Abstract

Chromium (III) oxide (Cr2O3) nanoparticles are generated by thermal treatment (calcination) of precursor materials such as chromium nitrate along with a poly (vinyl pyrrolidone) capping agent. The samples produced were characterised by various techniques, including X-ray diffraction (XRD), energy dispersive X-ray spectroscopy (EDX), transmission electron microscopy (TEM) and Fourier transform infrared spectroscopy (FT-IR). Examination results obtained from XRD showed that Cr2O3 nanoparticles exhibit hexagonal crystalline structures, with the presence of Cr and O in these novel materials being confirmed by results of analyses of both EDX and FT-IR. Results of TEM have pointed out that the average nanoparticle size was noticeably increased from 28 to 46 nm in relation to increase of calcination temperature of a range between 500 and 800 °C. The surface composition and valence state of the produced nanoparticles were examined by X-ray photoelectron spectroscopy (XPS), the optical energy gap has been evaluated using UV–visible reflectance spectra with the help of Kubelka–Munk equation. The energy band gap had a reversely proportional relationship with calcination temperature with a reduction in energy band gap from 3.12 to 3.01 eV. Photoluminescence (PL) spectra indicated an increase in photoluminescence with increasing particle size. The antibacterial activity of the Cr2O3 nanoparticles was evaluated in-vitro using gram-negative Escherichia coli ATCC 25922 and gram-positive Bacillus subtilis UPMC 1175.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Recent progress in nanoscience have facilitated the development of numerous novel devices, structures, systems and nanoplatforms with a variety of applications in several different fields [1, 2]. Many applications are designed to take advantage of the physical and chemical features associated with structural characteristics of nanoparticles [3, 4]. For instance, the increased use of metal oxide nanostructures the development of biocompatible, biodegradable and functionalized nanomaterials provides an appealing topic for research [5,6,7,8]. In particular, the unique individual or combined features of chromium (III) oxide (Cr2O3) led several researchers to investigate its use as a semiconductor nanomaterial [9,10,11,12,13,14]. Chromium (III) oxide, also known as eskolaite or chromia, is referred to as a II–VI composite semiconductor because it is composed of elements from Groups II and VI of the Periodic Table. It has direct and indirect energy band gaps of 3.00 eV and 3.40 eV, respectively [15, 16]. The unique morphology of the chromia nanoparticles, involving an atypical hexagonal crystalline structure in association with a metal p-type oxide, along with the high melting point, good high-temperature electrical conductivity and superior corrosion resistance of this nanomaterial, has led to its consideration as a potentially beneficial electrode material for resistive sensors [13, 17, 18]. Indeed, a range of applications can benefit from these distinctive properties of Cr2O3 nanomaterials [19,20,21]. Moreover, solar photovoltaics equipment has found to be in a pellucid form by the area of the observable solar spectrum [22,23,24]. Other nanostructure characteristics have been exploited by biomedical, catalytic, gas sensing and diode applications [25,26,27,28].

A number of methods for the preparation of Cr2O3 nanostructures exist, including microwave irradiation [29], the sol–gel method [30], the precipitation method [31,32,33,34], the electrochemical method [35], the hydrothermal route [36,37,38,39], the solvothermal method [40], and the co-precipitation method [41]. However, none of these methods is able to generate the required product as as a powder form in highly purit. Moreover, production of the requisite Cr2O3 nanopowder on an industrial scale is challenged by complications in the synthetic process, such as the need for increased reaction times, as well as reagent toxicity and the generation of effluent by-products. Finally, no published studies have been found dealing with the production of Cr2O3 nanoparticles by thermal treatment in which the antibacterial activities were also examined. Recently, thermal treatment technique has been successfully used in our laboratory to produce signal and binary metal oxides [42,43,44,45,46,47,48,49,50].

The novelty of present research is that this technique (thermal treatment) offers various advantages such as thermal treatment can be used without the associated production of waste Cr2O3 nanoparticle by-products. In addition, the preparation method presented herein is therefore environmentally and economically beneficial. Other advantages include effective particle size control, reliable quality, good adaptability, simpler handling, and the generation of powder products with attractive band gap properties without the need for additional chemical agents.

In brief, the present paper describes a unique thermal-based production methodology capable of exclusively synthesising Cr2O3 nano-powder. Furthermore, this paper has reported effects of calcination temperature changing with Cr2O3 nano-powder properties e.g., morphological, structural and optical features. This technique involved the use of a chloride metallic ion precursor along with a poly (vinyl pyrrolidone) or PVP capping agent with a calcination stage to produce the pure final product. The structure and antimicrobial properties of the final product were examined using a range of analytical techniques.

2 Materials and methodology

2.1 Materials

The experimental work has used three essential materials which are as follows: Chromium (III) nitrate nonahydrate (Cr(NO3)3·9H2O, Mw = 400.15 g/mol), Poly (vinyl pyrrolidone) (PVP, (C6H9NO)n, Mw = 58,000 g/mol), and Deionised water.

These materials were the standard research grade, supplied by Sigma-Aldrich (USA) and they have been used without pre-treatment or further purification.

2.2 Methodology

Solutions were prepared by dissolving PVP (4 g) in 100 ml of deionised water and stirring vigorously at 70 °C for 2 h. Chromium (III) nitrate nonahydrate (0.2 mmol) was then added to each solution and thoroughly mixed. The resulting homogeneous solutions were then poured onto glass plates and oven-dried at 80 °C for 24 h. The resulting solids were ground with a mortar and pestle for 0.5 h to generate powders which were then calcined in a box furnace for 3 h at various temperatures. The resulting chromium (III) oxide (Cr2O3) nanoparticles were then characterised as described in the following subsection.

2.3 Characterisation

In this section, morphological, structural and optical properties of Cr2O3 nanoparticles were examined using several techniques which are as follows: TGA, XRD, TEM, FTIR, EDX, XPS, UV, and PL. TGA was was performed using a Mettler Toledo TGA/SBTA851e. The heating rate was 10 °C min−1 with nitrogen gas flow rate of 200 cm3 min−1. As for XRD, a Shimadzu 6000 model diffractometer under CuKα radiation with a wavelength (λ) of 0.154 nm over the 2θ range 4–80° was used to examine the crystalline structure. FTIR spectroscopy was performed using (Perkin Elmer model 1650) over the range of 280–4000 cm−1. TEM images were acquired using (JEOL TEM model 2010F UHR) with an acceleration voltage of 200 kV. EDX spectroscopy was performed using an EDX spectrometer (7353, Oxford Instruments, UK). XPS has been performed using a ULVAC-PHI Quantera II (Ulvac-PHI, Inc) with following conditions monochromatic AlKα (hυ = 1486.6 eV) at 25.6 W with a beam diameter of 100 µm. Also, a pass energy of 280 eV with 1 eV per step was used to perform a wide scan analysis. At C 1 s, and prior to deconvolution, charge correction was done while C–C and C–H binding energies were set to 284.8 eV. At room temperature over a wavelength range of between 200 and 800 nm, a UV–vis spectrophotometer (Model: Shimadzu UV-3600) was used in order to evaluate nanoparticles optical properties. At room temperature, a Perkin Elmer spectrofluorometer (LS-55) with a Xenon lamp was implemented,photoluminescence (PL) of products have been analysed. The antimicrobial activity of the Cr2O3 nanoparticles was studied by evaluating colony forming units after incubation on a suitable agar plate medium, as detailed in the following subsection.

2.4 Evaluation of antimicrobial activity

A disc diffusion method was used to evaluate antibiotic effectiveness of Cr2O3 nanoparticles against bacterial infections by an in vitro antimicrobial test. Thus, a comparison of the response of a microorganism to various antimicrobial compounds in terms of sensitivity could be carried out.

Specifically, prepared nanoparticles activity against gram-negative Escherichia coli ATCC 25922 and gram-positive Bacillus subtilis UPMC 1175 has been evaluated. Mueller–Hinton agar media has been done as nutrient. For each bacterium Streptomycin (100 mg/ml) standard was used as a positive control and distilled water was used as a negative control.

In this examined procedure, a 6 mm-diameter paper disc was immersed in a suspension containing 100 mg of each nanoparticle sample in 10 ml of deionised water. The discs were then dried and incubated on plates in order to enable microbes’ growth. The dynamical behaviour of microbe is standardised as per 0.5 McFarland turbidity standard; approximately 108 cells. In this procedure also, at 37 ± 0.5 °C, plates were inverted and incubated for 2 days to enable sufficient bacteria growth. After incubation, an evaluation process has been carried out for every plate. Their inhibition zone diameters have been measured to nearest millimetre. Every evaluation test was performed in triplicate and the average was reported as the result.

Furthermore, the antibacterial test of the ready bulk chromium (III) oxide has been compared to prepared nanoparticles.

3 Results and discussion

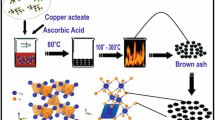

3.1 Nanoparticles growth mechanism

The behaviour and growth mechanism of the nanoparticles during calcination is shown schematically in Fig. 1. The use of PVP was initially intended for stabilising complex metallic salts by electrostatic and steric stabilisation of the methylene groups and the amide groups of the pyrrolidone rings. The metallic ions are trapped and suppressed during the mixing process by an ionic-dipole interaction with the amine groups in the polymer chains. The metallic cations then become stationary in the polymer cavity due to removal of H2O during drying. Subsequently, and during calcination, the organic components are decomposed to gaseous products such as N2, NO, CO or CO2. Also, during calcination, the PVP influences the nucleation of the chromium oxide nanoparticles. In the absence of PVP, an Ostwald ripening mechanism would cause the nanoparticles to continue growing in size as the surface energy increases. The role of PVP at this stage is that of steric stabilisation, thereby suppressing coagulation of the nanoparticles [51,52,53,54]. Hence, the addition of PVP functions as a method for decreasing the nanoparticle grain size by hindering and avoiding breakdown of the metal ions on the nanoparticle surface [42, 55,56,57,58,59,60,61,62].

3.2 Thermogravimetric analysis

Important data relating to the choice of a suitable calcination temperature is obtained by thermal analysis of the metal nitrate and the PVP. Figure 2 presents the thermogram obtained by TGA-DTG analysis of the un-calcined sample. This indicates two episodes of weight loss—the first taking place due to loss of water at around 88 °C, and the second (more substantial) weight loss taking place at approximately 432 °C due to the organic (PVP) decomposition [57]. At 325 °C, the weight loss starts, this was assumed to be caused by decomposition of NOx compounds. The resulting Cr2O3 nanoparticles were pure and stable at 492 °C. These results indicate that the optimum annealing temperature for the generation of Cr2O3 nanoparticles is above 492 °C.

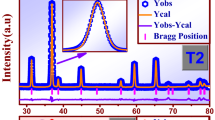

3.3 Structural analysis by XRD

The XRD patterns of the Cr2O3 nanoparticles before and after calcination are presented in Fig. 3. The broad spectrum obtained for the un-calcined sample (Fig. 3) demonstrates that Cr2O3 nanoparticles were not yet formed and the behaviour was that of an amorphous material. After calcination at temperatures greater than or equal to 500 °C (Fig. 3b–e) the XRD patterns displayed sharper peaks, indicating the formation of Cr2O3 nanoparticles. The peaks were seen to increase in intensity while becoming sharper and narrower during calcination, indicating enhanced crystallinity of the Cr2O3 nanoparticles at higher temperatures. This effect is explained by the change in the crystallite surface-area to volume ratio with increasing particle size, as demonstrated by the TEM images (Fig. 4, Sect. “TEM analysis”). The data presented in Table 1 indicate the increase in crystallite size with increasing temperature; indeed, the comparatively high crystallite size provides good confirmation of the crystalline character of the material [63]. Moreover, the polymer and temperature play an important role in determining the crystallite size. It is interesting, that in the preparation of nanoparticles using different temperatures and polymer play a dominant role in control crystalline size. In the present work, PVP and temperatures mediated samples (Fig. 3b–e) having high intensity peaks in the XRD patterns, show larger crystallite size due to their high temperature compared to those of an less temperatures (Fig. 3b–c). Among the prepared samples crytallite sizes, samples c, d and e showed the higher in terms of the controlled size, than those of the others.

The crystallite size was investigated by examining the position of the Bragg’s lines of the Cr2O3 nanoparticles. With reference to JCPDS Card 38-1479, the presence of multiple diffraction peaks of (006), (010), (012), (018), (024), (030), (104), (110), (113), (202), (211), (214) and (220) in the diffraction patterns suggests that the Cr2O3 sample displays a characteristic hexagonal structure. The crystallite sizes of the samples ranged from 27 to 43 nm. These were calculated for the most intense peak (012) according to Scherrer’s equation:

where the Scherrer constant K = 0.9, the wavelength of the X-ray irradiation λ = 1.5418 Å; θ is the diffraction angle and β is the FWHM of the XRD peak.

3.4 TEM analysis

The microstructure of the Cr2O3 nanoparticles was examined by transmission electron microscopy (TEM). The TEM images of the Cr2O3 nanoparticles calcined at various temperatures are presented in Fig. 4, indicating a generally uniform spherical morphology. As previously mentioned, the nanoparticle size increases significantly with increasing calcination temperature due to the aggregation of neighbouring particles in response to increasing surface energy at higher temperatures [64, 65]. The consistency of this result demonstrates the effectiveness of PVP in controlling the particle size via an agglomeration–suppression mechanism in a variety of Cr2O3 nanoparticles. The XRD and TEM results are compared in Table 1, which indicates the correlation between the calcination temperature and the particle sizes of 28 nm and 46 nm. Hence, the effectiveness of PVP for particle stabilisation, nucleation, growth and uniformity is clearly established. The PVP is subsequently used to constrain the particle size and circumvent nanoparticle aggregation [54, 60,61,62, 66].

3.5 EDX analysis

Figure 5 presents the EDX spectra of the Cr2O3 nanoparticles after calcination at various temperatures. The results clearly indicate the presence of the elements Cr and O, as the respective peaks are clearly visible. Moreover, the atomic percentages of Cr and O are 39.57% and 60.43 respectively and demonstrates that the final product is pure chromium (III) oxide. Furthermore, this atomic percentage of Cr and O is established only in the final product.

3.6 FTIR analysis

Figure 6 presents the FTIR spectrum of the un-calcinated and calcined Cr2O3 samples obtained at 280–4000 cm−1. In Fig. 6a, all absorption peaks relating to the organic compounds and the Cr2O3 nanoparticles can be seen. The spectrum of the un-calcined sample displayed absorption peaks corresponding to the bond stretching vibrations of N–H (3 414 cm−1), C–H (2 945 cm−1) and C=O (1 646 cm−1) [65]. In addition, the absorption peak at 1 428 cm−1 was assigned to the bending vibration of the methylene C–H, the peak at 1 277 cm−1 was assigned to the C–N stretching vibration, the peaks at 839 cm−1 and 639 cm−1 were due to the vibrations of the C–C ring bonds and to C–N=O bending, respectively, while the peak 540 cm−1 was due to the O–Cr–O vibration [10, 26, 34, 67].

For the calcined sample, the single absorption peak is believed to indicate the production of exceptionally pure chromium (III) oxide nanoparticles. This is also indicated by a shift in the wave number of the absorption for the Cr2O3 nanoparticles with increasing calcination temperature. This calcination effect is backed up by the enhancement in crystallinity of the produced chromium (III) oxide nanoparticles. Figure 6 therefore demonstrates that the calcination-related change leads to characteristic sharper peaks indicative of a more pronounced crystalline nature of the produced nanoparticles with increasing calcination temperature.

3.7 XPS analysis

The phase compositions and chemical state of the Cr and O species were investigated by X-ray photoelectron spectroscopy (XPS). The high resolution XPS spectra for Cr 2p1/2 (binding energy 584.5 eV) and Cr 2p3/2 (binding energy 577.4 eV) are indicated in Fig. 7a. This result is comparable to previous reports [68,69,70]. The deconvoluted O 1 s spectrum in Fig. 7b shows a binding energy of 529.8 eV, which corresponds to Cr2O3 [71]. These results demonstrate that each element is present in the nanoparticles with the pure oxidation states corresponding to chromium (III) oxide and that there are no impurities present.

3.8 UV–vis diffuse reflectance spectra (DRS)

Energy band gaps were determined from diffuse reflectance spectra of Cr2O3 NPs samples calcined at different temperatures by plotting the square of the Kubelka–Munk function F(R)2 against energy and extrapolating the linear part of the curve to F(R)2 = 0 as shown in Fig. 8. This indicates that the direct band gap energy for chromium (III) oxide nanoparticles has been obtained. As shown in Table 1, the energy band gaps decreased with increasing calcination temperature. This is thought to be the result of quantum size effects, although it could be due to transitions of the d-shell electrons in the Cr3+ ions between the partially filled valance band and the conduction band [72]. Moreover, the increase in calcination temperature may result in an increase in the number of defect states and, hence, to a change in the absorption coefficient. The absorption of photons generates electron–hole pairs which generate a field that may, in turn, change the electronic structure and optical properties of the nanomaterial. Eliminating the influence of particle size upon the band gap therefore presents a challenge. The particle size reduction has made possibility in changing the band structure and material properties as well. Conversely, Cr2O3 NPs size was increased with band gap reduction so that, at higher energy dynamical behaviours. In this, conduction bands of the s-electrons and p-electrons are separated. Hence, overlap could be noticeable under conditions involving smaller particle sizes. At a Fermi level distance, usually this is remote from its particle centre, the electron conduction’s nuclear potential is minimal therefore any transition with allowed quantum numbers leads to absorption in energy equals to the conduction band energy.

3.9 Photoluminescence

The photoluminescence (PL) spectra for the chromium (III) oxide nanoparticles prepared in the presence of PVP at various calcination temperatures are shown in Fig. 9.

In all the samples a broad emission peak was observed in the range of ~ 425–487 nm, which was attributed to the high purity and perfect crystallinity of the as-synthesized of the Cr2O3 nanoparticles using PVP. However, the emission peak was located at ~ 425 nm, which can be attributed to the transition involving 3d3 electrons of the Cr3+ ions [40, 73]. Moreover, oxygen vacancies are the most dominant defect centers in the oxide materials and give rise to photoluminescence emission by recombination with an electron, and the peak appears higher at a higher tempertures which may be attributed to the oxygen vacancies. It is believed that the emission wavelength of the oxide material depends mainly on the particles size and morphology. According to these results, it was concluded that this product nanoparticles prepared by using PVP at different temperatures show well dispersed fine particles, with control crystalline sizes. Moreover, the PL results reveal that the as-synthesized Cr2O3 nanoparticles are good candidate material for UV-light emitter using nanolasers, and in optical storage systems in the future [29, 72]. The observed rise in the PL intensity owing to rising temperature, until a maximal of 800 °C, was caused by improved crystallinity.

3.10 Antibacterial activity

Images in Fig. 10 illustrate the antimicrobial activities of the bulk Cr2O3 and the Cr2O3 nanoparticles against gram-negative Escherichia coli ATCC 25922 and gram-positive Bacillus Subtilis UPMC 1175. The diameters of the inhibition zones on the agar plates were recorded in millimetres (mm). The results presented in Fig. 11, the mean values of three repeat tests on the treated samples. It can be seen that the bulk chromium (III) oxide suspensions (5) exhibited lower antimicrobial activity, while the Cr2O3 nanoparticle suspensions calcined at 500 °C (1), 600 °C (2), 700 °C (3) and 800 °C (4) all exhibited enhanced antimicrobial activity.

A number of mechanisms have been suggested to explain the enhanced antimicrobial activity of the Cr2O3 nanoparticles. For example, it is proved that the antimicrobial activity has enhanced with the presence of Cr2O3 nanoparticle size [26, 35]. Alternatively, the antimicrobial activity may be influenced in some way by the Cr3+ ions. Either of these suggested mechanisms could lead to the antimicrobial activity of the Cr2O3 nanoparticles, which has been demonstrated fatal for the E. coli E26 and Bacillus subtilis B29 strains. The previously demonstrated high bactericidal activity of the Cr2O3 nanoparticles is retained even after treatment with peroxides, which is generally believed to interfere with antimicrobial action [74]. A possible explanation is that the bacterial surface membrane is completely surrounded by the metal oxide nanoparticles. It is interesting to note that more research projects aimed at addressing cell inhibition have focused on Cr2O3 nanoparticles than on standard antibiotics.

Several researches have revealed that nanoparticles have greater activity against Gram-positive bacteria than against Gram-negative bacteria, because the cell wall of Gram-negative bacteria is composed of lipopolysaccharides (LPS), lipoproteins, and phospholipids, which form a penetration barrier that allows the entrance of only macromolecules. In contrast, the cell wall of Gram-positive bacteria includes a thin layer of peptidoglycan as well as teichoic acid and abundant pores that allow foreign molecules to penetrate, resulting in cell membrane damage and cell death. In addition, compared with Gram-negative bacteria, Gram-positive bacteria have a high negative charge on the cell wall surface, which can attract nanoparticles [75,76,77,78]. Hence, small size of nanoparticle at low temperatures can penetrate, spread and damage the bacterial cell wall and as contrary in large size of nanoparticles which produced at high temperatures as in the present study (see Fig. 10).

4 Conclusions

The present report has demonstrated that chromium (III) oxide nanoparticles can be effectively generated by approaches involving thermal treatment. The hexagonal nanocrystalline chromium (III) oxide particles generated at various calcination temperatures were examined by XRD analysis. The nanoparticle size was shown to increase from 24 nm to 47 nm as the calcination temperature is varied from 500 to 800 °C. The relative proportions of Cr and O atoms in the initial mixture and in the product was examined by EDX analysis, while the characteristic vibrational modes of Cr–O were identified in the FT-IR spectrum. Examination by UV–vis absorption spectrophotometry demonstrated that the optical bandgap decreased with increasing calcination temperatures. Finally, the luminescence spectra indicated that the intensity of photoluminescence increased with increasing particle size. This demonstrated the potential usefulness of the nanoparticles for absorbing particular wavelengths of solar energy, thereby suggesting a potential application in solar cell technology.

The present work showed that an inhibition zone of 17 mm presents good antimicrobial action against gram-positive Bacillus subtilis UPMC 1175. Additional tests established that the proposed methodology is superior to other procedures and is applicable to a few number nanotechnological applications.

References

L. Dykman, N. Khlebtsov, S. Shchyogolev, I. Goryacheva, T. Rusanova, T. Smirnova, E. Zhelobitskaya, K. Brainina, N. Stozhko, M. Bukharinova, Nanoanalytics: nanoobjects and nanotechnologies in analytical chemistry (Walter de Gruyter GmbH & Co KG, Berlin, 2018)

N.A. Singh, Nanotechnology innovations, industrial applications and patents. Environ. Chem. Lett. 15, 185–191 (2017)

T.D. Dunbar, Method for making electronic devices using metal oxide nanoparticles, in, Google Patents, 2009

M. Vukomanović, Chap. 28 - advanced nanocomposites with noble metal antimicrobial nanoparticles: how to design a balance among antimicrobial activity, bioactivity, and safe delivery to the place of infection, in Nanostructures for antimicrobial therapy, ed. by A. Ficai, A.M. Grumezescu (Elsevier, Amsterdam, 2017), pp. 623–651

X. Liu, J. Iocozzia, Y. Wang, X. Cui, Y. Chen, S. Zhao, Z. Li, Z. Lin, Noble metal–metal oxide nanohybrids with tailored nanostructures for efficient solar energy conversion, photocatalysis and environmental remediation. Energy Environ. Sci. 10, 402–434 (2017)

M.B. Tahir, G. Nabi, M. Rafique, N. Khalid, Nanostructured-based WO3 photocatalysts: recent development, activity enhancement, perspectives and applications for wastewater treatment. Int. J. Environ. Sci. Technol. 14, 2519–2542 (2017)

N. Anicˇić, M. Vukomanović, T. Koklicˇ, D. Suvorov, Fewer defects in the surface slows the hydrolysis rate, decreases the ROS generation potential, and improves the non-ROS antimicrobial activity of MgO, Small, 14, 1800205 (2018)

N. Anicˇić, M. Vukomanović, T. Koklicˇ, D. Suvorov, MgO Antibacterial properties: fewer defects in the surface slows the hydrolysis rate, decreases the ROS generation potential, and improves the non-ROS antimicrobial activity of MgO (Small 26/2018), Small, 14, 1870123 (2018)

C.M. Welch, R.G. Compton, The use of nanoparticles in electroanalysis: a review. Anal. Bioanal Chem. 384, 601–619 (2006)

P. Gibot, L. Vidal, Original synthesis of chromium (III) oxide nanoparticles. J. Eur. Ceram. Soc. 30, 911–915 (2010)

Z.C. Zhong, R.H. Cheng, J. Bosley, P.A. Dowben, D.J. Sellmyer, Fabrication of chromium oxide nanoparticles by laser-induced deposition from solution. Appl. Surf. Sci. 181, 196–200 (2001)

M. Horie, K. Nishio, S. Endoh, H. Kato, K. Fujita, A. Miyauchi, A. Nakamura, S. Kinugasa, K. Yamamoto, E. Niki, Chromium (III) oxide nanoparticles induced remarkable oxidative stress and apoptosis on culture cells. Environ. Toxicol. 28, 61–75 (2013)

S. Sangeetha, R. Basha, K.J. Sreeram, S.N. Sangilimuthu, B.U. Nair, Functional pigments from chromium(III) oxide nanoparticles. Dyes Pigments 94, 548–552 (2012)

R.F.K. Gunnewiek, C.F. Mendes, R.H.G.A. Kiminami, Synthesis of Cr2O3 nanoparticles via thermal decomposition of polyacrylate/chromium complex. Mater. Lett. 129, 54–56 (2014)

M. Julkarnain, J. Hossain, K. Sharif, K. Khan, Optical properties of thermally evaporated Cr2O3 thin films. Can. J. Chem. Eng. Technol. 3, 81–85 (2012)

Y. Guo, S.J. Clark, J. Robertson, Electronic and magnetic properties of Ti2O3, Cr2O3, and Fe2O3 calculated by the screened exchange hybrid density functional. J. Phys. 24, 325504 (2012)

G. An, Y. Zhang, Z. Liu, Z. Miao, B. Han, S. Miao, J. Li, Preparation of porous chromium oxide nanotubes using carbon nanotubes as templates and their application as an ethanol sensor. Nanotechnology 19, 035504 (2007)

P. Jayamurugan, R. Mariappan, K. Premnazeer, S. Ashokan, Y.S. Rao, N.S. Rao, C. Shanmugapriya, Investigation of annealing temperature on structural and morphological properties of Cr2O3 nanoparticles for humidity sensor application. Sens. Imaging 18, 22 (2017)

M. Palimi, M. Rostami, M. Mahdavian, B. Ramezanzadeh, Application of EIS and salt spray tests for investigation of the anticorrosion properties of polyurethane-based nanocomposites containing Cr2O3 nanoparticles modified with 3-amino propyl trimethoxy silane. Prog. Org. Coat. 77, 1935–1945 (2014)

S.-W. Choi, A. Katoch, J.-H. Kim, S.S. Kim, Prominent reducing gas-sensing performances of n-SnO2 nanowires by local creation of p–n heterojunctions by functionalization with p-Cr2O3 nanoparticles. ACS Appl. Mater. Interfaces 6, 17723–17729 (2014)

S. Lei, X. Peng, Z. Liang, X. Li, C. Wang, B. Cheng, Y. Xiao, L. Zhou, Self-template formation and properties study of Cr 2 O 3 nanoparticle tubes. J. Mater. Chem. 22, 1643–1651 (2012)

S. Khamlich, O. Nemraoui, N. Mongwaketsi, R. McCrindle, N. Cingo, M. Maaza, Black Cr/α-Cr2O3 nanoparticles based solar absorbers. Phys. B 407, 1509–1512 (2012)

T.W. Kim, S.G. Hur, S.J. Hwang, H. Park, W. Choi, J.H. Choy, Heterostructured visible Lightn active photocatalyst of chromia nanoparticle layered titanate. Adv. Funct. Mater. 17, 307–314 (2007)

S. Ma, Y. Xu, X. Cheng, X. Zhang, S. Gao, H. Zhao, L. Huo, Green and facile synthesis of porous hierarchical Cr2O3/N-doped carbon composite with high Li-ion battery anodic performance. Int. J. Electrochem. Sci. 13, 6048–6058 (2018)

H. Ma, Y. Xu, Z. Rong, X. Cheng, S. Gao, X. Zhang, H. Zhao, L. Huo, Highly toluene sensing performance based on monodispersed Cr2O3 porous microspheres. Sens. Actuators B 174, 325–331 (2012)

C. Ramesh, K. Mohan Kumar, N. Latha, V. Ragunathan, Green synthesis of Cr2O3 nanoparticles using Tridax procumbens leaf extract and its antibacterial activity on Escherichia coli. Curr. Nanosci. 8, 603–607 (2012)

A.H. Shah, E. Manikandan, M.B. Ahamed, D.A. Mir, S.A. Mir, Antibacterial and Blue shift investigations in sol–gel synthesized CrxZn1 – xO Nanostructures. J. Lumin. 145, 944–950 (2014)

T.-W. Chiu, Y.-C. Yang, A.-C. Yeh, Y.-P. Wang, Y.-W. Feng, Antibacterial property of CuCrO2 thin films prepared by RF magnetron sputtering deposition. Vacuum 87, 174–177 (2013)

F. Farzaneh, Synthesis and characterization of Cr2O3 nanoparticles with triethanolamine in water under microwave irradiation. J. Sci. Islam. Repub. Iran 22, 329–333 (2011)

V. Balouria, A. Singh, A. Debnath, A. Mahajan, R. Bedi, D. Aswal, S. Gupta, Synthesis and characterization of sol-gel derived Cr2O3 nanoparticles, in: AIP Conference Proceedings, AIP, 2012, pp. 341–342

S.A. Makhlouf, Z.H. Bakr, H. Al-Attar, M.S. Moustafa, Structural, morphological and electrical properties of Cr2O3 nanoparticles. Mater. Sci. Eng. 178, 337–343 (2013)

I. Esparza, M. Paredes, R. Martinez, A. Gaona-Couto, G. Sanchez-Loredo, L.M. Flores-Velez, O. Dominguez, Solid state reactions in Cr2O3-ZnO nanoparticles synthesized by triethanolamine chemical precipitation. Mater. Sci. Appl. 2, 1584 (2011)

W. Zhao, H. Zhang, J. Liu, X. Deng, Y. Bi, S. Zhang, Preparation of Cr2O3 nanoparticles via surfactants-modified precipitation method and their catalytic effect on nitridation of silicon powders. J. Ceram. Soc. Jpn. 125, 623–627 (2017)

V.S. Jaswal, A.K. Arora, J. Singh, M. Kinger, V.D. Gupta, Synthesis and characterization of chromium oxide nanoparticles. Orient. J. Chem. 30, 559–566 (2014)

S. Rakesh, S. Ananda, N. Gowda, Synthesis of chromium (III) oxide nanoparticles by electrochemical method and Mukia maderaspatana plant extract, characterization, KMnO4 decomposition and antibacterial study. Mod. Res. Catal. 2, 127–135 (2013)

Z. Pei, H. Xu, Y. Zhang, Preparation of Cr2O3 nanoparticles via C2H5OH hydrothermal reduction. J. Alloys Compd. 468, L5–L8 (2009)

Z. Pei, Y. Zhang, A novel method to prepare Cr2O3 nanoparticles. Mater. Lett. 62, 504–506 (2008)

G.H. Mohammed, T.B. Hassan, Z.T. Abdulhamied, Structural characterization of NiO/Cr2O3 composites and hydrothermal synthesis, properties gas sensing. J. Al-Nahrain Univ.-Sci. 21, 59–64 (2018)

A.S. Gomes, N. Yaghini, A. Martinelli, E. Ahlberg, A micro-Raman spectroscopic study of Cr (OH) 3 and Cr2O3 nanoparticles obtained by the hydrothermal method. J. Raman Spectrosc. 48, 1256–1263 (2017)

K. Anandan, V. Rajendran, Studies on structural, morphological, magnetic and optical properties of chromium sesquioxide (Cr2O3) nanoparticles: synthesized via facile solvothermal process by different solvents. Mater. Sci. Semicond. Process. 19, 136–144 (2014)

J. Singh, V. Verma, R. Kumar, Structural and optical studies of Mg doped nanoparticles of chromium oxide (Cr2O3) synthesized by co-precipitation method, in: AIP Conference Proceedings, AIP Publishing, 2018, pp. 120013

N.M. Al-Hada, H.M. Kamari, A.A. Baqer, A.H. Shaari, E. Saion, Thermal calcination-based production of SnO2 nanopowder: an analysis of SnO2 nanoparticle characteristics and antibacterial activities. Nanomaterials 8, 250 (2018)

A.A. Baqer, K.A. Matori, N.M. Al-Hada, A.H. Shaari, H.M. Kamari, E. Saion, J.L.Y. Chyi, C.A.C. Abdullah, Synthesis and characterization of binary (CuO) 0.6 (CeO2) 0.4 nanoparticles via a simple heat treatment method. Results Phys. 9, 471–478 (2018)

A.A. Baqer, K.A. Matori, N.M. Al-Hada, A.H. Shaari, E. Saion, J.L.Y. Chyi, Synthesis, Structural and Optical Properties of Cerium Oxide Nanoparticles Prepared by Thermal Treatment Method, in: Solid State Phenomena, Trans Tech Publ, 2017, pp. 132–137

S.A. Gene, E. Saion, A.H. Shaari, M.A. Kamarudin, N.M. Al-Hada, A. Kharazmi, Structural, optical, and magnetic characterization of spinel zinc chromite nanocrystallines synthesised by thermal treatment method, J. Nanomater, 2014 (2014)

M. Hashem, E. Saion, N.M. Al-Hada, H.M. Kamari, A.H. Shaari, Z.A. Talib, S.B. Paiman, M.A. Kamarudeen, Fabrication and characterization of semiconductor nickel oxide (NiO) nanoparticles manufactured using a facile thermal treatment. Results Phys. 6, 1024–1030 (2016)

A. Salem, E. Saion, N.M. Al-Hada, H.M. Kamari, A.H. Shaari, S. Radiman, Simple synthesis of ZnSe nanoparticles by thermal treatment and their characterization. Results Phys. 7, 1175–1180 (2017)

L.B. Zakiyah, E. Saion, N.M. Al-Hada, E. Gharibshahi, A. Salem, N. Soltani, S. Gene, Up-scalable synthesis of size-controlled copper ferrite nanocrystals by thermal treatment method. Mater. Sci. Semicond. Process. 40, 564–569 (2015)

N.M. Al-Hada, E. Saion, A. Shaari, M. Kamarudin, S.A. Gene, The influence of calcination temperature on the formation of zinc oxide nanoparticles by thermal-treatment. Appl. Mech. Mater. 446, 181–184 (2014)

N.M. Al-Hada, H.M. Kamari, A.H. Shaari, E. Saion, Fabrication and characterization of Manganese–Zinc Ferrite nanoparticles produced utilizing heat treatment technique. Results Phys. 12, 1821 (2019)

N.M. Al-Hada, E.B. Saion, A.H. Shaari, M.A. Kamarudeen, M.H. Flaifel, S.A. Gene, Synthesis, structural and morphological properties of cadmium oxide nanoparticles prepared by thermal treatment method, in: Advanced Materials Research, Trans Tech Publ, 2015, pp. 291–294

A. Salem, E. Saion, N.M. Al-Hada, H.M. Kamari, A.H. Shaari, C.A.C. Abdullah, S. Radiman, Synthesis and characterization of CdSe nanoparticles via thermal treatment technique. Results Phys 7, 1556–1562 (2017)

N.M. Al-Hada, E. Saion, H.M. Kamari, M.H. Flaifel, A.H. Shaari, Z.A. Talib, N. Abdullahi, A.A. Baqer, A. Kharazmi, Structural, morphological and optical behaviour of PVP capped binary (ZnO) 0.4 (CdO) 0.6 nanoparticles synthesised by a facile thermal route. Mater. Sci. Semicond. Process. 53, 56–65 (2016)

N. Izu, T. Uchida, I. Matsubara, T. Itoh, W. Shin, M. Nishibori, Formation mechanism of monodispersed spherical core–shell ceria/polymer hybrid nanoparticles. Mater. Res. Bull. 46, 1168–1176 (2011)

A.A. Baqer, K.A. Matori, N.M. Al-Hada, H.M. Kamari, A.H. Shaari, E. Saion, J.L.Y. Chyi, Copper oxide nanoparticles synthesized by a heat treatment approach with structural, morphological and optical characteristics. J. Mater. Sci. 29, 1025 (2017)

A.A. Baqer, K.A. Matori, N.M. Al-Hada, A.H. Shaari, H.M. Kamari, E. Saion, J.L.Y. Chyi, C.A.C. Abdullah, Synthesis and characterization of of binary (CuO) 0.6 (CeO2) 0.4 nanoparticles via a simple heat treatment method. Results Phys. 9, 471 (2018)

A.A. Baqer, K.A. Matori, N.M. Al-Hada, A.H. Shaari, E. Saion, J.L.Y. Chyi, Effect of polyvinylpyrrolidone on cerium oxide nanoparticle characteristics prepared by a facile heat treatment technique. Results Phys. 7, 611–619 (2017)

H.M. Kamari, N.M. Al-Hada, E. Saion, A.H. Shaari, Z.A. Talib, M.H. Flaifel, A.A.A. Ahmed, Calcined solution-based PVP influence on ZnO semiconductor nanoparticle properties. Crystals 7, 2 (2017)

N.M. Al-Hada, H.M. Kamari, C.A.C. Abdullah, E. Saion, A.H. Shaari, Z.A. Talib, K.A. Matori, Down-top nanofabrication of binary (CdO) x (ZnO) 1–x nanoparticles and their antibacterial activity. Int. J. Nanomed. 12, 8309 (2017)

K.M. Koczkur, S. Mourdikoudis, L. Polavarapu, S.E. Skrabalak, Polyvinylpyrrolidone (PVP) in nanoparticle synthesis. Dalton Trans. 44, 17883–17905 (2015)

N.T. Thanh, N. Maclean, S. Mahiddine, Mechanisms of nucleation and growth of nanoparticles in solution. Chem. Rev. 114, 7610–7630 (2014)

N. Visaveliya, J.M. Köhler, Control of shape and size of polymer nanoparticles aggregates in a single-step microcontinuous flow process: a case of flower and spherical shapes, Langmuir, 30, 12180–12189 (2014)

M. Abdullah, F.M. Rajab, S.M. Al-Abbas, Structural and optical characterization of Cr2O3 nanostructures: evaluation of its dielectric properties. AIP Adv. 4, 027121 (2014)

N.M. Al-Hada, E.B. Saion, A.H. Shaari, M.A. Kamarudin, M.H. Flaifel, S.H. Ahmad, A. Gene, A facile thermal-treatment route to synthesize the semiconductor CdO nanoparticles and effect of calcination. Mater. Sci. Semicond. Process. 26, 460–466 (2014)

N.M. Al-Hada, E.B. Saion, A.H. Shaari, M.A. Kamarudin, M.H. Flaifel, S.H. Ahmad, S.A. Gene, A Facile Thermal-treatment route to synthesize ZnO nanosheets and effect of calcination temperature. PLoS ONE 9, e103134 (2014)

N.M. Al-Hada, E. Saion, Z.A. Talib, A.H. Shaari, The Impact of polyvinylpyrrolidone on properties of cadmium oxide semiconductor nanoparticles manufactured by heat treatment technique. Polymers 8, 113 (2016)

K. Prashanth, S. Mahesh, M.N. Prakash, L. Munirathnamma, S. Ningaraju, H. Ravikumar, R. Somashekar, B. Nagabhushana, Solution combustion synthesis of Cr2O3 nanoparticles and derived PVA/Cr2O3 nanocomposites-positron annihilation spectroscopic study. Mater. Today 3, 3646–3651 (2016)

J. Dai, J. Tang, H. Xu, L. Spinu, W. Wang, K. Wang, A. Kumbhar, M. Li, U. Diebold, Characterization of the natural barriers of intergranular tunnel junctions: Cr2O3 surface layers on CrO 2 nanoparticles. Appl. Phys. Lett. 77, 2840–2842 (2000)

X. Li, J. Cao, W. Zhang, Stoichiometry of Cr (VI) immobilization using nanoscale zerovalent iron (nZVI): a study with high-resolution X-ray photoelectron spectroscopy (HR-XPS). Indus. Eng. Chem. Res. 47, 2131–2139 (2008)

B. Sone, E. Manikandan, A. Gurib-Fakim, M. Maaza, Single-phase α-Cr2O3 nanoparticles’ green synthesis using Callistemon viminalis’ red flower extract. Green Chem. Lett. Rev. 9, 85–90 (2016)

W.S. Zhang, E. Brück, Z.D. Zhang, O. Tegus, W.F. Li, P.Z. Si, D.Y. Geng, K.H.J. Buschow, Structure and magnetic properties of Cr nanoparticles and Cr2O3 nanoparticles. Phys. B 358, 332–338 (2005)

H. Cao, X. Qiu, Y. Liang, M. Zhao, Q. Zhu, Sol-gel synthesis and photoluminescence of p-type semiconductor Cr 2 O 3 nanowires. Appl. Phys. Lett. 88, 241112 (2006)

A. Murtazaev, I. Kamilov, K.K. Aliev, Finite-size scaling and critical exponents of the real antiferromagnetic model. J Magn. Magn. Mater. 204, 151–158 (1999)

R. Kohen, A. Nyska, Invited review: Oxidation of biological systems: oxidative stress phenomena, antioxidants, redox reactions, and methods for their quantification. Toxicol. Pathol. 30, 620–650 (2002)

A. Lesniak, A. Salvati, M.J. Santos-Martinez, M.W. Radomski, K.A. Dawson, C. Åberg, Nanoparticle adhesion to the cell membrane and its effect on nanoparticle uptake efficiency. J. Am. Chem. Soc. 135, 1438–1444 (2013)

A. Sarwar, H. Katas, S.N. Samsudin, N.M. Zin, Regioselective sequential modification of chitosan via azide-alkyne click reaction: synthesis, characterization, and antimicrobial activity of chitosan derivatives and nanoparticles. PLoS ONE 10, e0123084 (2015)

J. Yu, W. Zhang, Y. Li, G. Wang, L. Yang, J. Jin, Q. Chen, M. Huang, Synthesis, characterization, antimicrobial activity and mechanism of a novel hydroxyapatite whisker/nano zinc oxide biomaterial. Biomed. Mater. 10, 015001 (2014)

L. Wang, C. Hu, L. Shao, The antimicrobial activity of nanoparticles: present situation and prospects for the future. Int. J. Nanomed. 12, 1227 (2017)

Acknowledgements

The authors appreciate the financial support for the work from Universiti Putra Malaysia through Geran Putra Berimpak (9597200).

Author information

Authors and Affiliations

Contributions

NMA and HMK conceived and designed the experiments; NMA performed the experiments; NMA and HMK analysed the data; NMA, HMK, AAB,AHS and ES contributed reagents/materials/analysis tools; NMA, HMK and AAB wrote the paper. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kamari, H.M., Al-Hada, N.M., Baqer, A.A. et al. Comprehensive study on morphological, structural and optical properties of Cr2O3 nanoparticle and its antibacterial activities. J Mater Sci: Mater Electron 30, 8035–8046 (2019). https://doi.org/10.1007/s10854-019-01125-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01125-2