Abstract

We have investigated the electrical and optical properties of erbium (Er3+) doped TiO2 thin films (Er:TiO2 TFs) grown by sol–gel technique on glass and silicon substrates. The samples were characterized by field emission gun–scanning electron microscopes (FEG–SEM), energy dispersive X-ray spectroscopy (EDX), atomic force microscopy (AFM), X-ray diffraction (XRD), photoluminescence (PL) and current–voltage measurement techniques. FEG–SEM and AFM images showed the morphological change in the structure of Er:TiO2 TFs and EDX analysis confirmed the Er3+ doped into TiO2 lattice. Broad PL emissions in visible and infrared regions were observed in undoped TiO2 samples and associated to different mechanisms due to the anatase and rutile phases. PL spectra revealed sharp peaks at 525 nm, 565 nm, 667 nm and 1.54 µm which are related to Er3+ emissions in Er:TiO2 samples. The undoped TiO2 and Er:TiO2 TFs based UV-photodetectors were fabricated, and various device parameters were investigated. The doped devices exhibit high photoresponse upon illuminating 350 nm UV light at 2 V bias with faster response time compared to undoped device.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

TiO2 is an attractive material due to its efficient photo activity, high chemical stability, nontoxicity and cost-effectiveness [1,2,3]. It has been extensively used for making sensors [4, 5], ultraviolet (UV) detectors [6, 7], low cost solar cells [8] and for applications in photo-electrochemical water splitting [2]. The technological interests of rare earth luminescence are in the field of telecommunications [9], flat panel displays [10], laser materials [11], data storage [12], radiation detection [13], medical applications [14] etc. Several attempts have been made to enhance the photo activity of TiO2 into the visible region by doping it with lanthanide materials like erbium (Er), europium (Eu), terbium (Tb) and cerium (Ce) [15,16,17]. Particularly, incorporation of Er3+ ions into TiO2 semiconductors draws special attention due to some interesting features associated with its unique optical and electrical characteristics. The sharp photoemission from Er3+ doped TiO2 at 1.54 µm due to intra 4f-shell transition of Er3+ ions, which has been reported by several groups [9, 11, 18], is important for telecommunication applications [18]. In addition, the interaction between the local electric field of the host and the 4f electrons is weak. Therefore, the local host structure around Er3+ would result in minor splitting of the free-ion energy levels, 2S+1LJ, into multiplets. This splitting is usually called crystal-field (CF) splitting or Stark splitting, and the number of CF sublevels is determined by the symmetry of the surrounding crystal host, such that a reduction in the symmetry around the lanthanide ions will introduce a higher number of sub-levels. It was previously observed that in Er3+ doped TiO2 materials the crystallinity of TiO2 affects considerably the light emission from Er3+, and the CF splitting of the energy levels of Er3+ ions. Particularly, this emission from a polycrystalline host depends on anatase or rutile phases that were observed in the Er:TiO2 samples. Different methods such as sputtering [19], electron beam evaporation [20], hydrothermal [21], chemical bath deposition [22] spray pyrolysis [23] and sol–gel [24] have been demonstrated for the synthesis of TiO2 nanostructures. Among these methods, sol–gel spin-on has the advantages of being relatively easy preparation technique, employing less sophisticated instruments and having short operation time to synthesize TFs. In recent years a lot of attempts have been made to improve the properties of TiO2 based UV photodetectors. For example, Xing et al. reported that the TiO2 nanocrystalline films photodetector exhibited a maximum photoresponse of 3.63 A/W at 310 nm [25]. Lv et al. prepared TiO2 nanocrystalline film UV photodetectors with responsivity of 31.7 A/W at 5 V bias with response rise and fall times of 550 ms and 380 ms, respectively [26]. Selman et al. reported rutile TiO2 nanorods based devices with responsivity and internal gain of 460 mA/W and 4.79, respectively, upon illuminating UV pulsed (325 nm) at 5 V [7]. In a recent report Patel et al. demonstrated that they fabricated high responsivity (2.023 A/W) with faster rise time (0.14 ms) nanocrystalline TiO2 thin film based UV detector at 1 V reverse bias [27]. Xiang reported work on a commercial TiO2 based UV photodiode (TW30SX photodiode from sglux SolGel Technologies GmbH) which had a maximum spectral sensitivity of 0.021 A/W (active area of 4.18 mm2) at 1 V reverse bias [28]. However, the photoresponse value of the detector can be different under different applied biasing conditions. In addition, due to the complicated and costly fabrication process [29] of TiO2 semiconductor based photodetectors their use is not suitable in large scale production.

In this article, we report an enhancement in photoresponse due to Er3+ ions incorporation into the TiO2 host by using easy and cost effectiveness chemical synthesis method. We have shown that responsivity of doped UV photodetector (Er:TiO2 TF) significantly increases as compared to undoped TiO2 upon illuminating 350 nm under applied bias of 2 V. The doped device also exhibits faster response time than that of undoped device. The Er3+-doped TiO2 lattice has been confirmed by optical and electrical characterization techniques.

2 Experimental details

Undoped and Er-doped TiO2 TFs were deposited on glass and p-type silicon (Si) substrates using sol–gel technique followed by spin coating. Titanium isopropoxide (TTIP) was used as a precursor (Sigma-Aldrich, purity ≥ 97%) of TiO2 material. Erbium oxide nanopowder (Er2O3, Sigma-Aldrich, purity ≥ 99.9%) was used to dope TiO2 TFs with Er3+ ions. To produce a proper solution for spin coating of undoped TiO2 TFs, firstly, a homogeneous solution was prepared by mixing 10 ml ethanol (purity ≥ 99.9%, analytic reagent, Changshu Yanguan Chemical) and 2 ml glacial acetic acid (purity ≥ 99.8%, Merck) under ultra-sonication for 10 min duration. Then, 2 ml TTIP was added to the solution. The final solution was ultra-sonicated for 30 min and was left for 48 h of ageing in a test tube to form the gel. To make Er:TiO2 solutions, 0.04 g and 0.06 g Er2O3 nanopowder were mixed into two other undoped TiO2 solutions prepared by same compositions as mentioned before. To dissolve Er2O3 nano powder, 2 ml hydrochloric acid (HCl) was mixed into the solution which has 0.04 g Er2O3 and 3 ml HCl was mixed into the other solution which has 0.06 g Er2O3. Finally the solutions were ultra-sonicated for 30 min and were aged for a period of 48 h to form the gel. The glass and (100) p-type Si substrates (MTI, USA) were rinsed well with de-ionized water and finally cleaned with acetone followed by Radio Corporation of America and HF dip cleaning for Si substrates. The TFs were deposited by spin coating (spin NXG-P1, apexicindia) technique with substrate rotation speed of ~ 3000 rpm for 1 min on glass substrates and 4000 rpm for 1.5 min on Si substrates. The films were open-air annealed at 200 °C for 2 min in a muffle furnace. To obtain uniform TFs, the entire coating and annealing process were repeated three times with final annealing at 450 °C for 1.5 h in air atmosphere. Gold (Au) was evaporated through a shadow mask with holes of a diameter of 1 mm using a thermal evaporator (Pro-Vak, Pune) to form Schottky contact on the TFs.

The surface and structural morphology of the TFs was characterized by using field emission gun–scanning electron microscopes (JEOL JSM-7600F FEG–SEM), energy dispersive X-ray spectroscopy (EDX), atomic force microscopy (AFM: NT-MDT-INTEGRA) and X-ray diffraction (XRD: Bruker D8 Discover Diffractometer) using Cu Kα radiation (λ = 1.5418 Å). The room temperature diffraction pattern was obtained at diffraction angles between 20° and 80° with geometry 2θ. Temperature-dependent photoluminescence (PL) measurements were performed using a 325 nm Kimmon He–Cd laser and a closed cycle Janis cryostat. The PL spectra were obtained by using Triax Horiba spectrometer coupled with GaAs photomultiplier for visible emission or liquid-N2 cooled Ge detector for near-infrared emission. The current–voltage (I–V) characteristics and photo-response of the Schottky contact based devices were measured using a Keithley 2401 source meter with a 300 W xenon arc lamp and a monochromator (Sciencetech, Canada) connected in open beam configuration.

3 Results and discussions

3.1 FEG–SEM with EDX and AFM analysis

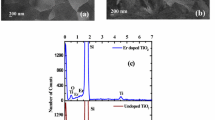

The surface morphology of undoped and Er-doped TiO2 TFs are shown in (Fig. 1a, c, e). The top view of FEG–SEM image of the undoped sample shows that the Ti nanoparticles (NP) are evenly distributed over the cracked surface. The images of doped TFs show that the surface become gradually smooth and grain structure lost with an increase of Er3+ ions doping concentration. The particle size histogram (inset), which are plotted based on FEG–SEM images show that the samples consist of different size NPs ranging from 10 to 40 nm. The average particles size is 27 nm for undoped TF and gradually reduces as the dopant level increases to 22 nm for 0.75 at.% Er and 16 nm for 0.98 at.% Er doped into TiO2 lattice as confirmed by EDX analysis. This can be attributed to the increase of Er3+ ions in the solution, the electrostatic interaction between the particles becomes larger, which increases the probability of gathering more ions together. This demonstrates that the Er3+ doping affects the morphology of pure TiO2 material and the size of NPs reduces due to the strong influence of doping ions. Besides that Er3+ ions can react strongly with TiO2 host in solid state phase and changes the thin film structure. Similar reaction mechanism of Er3+ ions with ZnO and In2O3 host have been reported by Miao, Ghosh et al. [30, 31]. The EDX spectra (Fig. 1b) shows the presence of titanium (Ti), and oxygen (O2) elements in the undoped sample and the element erbium (Er) atoms along with Ti and O atoms are observed in all the doped TFs, showing that definite doping of Er3+ ions into TiO2 (Fig. 1d, f). The atomic fraction of Er3+ ions in the doped films are estimated to be 0.75 at.% and 0.98 at.% for the 0.04 g Er2O3 and 0.06 g Er2O3 containing samples, respectively. The chemical mapping of FEG–SEM images (inset of Fig. 1b, d, f) of the samples, which show the presence of Ti (green color), O2 (red color) and Er (blue color).

FEG–SEM images: a top and cross-sectional view (inset) of undoped TiO2 TF, c, e top view of 0.75 at.% Er and 0.98 at.% Er doped TiO2 TF respectively. The insets correspond to the particle size histogram. b, d, f Show the EDX spectra and corresponding chemical mapping (inset) of undoped and doped samples. (Color figure online)

The surface topography, roughness and particle size of undoped and doped TFs are also examined using AFM images which are shown in Fig. 2. The average peak height and root mean square roughness (Sq) of undoped film surface are 6.09 nm and 1.79 nm, respectively. Whereas for the doped film surfaces these are 2.17 nm and 0.53 nm (0.75 at.% Er) and 1.74 nm and 0.44 nm (0.98 at.% Er), respectively which indicate that the surfaces are becoming flatten and smooth with increasing doping concentration. The particle sizes are also estimated from 3D view of AFM images which are about 30 nm for undoped sample and reduce as doping increases. The thickness of thin films are about 150 nm as measured from the cross-sectional views of FEG–SEM image of undoped sample shown in the inset of Fig. 1a.

3.2 XRD analysis

The θ/2θ XRD patterns of the undoped TiO2 and Er:TiO2 TFs are shown in Fig. 3a. As can be seen from this figure, all detectable diffraction peaks from these samples have the signature of single-phase anatase TiO2 at room temperature. The diffraction peaks occur around 2θ = 25.3°, 48.1°, and 61.9° for undoped and doped TFs, which correspond to the (101), (200), and (213) planes of body-centered tetragonal anatase TiO2 crystal structure, respectively. All the peaks of TiO2 are in good agreement with the standard spectrum (JCPDS Card no: 84-1286). However, using a grazing incidence with the ω angle equal to 1°, rutile (JCPDS Card no. 21-1276) peaks are also observed at 2θ values of 54.2° and 56.3°, which correspond to crystal planes of (211) and (220), as shown in Fig. 3b. This result shows that the anatase phase is the predominant phase. Our XRD results are also in agreement with the PL results, as will be discussed below. There are two another diffraction peaks occurring at 2θ = 33° and 69.2° which can be attributed to Si (100) substrate. The crystallite sizes were calculated from the full width at half maximum (FWHM) of (101) anatase peak using the Scherrer formula [32] (Eq. 1):

where \({D_{hkl}}\) denotes the crystallite size, λ = 0.154 nm is the X-ray wavelength of Cu Kα radiation, β is the FWHM in radian, and θ is the Bragg’s angle. The calculated average crystallite sizes are ~ 22 nm (for undoped TiO2 TF), 20 nm (for 0.75 at.% Er doped TiO2 TF) and 14 nm (for 0.98 at.% Er doped TiO2 TF). These results show that the crystallite size decreases with the increase in concentration of Er3+ ions. Thus, it can be established that the larger amount of Er3+ ions doping causes widening of the width of the diffraction peaks and a reduction in the TiO2 crystallite sizes. This decrease in crystallite size also may be due to the difference between the ionic radius of Er3+ (0.0881 nm) and Ti4+ (0.0605 nm). The incorporation of Er3+ ions into TiO2 host matrix would create a tensile stress which restrict the growth of grain size and reduce the extent of crystallinity [33]. The reduction of particle size with doping concentration has also been confirmed from FEG–SEM and AFM analysis, and the particle diameters are in close agreement as shown in Fig. 3c.

3.3 Photoluminescence

The PL spectra of the TiO2 TFs deposited on glass were investigated as a function of temperature and laser power using a laser excitation wavelength of 325 nm. Figure 4 shows the typical temperature dependence of PL spectra for the undoped TiO2 TF (reference sample) in visible (Fig. 4a) and infrared range (Fig. 4b). The PL spectra in Fig. 4 has been normalized by taking the maximum of the emission observed at around 403 nm and 1600 nm in Fig. 4a, b, respectively.

Three broad PL bands were observed around 403 nm (blue), 530 nm (green) and 750 nm (NIR). The nature of these bands for undoped samples will be discussed below.

It is well known that the PL spectrum of TiO2 usually depends on the crystal phase (anatase, rutile or mixed phases) [34]. For the anatase phase, it was reported previously that the PL spectra show only green (~ 520 nm) and red (~ 620 nm) emissions. In general, the nature of these emissions is not well understood and there is not a well-established consensus on the processes and chemical nature of the states involved in the radiative transitions [34]. For example, the green band was previously associated to self-trapped excitons [35]. However, it was also reported that surface states of anatase TiO2 phase could possibly contribute to the PL bands [36]. More recently, a detailed study of these emissions has evidenced that the green emission could be related to the following process: band gap absorption, followed by relaxation and optical recombination of free electrons with trapped holes. These trapped holes could be localized at oxygen vacancies sites (VO) or at Ti sites adjacent to VO [34]. On the other hand, it was shown that the red emission is related to recombination between trapped electrons and free holes [34]. The electron trap contributing to this red emission was associated to oxygen vacancies positioned below the anatase surface [34]. Both emissions quench during UV + O2 exposure and are partially degraded by this treatment [34]. In fact, it was also demonstrated that the PL intensity of both emissions depends on the effect of absorption or desorption of O2. However, this change is more important for the green band. Usually, its intensity increases considerably by O2 desorption. The possible mechanisms that could explain the green and red emission bands are illustrated in Fig. 5a [34]. For rutile phase, the emission band usually shows only one band at near-infrared emission (NIR) region around 830 nm. The nature of this emission is more difficult to explain. It was previously associated with a different mechanism related to optical recombination involving free holes at the valence band [34]. In fact, the NIR PL was attributed to a possible radiative recombination between mid-gap trapped electrons and free holes at the valence band. Figure 5b illustrates the typical optical transitions for rutile TiO2.

The blue band observed in reference sample around 403 nm (Fig. 4a) was previously reported and associated with the possible contribution of rutile phase (dipole-forbidden direct transition) usually observed in crystals around 3.03 eV [35] or to the band tail emission of the anatase TiO2 [18]. We remark that this band does not present important changes with the temperature. As mentioned previously the anatase phase is the dominant phase confirmed by XRD measurements. Therefore, this blue emission was mainly associated with band tail emission in the anatase phase. As stated above we have also observed a very broad band around 530 nm. This broad band seems to be a combination of two bands previously reported in the literature for the anatase phase: a green band (~ 520 nm) and a red band (~ 620 nm) [34]. However, we have observed that the intensity of the green emission dominates. Its total intensity decreases, and its peak energy presents a small blue shift with the increase of the temperature (from 530 to 515 nm, 68 meV). This band seems to have two unresolved bands: green and red emissions. We attribute this broad band to different recombination processes: (1) band gap absorption, followed by relaxation and optical recombination with trapped holes (contribution of the green band) and (2) recombination between trapped electrons and holes (contribution of the red emission). The emission around 750 nm (NIR) was previously observed only for the rutile phase and associated with the Ti3+ ions [37]. The rutile phase which was detected by XRD measurements using grazing method could explain our PL results in the infrared region. A possible local annealing by the UV laser could also enhance the rutile phase contribution. Actually, laser induced phase transition from anatase to rutile was previously reported [38]. As the rutile phase was detected by XRD we mainly attributed this result to the presence of the rutile phase in our samples.

In addition, two other broad peaks were also observed in the infrared region around 1000 nm and 1600 nm. There are no previous reports for the observation of these bands in TiO2. Actually, all previous studies of PL of TiO2 are usually performed in the spectral region of 300–900 nm. Therefore these infrared emissions have not been previously reported in the literature yet. We associated them with the rutile phase. In order to investigate in more detail the infrared emission, we have fitted the temperature dependence of the PL intensity of the 1000 nm band by:

where I0 = PL intensity at 0 K, E1 and E2 are activation energies, A1 and A2 are temperature independent constants, and kB = Boltzmann constant. Using Eq. (2), activation energies E1 = 57.5 meV and E2 = 9.6 meV were obtained. This emission may be associated with possible trapped electrons contribution of rutile phase as illustrated in Fig. 5b. Therefore, our results evidence the presence of two crystal phases, anatase and rutile phases: the visible PL emission is due to anatase phase in the TiO2 host lattice, showing PL bands in the visible region around 403 and 530 nm, while the rutile phase is related to the PL bands in the infrared region around 750, 1000 and 1600 nm.

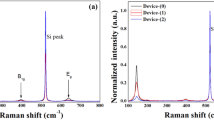

Figure 6a shows the PL spectra of Er-doped samples for different Er3+ concentrations at room temperature. In addition to the broad bands, several sharp intense PL bands associated to optical transitions of Er3+ ions are observed for both samples. Particularly, these sharp peaks are more important for the highly Er-doped TiO2 (0.98 at.% Er) samples. It is well known that the Er-related emissions occur by indirect excitation of the Er3+ ions. The Er3+ ions are particularly excited by energy transfer of electron–hole pairs which are optically generated in the TiO2 host. The observed emission lines are assigned to the intra-4f transitions in the Er3+ ions. Similarly, PL peaks observed at 525 nm, 565 nm, and 667 nm were previously observed for Er3+-doped TiO2 grown on Si substrates [18] and were associated with the transitions from the excited states (2H11/2,4S3/2 and 4F9/2) to the ground state (4I15/2) of the Er3+ ions. The intensity of these sharp peaks presents a decrease of PL intensity at low temperature (Fig. 6b). Similar behavior was observed previously [18]. In addition, the Er3+ PL emission is stable, and no sample degradation was observed under UV excitation. The spectra in Fig. 6 has been normalized by taking the maximum of the emission observed at around 403 nm.

We have also investigated the PL spectra in the infrared region. Figure 7 shows the PL spectra at 12 K for undoped and Er3+-doped TiO2 samples. As mentioned before the energy levels of Er3+ are only slightly affected by the host because the 4f electrons, which are responsible for the luminescence around 1540 nm and the up-conversion properties, are shielded by the outer 5s and 5p electrons [39]. Therefore, the interaction between the local electric field of the TiO2 host and the 4f electrons would be weak. As a result, the local host structure around Er3+ would only result in the minor splitting of the free-ion energy levels, 2S+1LJ, into multiplets. This splitting is usually called CF splitting or Stark splitting, and the number of CF sublevels is determined by the symmetry of the surrounding crystal host, such that a reduction in the symmetry around the lanthanide ions will introduce a higher number of sub-levels. It was previously observed that the crystallinity of TiO2 affects considerably the light emission from Er3+, and the CF splitting of the energy levels of Er3+. In the polycrystalline TiO2 TF, light emission from two different Er3+ environments was observed. These effects were associated with Er3+ ions populating the dominant anatase phase or rutile environment which results in some different light emission behavior [39].

It was also observed that at higher Er3+ concentration the broad bands are suppressed and emissions from Er3+ ions are the main contribution for the PL spectrum (Fig. 7c). The emission associated with 4I13/2 → 4I15/2 transition in Er3+ ions is observed at around 1.54 µm and can be observed at room temperature (Fig. 8), where the spectra were normalized by taking the maximum of this emission. As the temperature was decreased to 12 K, the main peak position at 1.54 µm did not present important changes. Actually, this Er-related emission is nearly independent of the host and temperature because of the screening of the unfilled inner 4f11shell by the outer closed 5s25p6 shells [40]. However, the FWHM decreases from 4.97 to 3.4 meV. In addition, more peaks can be observed at 300 K and the PL intensity at 1.537 µm of the Er-doped TiO2 TF (0.98 at.% Er) increases to about four times with decrease in temperature to 12 K. Similar behavior of increase in PL intensity at lower temperatures was observed previously [18]. The inset of Fig. 8 shows the temperature dependence of PL intensity of sharp peaks in the infrared region. In conclusion, Er3+ doped TiO2 TFs exhibit broad and sharp emissions. The broad emissions are due to the TiO2 host and sharp peaks are associated with optical transitions in Er3+ ions. The PL peaks in the infrared region (900–1700 nm) are observed here for the first time in TiO2 reference samples and are associated with rutile phase. A strong emission near infrared region due to Er3+ was detected at 1.54 µm. In addition, it was observed that broad bands in infrared region are suppressed with the incorporation of Er3+ due to the energy transfer from the TiO2 host to Er3+ ions.

3.4 Current–voltage (I–V) characteristics

Figure 9a shows the room temperature ln I–V characteristics of Au/TiO2 TF/p-Si and Au/Er-doped TiO2 TF/p-Si devices in dark condition. The ratio of light current to dark current versus voltage characteristics for the devices (under white light illumination using a xenon arc lamp) is shown in Fig. 9b. The ideality factor (\(n\)) and barrier height (\({\phi _b}\)) of the devices were calculated from Fig. 9a using Eqs. (3) and (4) [41].

a ln I–V characteristics of the devices. The inset shows the variation of ideality factor and barrier height of the devices as a function of doping concentration. b Current ratio (light/dark) versus voltage of the undoped and doped TF based devices. The inset shows a schematic diagram of the devices

where q is the charge of an electron, k is the Boltzmann constant, V is the applied voltage across the electrodes, T is the absolute temperature in Kelvin, \(\frac{{\partial \left( {\ln ~I} \right)}}{{\partial V}}\) is the slope of the ln I–V curve (taken between 0.2 and 1 V), A is the surface area of a single Au dot, A* (671 A/cm2/K2) [42] is the effective Richardson constant of TiO2 and \({I_0}\) is the reverse saturation current given by Eq. (5).

From the intercept of the linear fit (between 0.2 and 1 V) of the dark ln I–V plot, \({I_0}\) is found to be equal to 1.38 × 10−9 A, 5.10 × 10−8 A and to 2.53 × 10−11 A for the undoped TiO2 TF, Er-doped TiO2 (0.75 at.% Er), and Er-doped TiO2 (0.98 at.% Er), respectively. \({I_0}\) first increases then decreases as the Er doping increases. The \({\phi _b}~\) and n for the undoped TiO2 TF are ~ 0.87 eV and ~ 16, respectively. The high value of n suggests the presence of large number of defects in the metal/semiconductor interface. First, the barrier height decreases to ~ 0.77 eV for Er-doped TiO2 TF (0.75 at.% Er) and then increases to ~ 0.99 eV for the higher Er-doped sample (0.98 at.% Er). The value of n gradually decreases to ~ 11 and ~ 5 with increasing Er3+ concentration as shown in Fig. 9a (inset). The gradual decrease in n value indicates the better diode performance with the increase of Er3+ doping, which may be due to simultaneous removal of the oxygen related defects as observed in Er3+ doped In2O3 material [31]. The barrier heights of 0.77–0.99 eV deduced from I–V characteristics using the classical thermionic emission theory are in good agreement with other reported values [43]. There was a decrease in barrier height due to the role of the electron affinity (~ 4 eV for TiO2) in the band bending formation [44]. With high Er3+ doping concentration, those oxygen related defects were mostly neutralized and it results in the non-availability of excessive free electrons and subsequently there was a reduction in \({I_0}\) value. The barrier height then increases more to match the new band alignment with gold (work function ~ 4.9 eV) [43].

3.5 Responsivity, internal gain and temporal response

The suitability of devices as optical detectors is verified by measuring the responsivity and temporal response, which are shown in Fig. 10. The responsivity (R) of the devices at room temperature was calculated at different wavelengths under the applied bias voltage of 2 V using Eq. (6) and is shown in Fig. 10a.

where \({I_{photo}}\) is the photocurrent and \({P_{opto~}}\) is the optical power.

The responsivity of the highest doped TiO2 TF device is bigger than that of the undoped TiO2 TF over the wavelength range 250–550 nm (Fig. 10a). The highest doped device showed maximum responsivity at 370 nm, which is ~ 13 times higher than the undoped device (Fig. 10a). The corresponding photon energy ~ 3.35 eV of the Er-doped TiO2 material can be attributed to the near band edge absorption of light as TiO2 material is only active to UV light of energy > 3.0 eV [45]. In forward bias, a large number of photo-generated electron–hole pair increases the majority carrier and ionizes the interface states. The ionization of interface states increases the barrier height, but the large number of electrons, generated upon UV illumination, effectively reduces the barrier height under forward bias resulting in band bending changes and current increases. Again the doping of TiO2 with Er3+ ions efficiently traps the photo generated electrons, which prevent the electron–hole recombination process resulting in an enhancement of the photo responsivity of the detector [46].

However, there was no significant responsivity recorded for the undoped TiO2 material. A broad peak in the visible region of light around 425 nm was observed, which may be due to the release of trapped electron–holes at oxygen vacancies in the undoped TiO2 material [47]. The maximum internal gain (G) of ~ 15 was calculated at a wavelength of 370 nm by using Eq. (7), which is much greater than the undoped TiO2 TF (~ 1.5).

where \(h\) is the Planck’s constant, \(c\) is the speed of light, λ is the wavelength of incident radiation, \(q\) is the electronic charge, and η is the quantum efficiency (assuming η = 1).

The temporal response of undoped and Er-doped TiO2 TFs under illumination of 350 nm wavelength of light at an applied bias of 2 V is shown in Fig. 10b. The rise time (Tr) and fall time (Tf) of the devices were obtained by considering the time required by the pulse to increase from 10 to 90% of its peak value and the time required by the pulse to decrease from 90% of the peak value to 10%, respectively. The undoped TiO2 shows Tr ~ 0.21 s and Tf ~ 0.14 s. Those values showed a continuous improvement in switching behavior and calculated values were Tr ~ 0.13 s, Tf ~ 0.13 s and Tr ~ 0.11 s, Tf ~ 0.12 s for lowest and highest doped devices, respectively. The current value rises slowly from a minimum to a maximum value for the highest doped device under light on condition due to the diffusion of charge carriers for a longer time [32]. However, the drift velocity of the carriers is larger than diffusion velocity. Thus, ultimately the photo generated carriers drift faster and reduce Tr and Tf for the highest Er-doped photodetector. In the case of the undoped TiO2 device, the depletion width is less under reverse bias (as holes are trapped in oxygen defects), which results in absorption of incident photons in the diffusion region. Therefore, the temporal response of the undoped device is affected by diffusion carriers and makes it unreliable in light on condition. The device shows improved performance with more Er3+ doping into TiO2 sample by enlarging the depletion region at the metal/semiconductor junction and by reducing the oxygen defects. As the incident photons are mostly absorbed in the depletion region, this results in the generation of drift carriers and a reduction in the effect of diffusion on the temporal response of the device. A similar effect was also described by Ghosh et al. [31]. From the above experiment, it can be concluded that the Er3+ doped detector possesses reliable photo-switching characteristics at the particular wavelength of 350 nm and applied voltage of 2 V.

4 Conclusions

In conclusion, we have synthesized Er3+-doped TiO2 TFs using sol–gel synthesis method. The XRD spectra revealed the presence of various planes of body-centered tetragonal anatase phase of TiO2 and small contribution of rutile phase. An increase in the concentration of Er3+ ions resulted in a decrease of the crystallite size. The average particle sizes calculated from FEG–SEM images were ~ 27 nm, 22 nm and 16 nm for undoped TiO2 TF, 0.75 at.% Er doped TiO2 TF and 0.98 at.% Er-doped TiO2 TF respectively which is analogous the particle size estimated from AFM and XRD analysis. From temperature dependent PL spectra of undoped TiO2 TF, broad bands in visible and infrared region were detected. The emissions in visible region were associated with the dominant anatase phase and in the infrared region with the rutile phase. Particularly we report for the first time PL bands for TiO2 in the region of 800–1700 nm. For Er3+ doped TiO2 samples, the PL peaks observed at 525, 565, and 667 nm were associated with the transitions from the excited states (2H11/2, 4S3/2 and 4F9/2) to the ground state (4I15/2) of the Er3+ ions. At higher Er3+ concentration, the emission from 4I13/2 → 4I15/2 transition in Er3+ ions was prominent at around 1.54 µm. The PL intensity at 1.537 µm of the Er-doped TiO2 TF (0.98 at.% Er) increased to about four times with decrease in temperature down to 12 K. From I–V characteristics of the doped and undoped devices, the barrier height of the undoped TiO2 TF was calculated to be ~ 0.87 eV which decreases to ~ 0.77 eV for moderately Er-doped TiO2 TF (0.75 at.% Er) and increased to ~ 0.99 eV for higher Er-doped TiO2 (0.98 at.% Er). With an increase in Er doping, there was a gradual decrease in ideality factor as well as the reverse saturation current due to simultaneous removal of the oxygen related defects. At 370 nm, the Er-doped TiO2 TF (0.98 at.% Er) based devices showed ~ 13 times enhanced responsivity as compared to the undoped device. The Er-doped TiO2 TF (0.98 at.% Er) based devices exhibited a maximum internal gain (G) of ~ 15 at a wavelength of 370 nm. From the temporal response, the undoped TiO2 showed rise and fall times of ~ 0.21 s and ~ 0.14 s, respectively, while for the lowest and highest doped devices parameters were ~ 0.13 s and ~ 0.13 s; ~ 0.11 s and ~ 0.12 s, respectively. This clearly indicates the enhancement in switching performance with an increase in Er doping concentration.

References

A. Fujishima, T.N. Rao, D.A. Tryk, J. Photochem. Photobiol. C 1, 1–21 (2000). https://doi.org/10.1016/S1389-5567(00)00002-2

X. Chen, S.S. Mao, J. Chem. Rev. 107(7), 2891–2959 (2007). https://doi.org/10.1021/cr0500535

A.-W. Xu, Y. Gao, H.-Q. Liu, J. Catal. 207, 151–157 (2002). https://doi.org/10.1006/jcat.2002.3539

M. Ferroni, V. Guidi, G. Martinelli, G. Faglia, P. Nelli, G. Sberveglieri, Nanostruct. Mater. 7(7), 709–718 (1996). https://doi.org/10.1016/S0965-9773(96)00050-5

N. Savage, B. Chwieroth, A. Ginwalla, B.R. Patton, S.A. Akbar, P.K. Dutta, Sens. Actuators B 79, 17–27 (2001). https://doi.org/10.1016/S0925-4005(01)00843-7

T. Xie, A. Rani, B. Wen, A. Castillo, B. Thomson, R. Debnath, T.E. Murphy, R.D. Gomez, A. Motayed, Thin Solid Films 620, 76–81 (2016). https://doi.org/10.1016/j.tsf.2016.07.075

M. Selman, Z. Hassan, Sens. Actuators A 221, 15–21 (2015). https://doi.org/10.1016/j.sna.2014.10.041

F. Li, Y. Gu, Mater. Sci. Semicond. Process. 15, 11–14 (2012). https://doi.org/10.1016/j.mssp.2011.04.008

Y.Y. Hui, P.H. Shih, K.J. Sun, C.F. Lin, Thin Solid Films 515, 6754–6757 (2007). https://doi.org/10.1016/j.tsf.2007.02.013

D.S. Lee, A.J. Steckl, Appl. Phys. Lett. 80, 1888–1890 (2002). https://doi.org/10.1063/1.1461884

L. Yang, T. Carmon, B. Min, S.M. Spillane, K.J. Vahala, Appl. Phys. Lett. 86, 091114 (2005). https://doi.org/10.1063/1.1873043

S.G. Krishnan, P.S. Archana, B. Vidyadharan, I.I. Misnon, B.L. Vijayan, V.M. Nair, A. Gupta, R. Jose, J. Alloys Compd. 684, 328–334 (2016). https://doi.org/10.1016/j.jallcom.2016.05.183

A. Ganguly, A. Mondal, B. Choudhuri, T. Goswami, K.K. Chattopadhyay, J. Adv. Sci. Eng. Med. 6, 797–801 (2014). https://doi.org/10.1166/asem.2014.1566

H. Ishiguro, R. Nakano, Y. Yao, J. Kajioka, A. Fujishima, K. Sunada, M. Minoshima, K. Hashimoto, Y. Kubota, J. Photochem. Photobiol. Sci. 10, 1825–1829 (2011). https://doi.org/10.1039/c1pp05192j

J. Reszczyn´ska, T. Grzyb, J.W. Sobczak, W. Lisowski, M. Gazda, B. Ohtani, A. Zaleska, Appl. Surf. Sci. 307, 333–345 (2014). https://doi.org/10.1016/j.apsusc.2014.03.199

T.K. Srinivasan, B.S. Panigrahi, N. Suriyamurthy, P.K. Parida, B. Venkatraman, J. Rare Earths 33(1), 20 (2015). https://doi.org/10.1016/S1002-0721(14)60377-X

G. Xing, Z. Zhang. S. Qi, G. Zhou, K. Zhang, Z. Cui, Y. Feng, Z. Shan, S. Meng, Opt. Mater. 75, 102–108 (2018). https://doi.org/10.1016/j.optmat.2017.10.006

S. Kumoro, T. Katsumata, H. Kokai, T.M.X. Zhao, Appl. Phys. Lett. 81(25), 4733–4735 (2002). https://doi.org/10.1063/1.1530733

L. Skowronski, R. Szczesny, K. Zdunek, Thin Solid Films 632, 112–118 (2017). https://doi.org/10.1016/j.tsf.2017.04.041

S. Wang, G. Xia, H. He, K. Yi, J. Shao, Z. Fan, J. Alloys Compd. 431, 287–291 (2007). https://doi.org/10.1016/j.jallcom.2006.05.091

M. Ueda, Y. Uchibayashi, S. Otsuka-Yao-Matsuo, T. Okura, J. Alloys Compd. 459, 369–376 (2008). https://doi.org/10.1016/j.jallcom.2007.04.266

D.S. Gospodinova, L.P.H. Jeurgens, U. Welzel, L. Bauermann, R.C. Hoffmann, J. Bill, Thin Solid Films 520, 5928–5935 (2012). https://doi.org/10.1016/j.tsf.2012.03.047

H.-Y. Liu, W.-H. Lin, W.-C. Sun, S.-Y. Wei, S.-M. Wu, Mater. Sci. Semicond. Process. 57, 90–94 (2017). https://doi.org/10.1016/j.mssp.2016.10.005

T. Watanabe, S. Fukayama, M. Miyauchi, A. Fujishima, K. Hashimoto, J. Sol-Gel Sci. Technol. 19, 71–76 (2000). https://doi.org/10.1023/A:1008762121743

J. Xing, H. Wei, E.-J. Guo, F. Yang, J. Phys. D 44, 375104 (2011). https://doi.org/10.1088/0022-3727/44/37/375104

K. Lv, M. Zhang, C. Liu, G. Liu, H. Li, S. Wen, Y. Chen, S. Ruan, J. Alloys Compd. 580, 614–617 (2013). https://doi.org/10.1016/j.jallcom.2013.07.161

D.B. Patel, K.R. Chauhan, S.-H. Park, J. Kim, Mater. Sci. Semicond. Process. 64, 137–142 (2017). https://doi.org/10.1016/j.mssp.2017.03.024

W.F. Xiang, P.R. Yang, A.J. Wang, K. Zhao, H. Ni, S.X. Zhong, Thin Solid Films 520, 7144–7146 (2012). https://doi.org/10.1016/j.tsf.2012.07.110

M. Zhang, D. Li, J. Zhou, W. Chen, S. Ruan, J. Alloys Compd. 618, 233–235 (2015). https://doi.org/10.1016/j.jallcom.2014.07.040

L. Miao, X. Xiao, F. Ran, S. Tanemura, G. Xu, Jpn. J. Appl. Phys. 50, 061101 (2011). https://doi.org/10.1143/JJAP.50.061101

A. Ghosh, A. Mondal, A. Das, S. Chattopadhyay, K.K. Chattopadhyay, J. Alloys Compd. 695, 1260–1265 (2017). https://doi.org/10.1016/j.jallcom.2016.10.254

R. Lahiri, A. Ghosh, S.M.M. Dhar Dwivedi, S. Chakrabartty, P. Chinnamuthu, A. Mondal, Appl. Phys. A 123, 573 (2017). https://doi.org/10.1007/s00339-017-1180-2

D.Y. Lee, J.-T. Kim, J.-H. Park, Y.-H. Kim, I.-K. Lee, M.-H. Lee, B.-Y. Kim, Curr. Appl. Phys. 13, 1301–1305 (2013). https://doi.org/10.1016/j.cap.2013.03.025

D.K. Pallotti, L. Passoni, P. Maddalena, F. Di Fonzo, S. Lettieri, J. Phys. Chem. C 121, 9011–9021 (2017). https://doi.org/10.1021/acs.jpcc.7b00321

H. Tang, K. Prasad, R. Sanjinès, P.E. Schmid, F. Lévy, J. Appl. Phys. 75(4), 2042–2047 (1994). https://doi.org/10.1063/1.356306

W. Luo, C. Fu, R. Li, Y. Liu, H. Zhu, X. Chen, Small 7(21), 3046–3056 (2011). https://doi.org/10.1002/smll.201100838

Y. Yang, C. Wang, L. Xiang, X. Ma, D. Yang, AIP Adv. 4, 047109 (2014). https://doi.org/10.1063/1.4871188

G.C. Vásquez, M.A. P-Herrero, D. Maestre, A. Gianoncelli, J. R-Castellanos, A. Cremades, J. G-Calbet, J. Piqueras, J. Phys. Chem. C 119(21), 11965–11974 (2015). https://doi.org/10.1021/acs.jpcc.5b01736

S.R. Johannsen, S. Roesgaard, B. Julsgaard, R.A.S. Ferreira, J. Chevallier, P. Balling, S.K. Ram, A.N. Larsen, Opt. Mater. Express 6(5), 1664–1678 (2016). https://doi.org/10.1364/OME.6.001664

M. Jiang, C. Zhu, J. Zhou, J. Chen, Y. Gao, X. Ma, D. Yang, J. Appl. Phys. 120, 163104 (2016). https://doi.org/10.1063/1.4966224

A. Mondal, A. Ganguly, A. Das, B. Choudhuri, R.K. Yadav, Plasmonic 10(3), 667–673 (2015). https://doi.org/10.1007/s11468-014-9852-7

P.B. Pillai, A.N. Corpus Mendoza, M.M. De Souza, G. Bree, D. Jeng, J. Renew. Sustain. Energy 6, 013142 (2014). https://doi.org/10.1063/1.4866260

N. Szydlo, R. Poirier, J. Appl. Phys. 51, 3310 (1980). https://doi.org/10.1063/1.328037

J.G. Mavroides, D.I. Tchernev, J.A. Kafalas, D.F. Kolesar, Mater. Res. Bull. 10, 1023–1030 (1975). https://doi.org/10.1016/0025-5408(75)90210-X

T. Umebayashi, T. Yamaki, H. Itoh, K. Asai, Appl. Phys. Lett. 81(3), 454–456 (2002). https://doi.org/10.1063/1.1493647

S.N. Das, K.-J. Moon, J.P. Kar, J.-H. Choi, J. Xiong, T. Lee, J.-M. Myoung, Appl. Phys. Lett. 97, 022103-1–022103-3 (2010). https://doi.org/10.1063/1.3464287

P. Chinnamuthu, J.C. Dhar, A. Mondal, A. Bhattacharyya, N.K. Singh, J. Phys. D 45, 135102 (2012). https://doi.org/10.1088/0022-3727/45/13/135102

Acknowledgements

The authors would gratefully acknowledge SAIF IIT Bombay, India, for providing FEG-SEM and EDX facilities, IIC Roorkee, India for providing AFM facility and Department of Physics, N.I.T. Durgapur, CSIR (03(1355)/16/EMR-II), Government of India for financial support. The Brazilian authors acknowledge the financial support from the Brazilian agencies: Fundação de Amparo a Pesquisa do Estado de São Paulo (FAPESP 2016/10668-7), FAPDF, Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (Capes).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mondal, S., Ghosh, A., Piton, M.R. et al. Investigation of optical and electrical properties of erbium-doped TiO2 thin films for photodetector applications. J Mater Sci: Mater Electron 29, 19588–19600 (2018). https://doi.org/10.1007/s10854-018-0090-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0090-1