Abstract

novel low-firing microwave dielectric ceramic BiZn2VO6 was prepared using the solid state reaction method. The phase composition, sintering behavior, and microwave dielectric properties were investigated. BiZn2VO6 ceramic could be well densified at relatively low temperature 780 °C and exhibited promising microwave dielectric properties with a ε r = 15.0, Q × f = 20,640 GHz, and τ f = −88 ppm/°C. BiZn2VO6 ceramic has chemically compatibility with Ag electrodes when sintered at 780 °C for 4 h.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, low-temperature co-fired ceramic (LTCC) technology has been extensively investigated because it can satisfy the requirement for minimization to meet the rapid growth of wireless communication industry [1]. The development of LTCC technology has opened up a new stage for the fabrication of miniature multilayer devices [2, 3]. LTCC materials for microwave integrated circuits should possess a low sintering temperature lower than the melting temperature of the inner electrode, such as Ag (~960 °C), a appropriate dielectric constant, a high quality factor and a near-zero temperature coefficient of resonance frequency. The addition of low-melting glass or oxide has been proved to be an effective method to reduce the sintering temperatures but at the cost of deterioration in the microwave properties [4–6]. Thus to obtain glass-free microwave dielectric ceramics with excellent microwave properties is still a challenging research.

More recently, some vanadate ceramics with good microwave dielectric properties have gained considerable attention mainly due to their relatively low sintering temperatures, such as Mg2V2O7 (sintered at 900 °C, ε r = 10.4, Q × f = 31,500 GHz, τ f = −20 ppm/°C [7], LiMVO4 (M = Mg, Zn) (sintered at 675–750 °C, Q × f = 22,000–33,730 GHz, τ f = −160 to −110 ppm/°C) [8], LiCa3MgV3O12 (sintered at 900 °C, ε r = 10.5, Q × f = 74,700 GHz, τ f = −61 ppm/°C) [9]. BiA2VO6 (A = Ca, Mg, Zn, Cu or Pb) compounds constitute a family of functional materials. These compounds have been widely investigated due to their photocatalytic properties, luminescent properties, magnetic properties and nonlinear optical properties [10–13]. Up to date, however, there are few reports on the microwave dielectric properties of BiA2VO6 compounds. Xie et al. [14] firstly reported the microwave dielectric properties of the BiMg2VO6 ceramic (ε r ~ 13.4, Q × f ~ 15,610 GHz, and τ f ~ −87.2 ppm/°C) sintered at 780 °C and its chemical compatibility with silver electrodes. Therefore, it is worthwhile to search for novel microwave dielectric ceramics with intrinsically low sintering temperature in BiA2VO6 system.

In this work, BiZn2VO6 ceramic was prepared by the conventional solid state reaction method, and its crystal structure, sintering behavior and microwave dielectric properties were studied. The chemical compatibility of BiZn2VO6 with silver electrodes was also investigated.

2 Experimental procedure

Using solid-state route, BiZn2VO6 was prepared from high-purity (99 %) powders of Bi2O3, ZnO and NH3VO3. Powders were milled with zirconia balls for 6 h. After dried, the mixtures were calcined at 720 °C for 4 h, followed by re-milling for 4 h. The obtained powder was mixed with 5 wt% polyvinyl alcohol as a binder and then crushed into a fine powder though a sieve with 200 mesh. The fine powder was pressed into pellets with 12 mm in diameter and 7 mm in height under a pressure of 200 MPa. The samples were heated at 550 °C for 4 h to remove the PVA and then sintered at 760–810 °C for 4 h. To research the chemical compatibility of BiZn2VO6 with Ag powders, 20 wt% Ag was mixed with the compound and co-fired at 780 °C for 4 h.

The crystal structure and phase composition of the specimens were analyzed with X-ray diffraction (XRD; Model X’Pert PRO, PANalytical, Almelo, the Netherlands). The bulk densities of the sintered samples were measured using Archimede’s method. The surface microstructures of the samples were performed by scanning electron microscopy (SEM; JSM6380-LV, JEOL, Tokyo, Japan). The microwave dielectric properties were measured using a network analyzer (N5230A, Agilent Co., Palo Alto, California) and a temperature chamber (Delta 9039; Delta Design, San Diego, California). The temperature coefficient of resonant frequency τf values were calculated with the formula as follows:

where, f 85 and f 25 are the resonant frequencies at the measuring temperature 85 and 25 °C, respectively.

3 Results and discussion

XRD patterns of BiZn2VO6 ceramics sintered at different temperatures (760–810 °C) are presented in Fig. 1. Over the sintering temperature range 760–810 °C, pure BiZn2VO6 phase was obtained. It crystallized into a triclinic structure with space group P-1, which is in well agreement with the previous report by Nunes et al. [15] The XRD of the co-fired BiZn2VO6 ceramic with 20 wt% Ag is also shown in Fig. 1. As shown, only the peaks of BiZn2VO6 and Ag (JCPDS No. 004-0783) were observed, implying that BiZn2VO6 did not react with Ag electrodes after sintered at 780 °C for 4 h. From the EDS analysis, two distinct grains with different sizes were detected. The larger grains were rich in Bi, Zn, and V belonging to BiZn2VO6 phase, whereas the smaller grains were detected to be silver. This result further confirmed the chemical compatibility of BiZn2VO6 with Ag electrodes.

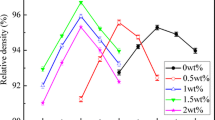

SEM micrographs of the surfaces of BiZn2VO6 ceramics sintered at different temperatures are shown in Fig. 2. As shown in Fig. 2a, a dense microstructure with some pores was observed in the sample sintered at 760 °C with average grain size about 2–3 μm. As the sintering temperature increased, the amount of pore decreased along with an obvious increase in the grain size. For the sample sintered at 780 and 790 °C, much denser microstructures with closely packed grains were achieved and the average grain size was in the range of 3–6 μm. Exaggerated large grains (10–15 μm) appeared in the ceramic sintered at 810 °C. The bulk densities and relative densities of BiZn2VO6 ceramics are shown in Fig. 3 as a function of sintering temperature. The theoretical density of BiZn2VO6 is 6.22 g/cm3. As seen, all the sintered ceramics had high relative densities (>92 %). The bulk density firstly increased with the sintering temperature, and then decreased thereafter, giving rise to a maximum density of 5.94 g/cm3 (95.5 % of the theoretical density) at 780 °C.

The microwave dielectric properties (ε r , Q × f and τ f ) of the sintered BiZn2VO6 ceramics are shown in Fig. 3. As seen, both ε r and Q × f values exhibited clear dependence on the sintering temperature. With increasing sintering temperature, both ε r and Q × f increased firstly, reached a saturated value, and thereafter decreased. τ f values of both ceramics did not change significantly with increasing sintering temperature and remained stable with a value about −87 ppm/°C. The best microwave dielectric properties with a ε r = 15.0, Q × f = 20,640 GHz, and τ f = −88 ppm/°C was obtained for the sample sintered at 780 °C.

It is well known that the factors affecting the microwave dielectric properties are classified into two categories: the intrinsic factors related to the lattice vibration, and the extrinsic ones related to the secondary phases, porosity, densification, and grain boundaries, etc. [16–18]. Based on the similar variation trend in and ε r and Q × f values with that of the density, it is proposed that the primary factor affecting the microwave dielectric properties is densification in the present work. Similar phenomena were reported in BaMV2O7 (M = Mg, Zn) [19] and Ca5A4(VO4)6 (A2+ = Mg, Zn) [20] systems. In order to eliminate the influence of the porosity on the relative permittivity, the Bosman and Having’s correction [21] equation was applied:

where, ε corrected and ε m are the corrected and measured values of permittivity, respectively. P is the fractional porosity. The porosity-corrected ε r value of BiZn2VO6 (in the range 15.9–16.0) showed a slight variation with the sintering temperature, which further confirms that the density primarily affects the permittivity of the BiZn2VO6 ceramics. Moreover, the theoretical relative permittivity was calculated according to the Clausius–Mossotti equation [22, 23]:

where b = 4π/3,α T D is the sum of ionic polarizabilities of individual ions and the V m is the molar volume. The theoretical relative permittivity of BiZn2VO6 ceramic is 13.87. The relative error of BiZn2VO6 is about 7.5 % for the measured value and 13.3 % for the porosity corrected value, which implies that there is no other polarization mechanism in the BiZn2VO6 ceramic at microwave region beside ionic and electronic displacement polarization [24].

By comparison with BiMg2VO6 ceramic, the sintering temperature of BiZn2VO6 is comparable with that of BiMg2VO6 ceramic, while the relative permittivity and quality factor of BiZn2VO6 are a little higher. However, it should be noted that the high negative τ f values of these materials limit their commercial applications. Further efforts are needed to tune the large negative τ f values of BiZn2VO6 and BiMg2VO6 ceramics to be near-zero by forming a composite materials such as TiO2 or CaTiO3 with positive sign of τ f values.

4 Conclusions

In summary, BiZn2VO6 ceramic was prepared through traditional solid-state reaction method. XRD analysis shows that at room temperature BiZn2VO6 crystallizes into a triclinic structure with space group P-1. The bulk density, the relative permittivity, and the quality factor exhibited obvious dependence on the sintering temperature, while the τ f value was insensitive to the sintering temperature. The ceramic sintered at 780 °C exhibited good microwave dielectric properties: ε r = 15.0, Q × f = 20,640 GHz and τ f = −88 ppm/°C. The BiZn2VO6 ceramic is found to be chemically compatible with Ag electrodes when sintered at 780 °C for 4 h. These results open up the possibility of BiZn2VO6 ceramic for LTCC application.

References

D. Zhou, L.X. Pang, Z.M. Qi, B.B. Jin, X. Yao, Sci. Rep. 4, 5980 (2014)

M.T. Sebastian, H. Jantunen, Int. Mater. Rev. 53, 57–90 (2008)

N. Wang, M.Y. Zhao, Z.W. Yin, J. Inorg. Mater. 17, 915–924 (2002)

J.M. Wu, H.L. Huang, J. Mater. Res. 15, 222–227 (2000)

R. Umemura, H. Ogawa, A. Kan, J. Eur. Ceram. Soc. 26, 2063–2068 (2006)

S.X. Dai, R.-F. Huang, D.L. Wilcox, J. Am. Ceram. Soc. 85, 828–832 (2002)

M.R. Joun, J.S. Kim, M.E. Song, S. Nahm, J.H. Paik, B.H. Choi, J. Am. Ceram. Soc. 92, 1621–1624 (2009)

W.B. Li, H.H. Xi, D. Zhou, Ceram. Int. 41, 9063–9068 (2015)

L. Fang, C.X. Su, H.F. Zhou, Z.H. Wei, H. Zhang, J. Am. Ceram. Soc. 96, 688–690 (2013)

J. Huang, A.W. Sleight, J. Solid State Chem. 100, 170–178 (1992)

A. Mizrahi, J.P. Wignacourt, M. Drache, P. Conflant, J. Mater. Chem. 5, 901 (1995)

R. Guo, G. Zhang, J. Liu, Mater. Res. Bull. 48, 1857–1863 (2013)

A. Barros, R. Deloncle, J. Deschamp, P. Boutinaud, G. Chadeyron, R. Mahiou, E. Cavalli, M.G. Brik, Opt. Mater. 36, 1724–1729 (2014)

H.D. Xing, H.H. Xi, L. Fei, C. Chao, J. Inorg. Mater. 30, 202–206 (2015)

S.E. Nunes, C.H. Wang, K.W. So, J.S.O. Evans, I.R. Evans, J. Solid State Chem. 222, 12–17 (2015)

N.M. Alford, J. Breeze, X. Wang, S.J. Penn, S. Dalla, S.J. Webb, N. Ljepojevic, X. Aupi, J. Eur. Ceram. Soc. 21, 2605–2611 (2001)

S.J. Penn, N.M. Alford, A. Templeton, X. Wang, M. Xu, M. Reece, K. Schrapel, J. Am. Ceram. Soc. 80, 1885–1888 (1997)

Y.C. Chen, Y.N. Wang, C.H. Hsu, Mater. Chem. Phys. 133, 829–833 (2012)

L. Fang, Z.H. Wei, C.X. Su, F. Xiang, H. Zhang, Ceram. Int. 40, 16835–16839 (2014)

G.G. Yao, P. Liu, H.W. Zhang, J. Am. Ceram. Soc. 96, 1691–1693 (2013)

A.J. Bosman, E.E. Havinga, Phys. Rev. 129, 1593–1600 (1963)

S.H. Yoon, D.W. Kim, S.Y. Cho, H.K. Sun, J. Eur. Ceram. Soc. 26, 2051–2054 (2006)

R.D. Shannon, J. Appl. Phys. 73, 348–366 (1993)

D. Zhou, C.A. Randall, H. Wang, X. Yao, J. Am. Ceram. Soc. 94, 348–350 (2011)

Acknowledgments

This work was supported by Natural Science Foundation of China (Nos. 21261007, 21561008, and 51502047), the Natural Science Foundation of Guangxi Zhuang Autonomous Region (Grant No. 2015GXNSFBA139234 and 2015GXNSFFA139003), Project of Department of Science and Technology of Guangxi (No. 114122005-28), and Projects of Education Department of Guangxi Zhuang Autonomous Region (No. ZD2014160, KY2015YB341, and KY2015YB122).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Luo, H., Li, J., Xu, J. et al. A novel low-firing BiZn2VO6 microwave dielectric ceramic with low loss. J Mater Sci: Mater Electron 27, 210–214 (2016). https://doi.org/10.1007/s10854-015-3739-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-3739-z