Abstract

The Fe3O4 quantum dots anchored SnO2 nanofibers (Fe3O4 QDs/SnO2 NFs) and CdTe quantum dots anchored SnO2 nanospheres have been prepared via hydrothermal method. The characteristic structure of Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs was analyzed using several techniques such as X-ray diffraction, transmission and scanning electron microscopy, UV–Vis and photoluminescence spectroscopy, and N2 adsorption–desorption instruments. The average diameters of Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs were 7.25 and 3.75 nm, respectively. BET surface area of Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs has been found 53.064 and 148.59 m2/g, respectively. The Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs sample were used for removal and photo-catalytic of carcinogenic compounds such as ethyl methanesulfonate (EMS) and N-nitrosonornicotine (NNN). The Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs demonstrates up to 90 and 56% photo degradation and adsorption activity against EMS and NNN solution, respectively. Additionally, cytotoxicity test indicated that the prepared catalyst has low cytotoxic influences. The antibacterial activity of prepared catalyst has excellent effect against Staphylococcus aureus, and Pseudomonas aeruginosa.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ethyl methanesulfonate (EMS) is a sulfonoxyalkane with carcinogenic and teratogenic properties. EMS is a monofunctional ethylating agent that has been found to be mutagenic and carcinogenic in mammals [1]. N-Nitrosonornicotine (NNN) is a tobacco-specific nitrosamine produced and it has been classified as a Group 1 carcinogen [2]. Although no adequate studies of the relationship between exposure to NNN and human cancer have been reported, there is sufficient evidence that NNN causes cancer in experimental animals. Recently, the several techniques used for removal of pollutants could be broadly divided into four categories: i.e., precipitation-coagulation, ion exchange, membrane-separation, and adsorption [3,4,5,6]. Therefore, adsorption or photocatalysis process is economically effective for removal of contaminants in aquatic environment [7, 8]. Nanostructured materials with high specific surface area and active sites have been used to water treatment methods [9]. SnO2 is one of the most vital and classical semiconductors with a band gap of 3.6 eV at room temperature. SnO2 nanofibers have stimulated great interest due to their importance properties and broad technological applications. SnO2 nanospherical are of regular shapes, large specific surface areas, and have potential applications in chemical sensing, selectable shape absorbents and catalysts [10, 11]. Quantum dots (QDs), a new material, have attention research due to their major properties [12,13,14]. Nowadays, Fe3O4 and CdTe QDs have also been applied as a photocatalyst due to high electron-accepting and-transport and photo-luminescence properties [15,16,17]. Therefore, in the present work, a synthesis of Fe3O4 quantum dots anchored SnO2 nanofibers, and CdTe quantum dots anchored SnO2 nanospheres characterization, and use for adsorption and removal. The toxicological effects of the catalyst were investigated.

2 Materials and methods

2.1 Materials

All the chemicals were obtained from Sigma-Aldrich Ltd, USA.

2.2 Synthesis of nanomaterials

2.2.1 Synthesis of Fe3O4 quantum dots and SnO2 nanofibers

To 0.5 g of FeCl3·6H2O dissolved in a mixture of deionized water (25 mL) and CH3COOH (5 mL) under magnetic stirring. The mixture was heated in a Teflon lined autoclave at 180 °C for 10 h and then cooled to room temperature. The precipitate was separated to obtain the Fe3O4 QDs. Three grams of SnCl4·5H2O was added into mixture of PVP-ethanol/DMF solvent (weight ratio 1:1), under magnetic stirring at 25 °C for 24 h. Later, prepared solution was introduced in 10 mL syringe with a hypodermic needle (dia. 2 mm) in a controlled electro spinning setup (flow rate 0.2 mL/h; applied electric field 1.25 kV/cm). This electric field strength was needed to enable for the high stretch rates of the electrospun jet. The fiber obtained was then annealed to obtain SnO2 nanofibers. The electrospun fibers were calcined at 550–650 °C for 4 h.

2.2.2 Synthesis of Fe3O4 quantum dots anchored SnO2 nanofibers

SnO2 nanofiber (200 mg) and Fe3O4 QDs (50 mg) were mixed into 20 mL of distilled water and 10 mL of alcohol. The mixture was kept stirring for 30 min at room temperature to make a clear dispersion of QDs. After that, the dispersed solution was transferred into a 40 mL Teflon-sealed autoclave and maintained at 140 °C for 4 h. Finally, the resulting solution was cooled, filtered, washed with distilled water three times and dried under vacuum at 40 °C overnight. The product was calcined at 400 °C for 2 h.

2.2.3 Synthesis of SnO2 nanospheres

1.5 g C2H2O4·2H2O and 1.8 g SnCl2·2H2O were dissolved in 30 mL distilled water, separately. These two solutions were mixed under constant stirring with a magnetic stirrer. The mixed solution was transferred to 50 mL Teflon-lined stainless steel autoclave (sealed and heated at 140 °C for 12 h). After heating treatment, the autoclave was cooled to room temperature. Product was washed with distilled water and absolute ethanol several times and dried in vacuum at 80 °C. The as-synthesized precursor was annealed in muffle furnace at 400 °C for 10 h.

2.2.4 Synthesis of CdTe quantum dots anchored SnO2 nanospheres

The SnO2 nanospheres were dispersed in 50 mL of water and CdCl2 (0.1 M) and NaHTe (0.1 M) were added. Cysteamine was added as a capping ligand. The reaction was stirred for 12 h. Then the pH value of the mixed solution was adjusted to 6.0 by dropwise addition of 1 M NaOH solution. The solution was transferred to a 50 mL Teflon-lined stainless steel autoclave, and heated at 150 °C for 15 h. The resulting product was collected and dried at 100 °C for 10 h.

2.3 Characterization instruments

A scanning electron microscopy (SEM-Hitachi SU8000) and X-ray diffractometer (XRD) Philips X’Pert were used to examine the morphology of the catalyst synthesized here. The particle size of catalyst was measured using transmission electron microscope (TEM) (Zeiss EM-900). The Brunauer–Emmett–Teller (BET) of the nanocomposites was analyzed by nitrogen adsorption instrument in an ASAP2020 surface area. Zeta potential measurements of the dilute dispersions (0.1 mg/mL) of the various the nanocomposites were performed with a Brookhaven NanoBrook Omni Instrument at 25 °C. Photoluminescence and UV–Vis spectroscopy were carried out using TEC Avaspec 2048 Spectrophotometer (excitation source = Xenon arc lamp 450 W).

2.4 Adsorption performance of EMS and NNN

In order to the adsorption capability of SnO2 NFs, SnO2 NSs, Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs, definite amount of adsorbents (0.3 g) were contacted EMS and NNN solution of 10 mg/L at different pH condition. pH of solution was maintained by adding 0.1 N HCl or 0.1 N NaOH and varied in the range of 1–9. Volume of solution was 50 mL. The samples were collected after operation. The solution containing nanomaterial were centrifuged and collected for residual EMS and NNN concentration solution using 2D Gas Chromatography (GC∗GC) (Kimia Shangarf Pars Research CO., Iran).

2.5 Degradation performance of EMS and NNN

The bath method was conducted in an open glass cylinder (diameter = 10.0 cm, height = 30 cm) with the temperature controlled at 25 ± 0.5 °C using a water bath. An 11 W low-pressure mercury lamp emitting at 254 nm was used in the apparatus and preheated until EMS and NNN were spiked into solutions to activate the reactions. A magnetic stirrer under the reactor was adopted to ensure homogeneous exposure, and 0.1 M HCl and NaOH were used for the pH adjustment. N2 was conducted before the degradation reaction started to remove dissolved oxygen in the solutions.

2.6 Toxicity test

The cytotoxic effects of Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs on humans were investigated using by three human cell types. A human lung epithelial cell line (A549), melanoma cell line (CHL-1) and neuroblastoma (SH-SY5Y) cells were purchased from the American Type Culture Collection ATCC (NY, USA). A549 and CHL-1 cells were grown in an RPMI-1640 medium supplemented with penicillin (100 U/mL), streptomycin (100 mg/mL), 1 mM sodium pyruvate and 10 mM of HEPES with 10–20% FBS humidified incubator under 5% CO2. SH-SY5Y cells were grown in a 90% culture medium (50% F-12 and 50% MEM; GIBCO BRL) supplemented with 10% FBS plus sodium bicarbonate sodium pyruvate, penicillin (100 U/mL), streptomycin (100 mg/mL) [18, 19]. To determine the cytotoxicity and its effects on cell growth, an MTT cell proliferation assay was performed [20]. Dimethyl sulfoxide (DMSO) was added to remove medium. The A549, SH-SY5Y, and CHL-1 cells were seeded in a 24-well cell culture plate (BD Falcon TM; USA) at a density of 7 × 104, 24 × 104, and 12 × 104 cells/mL per well in 500 mL of media, respectively. The cells were exposed to various concentrations of adsorbent for 48 h. For measurements, the absorbance wavelength is 540 nm for each sample. The MTT assay was carried out in triplicate for each sample.

2.7 Antibacterial activity assay

The Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs antibacterial activity was evaluated using a microdilution method and the minimum inhibitory concentration (MIC) values were measured toward Gram-positive Staphylococcus aureus and Gram-negative Pseudomonas aeruginosa bacteria were revived with brain heart infusion (BHI, Sigma-Aldrich) agar at 37 °C for 24 h. In a typical experiment, aliquots of 100 µL of (Fe3O4QDs/SnO2 NFs) stock solutions were each diluted with 100 µL of BHI and 20 µL of the bacteria suspension (1.5 × 108 cfu/mL). Thus, the MIC value is the lowest concentration at which a color change occurred and, consequently, no visible bacterial growth was observed.

3 Results and discussion

3.1 Characterization of the Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs

3.1.1 Morphological and surface studies

Figures 1 and 2 represented the SEM images of SnO2 nanofibers, Fe3O4QDs/SnO2 NFs and SnO2 nanospheres, CdTe QDs/SnO2 NSs, respectively. As can be seen, SnO2 nanofibers look like exhibit smooth, bead-free form. The surfaces of SnO2 nanofibers material have been the incorporated Fe3O4 QDs (Fig. 1b). One can see that the as-prepared product consists of a large number of nearly intact nanospheres with diameters ranging from 40 to 120 nm. In Fig. 2b, CdTe QDs was impregnated on the SnO2 nanospheres. EDX study of Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs has been shown in Figs. 1c and 2c. The samples contain iron (Fe), cadmium (Cd), tellurium (Te), oxygen (O), and tin (Sn). Figure 3a, c indicated TEM image of Fe3O4 QDs anchored SnO2 nanofiber and CdTe QDs/SnO2 NSs. The Fe3O4 QDs particle coverage demonstrates good contact with the fiber. The average size of the Fe3O4QDs/SnO2 NFs is about 7.25 nm (Fig. 3b). It can be seen from Fig. 3c, surface of SnO2 was densely covered with CdTe QDs. The lattice fringe spacing of SnO2 nanospheres is 0.25 nm. Figure 3d shows average size histogram of the CdTe QDs/SnO2 NSs and it’s 3.75 nm. The surface area was determined by using the BET and N2 sorption methods. N2 sorption demonstrated typical type IV isotherm [21]. BET surface area of Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs has been found as 53.064 and 148.59 m2/g.

3.1.2 X-ray diffraction analysis

Figure 4 represents the XRD patterns of SnO2 nanofibers and Fe3O4QDs/SnO2 NFs prepared. The diffraction peak with circle and square marks are ascribed to the crystal planes of SnO2 (tetragonal phase) and Fe3O4 (cubic phase) [22]. The crystallite size from the Scherrer equation [22,23,24,25,26,27] is distinguished to be 7.0 nm Fe3O4QDs/SnO2 NFs. Figure 4c, d demonstrate the XRD plot of SnO2 nanospheres and CdTe QDs/SnO2 NSs. All the diffraction peaks corresponded to tetragonal rutile phase SnO2 and were in good agreement with standard JCPDS card no. 41–1445. The diffraction peaks of CdTe what cubic phase were observed in CdTe QDs/SnO2 NSs samples (JCPDS card no. 19–0191). The XRD pattern of the Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs were analyzed using Rietveld refinement for the average size of the crystallites, lattice parameters, and the presence of any lattice strains in the samples. The Le Bail algorithm employed in the PowderCell 2.4 program was used for Rietveld analysis. Figure 5 shows the Rietveld refinement plot of Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs fitted. The residues of the fitting were (Rp = 3.12, 3.24), (Rwp = 4.16, 4.35), and (Rp expected = 13.58, 14.54), where the symbols have their usual meaning.

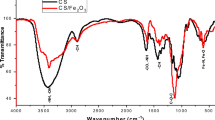

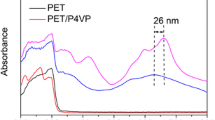

3.1.3 Optical studies

Figure 6A depicts the UV–Vis diffuse reflectance spectra of Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs. The introduction of Fe3O4 and CdTe QDs into the SnO2 NFs and SnO2 NSs leads to a significant shift (UV region). In Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs, the spectra observed at UV range. The light absorption edge of all samples indicating that the four samples prepared cannot absorb visible light. The coupling Fe3O4 and CdTe into SnO2 NFs and SnO2 NSs increases the UV light absorption intensity of SnO2 NFs and SnO2 NSs and leads to the positive shift of the near UV absorption edge. The band gap energy of a sample can be determined by Kubelka–Munk function [28,29,30]. The band gap energy of SnO2 NFs, SnO2 NSs, Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs were found out to be 3.6, 3.5 2.9 and 2.6 eV, respectively; with incorporation of Fe3O4 and CdTe QDs to SnO2 NFs and SnO2 NSs, the band gap energy decreases. Figure 6B shows the room temperature PL spectrum of prepared Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs. was centered at 388 and 354 nm with excited at 230 nm, which is indicated to the blue and green emissions which results from a photon-generated hole recombination with a the specific defect charge state. The PL intensity of CdTe QDs/SnO2 NSs is higher than that of Fe3O4QDs/SnO2 NFs, implying that the addition of CdTe would enhance the electron–hole recombination rate.

3.2 Adsorption efficiency

When pH is increased from 1 to 5, increased from 5 to 9, EMS and NNN initially removal gradually increase and then decreased (Figure not shown). Such trend of removal could be attributed to the positive charged surface SnO2 NFs, SnO2 NSs, Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs at acidic pH conditions to which EMS and NNN gets easily bound. The pHzpc of SnO2 NFs, SnO2 NSs, Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs have been found to be 5.0 and 5.5, respectively (Figure not shown). The favorable condition for the EMS and NNN removal process as positively charged surface can easily bind the non-bonding electron as electrostatic bond of EMS and NNN in pH solution less than pHzpc of prepared samples. In the present study, pH 5 has thus been chosen as the optimum pH for removal of EMS and NNN. It is observed that, adsorption capacity of SnO2 NFs, SnO2 NSs, Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs for removal EMS and NNN are achieved within 40 min and the system attains equilibrium in 40 min, with 4 g/L adsorbent dose and pH 5 of EMS and NNN solution (Fig. 7).

3.3 Photocatalysis efficiency

The degradation efficiency of SnO2 NFs, SnO2 NSs, Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs photocatalysts is calculated by using the degradation percent of EMS and NNN as a function of time. About up to 80.0% of EMS and NNN molecules degrade in 30 min in the presence of SnO2 NFs, SnO2 NSs, Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs, respectively, demonstrating that Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs possess higher photocatalytic activity than SnO2 NFs, and SnO2 NSs (Fig. 8) due to the Fe3O4QDs/SnO2 NFs and CdTe QDs/SnO2 NSs have low values of energy band gap and all samples can adsorb UV light under the present condition according to its UV–Vis DRS shown in Fig. 6A, due to the SPR effect of photocatalyst which in-situ formed under ultraviolet light illumination [30,31,32,33,34,36]. As can be seen from Figs. 7 and 8, adsorption and degradation reaction took place in 40 and 30 min for SnO2 NFs, SnO2 NSs, Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs (Table 1). It can be seen, time of EMS and NNN degradation process is faster than adsorption process. The absorption of light leads to charge separation due to the excitation of the photoelectrons (e−) from the valence band (VB) to the conduction band (CB) causing the generation of holes (h+) in the VB.

3.4 Toxicological affects

The relative survival of human cells following exposure to a range of concentrations of the Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs was distinguished using the MTT assay. The percentage relative of cell survival to the control solvent (DMSO) was determined as the OD percentage value measured after treatment. All three types of cell lines demonstrated more than 80% cell survival in the process group with a maximum concentration (100 mg/L) (Figure not shown). Then, the Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs do not have a toxic influence to humans when used to actual wastewater technology.

3.5 Antibacterial activity

Gram-positive bacteria Staphylococcus aureus and Gram-negative bacteria Pseudomonas aeruginosa were used as target for evaluating the antibacterial activities of Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs. Thus, MIC values were established as the minimum concentration of the material necessary to inhibit the bacteria growth. It was found that the MIC values for the antibacterial assay in the presence of Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs were around 0.38 mM. The inhibition values of Fe3O4 QDs/SnO2 NFs for S. aureus, and P. aeruginosa bacterial strains are 83.4, 85.5 and 85.9, 89.7%, respectively.

4 Conclusions

Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs have been synthesized and investigated for EMS and NNN removal. Acidic pH has been found to favor the adsorption process and thus, all studies have been carried out at pH 5. The synthesized materials are treated as efficient photocatalyst as well as adsorbents for removal of EMS and NNN in 30 and 40 min for photocatlytic and adsorption, respectively. This Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs can be applied to actual wastewater processing due to its low cytotoxic effects on human cells. However, Fe3O4 QDs/SnO2 NFs and CdTe QDs/SnO2 NSs sample presented superior antibacterial activity.

Change history

25 May 2024

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1007/s10854-024-12825-9

References

G.A. Sega, Mutat. Res. 134, 113–142 (1984)

B. Siminszky, L. Gavilano, S.W. Bowen, R.E. Dewey, Proc. Natl. Acad. Sci. 102, 14919–14924 (2005)

T. Uragami, Y. Matsuoka, T. Miyata, J. Membr. Sci. 506, 109–118 (2016)

Y. Hu, T.H. Boyer, Water Res. 115, 40–49 (2017)

T. Park, V. Ampunan, S. Maeng, E. Chung, Chemosphere 167, 91–97 (2017)

A. Fakhri, S. Behrouz, J. Ind. Eng. Chem. 26, 61–66 (2015)

A. Fakhri, S. Adami, J. Taiwan Inst. Chem. Eng. 45, 1001–1006 (2014)

Z.X. Jin, H.Y. Gao, L.H. Hu, RSC Adv. 5, 88520–88528 (2015)

W.X. Zhang, J. Nanopart. Res. 530, 323–332 (2003)

H. Wang, S. Baek, J. Lee, S. Lim, Chem. Eng. J. 164, 355 (2009)

J. Liu, T. Luo, T.S. Mouli, F. Meng, B. Sun, M. Li, Chem. Commun. 46, 472 (2010)

P.G. Luo, S. Sahu, S.T. Yang, S.K. Sonkar, J. Wang, H. Wang, G.E. LeCroy, L. Cao, Y.P. Sun, J. Mater. Chem. 1, 2116–2127 (2013)

X. Guo, C.F. Wang, Z.Y. Yu, L. Chen, S. Chen, Chem. Commun. 48, 2692–2694 (2012)

H. Yu, Y. Zhao, C. Zhou, L. Shang, Y. Peng, Y. Cao, L.Z. Wu, C.H. Tung, T. Zhang. J. Mater. Chem. A 7, 465–471 (2012)

X. Zhang, H. Huang, J. Liu, Y. Liu, Z. Kang, J. Mater. Chem. A 1, 11529–11533 (2013)

A. Fakhri, M. Naji, P.A. Nejad, J. Photochem. Photobiol. B 173, 204–209 (2017)

A.Y. Shenouda, E.M. El Sayed, Ain Shams Eng. J. 6, 341–346 (2015)

H. Zhang, H. Huang, H. Ming, H. Li, L. Zhang, Y. Liu, Z. Kang, J. Mater. Chem. 22, 10501–10506 (2012)

A. Fakhri, S. Tahami, M. Naji, J. Photochem. Photobiol. B 169, 21–26 (2017)

A. Fakhri, P.A. Nejad, J. Photochem. Photobiol. B 159, 211–217 (2016)

A. Fakhri, S. Behrouz, Process Saf. Environ. Protect. 94, 37–43 (2015)

A. Fakhri, S. Behrouz, M. Pourmand, J. Photochem. Photobiol. B 149, 45–50 (2015)

A. Fakhri, Process Saf. Environ. Protect. 93, 1–8 (2015)

A. Fakhri, J. Saudi Chem. Soc. 18, 340–347 (2014)

A. Fakhri, S. Rashidi, I. Tyagi, S. Agarwal, V.K. Gupta, J. Mol. Liq. 214, 378–383 (2016)

V.K. Gupta, S. Agarwal, I. Tyagi, M. Sohrabi, A. Fakhri, S. Rashidi, N. Sadeghi, J. Ind. Eng. Chem. 41, 158–164 (2016)

V.K. Gupta, S. Agarwal, M. Asif, A. Fakhri, N. Sadeghi, J. Colloid Interface Sci. 497, 193–200 (2017)

A. Fakhri, R. Khakpour, J. Lumin. 160, 233–237 (2015)

V.K. Gupta, S. Agarwal, A.K. Bharti, A. Fakhri, M. Naji, J. Mol. Liq. 229, 514–519 (2017)

P. Maneechakr, S. Karnjanakom, J. Chem. Thermodyn. 106, 104–112 (2017)

A. Fakhri, S. Behrouz, Sol. Energy 117, 187–191 (2015)

A. Fakhri, S. Behrouz, Sol. Energy 112, 163–168 (2015)

M.A. Sousa, C. Gonçalves, J.H.O.S. Pereira, V.J.P. Vilar, R.A.R. Boaventura, M.F. Alpendurada, Sol. Energy 87, 219–228 (2013)

J.H.O.S. Pereira, V.J.P. Vilar, M.T. Borges, O. Gonzalez, S. Esplugas, R.A.R. Boaventura, Sol. Energy 85, 2732–2740 (2011)

L.A. Ioannou, E. Hapeshi, M.I. Vasquez, D. Mantzavinos, D. Fatta-Kassinos, Sol. Energy 85, 1915–1926 (2011)

A. Fakhri, M. Naji, P.A. Nejad, J. Photochem. Photobiol. B: Biol. 173, 204–209 (2017)

Acknowledgements

The authors gratefully acknowledge supporting of this research by the Young Researchers and Elites club, Islamic Azad University, Science and Research Branch.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Fakhri, A., Naji, M., Fatolahi, L. et al. RETRACTED ARTICLE: Synthesis and characterization of Fe3O4 and CdTe quantum dots anchored SnO2 nanofibers and SnO2 nanospheres for degradation and removal of two carcinogen substance. J Mater Sci: Mater Electron 28, 16484–16492 (2017). https://doi.org/10.1007/s10854-017-7560-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7560-8