectric and ferromagnetic properties of Ba0.7Sr0.3TiO3 thin films. Appl. Sur. Sci. 255(8), 4521–4525 (2009)

F. Stemme, M. Bruns, H. Geßwein, M. Schroeder, M. Sazegar, M. Drahus, R.A. Eichel, F. Paul, C. Azucena, J. Binder, Fabrication and characterization of iron and fluorine co-doped BST thin films for microwave applications. J. Mater. Sci. 48, 3586–3596 (2013)

W. Hu, C. Yang, X. Liu, W. He, X. Tang, Characterization of Sn-doped BST thin films on LaNiO3-coated Si substrate. J. Mater. Sci: Mater. Electr. 19, 61–66 (2008)

J.Y. Ha, L. Lin, D.Y. Jeong, S.J. Yoon, J.W. Choi, Improved figure of merit of (Ba, Sr)TiO3-based ceramics by Sn substitution. Jpn. J. Appl. Phys. 48(011402), 1–4 (2009)

I. Souza, A. Simoes, E. Longo, J. Varela, Synthesis of Ba0.5Sr0.5(Ti0.8Sn0.2)O3 prepared by the soft chemical method. Mater. Lett. 61, 4086–4089 (2007)

I. Souza, L. Cavalcante, J. Sczancoski, F. Moura, C. Paiva-Santos, J. Varela, A. Simoes, E. Longo, Structural and dielectric properties of Ba0.5Sr0.5(SnxTi1−x)O3 ceramics obtained by the soft chemical method. J. Alloy Comp. 477(1), 877–882 (2009)

I. Gong, J. Cheng, W. Zhu, S. Yu, W. Wu, Z. Meng, Improvement in dielectric and tunable properties of Fe doped Ba0.6Sr0.4TiO3 thin films grown by pulsed-laser deposition. IEEE. Trans. Ultrason. Ferric. 54(12), 2579–2582 (2007)

Y. Ye, T. Guo, Dielectric properties of Fe-doped Ba0.65Sr0.35TiO3 thin films fabricated by the sol–gel method. Ceramics Integrated 35, 761–2765 (2009)

Z. Guo, L. Pan, C. Bi, H. Qiu, X. Zhao, L. Yang, M. Yasir, Structural and multiferroic properties of Fe-doped Ba0.5Sr0.5TiO3 solids. J. Magnetism. Magnetic. Mater. 325, 24–28 (2013)

O. Nur, M. Willander, Q. Muhammad, F.G. Desouky, El Salem, A. Mohamed, A. Hamad, B. AIi, K. Inas, Effect of elevated concentrations of strontium and iron on the structural and dielectric characteristics of Ba(1–x–y)Sr(x)Ti Fe(y)O3 prepared through sol–gel technique. Phys. B: Phys. Conc. Mater. 407(14), 2697–2704 (2012)

M. Asad, N. Abdul, U. Asad, Mn-doped Ba0.45Sr0.55TiO3 ceramic systems dielectric and impedance spectroscopic characterization. Int. J. Appl. Cerem. Technol. 13(6), 1084–1089 (2016)

J. Cui, G. Dong, Z. Yang, J. Du, Low dielectric loss and enhanced tunable properties of Mn-doped BST/MgO composites. J. Alloy Comp. 490, 353–357 (2010)

X. Wang, S. Lv, C. Zhang, Q. Hu, L. Li, The structural and electrical properties of Mn-doped Ba0.6Sr0.4TiO3 films prepared by metal organic deposition method. J. Alloy Comp. 576, 262–264 (2013)

M. Kwak, Y. Kim, S. Moon, H. Ryu, S. Lee, K. Kang, Microwave properties of Mn Doped (Ba1-x,Srx)TiO3 thin films for tunable phase shifter. Integrated Ferroelectrics 66(1), 283–289 (2004)

C. Diao, H. Liu, H. Hao, M. Cao, Z. Yao, Enhanced recoverable energy storage density of Mn-doped Ba0.4Sr0.6TiO3 thin films prepared by spin-coating technique. J. Mater. Sci.: Mater. Electron. 29, 5814–5819 (2018)

Y. Fan, S. Yu, R. Sun, L. Li, Y. Yin, K. Wong, R. Du, Microstructure and electrical properties of Mn-doped barium strontium titanate thin films prepared on copper foils. Appl. Surf. Sci. 256, 6531–6535 (2010)

C. Ma, L. Shan, F. Wang, Dielectric properties for tantalum-doped strontium barium titanate thin films prepared by sol–gel method. Integrated Ferroelectrics 176(1), 220–227 (2016)

K. Kim, C. Kim, The effect of Cr doping on the microstructural and dielectric properties of (Ba0.6Sr0.4)TiO3 thin films. Thin Sol. Film 472, 26–30 (2005)

M. Hu, Y. Zhuo, S. Wang, Y. Tian, Study on dielectric and tunable properties of Cr-doped Ba0.6Sr0.4TiO3 thin films by RF sputtering. J. Mater. Sci. 43, 3162–3165 (2008)

Z. Potucek, Luminescence properties of BaSrTiO3 thin films deposited by RF hollow cathode plasma jet system. Ferroelectrics 335(1), 95–102 (2006)

C. Liang, J. Wu, Electrical properties of W-doped (Ba0.5Sr0.5)TiO3 thin films. J. Cry. Gro. 274, 173–177 (2005)

M. Zhang, J. Zhai, B. Shen, X. Yao, Microwave dielectric properties of low loss and highly tunable Ba0.5Sr0.5Ti1-3y/2WyO3 ceramics. J. Mater. Res. 27(6), 910–914 (2012)

K. Chong, L. Kong, L. Chen, L. Yan, C. Tan, T. Yang, C. Ong, T. Osipowicz, Improvement of dielectric loss tangent of Al2O3 doped Ba0.5Sr0.5TiO3 thin films for tunable microwave devices. J. Appl. Phys. 95(3), 1416–1419 (2004)

X. Zhang, X. Zuo, Y. Niu, H. Xiong, X. Zuo, Low temperature sintering and nonlinear dielectric properties of lithium-doped Ba0.6Sr0.4TiO3 thick films prepared by tape-casting. J. Mater. Sci.: Mater. Electron. 30, 3488 (2019)

L. Zhao, B. Zhang, P. Zhou, L. Zhu, J. Li, Effect of Li2O addition on sintering and piezoelectric properties of (Ba, Ca)(Ti, Sn)O3 lead-free piezoceramics. J. Eur. Ceram. Soc. 35, 533–540 (2015)

M. Valant, D. Suvorov, R.C. Pullar, K. Sarma, N.M. Alford, A mechanism for low-temperature sintering. J. Eur. Ceram. Soc. 26(13), 2777–2783 (2006)

L. Song, Y. Chen, G. Wang, L. Yang, T. Li, F. Gao, X. Dong, Dielectric properties of La/Mn codoped Ba0.63Sr0.37TiO3 thin films prepared by RF magnetron sputtering. Ceramics Integrated 40, 12573–12577 (2014)

J. Huang, J. Liao, W. Zhang, S. Wang, H. Yang, M. Wu, Structures and dielectric properties of K and Mg alternately doped BST films. Integrated Ferroelectrics 162(1), 94–101 (2015)

A. Tkach, P. Vilarinho, A. Kholkin, Structure–microstructure–dielectric tunability relationship in Mn-doped strontium titanate ceramics. Act. Mater. 53, 5061–5069 (2005)

J. Liao, Z. Xu, X. Wei, B. Wei, P. Wang, B. Yang, Influence of preheating on crystallization and growing behavior of Ce and Mn doped Ba0.6Sr0.4TiO3 film by sol–gel method. Surf. Coal Technol. 206(22), 4518–4524 (2012)

J. Liao, P. Wang, X. Wei, B. Yang, Preparation and dielectric properties of cerium and manganese codoped Ba0.6Sr0.4TiO3 ferroelectric films. Integrated Ferroelectrics 144(1), 107–111 (2013)

J. Liao, S. Wang, X. Wei, Z. Xu, P. Wang, Improved mechanisms for excellent tunable microwave Ce and Mn codoped Ba0.6Sr0.4TiO3 thin films. Integrated Ferroelectrics 152(1), 104–112 (2014)

H. Kim, I. Kim, M. Lim, C. Lee, M. Kim, H. Kim, Characterization of Ni/Ce Co-doped BST thin film grown on LSCO/Pt electrodes prepared by pulsed laser deposition. Integrated Ferroelectrics 55, 923–931 (2003)

S. Chen, H. Wang, L. Huang, Electrical properties of Mg/La, Mg/Nb Co-Doped (Ba0.7Sr0.3)TiO3 thin films prepared by metallo-organic deposition method. Jpn. J. App. Phy. 40(8), 4974–4978 (2001)

Y. Zhang, G. Wang, Y. Chen, F. Cao, L. Yang, X. Dong, Effect of donor, acceptor, and donor-acceptor codoping on the electrical properties of Ba0.6Sr0.4TiO3 thin films for tunable device applications. J. Am. Ceram. Soc. 92(11), 2759–2761 (2009)

J. Oh, S. Delprat, M. Ismail, M. Chaker, E. Djoumessi, K. Wu, Improvement of Ba0.5Sr0.5TiO3 thin films microwave properties using doping with Mg–W and Al–W. Integrated Ferroelectrics 112, 24–32 (2010)

J. Saal, J. Andelm, W. Nothwang, M. Cole, The impact of acceptor dopant and oxygen vacancy defects on the lattice of barium strontium titanate. Integrated Ferroelectrics 101, 142–151 (2008)

S. Xu, Y. Qu, C. Zhang, Effect of Mg2+ content on the dielectric properties of Ba0.65-xSr0.35MgxTiO3 ceramics. J. Appl. Phys 106, 14107–14112 (2009)

W. Zhang, J. Liao, J. Huang, Influence of film thickness on dielectric properties of Y and Mn alternately doped BST films. Integrated Ferroelectrics 152, 97–103 (2014)

S. Wang, J. Liao, Y. Hu, F. Gong, Z. Xu, M. Wu, Structures and dielectric performances of Mn/Yalternately doped BST films prepared by a novel preheating process. Mater. Chem. Phy. 193, 50–56 (2017)

J. Liao, X. Wei, Z. Xu, X. Wei, P. Wang, The structure and dielectric properties of a novel kind of doped Ba0.6Sr0.4TiO3 film. Mater. Chle. Phys. 135, 1030–1035 (2012)

H. Qiang, Z. Xu, Low dielectric loss and enhanced tunable properties of donor–acceptor co-doped Ba0.67Sr0.33TiO3 ceramics. J. Mater. Sci. Mater. Elec. 27, 9976–9980 (2016)

Acknowledgements

The authors grateful acknowledge the support from the Natural Science Foundation of China (Grant No. 51602037) and the Open Foundation of State Key Laboratory of Electronic Thin Films and Integrated Devices (KFJJ201510).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, L., Guan, Z., Huang, S. et al. Enhanced dielectric properties of barium strontium titanate thin films by doping modification. J Mater Sci: Mater Electron 30, 12821–12839 (2019). https://doi.org/10.1007/s10854-019-01670-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01670-w