Abstract

Graphene quantum dots (GQDs) have fascinating potential optical applications such as in living cell fluorescent imaging and luminescent sensors and devices. Therefore it is rather important to prepare GQDs with excellent optical performance and high stability. We report here a set of optimum parameters to synthesize GQDs by hydrothermal method, including hydrothermal temperature at 140 °C, hydrothermal time of 9 h and dialysis time of 24 h. By analyzing the parameters, we conclude a surface functional group assisted PL mechanisms of GQDs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Graphene, a two-dimensional material composed of sp2-hybridized carbon atoms, has exhibited numerous extraordinary properties [1–5] and potential applications [6–10]. It provides an excellence platform to study the properties of Dirac like fermions [11]. What is more, the so-called Graphene Quantum Dots (GQDs), obtained by surface modification or size tailoring of one or a few layers of graphene oxide, possess 3D quantum confinement and edge effects [12]. The band gap of GQDs can be regulated by controlling their sizes, while edge effects make dispersion of GQDs feasible in solvents such as water [13].

Top-down and bottom-up are two main protocols of synthesizing GQDs. Cutting graphene sheets into smaller size like ten or a few nanometers by physical or chemical methods are called top-down protocols. Including electrochemical [14], chemical stripping of carbon fiber [15] and hydrothermal method [16]. On the contrary, bottom-up protocol normally controls the prodromal micro molecules to form the structure of nano-sized graphene by polymerization. The main bottom-up methods contain microwave-assisted hydrothermal method [17], direct polymerization [18] and controlled pyrolysis of polycyclic aromatic hydrocarbons [19]. Among these studies, the top-down hydrothermal method expresses advantages such as less reaction time, safer and feasible experimental scheme and low cost. Unfortunately, GQDs synthesized by hydrothermal parameters are usually not uniform and stable [16, 20–22]. In this report, we studied the influence of temperature, hydrothermal time and dialysis time on the photoluminescence of GQDs and obtained stable GQDs with strong photoluminescence which are of great potential in optoelectronics applications.

2 Experimental

2.1 Preparation of graphene oxide

Graphene Oxide (GO) sheets were prepared from natural graphite flakes by a modified Hummers method [23]. Typically, about 3.0 g of natural graphite powder mixed with about 12.0 g KMnO4 was added to acid liquor which consisted of 90 ml of concentrated sulfuric acid and 30 ml of concentrated nitric acid. We then stirred the mixture in a controlled water bath temperature of 50 °C for 24 h. Next, the reaction system was transferred into the ice bath which was kept in 0–2 °C while slowly adding about 150 ml of deionized water in the mixture. After that, about 25 ml of hydrogen peroxide was added and the color of the mixture turned from modena to gold. When the whole mixture turned into gold color, it was mixed with diluted hydrochloric acid in centrifuge tubes. After centrifugation at 8000r/min for 30 min, supernatant liquid was poured out and centrifuge tubes were filled with diluted hydrochloric acid again. Then, the liquid in centrifuge tubes was well mixed and centrifuged again with the same parameters. After three times repetition with diluted hydrochloric acid and five times with deionized water, sediments were extracted out and put into drying oven with 50 °C for 24 h. Finally, prepared GO sheets were pulverized to powder.

2.2 Preparation and characterization of GQDs

GQDs were obtained from the GO prepared by top-down hydrothermal method [16]. About 50 mg of GO was added to 80 ml of deionized water and the PH was tuned to 10. After 20 min ultrasonic, the suspension was transferred into an autoclave and heated for hours. When cooling to room temperature, the resulting black suspension was filtered by 0.22 mm microporous membranes and the transparent golden solution was separated. The colloidal solution was finally dialyzed (1000 Da) and the GQDs were obtained with strong fluorescent recorded at room temperature in Fluoromax-4 fluorescence spectrophotometer using a xenon light source. AFM images were taken using a MultiMode SPM atomic force microscope.

It is still a debatable issue of GQDs photoluminescence (PL) mechanism [24]. In order to better study it, we thus search for a stable high performance sample in this work. The optimum parameters studied here include hydrothermal temperature, hydrothermal time and dialysis time. Firstly, we set the hydrothermal time from 6 to 10 h while hydrothermal temperature and dialysis time were constant at 150 °C and 12 h, respectively. We then vary the dialysis time and hydrothermal temperature in an order, and finally conclude a stable set of parameters exhibiting excellent photoluminescence with a reasonable repetition rate.

3 Results and discussion

3.1 AFM images of GQDs

Figure 1a using a 5 × 5 μm2 AFM image shows GQDs dispersed on GaAs wafer. The white spots distributed on the wafer are considered to be GQDs judged by their sizes. Figure 1b is a 3D image of Fig. 1a. We choose three different axes in Fig. 1a as AB, CD and EF, all crossing the white dots. Figure 1c–e are height curves of AB, CD and EF, respectively. The average height of our GQDs are ranging from 3 to 5 nm, which is similar to the previous literature [25]. Note the size of GQDs are clearly different including a few large crystals over 100 nm, and the various size distribution is common seen in all our samples [26]. This could be resulted from none sufficiently cutting during the hydrothermal processes. Though the sizes are different, it does not change the fact that our GQDs illuminates, and are spectrally differing from graphene oxide [27].

3.2 Varying the parameters to obtain high quality samples

Figure 2 is the emission spectra of GQDs in different hydrothermal time. In accordance with previous reports [16], we firstly set the reaction conditions as 0.05 g of GO, 80 ml of deionized water, PH 10, 12h of dialysis time and hydrothermal time from 6 to 10 h. All peaks are centered at 435 nm in emission spectra with different intensity. The strongest photoluminescent (PL) intensity is obtained when hydrothermal time reaches 9 h. Further increase hydrothermal time will damper the emission intensity as the hydrothermal process is a deoxidization process, which cut the GO sheets into smaller GQDs [28]. From 6 to 9 h, the concentration of GQDs is increasing constantly because of the longer reaction time. After 9 h, however, most of the GO sheets has been cut into small pieces. The main reaction of deoxidization becomes the GQDs themselves.

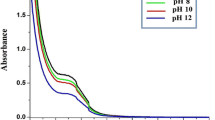

Figure 3 is the emission spectra of GQDs in different dialysis time from 12 to 60 h. The hydrothermal time and hydrothermal temperature were set as 9 h and 150 °C without changing other parameter. The strongest PL intensity appears in the sample of 24 h dialyzed. The inset is the variation trend of emission peaks of 5 samples, showing the PL intensity is increasing with dialysis time and then decreases after 24 h. Dialysis is a common laboratory technique to remove unwanted small molecules. In our case here, dialysis is of great importance to reduce the non-luminant particles which can cause the fluorescence quenching. Non-luminant particles are decreasing constantly with the rise of dialysis time. When the equilibrium is reached by 24 h, the dialysate is rather stable so as the PL intensity. However, it was reported that the PL intensity of GQDs has a strong PH-dependence, as higher PH environment produces stronger PL intensity [16]. We heated the solution of GQDs in alkaline condition by adding NaOH. Not only can the non-luminant particles be reduced following dialysis, but can NaOH particles as well, which will result in the weakening of PL intensity after 24 h.

Figure 4 is the emission spectra of GQDs in different hydrothermal temperature from 100 to 150 °C. With the rising of hydrothermal temperature, the GQDs PL intensity is increasing and then weakened after 140 °C. There are many oxygen-containing groups on GQDs surface which builds up GQDs water solubility, such as hydroxyl and carboxyl. A large amount of GQDs lose their oxygen-containing groups in deoxidization process during 9–10 h and above 140 °C, which declines their water solubility, thus the GQDs PL intensity dramatically decreases as shown in Fig. 4.

3.3 Bright and stable GQDs obtained

Figure 5a is a comparison of the emission spectra of GQDs in different synthesis parameters. Red curve is the PL obtained using our optimum parameters and black curve is the PL produced by choosing the parameters mentioned in Pan’s report [16]. The detailed parameters differences are listed in Table 1. From Fig. 4, we can find the peak value of red curve is three times higher than the black one. The inset illustrated the PL mechanisms of GQDs. When UV lights irradiate on the GQDs, the oxygen-contained functional groups on the GQDs surface will act as luminescence centers and emit blue light [27]. The cutting procedure in hydrothermal method inhibits their optical properties, especially when the GQDs are overreacted. We thus exhibit here the optimum parameters to synthesize GQDs with better PL performance. What is more, we have compared the PL intensity of our samples after 6 months under the same condition and it still illuminates as shown in Fig. 5b. Our findings support the reliability of our optimum parameters for stable high quality GQDs, which are of potential benefits to the optical applications of GQDs.

4 Conclusions

In conclusion, we have developed a set of optimum parameters of preparing GQDs by hydrothermal method. By varying the hydrothermal time, dialysis time and hydrothermal temperature step by step, it is possible to control the PL intensity of GQDs. Eventually, the strongest PL intensity of GQDs is achieved by setting 140 °C as hydrothermal temperature during 9 h hydrothermal time and dialyzing 24 h. The PL mechanism has been discussed and the PL intensity can be kept much more than 6 months. Therefore, the study we accomplished can provide a more bright, stable and controllable experimental basis and is of great importance to the applications of graphene-based materials such as living cell fluorescent imaging and luminescent sensors and devices.

References

K.S. Novoselov, A.K. Geim, S.V. Morozov, D. Jiang, Y. Zhang, S.V. Dubonos, I.V. Grigorieva, A.A. Firsov, Science 306, 666 (2004)

Y. Zhang, J.W. Tan, H.L. Stormer, P. Kim, Nature 438, 201 (2005)

A.K. Geim, K.S. Novoselov, Nat. Mater. 6, 183 (2007)

K.I. Bolotin, K.J. Sikes, Z. Jiang, M. Klima, G. Fudenberg, J. Hone, P. Kim, H.L. Stormer, Solid-State Electron, 146, 351 (2008)

B.R. Matis, J.S. Burgess, F.A. Bulat, A.L. Friedman, B.H. Houston, J.W. Baldwin, Acs Nano 6, 17 (2016)

X. Li, X. Wang, L. Zhang, S. Lee, H. Dai, Science 316, 1229 (2008)

X. Huang, Z. Yin, S. Wu, X. Qi, Q.Y. He, Q.C. Zhang, Q.Y. Yan, F. Boey, H. Zhang, Small 7, 1876 (2011)

Z. Zhang, Y. Pan, Y. Fang, L. Zhang, J. Chen, C. Yi, Nanoscale 8, 500 (2016)

Y. Liu, X. Dong, P. Chen, Chem. Soc. Rev. 41, 2283 (2012)

F. Akbar, M. Kolahdouz, S. Larimian, B. Radfar, H.H. Radamson, J. Mater. Sci. 26, 4347 (2015)

L. Zhu, X. Wang, Phys. Lett. A 380, 2233 (2016)

L.A. Ponomarenko, F. Schedin, M.I. Katsnelson, R. Yang, E.W. Hill, K.S. Novoselov, A.K. Geim, Science 320, 356 (2008)

J.H. Kim, J.S. Suh, ACS Nano 8, 4160 (2014)

Y. Li, Y. Zhao, H.H. Cheng, Y. Hu, G.Q. Shi, L.M. Dai, L.T. Qu, J. Am. Chem. Soc. 134, 15 (2012)

J. Peng, W. Gao, B.K. Gupta, Z. Liu, R. Romero-Aburto, L.H. Ge, L. Song, L.B. Alemany, X.B. Zhan, G.H. Gao, S.A. Vithayathil, B.A. Kaipparettu, A.A. Marti, T. Hayashi, J.J. Zhu, P.M. Ajayan, Nano Lett. 12, 844 (2012)

D.Y. Pan, J.C. Zhang, Z. Li, M.H. Wu, Adv. Mater. 22, 734 (2010)

L.B. Tang, R.B. Ji, X.K. Cao, J.Y. Lin, H.X. Jiang, X.M. Li, K.S. Teng, C.M. Luk, S.J. Zeng, J.H. Hao, S.P. Lau, ACS Nano 6, 5102 (2012)

Y.Q. Dong, J.W. Shao, C.Q. Chen, H. Li, R.X. Wang, Y.W. Chi, X.M. Lin, G.N. Chen, Carbon 50, 4738 (2012)

R.L. Liu, D.Q. Wu, X.L. Feng, K. Mullen, J. Am. Chem. Soc. 133, 15221 (2011)

M. Nurunnabi, Z. Khatun, K.M. Huh, S.Y. Park, D.Y. Lee, K.J. Cho, Y.K. Lee, ACS Nano 7, 6858 (2013)

Q. Chen, C.T. Shi, C.F. Zhang, S.Y. Pu, R. Wang, X.W. Wu, Appl. Phys. Lett. 108, 061904 (2016)

Q.F. Xu, Q. Zhou, Z. Hua, Q. Xue, C.F. Zhang, X.Y. Wang, D.Y. Pan, M. Xiao, ACS Nano 7, 10654 (2013)

R. Kannan, A.R. Kim, K.S. Nahm, D.J. Yoo, Int. J. Hydrogen Energy 40, 11960 (2015)

F.A. Permatasari, A.H. Aimon, F. Iskandar, T. Ogi, K. Okuyama, Sci. Rep. 6, 21042 (2016)

T. Ogi, H. Iwasaki, K. Aishima, F. Iskandar, W.N. Wang, K. Takimiya, K. Okuyama, RSC Adv. 4, 55709 (2014)

X. Wang, J.A. Alexander-Webber, W. Jia, B.P.L. Reid, S.D. Stranks, M.J. Holmes, C.C.S. Chan, C.Y. Deng, R.J. Nicholas, R.A. Taylor, Sci. Rep. 6, 37167 (2016)

Z. Gan, H. Xu, Y. Hao, Nanoscale 8, 7794 (2016)

L. Wang, Y.L. Wang, T. Xu, H.B. Liao, C.J. Yao, Y. Liu, Z. Li, Z.W. Chen, D.Y. Pan, L. Sun, M.H. Wu, Nat. Commun, 5, 5357 (2014)

Acknowledgements

We would like to thank the technical support of Prof. Xiaosi Qi and this work is supported by the National Natural Science Fund of China (No. 61404033) and Returned Overseas Students Funding from Ministry of human resources and social security of China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ma, M., Hu, X., Zhang, C. et al. The optimum parameters to synthesize bright and stable graphene quantum dots by hydrothermal method. J Mater Sci: Mater Electron 28, 6493–6497 (2017). https://doi.org/10.1007/s10854-017-6337-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6337-4