Abstract

A best-performing morphology was proposed for poly(3-hexylthiophene):phenyl-C71-butyric acid methyl ester (P3HT:PC71BM) bulk heterojunction (BHJ) solar cells by thermal and solvent annealings in the presence of rod-coil block copolymers subsuming hydrophilic and hydrophobic coily blocks. Unlike uncompatibilized photovoltaic cells, the power conversion efficiency (PCE) dropping during both thermal and solvent annealings was prevented for all BHJ devices compatibilized with either hydrophobic- or hydrophilic-based copolymers. The observed behavior was assigned to ever increasing trend of the fill factor (FF) and increasing or marginally decreasing trend of short circuit current density (Jsc). Although PCEs were higher in untreated hydrophobic-compatibilized devices (e.g., 4.07 vs. 1.52%), the hydrophilic-compatibilized systems further benefited from thermal and solvent annealings (e.g., 4.78 vs. 3.71%). The Jsc and PCE peaked at 12.10 mA/cm2 and 4.85%, respectively, within 1 h under solvent annealing by 20 wt% of P3HT7150-b-polystyrene compatibilizer. Based on dynamic secondary ion mass spectrometry (DSIMS) analyses, the vertical homogeneity increased for compatibilized BHJs during both thermal and solvent annealings, leading to very high FFs (~69%).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

One of the main concerns in recent years has been control of the active layer morphology in the bulk heterojunction (BHJ) mixtures of the polymer donors and the fullerene acceptors. The optimum morphology generally contains two major factors comprising the molecular ordering within and the phase separation between the donor and acceptor phases. Poly(3-hexylthiophene) (P3HT) and [6,6]-phenyl-C61-butyric acid methyl ester (PCBM) solar cells have attracted a great deal of interest over the past decade [1–3] being routinely employed to produce the high efficient photovoltaic devices [4–6]. Unraveling the complex morphology of the P3HT:PCBM hybrid systems still remained a significant challenge. The large P3HT free region in the P3HT:PCBM BHJs can be frozen in during spin-coating, because the PCBM molecules disperse between the polymer chains and act as defects, which suppress the P3HT crystallization by destroying the chain stacks. Therefore, the P3HT crystallization requiring a free region is generally produced by the driving force provided with either the external treatments including thermal and solvent annealings [7–13] or the internal healing effect of the compatibilizers [14–16], allowing for an increased crystallinity of the P3HT without disruption by the fullerene during drying.

Some publications about the effects of thermal annealing focused on the high temperatures to improve the device performance [17]. However, the device stability was degraded resulting from the formation of the large PCBM clusters under the high-temperature annealings [18]. Because, the phase segregation of the active layer dramatically changed upon heating thanks to the aggregation and diffusion of the PCBM clusters [19]. The phase separation decreases the interfacial area and causes insufficient exciton dissociation between P3HT and PCBM. Moreover, the conjugated polymer may also suffer degradation or large-scale phase separation during thermal annealing at elevated temperatures, leading to poor photovoltaic cell performances [20]. To this end, the solvent treatments have been explored as alternative approaches to impart the molecular mobility and the crystallinity [8].

Including a third component to modify the interfaces in a binary blend provides better opportunities to achieve interesting microstructures [21, 22]. Incorporating the block copolymers in the BHJ film is capable of stabilizing the device structure against the destructive thermal phase segregation as well [23, 24]. They promote the long-term thermal stability of the photovoltaic devices; however, most of acquired power conversion efficiencies (PCEs) are poorer than or similar to that of the pristine solar cells. Furthermore, the compatibilizers have a little effect on the morphological structures before annealing [16]. Recently, some copolymers with pendent donor and acceptor units have been also reported to manipulate the properties of BHJ systems [25, 26].

In this work, we systematically studied the influence of thermal and solvent annealings on the performances of the P3HT:PCBM BHJs compatibilized by the rod (conductive)-coil (dielectric) block copolymers. The photovoltaic devices simultaneously benefited from the thermal stabilities and the high efficiencies. These systems could serve as a model to develop a comprehensive understanding of the strategies necessary for improving the performance of new emerging materials.

2 Experimental

2.1 Synthesis

The highly regioregular P3HTs (>99%) with the polydispersity index (PDI) ranged between 1.21 and 1.25 were synthesized using Grignard metathesis polymerization [27]. The diblock copolymers, i.e., P3HT-b-PEG, P3HT-b-PMMA, and P3HT-b-PS were synthesized with Suzuki coupling [28] and atom transfer radical polymerization [29]. The 1HNMR spectra of synthesized P3HT21000-b-PEG750 and P3HT7150-b-PMMA497 block copolymers are reported in Fig. S1a, b, respectively. The PDIs of the final homo and block copolymers (=1.28–1.35) were determined with a single unimodal peak reflecting in the size exclusion chromatography (SEC) elutogram. The SEC traces of synthesized PS-based homo and copolymers are illustrated as a type in Fig. S2. Thermogravimetric analyses (TGA) of PEG750 (200–398 °C), P3HT21000 (>460 °C)-b-PEG750 (395–460 °C) and P3HT21000 (>470 °C) are reported in Fig. S3. The UV–Vis spectra of P3HT7150-b-PEG, P3HT7150-b-PS and P3HT7150-b-PMMA block copolymers were detected in tetrahydrofuran (THF) and anisole (Fig. S4). For further details, see discussion in the Supplementary Information.

2.2 Fabrication

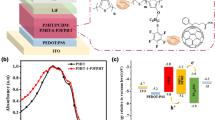

The ternary blend solutions of the P3HT:PCBM (purity >99%):compatibilizer were spin-coated inside a nitrogen glove box with O2 and H2O concentrations maintained at levels less than 1 ppm onto the poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) modified indium tin oxide (ITO) on the glass to yield 150 nm films. The weight ratio of P3HT:PCBM was 1:1.5 wt/wt and the P3HT-b-PS, P3HT-b-PMMA, and P3HT-b-PEG750 were dissolved at different ratios (10–80 wt%) in 1,2-dichlorobenzene with a total concentration of 20 mg/ml. The solvent and thermal annealings were conducted at room temperature (in a glass Petri dish covered with a glass cap) and 150 °C (on a temperature controlled hot plate), respectively. The samples were then kept at room temperature in a N2-filled glove box before analyzing. To complete the device fabrication, a thin LiF interfacial layer (ca. 1 nm) and a 100 nm film of Al were thermally evaporated onto the device under a high vacuum (base pressure less than 2 × 10−4 Pa).

2.3 Characterization

The grazing incidence wide angle X-ray scattering (GISAXS) and grazing incidence small angle X-ray scattering (GIWAXS) patterns were collected by a CMOS flat panel X-ray detector (C9728DK, 52.8 mm square, situated 7.2 cm from the sample) and a CCD detector (MAR165, 165 mm in diameter, 1024 by 1024 pixels resolution, situated 309.5 cm from sample), respectively. The details of the instrumental configuration, operation, and data reduction procedures of the GISAXS and GIWAXS measurements have been described in the literature [30]. The current density–voltage (J–V) characterizations of the organic photovoltaic cells were conducted using a computer-controlled measurement unit from Newport under the illumination of AM1.5G, 100 mW/cm2. The hole-only (ITO/PEDOT:PSS/P3HT:PCBM/Pd) and electron-only (Al/P3HT:PCBM/Al) devices were also prepared separately and the carrier mobility in the active layer was calculated by the space charge limited current model [31].

3 Results and discussion

To the best of our knowledge, the compatibilizing effect of P3HT-b-PMMA rod-coil block copolymers has not been reported previously. Furthermore, in this work for first time, the influences of various types of P3HT-based rod-coil block copolymers having hydrophilic and hydrophobic end coily blocks were systematically compared with together. The improved photovoltaic characteristics (PCE = 4.85%, Jsc = 12.10 mA/cm2, FF = 69%) judged based on cell fabrication under standard conditions were also unprecedented. More details will be rendered in the following sections.

3.1 Vertical homogeneity in compatibilized and annealed BHJs

The dynamic secondary ion mass spectrometry (DSIMS) analyses of uncompatibilized P3HT:PC71BM BHJs, before thermal and solvent treatments, proved an accumulation of P3HT chains and a depletion of PCBM molecules at the interface of the active layer and air (Fig. 1a). The P3HT enrichment served as a blocking layer for electron transport to the cathode, thereby increasing recombination and decreasing the open circuit voltage (Voc), as reported before [32]. Besides, the distribution of P3HT and PCBM in the vertical direction of the active layer was not comprehensively homogeneous. By performing the thermal annealing at 150 °C for 60 min, this heterogeneity became more considerable, because accumulation of the P3HT chains and depletion of the PCBM molecules were intensified at the interface of the active layer and air (Fig. 1a), which was to detriment of the function of respective photovoltaic cells. However, this thermal treatment reflected a better distribution of the PCBM molecules at the interface of the active layer and PEDOT:PSS buffer layer. The solvent annealing at room temperature for 90 min provided a milder treatment condition for the BHJ films. Therefore, the accumulation of the P3HT chains and depletion of the PCBM molecules during the solvent annealing were marginally lower than those occurred during the thermal annealing.

DSIMS results of uncompatibilized P3HT:PC71BM (TA: 60 min and SA: 90 min) (a); P3HT:PC71BM:P3HT7150-b-PMMA (TA: 30 min and SA: 60 min) (b); P3HT:PC71BM: P3HT7150-b-PEG (TA: 210 min and SA: 240 min) (c); BHJs under thermal (TA) and solvent (SA) annealings. The weight percentage of the compatibilizers was 40 wt%. The S and D signals were used to locate the P3HT (or PEDOT:PSS) and deuterated PCBM, respectively

When the P3HT:PC71BM thin films were compatibilized with 40 wt% of P3HT7150-b-PMMA block copolymers, before treatment, the accumulation of the P3HT chains at the active layer/air interface was higher than that of the uncompatibilized films (Fig. 1b). Possibly, in the presence of P3HT7150-b-PMMA compatibilizers, a slight movement occurred for all P3HT chains towards the upper layers of the active layer. Because, the PEC of the photovoltaic cells compatibilized using 40 wt% of P3HT7150-b-PMMA block copolymers reached 3.13% (from 1.65% for corresponding uncompatibilized devices). When the compatibilized system in question underwent a thermal annealing at 150 °C for 30 min, the homogeneity of distribution for donor and acceptor components increased in the vertical direction of the active layer. This homogeneity enhancement reflected the efficiency improvement from 3.13 to 4.03%. By conducting the solvent annealing at room temperature for 60 min, the homogeneous distribution of the P3HT and PCBM became more significant, leading to a higher PEC (= 4.13%). This homogeneity in the vertical direction of the active layer significantly affected FF by increasing it from 52% for untreated films to 59% for the thermal annealed and also to 61% for the solvent annealed films.

Likewise, in the systems compatibilized with P3HT7150-b-PEG (40 wt%), by performing thermal and solvent annealings, the distribution homogeneity of the P3HT and PCBM increased in the vertical of the active layer (Fig. 1c). During these treatments, FF increased from 42% for untreated films to 58 and 59% for the thermal- and solvent-annealed films, respectively. In the presence of the block copolymer compatibilizers having either hydrophobic or hydrophilic coily blocks, the vertical homogeneity of the donor and acceptor components increased during both thermal and solvent annealings (Fig. 1b, c). However, in the uncompatibilized BHJs, these treatments induced a higher heterogeneity (accumulation and depletion) in the vertical direction of the active layer (Fig. 1a). The thermal annealing with the cathode at the top surface was previously found to reduce the P3HT enrichment [33] and lead to higher Voc, Jsc and FF compared to the identical annealing conditions but without the cathode. In this work, this fundamental purpose was met without cathode layer deposition but employing the compatibilizing effect of the rod-coil block copolymers.

3.2 Variation of the P3HT crystallite features in compatibilized BHJs during thermal and solvent annealings

Either in the presence of the compatibilizers or without them, the aspect ratio (the ratio of the P3HT crystallite dimensions in the hexyl side chains direction (a-axis or (100)) to π-π stacking direction (b-axis or (020))) was larger for the thermal annealed BHJs compared to the solvent annealed ones. In fact, by going towards the milder treatments, stacking in π–π direction for the P3HT crystallites became more dominant in comparison to stacking in the hexyl side chains direction. Figure 2 depicts the schemes of the P3HT crystallites in the uncompatibilized, hydrophobic- and hydrophilic-compatibilized films in three states of untreated, thermal and solvent annealed.

The changes in the dimensions of the P3HT crystallites were monitored from the widths of (100) and (020) peaks based on the Scherrer equation (D = 2π/ΔQ, where ΔQ was the full width at half maximum (FWHM)) [34]. In Fig. 3a, the variation of the aspect ratio versus the annealing time is reported for some uncompatibilized and compatibilized BHJ systems with P3HT7150-b-PS, P3HT21000-b-PMMA, and P3HT7150-b-PEG rod-coil block copolymers. By proceeding the solvent annealing, the P3HT crystallites grew faster in b or π–π stacking direction compared to a or the hexyl side chains direction. In contrast, during the thermal annealing at 150 °C, the growth rate became faster in a-axis than b-axis.

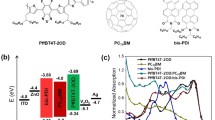

Another conspicuous discrimination between fast and slow growth conditions in this work was in the crystallinity of the BHJ films. In both uncompatibilized and compatibilized systems, the solvent-treated films possessed a higher crystallinity compared to those treated under thermal annealing at high temperature. The enhanced crystallinity of P3HT and its larger crystallites facilitate the hole transport in the active layer [15]. Figure 3b illustrates the peak intensity of (100)OOP for some analyzed films. The milder condition of the solvent annealing allowed the P3HT crystallites to grow with a higher order and regularity. The variation of (100)OOP peak intensity was different for the hydrophilic- (P3HT-b-PEG) and hydrophobic-compatibilized (P3HT-b-PS and P3HT-b-PMMA) systems. More details are represented in Supplementary. An enhanced crystallinity in the hydrophobic-compatibilized BHJs, which improved Jsc [35], was also detected through a red-shift of the spectrum in the wavelength range of the P3HT absorption thanks to the increase of the effective conjugations. Clearer vibronic shoulders (∼550 and 600 nm [36]), due to enhanced interchain interactions proved the crystallinity increase as well.

In the presence of P3HT7150-b-PEG compatibilizers, the external treatments particularly thermal annealing remarkably reflected a phase separation between donor and acceptor components compared to the BHJs compatibilized by P3HT7150-b-PS and P3HT7150-b-PMMA block copolymers. In fact, the hydrophobic-based compatibilizers prevented the donor and acceptor domains from extremely coarsening during annealing (Fig. 4). The energy filtered TEM (EFTEM) images of uncompatibilized and compatibilized active layer by 40 wt% of P3HT7150-b-PS, P3HT7150-b-PMMA, and P3HT7150-b-PEG block copolymers in the untreated as well as the thermal (150 °C) and solvent (25 °C) annealed systems for 180 min are depicted in Fig. 4. The P3HT regions appeared as brighter regions in EFTEM 19 eV images because of their higher low-loss contribution.

EFTEM images of uncompatibilized (first row) and compatibilized active layers by 40 wt% of P3HT7150-b-PS (second row), P3HT7150-b-PMMA (third row), and P3HT7150-b-PEG (fourth row) block copolymers. The first column represents the untreated BHJs and second and third columns denotes the thermal (150 °C) and solvent (25 °C) annealed systems for 180 min. The scale bars are 300 nm

During thermal and solvent annealings, the P3HT crystallite sizes had an ever increasing trend. The coarsening slope for the P3HT crystallites in P3HT-b-PS and P3HT-b-PMMA compatibilized systems decreased versus the annealing time. It infers that the P3HT crystallites grew faster in the shorter periods of time, thereby by proceeding the annealing processes, the rate of the crystallite growth reduced. In the presence of 40 wt% of P3HT7150-b-PS block copolymers under thermal annealing, the difference of the P3HT crystallite sizes in (100)OOP direction in 5 min (D(100)OOP = 76.70 nm) and in 10 min (D(100)OOP = 95.64 nm) was 18.94 nm. However, in the longer periods of time, i.e., 210 min (D(100)OOP = 163.35 nm) and 240 min (D(100)OOP = 165.71 nm), the size difference decreased to 2.36 nm. A similar phenomenon occurred during the solvent annealing. For example, in the presence of 20 wt% of P3HT21000-b-PMMA block copolymers under solvent annealing (Fig. 5a), the difference of the P3HT crystallite sizes within 90 min (D(100)OOP = 102.53 nm) and 120 min (D(100)OOP = 127.65 nm) was 25.12 nm. This crystallite size variation in 210 min (D(100)OOP = 183.29 nm) and 240 min (D(100)OOP = 196.68 nm) reduced to 13.39 nm.

In the BHJ systems compatibilized with P3HT-b-PS and P3HT-b-PMMA block copolymers, within the shorter periods of annealing time, the P3HT crystallite sizes were almost larger in the thermal annealed films compared to those detected for the solvent annealed ones. It was assigned to the higher mobility of the P3HT chains at elevated temperature (150 °C) during the thermal annealing, resulting in coarser P3HT crystallites within the similar annealing times. Here, the BHJ features were governed by the kinetics. After elapsing a given annealing time, the P3HT crystallites were larger in the solvent annealing within the similar annealing time. In longer periods of the annealing time in both solvent and thermal annealed systems, the P3HT crystallites reached a marginally saturated state, i.e., they sufficiently grew. Here, this was the thermodynamics (solvent effect) which controlled the system, and facilitated further growth of the P3HT crystallites. In contrast, in P3HT-b-PEG modified systems, always the influence of the thermal annealing on the P3HT crystallites was more conspicuous compared to the solvent annealing. In the P3HT:PC71BM active layer compatibilized by 40 wt% of P3HT7150-b-PEG, the growth of the P3HT crystallites under thermal annealing within 180 min (D(100)OOP = 140.50 nm) and 210 min (D(100)OOP = 168.69 nm) was 28.19 nm. On the other hand, in the same system but under solvent annealing, the P3HT crystallites grew 21.26 nm in (100)OOP direction (from 105.03 nm in 180 min to 126.29 nm in 210 min). Because in compatibilized systems with 40 wt% of P3HT7150-b-PEG block copolymers, the size of the P3HT crystallites in (100)OOP direction was 8.54 nm, whereas in the presence of a similar composition of P3HT7150-b-PS compatibilizers, their size was 60.38 nm. Therefore, for coarsening the small P3HT crystallites in the presence of the compatibilizers having the hydrophilic coily blocks a strong external deriving force was required. The thermal annealing as a fast growth treatment provided this deriving force better than the solvent annealing as a slow growth treatment. The P3HT-b-PEG compatibilized systems, due to having smaller P3HT crystallites in the untreated state, significantly benefited from the annealing processes for modifying the active layer morphology (see the fourth row in Fig. 4) and, consequently, increasing the PCE. Given the strong dependence of the device Jsc on the morphology of the active layer [37], the external treatments mainly improved Jsc in the hydrophilic-compatibilized BHJs.

The P3HT crystallite size variations in (020)IP direction versus the thermal and solvent annealing time is reported in Fig. 5b for the BHJ systems compatibilized using 40 wt% of P3HT7150-b-PS, P3HT7150-b-PMMA, and P3HT7150-b-PEG block copolymers. Coarsening slopes of the P3HT crystallites during annealing processes were steeper for the hydrophilic-compatibilized systems. In fact, in the hydrophobic-compatibilized systems, the P3HT crystallites demonstrated a higher resistance against coarsening during annealing processes, and thus their coarsening slope versus the annealing time was lower. Furthermore, this resistance against coarsening of the P3HT crystallites was intensified by further passing the annealing time. This could be attributed to the coherent BHJ network and dense P3HT crystallites in the presence of the hydrophobic based block copolymers. However, coarsening in the P3HT crystallites versus the annealing time for P3HT-b-PEG compatibilized systems strongly continued even in the longer periods of the annealing time (Fig. 5a, b). The hole mobility was commensurate with the crystallite size and crystallinity, as reported before [38]. The GIWAXS analyses demonstrated that the P3HT crystallites were mainly edge-on oriented (strong out of plane (100) ((100)OOP) and in plane (020) ((020)IP) peaks), thereby the crystallite sizes acquired from EFTEM images using gray value line-scans of films were correlated with the crystallite dimensions in (020)IP direction.

In all BHJ systems, either uncompatibilized or compatibilized, during both thermal and solvent annealings, d-spacing depicted an ever soaring trend (Fig. 6a, b). The distances between the crystallographic planes were calculated from (100)OOP and (020)IP Bragg peaks position for the edge-on (with the alkyl chain perpendicular to the substrate) and from (100)IP and (020)OOP Bragg peaks position for the face-on (with the alkyl chain parallel with the substrate) P3HT crystallites [39]. The increasing slope of d-spacing in (100)OOP direction during thermal annealing was significantly steeper than that detected under the solvent annealing. Actually, the high-temperature (150 °C) thermal annealing further loosened the P3HT crystallites. In the system compatibilized with 40 wt% of P3HT21000-b-PMMA, d-spacing within 210 min of the thermal annealing increased from 14.15 to 16.10 Å, while in a similar condition but under solvent annealing, d-spacing changed only up to 14.73 Å. The variation of d-spacing versus the annealing time in (100)OOP and (020)IP directions for the systems compatibilized with 20 wt% of P3HT7150-b-PS, P3HT7150-b-PMMA, and P3HT7150-b-PEG block copolymers and also the uncompatibilized P3HT:PC71BM BHJ are reported in Fig. 6a, b, respectively. As shown in Fig. 6a, before conducting the treatments, d-spacings for the hydrophobic-compatibilized BHJs were considerably lower. In the presence of 20 wt% of P3HT7150-b-PS, P3HT7150-b-PMMA, and P3HT7150-b-PEG block copolymers, d-spacings in (100)OOP direction were 14.24, 14.90, and 17.36 Å, respectively. The d-spacings in the hydrophobic-compatibilized BHJs was due to their decisive role in preventing the PCBM molecules from diffusing into the P3HT crystallites. This resistance against loosening of the P3HT crystallites was also detected during the thermal annealing (Fig. 6a). Although there was a significant difference between the thermal and solvent annealings on d-spacing enhancement in (100)OOP direction of the P3HT crystallites, in (020)IP or π–π stacking direction, an infinitesimal distinct was detected (Fig. 6b). More explanations are represented in Supplementary.

3.3 PCBM cluster variations in compatibilized BHJs during thermal and solvent annealings

During annealing processes, coarsening also occurred in the PCBM clusters but with various slopes. Figure 7 depicts the schemes of the PCBM clusters for uncompatibilized (top), hydrophobic-compatibilized (middle), and hydrophilic-compatibilized (bottom) systems in untreated, thermal, and solvent annealed states. Guinier approximation [40] was used to determine mean PCBM cluster size (Rmean) from the low-Q scattering range (ca. 0.006–0.012 Å−1) of the GISAXS curves. Similar to the literature [41], in this work the PCBM scattering intensity increased as a result of forming the larger PCBM clusters. Coarsening versus the annealing time in the uncompatibilized systems was the highest as shown in Fig. 8a, because, P3HT:PC71BM BHJs were not resistant against coarsening during the external treatments. Among the modified systems, the steepest coarsening slope belonged to P3HT-b-PEG compatibilized ones. By using the block copolymers having more hydrophobic coily blocks, coarsening of the PCBM clusters versus the annealing time decreased (see EFTEM images shown in Fig. 4). It could be related to the stabilization of the BHJ morphology via the hydrophobic based compatibilizers, and subsequent increase of their resistance against coarsening during annealing processes. Before conducting any treatment, in P3HT-b-PEG compatibilized systems, the PCBM cluster sizes were the smallest among all BHJs. In the uncompatibilized P3HT:PC71BM as well as in the presence of 20 wt% of P3HT21000-b-PS, P3HT21000-b-PMMA, and P3HT21000-b-PEG block copolymers, the PCBM cluster sizes were equal to 21.06, 27.53, 23.30 and 18.70 nm, respectively. Therefore, smaller PCBM clusters before annealing showed a higher tendency and potential for coarsening under the external treatments. In parallel with the PCBM clusters coarsening, the weakened fluorescence quenching suggested decreased interface area, as previously reported [42]. The cluster coarsening assisted the charge collection through the formation of a network for the efficient electron transport, thus preventing losses due to bimolecular recombination [34]. Moreover, the coherent networking in the hydrophilic-compatibilized systems resulted in a slower PCBM cluster coarsening during annealings compared to the uncompatibilized BHJ. Coarsening slope was also steeper in P3HT-b-PMMA compatibilized films than P3HT-b-PS modified ones (Fig. 8a). By increasing the hydrophobicity of the coily blocks, they could further inhibit the cluster coarsening. They did this task by surrounding the PCBM clusters and inducing a higher order and coherency to the BHJ systems.

It is also notable that the PCBM clusters coarsening was more considerable during the thermal annealing in comparison to the solvent annealing. By moving towards more hydrophilic coily blocks in the compatibilizers, the discrimination between coarsening under the fast and slow growth treatments became more intensified. In the presence of 40 wt% of P3HT7150-b-PS, P3HT7150-b-PMMA, and P3HT7150-b-PEG block copolymers within 240 min, the PCBM cluster sizes (Rmean) under thermal and solvent annealings were equal to 116.94 and 113.98 nm, 132.18 and 123.99 nm, and 185.27 and 175.39 nm, respectively. The differences between the PCBM cluster sizes acquired under thermal and solvent treatments in these systems were 2.96, 8.19, and 9.88 nm, respectively.

Similar to the P3HT crystallites, in the PCBM clusters, d-spacing between the PCBM molecules increased during both thermal and solvent annealings. The d-spacings of PCBM molecules inside the PCBM clusters were calculated based on the peak center position of the PCBM clusters appeared in GIWAXS graphs [43]. The d-spacing enhancement of the PCBM molecules in respective clusters was milder under the slow growth annealing compared to the fast growth treatment. Furthermore, the slope of d-spacing increase in the BHJs compatibilized with the block copolymers having more hydrophobic coily blocks was lower. In fact, the hydrophobic coily blocks not only prevented the PCBM clusters from coarsening during annealing processes but also largely prohibited their loosening. Figure 8b represents the trends of d-spacing alterations versus the annealing time in the PCBM clusters for some uncompatibilized and compatibilized BHJ systems. More quantitative explanations are reported in Supplementary.

3.4 Thermal stability and photovoltaic characteristics of modified devices

In this section, the device performances correlate with the BHJ morphologies modified by the rod-coil block copolymers under thermal and solvent treatments. The increased PCEs, combined with a good thermal stability of devices using the block copolymer compatibilizers, indicated their promising potential for the polymer solar cell applications. The best photovoltaic characteristics, i.e., PCE (4.85%), Jsc (12.10 mA/cm2), FF (69%) and Voc (0.60 V) were obtained thanks to the nanoscale morphology promotion in the active layers. Some J-V curves for the uncompatibilized and compatibilized systems with various compatibilizers and treated under thermal and solvent annealings are reported in Fig. 9. Notably, even after long-term annealings, the PCEs were high. Within 210 min of the solvent annealing and 180 min of the thermal annealing in the presence of 40 wt% of P3HT21000-b-PEG block copolymers, the PCEs were equal to 4.31 and 4.20%, respectively. In contrast, even in the shorter annealing times, for example, 90 min of the solvent annealing and 60 min of the thermal annealing, the PCEs of the uncompatibilized photovoltaic cells were 2.41 and 2.14%, respectively. Therefore, the conspicuous enhancement in the PCEs during the annealing processes originated from the rod-coil block copolymer compatibilizers. In Fig. 10a, the variation of the PCEs versus the annealing time is reported for some uncompatibilized and compatibilized BHJs by 40 wt% of P3HT7150-b-PS, P3HT7150-b-PMMA, and P3HT7150-b-PEG block copolymers. By further proceeding the thermal and solvent annealings, the PCEs considerably dropped for the uncompatibilized photovoltaic cells. The PCE for these systems reached from 1.65 to 2.14% within 60 min of thermal annealing and then plummeted to 0.18% after 240 min. The PCE decrease was rather low for the solvent annealed uncompatibilized systems. The PCE of this device treated under solvent annealing peaked at 2.41% after 90 min and then reduced to 0.63% within 240 min.

In the photovoltaic devices compatibilized by P3HT-b-PS, P3HT-b-PMMA, and P3HT-b-PEG block copolymers, various behaviors were detected for the PCE alteration during solvent and thermal annealings. As illustrated in Fig. 10a, in the presence of 40 wt% of P3HT7150-b-PS block copolymers, the PCE was 4.07% before any treatment. By conducting the thermal annealing for 10 min, PCE peaked at 4.78%. Through further treating, the PCE reached somehow its primary value (=4.08%) within 120 min. Eventually, within 240 min, the PCE decreased to 3.42%. It is vital to mention that in the compatibilized system with 40 wt% of P3HT7150-b-PMMA block copolymers, after 240 min under both thermal (=3.56%) and solvent (=3.51%) annealings, the PCEs were greater than the corresponding PCE before external treating (=3.13%). On the other hand, in the presence of 40 wt% of P3HT7150-b-PEG block copolymers during both thermal and solvent annealings, the PCE depicted an ever soaring trend (Fig. 10a). For example, the PCE in the presence of 20 wt% of P3HT21000-b-PEG block copolymers (=2.35%) after 60, 150, and 210 min of the thermal annealing reached 3.14, 3.70, and 3.87%, respectively, and within the similar times of the solvent annealing obtained the values of 3.29, 3.73, and 3.89%, respectively.

Although before treatments, the PCEs were higher in the hydrophobic-compatibilized devices, the hydrophilic-compatibilized systems further benefited from the thermal and solvent annealings. The PCEs of the latter photovoltaic cells not only did not drop but also showed an ever increasing trend during the external treatments. The principal reason for this phenomenon was related to variations of Jsc (Fig. 10b) and FF (Fig. 10c) during the treatments. These two parameters (Jsc and FF) aided the photovoltaic functions to be more stabilized during the annealing processes. Even if one of them dropped the other compensated it.

Figure 10b depicts the variation of Jsc versus the annealing time for some uncompatibilized and compatibilized BHJs with 20 wt% of P3HT21000-b-PS, P3HT21000-b-PMMA, and P3HT21000-b-PEG block copolymers. For the uncompatibilized devices within 240 min, Jsc (=7.62 mA/cm2) plummeted to 1.30 mA/cm2 for thermal annealed and to 3.12 mA/cm2 for solvent annealed devices. This dropping in Jsc could originate from the crystallinity decrease, d-spacing enhancement in both (100)OOP and (020)IP directions (from d(100)OOP = 16.51 Å and d(020)IP = 3.78 Å for untreated film to d(100)OOP = 19.69 Å and d(020)IP = 4.97 Å for thermal annealed and to d(100)OOP = 17.29 Å and d(020)IP = 4.59 Å for solvent annealed films), coarsening of the P3HT crystallites (from D(100)OOP = 25.12 nm and D(020)IP = 11.63 nm for untreated film to D(100)OOP = 109.30 nm and D(020)IP = 47.52 nm for thermal annealed and to D(100)OOP = 113.65 nm and D(020)IP = 56.26 nm for solvent annealed films), coarsening of the PCBM clusters (from Rmean = 21.06 nm for untreated film to Rmean = 272.77 nm for thermal annealed and to Rmean = 253.25 nm for solvent annealed films), loosening of the PCBM clusters (d-spacing from 4.66 Å for untreated film to 5.80 Å for thermal annealed and to 4.94 Å for solvent annealed films), and also increase of heterogeneity in distributing the donor and acceptor components in the vertical of the active layer (Fig. 1a). The P3HT-b-PS and P3HT-b-PMMA block copolymers largely prevented Jsc from sharply decrease during annealing processes, especially under solvent annealing (Fig. 10b). As an instance, in the compatibilized devices with 40 wt% of P3HT7150-b-PMMA block copolymers, Jsc (=10.39 mA/cm2) after peaking at 12.08 mA/cm2 within 60 min of the solvent annealing, finally in 180, 210, and 240 min reached 11.07, 10.45, and 10.00 mA/cm2 respectively. During this 240 min of the solvent annealing, the hole mobility (μh) changed from 2.2 × 10−5 to 1.6 × 10−5 cm2/V s, and similarly, the electron mobility (μe) altered from 8.8 × 10−5 to 6.4 × 10−5 cm2/V s. Hence, in the presence of 40 wt% of the block copolymers possessing the PMMA blocks, Jsc, μh, and μe did not significantly decrease during external treatments. Moreover, in the mentioned system, FF had an ever soaring trend, i.e., increasing from 52% for the compatibilized but untreated BHJ to 65% within 240 min of the solvent annealing. The principal factors reflected a higher PCE even after 240 min solvent annealing (3.51%) than primary untreated PCE (3.13%) will be explained in the following.

In general, the resistance against the PCE dropping during both thermal and solvent annealings was detected for all BHJ devices compatibilized with the hydrophobic and hydrophilic based block copolymers. It was assigned to ever increasing trend of FF as well as increasing or marginally decreasing trend of Jsc originated from various conditions in distinct BHJ systems. In long-term annealing time, Voc enhancement participated in stabilizing the PCE as well (Fig. 10d). In the BHJ active layers compatibilized with the block copolymers having the hydrophobic coily blocks, due to stabilization of the morphology, extremely coarsening of the PCBM clusters during the annealing processes was significantly prohibited. Furthermore, the quality dropping of the donor and acceptor domains or their loosening during annealings was lower. These phenomena occurred due to a better control of the BHJ morphology and its stabilization by the hydrophobic coily blocks. The hydrophobic based rod-coil block copolymers did the modification and stabilization tasks by surrounding the donor and acceptor domains. In contrast, in the thin films compatibilized by the block copolymers having the hydrophilic coily blocks, coarsening of the PCBM clusters during annealing processes was conspicuously higher. Instead, during the annealing processes the crystallinity of these BHJs considerably increased even above the crystallinity of the hydrophobic-compatibilized systems. The crystallinity enhancement influenced the hole mobility, Jsc, and FF. Moreover, the P3HT crystallites in the presence of the hydrophilic based compatibilizers, which were even smaller than those in the uncompatibilized BHJs, grew intensively during annealing processes. The P3HT crystallite sizes were comparable for the hydrophilic- and hydrophobic-compatibilized systems under similar external treatments. This in turn promoted the photovoltaic characteristics of the devices whose active layers were modified using P3HT-b-PEG block copolymers during thermal and solvent annealings.

In addition to all differences mentioned for the hydrophilic- and hydrophobic-compatibilized BHJs, reaching a more homogeneous distribution of the donor and acceptor components in the vertical of the active layer during solvent and thermal annealings significantly improved FF. The hole and electron mobilities under annealings in the compatibilized BHJ thin films with either hydrophilic or hydrophobic coily blocks peaked at the maximum values. In fact, for each kind of compatibilizers and their composition, there existed an optimum morphology during solvent and thermal treatments. As an instance, in the presence of 40 wt% of P3HT21000-b-PS, the maximum hole and electron mobilities under thermal annealing within 30 min (μh = 4.6 × 10−3 cm2/V s and μe = 5.0 × 10−3 cm2/V s) and under solvent annealing within 60 min (μh = 4.7 × 10−3 cm2/V s and μe = 4.9 × 10−3 cm2/V s) were obtained. Furthermore, in the presence of 20 wt% of P3HT7150-b-PEG block copolymers, the hole and electron mobilities under thermal annealing maximized in 180 min (μh = 5.0 × 10−3 cm2/V s and μe = 5.3 × 10−3 cm2/V s), and during solvent annealing maximized in 210 min (μh = 4.9 × 10−3 cm2/V s and μe = 5.2 × 10−3 cm2/V s).

It worth noting that in the optimum morphology for each BHJ, μh, μe, Jsc and PCE were in their maximum values. In the compatibilized systems, FF most of the time had an increasing trend, whereas for the uncompatibilized devices, FF after peaking at the optimum morphology, depicted a declining trend (Fig. 10c). For example, in the uncompatibilized P3HT:PC71BM active layer, FF (=41%) peaked at 47% within 60 min of the thermal annealing, and then in 180 and 240 min decreased to 37 and 29%, respectively. In the parallel, Jsc (=7.62 mA/cm2) maximized in 9.13 mA/cm2 within 60 min and then in 180 and 240 min dropped to 4.12 and 1.30 mA/cm2, respectively. Here, the simultaneous dropping in FF and Jsc after the optimum morphology and the maximum PCE (PCEmax = 2.14%) led to the PCE reduction during thermal annealing. On the contrary, as an instance in the compatibilized system with 20 wt% of P3HT7150-b-PMMA block copolymers, although after the optimum morphology with the maximum Jsc (=11.98 mA/cm2) and PCE (=3.56%) within 60 min of the thermal annealing, Jsc decreased (to 9.34 mA/cm2 in 240 min), the increase of FF (from 55% in the optimum morphology to 59% in 240 min) as well as Voc (from 0.54 V in the optimum morphology to 0.57 V in 240 min) not only prevented the PCE from falling during the high-temperature thermal annealing, but also increased the PCE (=3.14% after 240 min) even above corresponding PCE before treating (=2.13%). The Voc enhancement was attributed to the crystallinity manipulation and, consequently, an upward shift in the highest occupied molecular orbital of P3HT [44]. The increase in FF was due to a better charge extraction in respective electrodes originated from a higher homogeneity in distribution of the donor and acceptor components. Coarsening of donor and acceptor domains under the external treatments could cause Jsc to decrease.

For the compatibilized active layers, the optimum morphology and the PCEmax acquired faster for the thermal annealing than the solvent annealing. Because the high-temperature thermal annealing (150 °C) was a fast growth condition, thereby made the BHJ system rapidly reach its best performance. Eventually, depending on the balance between the photovoltaic characteristics, the PCE could be higher in the optimum morphology of either solvent or thermal annealed active layers. As an instance, in the presence of 40 wt% of P3HT7150-b-PS block copolymers within 10 min of the thermal annealing, the PCEmax was 4.78% and within 30 min of the solvent annealing, it was 4.76%. However, in the presence of 40 wt% of P3HT21000-b-PEG compatibilizers after thermal annealing for 180 min, the PCE maximized in 4.20%, and it peaked at 4.31% within 210 min of the solvent annealing. The J–V curves for these photovoltaic devices are represented in Fig. 9.

4 Conclusions

The nanostructure of the P3HT:PC71BM, which was critical for the photovoltaic device performance, was modified by conducting the thermal and solvent treatments in the BHJ systems compatibilized with the rod-coil block copolymer compatibilizers. During the external treatments, the P3HT crystallites and the PCBM clusters were simultaneously coarsened and loosened, but with different manners in the hydrophobic- and hydrophilic-compatibilized active layers. In contrast to the uncompatibilized photovoltaic cells, the PCE did not plummet under thermal and solvent annealings for all devices compatibilized with either hydrophobic- or hydrophilic-based block copolymers. It was assigned to the compensation of Jsc decrease with FF and Voc enhancement within the long-term treatments. As evidenced by the DSIMS analyses, in the hydrophobic- and hydrophilic-compatibilized systems, the vertical homogeneity in distribution of the donor and acceptor components increased during both thermal and solvent annealings, leading to considerably high FFs. The hydrophilic-compatibilized systems further benefited from the thermal and solvent annealings compared to the hydrophobic-based ones through mainly increasing the crystallinity. The best photovoltaic characteristics comprising PCE (4.85%), Jsc (12.10 mA/cm2), FF (69%) and Voc (0.60 V) were correlated to the nanoscale morphology promotion in the active layer. These results indicated a promise for the practical usage of rod-coil block copolymers with different main chain moieties towards the fabrication of organic photovoltaic devices with superior stability and competitive optoelectronic properties.

Change history

29 September 2022

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1007/s10854-022-09185-7

27 September 2022

This article has been retracted. Please see the Retraction Notice for more detail: https://doi.org/10.1007/s10854-022-09185-7

References

M. Campoy-Quiles, T. Ferenczi, T. Agostinelli, P.G. Etchegoin, Y. Kim, T. Anthopoulous, P.N. Stavrinou, D.D.C. Bradley, J. Nelson, Nat. Mater. 7, 158–164 (2008)

P. Vanlaeke, A. Swinnen, I. Haeldermans, G. Vanhoyland, T. Aernouts, D. Cheyns, C. Deibel, J. D’Haen, P. Heremans, J. Poortmans, J.V. Manca, Sol. Energy Mater. Sol. Cells 90, 2150–2158 (2006)

T.F. Guo, T.C. Wen, G. L′Vovich Pakhomov, X.G. Chin, S.-H. Liou, P.H. Yeh, C.H. Yang, Thin Solid Films 516, 3138–3142 (2008)

J.L. Wu, F.C. Chen, Y.S. Hsiao, F.C. Chien, P. Chen, C.H. Kuo, M.H. Huang, C.S. Hsu, ACS Nano 5, 959–967 (2011)

M.S. Ryu, H.J. Cha, J. Jang, Curr. Appl. Phys. 10, S206–S209 (2010)

X. Guo, C.H. Cui, M.J. Zhang, L.J. Huo, Y. Huang, J.H. Hou, Y.F. Li, Energy Environ. Sci. 5, 7943–7949 (2012)

X. Lin, J. Seok, S. Yoon, T. Kim, B.S. Kim, K. Kim, Synth. Met. 196, 145–150 (2014)

B. Han, S.A. Gopalan, K.D. Lee, B.H. Kang, S.W. Lee, J.S. Lee, D.H. Kwon, S.H. Lee, S.W. Kang, Curr. Appl. Phys. 14, 1443–1450 (2014)

W. Aloui, T. Adhikari, J.M. Nunzi, A. Bouazizi, Mater. Res. Bull. 78, 141–147 (2016)

B. Jung, K. Kim, Y. Eom, W. Kim, ACS Appl. Mater. Interfaces 7(24), 13342–13349 (2015)

C.M. Fu, K.S. Jeng, Y.H. Li, Y.C. Hsu, M.H. Chi, W.B. Jian, J.T. Chen, Macromol. Chem. Phys. 216, 59–68 (2015)

S.K. Gupta, R. Jindal, A. Garg, ACS Appl. Mater. Interfaces 7, 16418–16427 (2015)

W. Huang, E. Gann, Y.B. Cheng, C.R. McNeill, ACS Appl. Mater. Interfaces 7, 14026–14034 (2015)

S. Miyanishi, Y. Zhang, K. Tajima, K. Hashimoto, Chem. Commun. 46, 6723–6725 (2010)

Z. Sun, K. Xiao, J.K. Keum, X. Yu, K. Hong, J. Browning, I.N. Ivanov, J. Chen, J. Alonzo, D. Li, B.G. Sumpter, E.A. Payzant, C.M. Rouleau, D.B. Geohegan, Adv. Mater. 23, 5529–5535 (2011)

J. Chen, X. Yu, K. Hong, J.M. Messman, D.L. Pickel, K. Xiao, M.D. Dadmun, J.W. Mays, A.J. Rondinone, B.G. Sumpter, S.M. Kilbey, J. Mater. Chem. 22, 13013–13022 (2012)

X.N. Yang, J. Loos, S.C. Veenstra, W.J.H. Verhees,, M.M. Wienk, J.M. Kroon, M.A.J. Michels,, R.A.J. Janssen, Nano Lett. 5, 579–583 (2005)

H. Hoppe, M. Niggemann, C. Winder, J. Kraut, R. Hiesgen, A. Hinsch, D. Meissner, N.S. Sariciftci, Adv. Funct. Mater. 2004, 14(10), 1005–1011

A. Swinnen, I. Haeldermans, M. vande Ven, J. D’Haen, G. Vanhoyland, S. Aresu, M. D’Olieslaeger, J. Manca, Adv. Funct. Mater. 16, 760–765 (2006)

C.H. Woo, B.C. Thompson, B.J. Kim, M.F. Toney, J.M.J. Fréchet,, J. Am. Chem. Soc. 130, 16324–16329 (2008)

B.M. Knickerbocker, C.V. Pesheck, H.T. Davis, L.E. Scriven, J. Phys. Chem. 86, 393–400 (1982)

N.R. Washburn, T.P. Lodge, F.S. Bates, J. Phys. Chem. B 104, 6987–6997 (2000)

K. Sivula, Z.T. Ball, N. Watanabe, J.M.J. Frechet, Adv. Mater. 18, 206–210 (2006)

J.H. Tsai, Y.C. Lai, T. Higashihara, C.J. Lin, M. Ueda, W.C. Chen, Macromolecules 43, 6085–6091 (2010)

Q. Hou, T. Jia, J. Liu, S. Luo, G. Shi, J. Mater. Sci. 24, 4284–4289 (2013)

T. Jia, Q. Hou, K. Xiong, Q. Li, L. Hou, J. Mater. Sci. 25, 1639–1646 (2014)

R.H. Lohwasser, M. Thelakkat, Macromolecules 44, 3388–3397 (2011)

F. Li, Y. Shi, K. Yuan, Y. Chen, New J. Chem. 37, 195–203 (2013)

Z. Gu, Y. Tan, K. Tsuchiya, T. Shimomura, K. Ogino, Polymers 3, 558–570 (2011)

H.C. Liao, C.S. Tsao, T.H. Lin, M.H. Jao, C.M. Chuang, S.Y. Chang, Y.C. Huang, Y.T. Shao, C.Y. Chen, C.J. Su, U.S. Jeng, Y.F. Chen, W.F. Su, ACS Nano 6, 1657–1666 (2012)

Z. Hu, J. Zhang, L. Huang, J. Sun, T. Zhang, H. He, J. Zhang, H. Zhang, Y. Zhu, Renew. Energy 74, 11–17 (2015)

N.C. Giebink, G.P. Wiederrecht, M.R. Wasielewski, S.R. Forrest, Phys. Rev. B 82, 155305 (2010)

S. Nam, J. Jang, H. Cha, J. Hwang, T.K. An, S. Park, C.E. Park, J. Mater. Chem. 22, 5543–5549 (2012)

T. Agostinelli, S. Lilliu, J.G. Labram, M. Campoy-Quiles, M. Hampton, E. Pires, J. Rawle, O. Bikondoa, D.D.C. Bradley,, T.D. Anthopoulos, J. Nelson, J.E. Macdonald, Adv. Funct. Mater. 21, 1701–1708 (2011)

P.E. Keivanidis, T.M. Clarke, S. Lilliu, T. Agostinelli, J.E. Macdonald, J.R. Durrant, D.D.C. Bradley, J. Nelson, J. Phys. Chem. Lett. 1, 734–738 (2010)

S. Samitsu, T. Shimomura, S. Heike, T. Hashizume, K. Ito, Macromolecules 41, 8000–8010 (2008)

H.Y. Chen, H. Yang, G. Yang, S. Sista, R. Zadoyan, G. Li, Y. Yang, J. Phys. Chem. C 113, 7946–7953 (2009)

M.J. Ima, S.Y. Son, B.J. Moon, G.Y. Lee, J.H. Kim, T. Park, Org. Electron 14, 3046–3051 (2013)

J.Y. Kim, C.D. Frisbie, J. Phys. Chem. C 112, 17726–17736 (2008)

W.L. Xu, F. Zheng, J.L. He, M.Q. Zhu, X.T. Hao, Chem. Phys. 457, 7–12 (2015)

D. Chirvase, J. Parisi, J.C. Hummelen, V. Dyakonov, Nanotechnology 15, 1317–1323 (2004)

J.W. Kiel, A.P.R. Eberle,, M.E. Mackay, Phys. Rev. Lett. 105, 168701 (2010)

Y.H. Lee, W.C. Chen, C.J. Chiang, K.C. Kau, W.S. Liou, Y.P. Lee, L. Wang, C.A. Dai, Nano Energy 13, 103–116 (2015)

J. Jo, S.S. Kim, S.I. Na, B.K. Yu, D.Y. Kim, Adv. Funct. Mater. 19, 866–874 (2009)

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

About this article

Cite this article

Agbolaghi, S., Nazari, M., Zenoozi, S. et al. RETRACTED ARTICLE: The highest power conversion efficiencies in poly(3-hexylthiophene)/fullerene photovoltaic cells modified by rod-coil block copolymers under different annealing conditions. J Mater Sci: Mater Electron 28, 10611–10624 (2017). https://doi.org/10.1007/s10854-017-6836-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6836-3