Abstract

A statistical approach (i.e. Taguchi robust design) was used to optimize a precipitation process for controlled preparation of nano-sized erbium carbonate particles. The parameters considered were the concentrations of the cation and anion solutions, as well as the flow rate at which the cation solution was added to the anion solution (Fy) and the temperature at which the reaction took place (Temz). The products were characterized to assess the effects of the parameters on the properties of the product and the optimal product, i.e. the product particles with the smallest size were then thermally treated to yield Er2O3 nanoparticles, which were found to be about 36 nm in average size. The morphology and chemical composition of both nano-structures were evaluated by X-ray diffraction, scanning electron microscopy, FT-IR and UV–Vis spectroscopies. Samples of both particles were tested as photodegradation catalysts for removing methyl orange under ultraviolet light.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The fact technological developments have increased concerns about energy and environmental issues [1,2,3,4]. The environmental pollutions resulting from the industrial effluents are causing serious impacts to the environment and economy [4,5,6,7]. Application of semiconductor-based photocatalysts as green and environment-friendly tools has proven to be very promising for the light-induced degradation of the organic pollutants [8,9,10,11] such as organic dyes that are widely used in various areas like textile, cosmetic, paper, pigment and food manufacturing applications. The emission of such compounds from different industries can majorly cause water pollution and lead to public health threats due to the toxic and carcinogenic influences they are suspected to cause. Hence the removal of these dyes from the environment is a contemporary need. Many approaches have been adopted to this end different physico-chemical methods including adsorption [12], nano-filtration [13, 14], and bio-adsorption [15]. These, like any other approach suffer disadvantages in terms of removal efficiency, which in turn leads to secondary pollution of water samples [16]. A recent solution to this problem is the application of photocatalytic semiconductors which has proven to be a quick approach with considerable yields [17].

Compound of rare earth elements especially carbonate and oxide salts of rare earth elements (REEs) have been found to offer considerable attractive physical and chemical properties [18], and have reportedly been used in applications ranging from scintillating, laser, magnetic, and high efficiency luminescent devices to biomedical, optoelectronic, solid-state, catalytic and photo-catalytic areas [19,20,21,22]. Most of the properties observed in the case of these compounds are very much dependent on the chemical compositions and structures of their compounds and hence the bonding properties of the REE atoms and/or ions. Consequently, nano-structured REE compounds can be anticipated to be very promising materials due to the shape-specific and quantum confinement effects present at such scales [23, 24].

More specifically, the synthesis of micro- and nano-sized erbium carbonate and oxide with various morphologies has been the subject of different studies based on electrochemical [25], magnetron sputtering [26], physical vapor deposition [27] and chemical vapor deposition [28] techniques, yet no such report exists on the application of the precipitation method and consequently this work was focused on the optimizing the different experimental factors influencing the precipitation method in terms of the size of the erbium carbonate particles produced thereby. To this end experiment design was used to study the effects of the concentrations of erbium and carbonate solutions, flow rate at which the cation solution was added to the anion solution (Fy) and the temperature at which the reaction took place (Temz). Next the resulting optimally prepared carbonate sale was used as a precursor to prepare erbium oxide nanoparticles, through calcination and this process was also monitored by thermal analysis techniques to pinpoint the appropriate calcination conditions. Eventually, both products were used as catalysts in the UV-induced degradation of methyl orange (MO).

2 Experimental

2.1 Preparing erbium carbonate and oxide particles

Sodium carbonate and erbium nitrate (analytical grade) were obtained from Merck (Germany) and used as received, in preparing the aqueous solutions used in the preparation procedure. The process for preparing the erbium carbonate nanoparticles included adding Er3+ solutions to those of carbonate ion, at different flow rates (Fy). The reaction mixture was kept under stirring and controlled temperatures. Once the reaction was over, the product was filtered and repeatedly washed with distilled water and ethanol and next dried at 80 °C for 4 h. Details on the values of the different parameters evaluated through the Taguchi robust design (TRD) approach are given in Table 1.

The erbium oxide particles were next prepared through the thermal decomposition of the prepared carbonate salts as the precursor in furnace at 700 °C for 3 h. Typically the thermal treatment step included loading 0.5 g of the precursor into an alumina crucible, and then subjecting the system to the reaction conditions for 3 h.

2.2 Characterization of the product particles

All samples were initially evaluated by scanning electron microscopy (SEM) using a Philips XL30 instrument and gold films by a BAL-TEC SCD Sputter Coater. Also XRD studies were conducted on a Rigaku D/max 2500 V diffractometer with a Cu target. The FT-IR studies were performed using a Perkin Elmer Spectrum 100 instrument and KBr pellet technique. UV–Vis diffuse reflectance spectra (DRS) were obtained under ambient conditions. An Avantes Spectrometer Avaspec-2048-TEC was used in the DRS studies and the data were used to evaluated the optical band gap energy (OBGE) of the product particles. According to the definition, OBGE of a semiconductor is the minimum energy a photon needs to excite one electron from its valence band to its conduction band and can be calculated using Tauc’s equation which illustrates the energy dependence of the absorption edge of semiconductors and is as follows [23]:

where h being Plank’s constant, υ being the frequency of light, α being the absorption coefficient, Eg representing the OBGE and A being a constant value. η Can be either ½ or 2 based on the transition mechanism and was considered ½ for both product particles.

2.3 Photocatalytic evaluations

The synthesized nanoparticles were evaluated in terms of their photo-catalytic activity in the degradation of methyl orange (MO) under UV light. The studies were performed in a cylindrical Pyrex double pipe air-lift photo-reactor equipped with a high pressure (250 W, λ > 254 nm) Hg lamp, placed inside a quartz pipe.

The reaction mixture composed of 500 mL of a 0.1 g/L aqueous suspension of each nano-photo-catalyst also containing 5 mg/L of MO. The mixture was stirred in the dark for 30 min prior to each reaction and then just before the onset of the reaction a sample of the solution was taken and analyzed to measure its initial MO concentration. Next the reaction suspensions were subjected to ultraviolet light under constant aeration and temperature (25 °C) and within the course of the reaction samples were taken and analyzed at 10 min intervals (i.e. 10, 20, 30, 40 and 50 min after the onset of the reaction). These samples were centrifuged before UV–Vis analysis and next their MO contents were measured the λmax of MO using the Beer–Lambert law (Eq. 2) [23, 29]:

with A, ε, b and C representing the absorbance at λmax, the molar absorptivity, the path length of light through the sample and the concentration of the analyte, respectively. Considering A and A0 as the absorbance of light at any time after the reaction and before the onset of the reaction respectively and C and C0 as the corresponding concentrations we have:

and

The kinetics of the degradation reaction was evaluated using the Langmuir–Hinshelwood model, that has been reported to be suitable for describing the photocatalytic degradation of organic molecules at low initial concentrations and is illustrated as follows [23, 30]:

C, kapp, t and \({{ - dC} \mathord{\left/ {\vphantom {{ - dC} {dt}}} \right. \kern-\nulldelimiterspace} {dt}}\) being the concentration, reaction rate constant, and degradation reaction time and rate.

3 Results and discussion

Being a very promising and simple technique for the small or large preparation of nano-sized particles in water [31, 32], co-precipitation is a rather complex process when it comes to controlling the properties of the resulting product. Luckily optimizing the effects of the different various parameters on the outcome of the precipitation can be achieved through statistical optimization techniques. As to the scope of the present study, the major factors influencing the reaction were the concentration of Er3+ and CO3 2− solutions, Fy and Temz, which were evaluated at three levels as illustrated in Table 1.

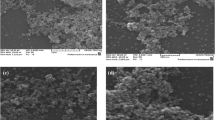

The SEM images obtained for four erbium carbonate samples prepared under different conditions are shown in Fig. 1 and the experimentally determined average particle sizes of the carbonate particles in each experiment are summarized in Table 1. Figure 2, on the other hand, illustrates the results obtained through computation of the effects of each variable under different conditions. The results show the dependence of the particles sizes on the variations in the levels of each factor.

SEM images of erbium carbonate nanoparticles obtained by different runs of OAD (Table 1) via precipitation method: a run 1, b run 3, c run 5, and d run 7

The influence of the different concentrations of Er3+ and CO3 2− solutions on the size of the erbium carbonate were studied using three different solutions of each ion at concentration levels of 0.01, 0.05 and 0.25 mol/L, and the results revealed that the concentration of the anion plays a significant role in determining the size of the solid erbium carbonate particles, while this is not the case with that of the erbium solutions (Fig. 2, Table 2). The effect of the flow rate at which the cation solution was added to the carbonate solution (Fy) was also evaluated at three levels (i.e. 2.5, 10, and 40 ml/min), and the results of ANOVA (Table 2) proved Fy to have a significant influence on the size of the erbium carbonate particles. Also, the effect of the temperature of the reactor (Temz) on the particles was studied at the three different levels of 0, 30 and 60 °C, and Temz was also found to be a significant parameter as to controlling the size of the erbium carbonate particles.

As stated above, based on ANOVA at a 90% confidence level (Table 2), only the concentration of the cation does not have a considerable influence on the properties of the product, given the fact that the present study did not consider the interactions among the four variables. Based on the results 0.01 mol/L was found to be the optimal concentration for the carbonate solution. Further 2.5 mL/min was determined as the optimal Fy, above which the size of the erbium carbonate particles increased. In the case of Temz, 0.0 °C was found to be the optimal value for the reactor temperature. Under the mentioned optimal conditions, obtained based on the OA9 (34) matrix (Table 1), the optimal diameter of the product particles could be predicted using the following expression [33, 34]:

in which T/N is average diameter of erbium carbonate particles plus the contribution of Cx, Fz and Temz above average performance; Yopt is diameter of the optimal particles CX, Fy, and Temz are the optimal CO3 2− concentration, flow rate and temperature values. Also, the confidence interval (CI) of the particle size is obtained using the equation below [35, 36]:

Fα(f1,f2) is a computed value of F at degrees of freedom (DOF) of f1 and f2 and desired confidence level (here, a = 90%), f1 = DOF of mean (which always equals 1), f2 = DOF of the error term, n e = number of equivalent replications, and given by n e = number of trials/[DOF of mean (always 1) + DOF of all factors results used in the estimated].

Based on the calculations on the size of the erbium carbonate particles, the optimal size was determined to be about 29 ± 2 nm, which very well complies with the results in run 1 of Table 1, which expresses the experimental under the optimal conditions from ANOVA (0.01 mol/L for carbonate concentation, 2.5 mL/min for Fy, and 0.0 °C as Temz). The results obtained from the SEM studies indicated that the erbium carbonate particles prepared in this run 1 is about 30 nm in average diameter (Fig. 1a). So the products prepared under the conditions of run 1 were used for further characterization studies including XRD, FT-IR and UV–Vis (Fig. 2).

3.1 Characterization of the optimal product

Using the FT-IR results the functional groups present on the synthesized product was evaluated and the result is given in Fig. 3. The broad band which can be observed around 3450 cm−1 in this figure are attributed to the stretching and bending of H2O molecules [37, 38], the bands at 1529.4 and 1403.2 cm−1 are considered as corresponding the υ3 mode of CO3 2− group, which is split into two bands due to the inhomogeneity of the crystallographic locations of the carbonate ions present in the compound. The bands at 1080.8, 848.6, 750.7 and 689.6 cm−1 further correspond to the stretching modes of the carbonate ion [23].

UV–Vis evaluation of a suspension of the optimal products in water (Fig. 4), included a major absorption peak around 205 nm, which as can be seen gradually decreases as one moves to higher wavelengths. The observations further confirmed the small crystal size of the particles [39].

3.2 Prpearing Er2O3 nanoparticles

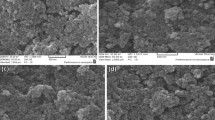

To prepare Er 2 O 3 nanoparticles the optimally prepared carbonate particles were thermally decomposed at 700 °C. The SEM image obtained for the resulting sample (Fig. 5), indicates the Er2O3 nanoparticles to be about 36 nm in average diameter. The sample was also characterized by XRD and FT-IR.

The XRD pattern illustrated in Fig. 6 shows strong intensity peaks in a relative smooth baseline and a wide and low diffraction, indicating the high crystallinty and purity of the sample. The XRD spectrum was found to fully comply with the reference data on cubic Er2O3 (JCPDS file no. 78-0390, space group Ia-3) with the calculated cell parameter of a = b = c (10.6250 Å). The average particle size of the product was calculated by the Scherrer equation [23]. It was concluded that the average particle size of the produced Er2O3 samples is about 66 nm.

The FT-IR results (Fig. 7) also comply with the reports in the literature [23] confirming the formation of Er2O3. Comparing the FT-IR spectra of the precursor (Fig. 3) and that of the thermal decomposition product (Fig. 7), it is clear that the absorption peak in 3450.4 cm−1 which corresponds to the stretching vibration of hydrogen bonds among the hydroxyl groups on the surface of the precursor greatly reduces in the case of the product. This is proof of the complete decomposition of the hydroxyl group due to calcination. Heating of the precursor to 700 °C, further led to the elimination of the characteristic absorption bands of carbonate ion at 1525 and 1403 cm−1, while those of cubic phase Er2O3 appears at 572.3, 479.3 and 422.5 cm−1 emerged (Fig. 7).

3.3 DRS analysis

Figure 8a, b illustrate the UV–Vis-DRS results obtained for the nanoparticles and Fig. 9a, b show Tauc’s plots for the resulting erbium carbonate and oxide nanoparticles. Based on the results, the OBGE of the carbonate nanoparticles is around 4.2 eV, and the oxide sample has two band gaps around 3 and 3.5 eV. The OBGEs lead to absorption edges around 295, 413 and 354 nm for the carbonate and oxide samples, respectively.

4 Photo-degradation of MO

Figure 10 illustrates the results of monitoring the photocatalytic activity of the optimally prepared erbium carbonate and oxide nanoparticles and Fig. 11 the changes in the MO concentration in the presence of the two nanoparticles as plots of C/C0 and degradation efficiency versus time. It can be seen that the degradation reaction in the presence of the pnotocatalytic nanoparticles reaches its ending point after 50 min, yielding maximum conversions of around 99 and 99.3% for the carbonate and erbium oxide salts, respectively.

The results of studying the kinetic behavior of the two reactions as illustrated in Fig. 12 indicates pseudo 1st order kinetics plot in both cases based on the plots of −ln(C/C0) versus irradiation time, and the slopes of the linear regressions provide the 1st order reaction rate constant. The rate constants and maximum conversions of the two photocatalysts are summarized in Table 3. Based on the results it could be concluded that both of erbium salts offer excellent photocatalytic abilities in the degradation of MO and can be considered as potential photocatalysts for removing other organic pollutions from water.

5 Conclusion

Erbium carbonate and oxide nanoparticles were synthesized through optimized direct precipitation of the carbonate salt and its thermal decomposition. The optimization of the carbonate salt was performed through using the TRD to optimize the parameters influencing the precipitation reaction. Analysis of variance (ANOVA) proved that the concentration of carbonate solution, the flow rate of the cation solution, and reactor temperature have considerable effects on the size of the resulting nanoparticles. This proved that the carbonate nanoparticles could be synthesized through a precipitation procedure in the absence of surfactants, templates or catalysts, as can the calcination of the caronate precursor be used for preparing the oxide nanoparticles. Experiments on the photocatalytic effects of the optimally prepared erbium carbonate and oxide nanoparticles, revealed that they can degrade MO up to 99 and 99.3% after 50 min of UV light irradiation.

References

M. Rahimi-Nasrabadi, H.R. Naderi, M. Sadeghpour Karimi, F. Ahmadi, S.M. Pourmortazavi, J. Mater. Sci. Mater. Electron. 28, 1877 (2017)

K. Adib, M. Rahimi-Nasrabadi, Z. Rezvani, S.M. Pourmortazavi, F. Ahmadi, H.R. Naderi, M.R. Ganjali, J. Mater. Sci. Mater. Electron. 27, 4541 (2016)

S.M. Hosseinpour-Mashkani, A. Sobhani-Nasab, J. Mater. Sci. Mater. Electron. 28, 4345 (2017)

B. Golzad-Nonakaran, A. Habibi-Yangjeh, Adv. Powder Technol. 27, 1427 (2016)

M. Rahimi-Nasrabadi, M.M. Zahedi, S.M. Purmortazavi, J. Jazayeri, Microchim. Acta 177, 145 (2012)

M. Rahimi-Nasrabadi, M. Behpour, A. Sobhani-Nasab, M. Rangraz Jeddy, J. Mater. Sci. Mater. Electron. 27, 11691 (2016)

S. Vadivel, D. Maruthamani, B. Paul, S.S. Dhar, A. Habibi-Yangjeh, S. Balachandran, B. Saravanakumar, A. Selvakumar, K. Selvam, RSC Adv. 6, 74177 (2016)

F. Ahmadi, M. Rahimi-Nasrabadi, A. Fosooni, M.H. Daneshmand, J. Mater. Sci. Mater. Electron. 27, 9514 (2016)

A. Akhundi, A. Habibi-Yangjeh, Mater. Chem. Phys. 174, 59 (2016)

A. Sobhani-Nasab, Z. Zahraei, M. Akbari, M. Maddahfar, S.M. Hosseinpour-Mashkani, J. Mol. Struct. 1139, 430 (2017)

M. Rahimi-Nasrabadi, F. Ahmadi, M. Eghbali-Arani, J. Mater. Sci. Mater. Electron. 27, 13294 (2016)

H. Jayasantha Kumari, P. Krishnamoorthy, T.K. Arumugam, S. Radhakrishnan, D. Vasudevan, Int. J. Biol. Macromol. 96, 324 (2017)

M. Liu, Q. Chen, K. Lu, W. Huang, Z. Lü, C. Zhou, S. Yu, C. Gao, Sep. Purif. Technol. 173, 135 (2017)

M.K. Mbacké, C. Kane, N.O. Diallo, C.M. Diop, F.C. Maurice Comtat, T. Tzedakis, J. Environ. Chem. Eng. 4, 4001 (2016)

R. Zhou, R. Zhou, X. Zhang, S. Tu, Y. Yin, S. Yang, L. Ye, J. Taiwan Inst. Chem. Eng. 68, 372 (2016)

A. Arabzadeh, A. Salimi, J. Colloid Interface Sci. 479, 43 (2016)

N. Haghighi, R. Hallaj, A. Salimi, Mater. Sci. Eng. 73, 417 (2017)

M. Rahimi-Nasrabadi, S.M. Pourmortazavi, M. Aghazadeh, M.R. Ganjali, M. Sadeghpour Karimi, P. Novrouzi, J. Mater. Sci. Mater. Electron. 28, 5574 (2017)

M.R. Ganjali, M.B. Gholivand, M. Rahimi-Nasrabadi, B. Maddah, M. Salavati-Niasari, F. Ahmadi, Sens. Lett. 4, 356 (2006)

K. Petermann, G. Huber, L. Fornasiero, S. Kuch, E. Mix, V. Peters, S.A. Basun, J. Lumin. 87–89, 973 (2000)

H. Rétot, A. Bessière, B. Viana, B. LaCourse, E. Mattmann, Opt. Mater. 33, 1008 (2011)

R. Manigandan, K. Giribabu, R. Suresh, L. Vijayalakshmi, A. Stephen, V. Narayanan, Mater. Res. Bull. 48, 4210 (2013)

A. Ziarati, A. Sobhani-Nasab, M. Rahimi-Nasrabadi, M.R. Ganjali, A. Badiei, J. Rare Earths 35, 374 (2017)

P. Aliberti, S.K. Shrestha, R. Li, M.A. Green, G.J. Conibeer, J. Cryst. Growth 327, 84 (2011)

S. Lee, S. Kim, Ceram. Int. 42, 18425 (2016)

P.A. Rayjada, N.P. Vaghela, R. Rahman, M. Bhatnagar, M. Ranjan, N.L. Chauhan, Amit Sircar, L.M. Manocha, P.M. Raole, Nucl. Mater. Energ. 9, 256 (2016)

A. Sawada, A. Suzuki, H. Maier, F. Koch, T. Terai, T. Muroga, Fusion Eng. Des. 75–79, 737 (2005)

M.P. Singh, T. Shripathi, K. Shalini, S.A. Shivashankar, Mater. Chem. Phys. 105, 433 (2007)

M. Rahimi-Nasrabadi, S.M. Pourmortazavi, M. Aghazadeh, M.R. Ganjali, M. Sadeghpour Karimi, P. Novrouzi, J. Mater. Sci. Mater. Electron. 28, 3780 (2017)

M. Rahimi-Nasrabadi, J. Mater. Sci. Mater. Electron. 28, 2200 (2017)

M. Rahimi-Nasrabadi, S.M. Pourmortazavi, M.R. Ganjali, A.R. Banan, F. Ahmadi, J. Mol. Struct. 1074, 85 (2014)

M. Rahimi-Nasrabadi, S.M. Pourmortazavi, M.R. Ganjali, S.S. Hajimirsadeghi, M.M. Zahedi, J. Mol. Struct. 1047, 31 (2013)

M. Rahimi-Nasrabadi, S.M. Pourmortazavi, M. Khalilian-Shalamzari, J. Mol. Struct. 1083, 229 (2015)

S.M. Pourmortazavi, M. Rahimi-Nasrabadi, Y. Fazli, M. Mohammad-Zadeh, Int. J. Refract. Met. Hard. Mater. 51, 29 (2015)

M. Rahimi-Nasrabadi, S.M. Pourmortazavi, M. Khalilian-Shalamzari, S.S. Hajimirsadeghi, M.M. Zahedi, Open. Chem. 11, 1393 (2013)

M. Rahimi-Nasarabadi, F. Ahmadi, S. Hamdi, N. Eslami, K. Didehban, M.R. Ganjali, J. Mol. Liq. 216, 814 (2016)

S.M. Pourmortazavi, S.S. Hajimirsadeghi, I. Kohsari, R. Fareghi Alamdari, M. Rahimi-Nasrabadi, Chem. Eng. Technol. 31, 1532 (2008)

S.M. Pourmortazavi, M. Rahimi-Nasrabadi, S.S. Hajimirsadeghi, J. Dispersion Sci. Technol. 33, 254 (2012)

M. Rahimi-Nasrabadi, S.M. Pourmortazavi, A.A. Davoudi-Dehaghani, S.S. Hajimirsadeghi, M.M. Zahedi, CrystEngComm 15, 4077 (2013)

Acknowledgements

The financial support of this work by Iran National Science Foundation (INSF) and University of Tehran is gratefully acknowledgments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rahimi-Nasrabadi, M., Pourmortazavi, S.M., Karimi, M.S. et al. Statistical optimization of experimental parameters for synthesis of two efficient photocatalyst: erbium carbonate and erbium oxide nanoparticles. J Mater Sci: Mater Electron 28, 15224–15232 (2017). https://doi.org/10.1007/s10854-017-7400-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7400-x