Abstract

In the current study three sets of Aluminum and Gallium co-sputtered Zinc Oxide films were grown with varying sputtering power (100, 200 and 300 W) on soda lime glass substrate using DC sputtering. Aluminum doped ZnO (Al2O3 2 wt%), Gallium doped ZnO (Ga2O3 2 wt%) sputtering targets were used. The thickness ratio of Al doped ZnO and Ga doped ZnO (1:1) was maintained same in all the Al and Ga co-sputtered (ZAG) thin films. Optical absorption data reveals the high transmission for the as grown films which achieved a maximum value of nearly 90 % in visible spectra for the 100 W deposited ZAG film. The XRD graph indicates a (002) preferred growth with other weak peaks at (102) and (103). This confirms the polycrystalline nature of the film. Intense peak is observed corresponding to (002) phase which implies a better crystallite size for the 300 W grown ZAG film. XRD results suggest that with increasing sputtering power the crystallite size shows an increasing trend. Hall Effect Measurement system was used to measure the electrical properties viz. carrier concentration, resistivity and mobility of the ZAG films. Lowest resistivity value of 5.46 × 10−4 Ω cm was obtained for the ZAG film deposited at sputtering power of 300 W. It was revealed from the obtained data with increasing sputtering power the resistivity value decreased and in the scale of 10−3 to 10−4 Ω cm with high optical transmittance.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Transparent conductive oxide (TCO) films are progressively substantive in rapidly growing optoelectronic applications such as flat panel displays and solar cells. Continuous development of the superior-performance optoelectronic devices induces the research on TCO films. For TCO films in solar cell applications, high conductivity and high transparency in the visible and near-infrared (NIR) wavelengths are demanded in order to enhance the conversion efficiency of solar cells [1]. In the present time research on ZnO puts an extraordinary trust on the development of new TCO films [2, 3]. ZnO has stable electrical, structural and better optical properties. It is a demanding and promising material for various applications. ZnO belongs to wide band gap semiconductor having a band gap of 3.37 eV. Al, Ga and In are being considered as dopants for ZnO to manufacture transparent electrodes [4, 5]. Study of both electrical and optical properties of doped Zinc oxide films is helpful in optimizing the film parameters. Researchers are now-a-days looking for both doped and co-doped ZnO films for further progress of energy conversion and optoelectronic devices [6]. These TCO films can be used in solar cells, flat panel displays and electro chromic windows [7]. For solar cell application, TCO films should have a large band gap (nearly 3.2 eV), low resistivity (10−3 to 10−4 Ω cm) and a very good optical transmittance (80–90 %) in the visible range [8, 9]. In the co-doping process, the third group elements viz. Aluminum and Gallium atoms become attached to ZnO by substitution and act as donors thus contributing to n-type conductivity. The present study focuses on the impact of sputtering power on structural, optical and electrical properties of Aluminum and Gallium (ZAG) co-doped thin films on glass substrates for solar cell application.

2 Experimental details

DC sputtering was used to deposit ZAG thin films on soda lime glass substrate using different sputtering powers. The glass substrates were cleaned first in the boiling soap solution followed by ultrasonic cleaning in propanol and deionized (DI) water. Then the glass substrates were dried in blowing N2. Different targets, such as ZnO:Al2O3 (2 wt%) and ZnO:Ga2O3 (2 wt%) having diameter 3, thickness 3 mm and purity 99.99 % were used for the deposition of ZAG thin films. All the depositions were carried out at room temperature. The chamber pressure was maintained at 6.8 × 10−6 mbar and the depositions were done under a working pressure of 8.1 × 10−3 mbar. During the deposition of ZnO film, the substrate rotation was kept at 20 rpm for uniform deposition of the film. The films were deposited at three different sputtering powers, viz. 100, 200 and 300 W. The sputtering time was adjusted such that we can achieve thickness of nearly 300 nm for all the deposition. The specific thickness was chosen as this the standard thickness used in thin film polycrystalline solar cells. X-ray diffraction with CuKα line (λ = 1.54 Å) was used to study the crystallographic properties of the ZAG films (XRD-6100, Shimadzu X-ray Diffractometer). The scan was done for 2θ from 20° to 80°. Resistivity, carrier concentration and hall mobility, were obtained by Hall-Effect Measurement System (Ecopia HMS 3000). The measurements were carried out at room temperature. The optical transmission spectra were obtained using UV–Visible spectrophotometer (Shimadzu 2450). The infrared spectra were obtained from Fourier transform infrared spectroscopy (FTIR). The thickness of all ZAG films was determined from Thin Film Analyzer (Filmetrics F10). The thickness of the films is given in Table 1.

3 Result and discussion

Figure 1 shows the optical transmission spectra of ZAG films (deposited at 100, 200 and 300 W) from 300 to 800 nm. From Fig. 1, it is revealed that the transmittance of ZAG thin film, deposited at 100 W shows higher transmission (above 90 %) in the visible range. Whereas for the samples deposited at 200 and 300 W around 80 % transmission is observed. The transmittance shows a decreasing trend with the increase in sputtering power which suggest that more electrons takes part in inter-band transition increasing the light absorption and subsequently decreasing the transmittance in the visible range [10–12]. Band gap of the ZAG films were estimated from

where B is a constant, Eg is the band gap energy and n = 2 for direct bandgap transition. The direct bandgap value of the ZAG films is determined by a plot of (αhν)2 as a function of photon energy hν (Fig. 1) [13]. The bandgap values are given in Table 1. From Fig. 1 film deposited at 200 W shows lower band gap as compared to the film deposited at 100 W. This may be linked to the shrinkage of band gap which occurs when the impurity concentration becomes high [14]. This effect is known as band gap narrowing (BGN) which leads to emerging of impurity band by the overlapping of impurity states [15]. On the other hand, the film obtained at 300 W shows an increase in band gap value. This increase in band gap value can be understood by Burstein-Moss shift which is expressed as follows:

where h and Mvc are Planck’s constant and the reduced mass (M −1vc = M −1e + M −1h , where Me and Mh are the effective masses of electron and hole respectively). The above equation suggests that the band gap energy varies linearly with n2/3. Therefore the observed increase in bandgap is due to increase in carrier concentration of the film [16]. From Hall Effect Measurement data which is shown in Table 2, it shows that the carrier concentration is more for the film which was deposited at a higher sputtering power. But for ZAG film deposited at 200 W, in spite of higher carrier concentration, the energy gap value is lower than the film. So in case of 200 W deposited film, rather than B–M effect the decrease in band gap is explained in terms of BGN effect as discussed above.

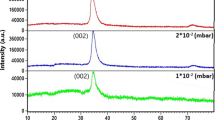

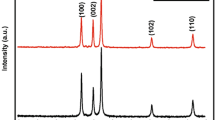

XRD pattern of ZAG thin films is shown in Fig. 2. All the ZAG films grown at room temperature show a (002) preferred orientation, which indicates the hexagonal wurtzite phase of ZnO. Few other weak peaks are also observed at (102) and (103) respectively, which confirms the polycrystalline nature of the films. These weak peaks correspond to wurtzite hexagonal structure of ZnO. The presences of these weak peaks in the present films show the crystal reorientation effect [17]. The main peak (002) intensity increases with the increase in sputtering power. The reason may be the c-axis preferred orientation which increases with the increasing sputtering power [18]. The existence of c-axis preferred orientation is mainly due to reduction of surface energy and internal stress [19]. The XRD data are useful in determination of the crystallite size of the ZAG films. The crystallite size corresponding to (002) phases of the respective co-doped ZnO (ZAG) thin films are found using Scherrer’s formula, expressed as

where D is the crystallite size, λ is the X-ray radiation wavelength, β is the full width at half maximum (FWHM) of the diffraction peak and θ is the Bragg diffraction angle [20, 21]. FWHM value is useful for crystallite size calculation. The above equation suggests a decrease in FWHM will give an increase in crystallite size. The present result shows that by increasing the sputtering power for deposition of ZAG film, the crystallite size increases. This is because of increase of electron mobility on the surface of the film resulting enhanced kinetic energy of the sputtered particles [22]. The FWHM and the crystallite size values are given in Table 1.

Figure 3 shows the FTIR spectra of the deposited ZAG thin films. For all ZAG films peak at 475 cm−1 is observed in the stretching modes. The intensity of the peak is prominent for a ZAG thin film, which was deposited at 300 W. It implies that the crystallite size suddenly increases at 300 W deposition [23]. The same trend is also confirmed from the XRD results of the films.

Table 2 gives the measured electrical properties such as carrier concentration, mobility and resistivity for all the ZAG thin films using Hall Effect Measurement. From Table 2 it was confirmed that the carrier concentrations increase with the increase in sputtering power. This is attributed to increase in lattice distortion in the film [5]. With increasing sputtering power, the energy of the sputtered particles increases. It allows them to form intended bonding with the neighboring atoms. The energetic particles also lead to increase of the density of various defects in the film which in turn increase the carrier concentration [24, 25]. From the literature, we found that both films deposition methods and the deposition process parameters have influence on the resistivity of the film [26, 27]. The decrease in resistivity for the ZAG films deposited at high sputtering power indicates the decrease in the grain boundary related barriers and corresponding increase of crystallite size [28]. The increase in crystallite size increases the mobility of the ZAG films [5, 26, 29]. With increasing sputtering power, improvement in grain growth is noticed which lead to less scattering at grain boundaries as well as intra-grain defects [15]. As a result the thickness of potential barrier at the grain boundary decreases and the tunneling probability of carriers become large. This leads to increase in mobility of the ZAG films [30]. The resistivity obtained for ZAG thin films which were deposited at high sputtering power in the present case is better as compared to the previous reported resistivity for doped ZnO thin film [15, 31] and the optical transmission of the films are also comparable and/or better to the reported transmission for the application of front contact layer in thin film photovoltaic devices [32, 33].

4 Conclusion

In the current study, the co-sputtered doped ZnO (ZAG) thin films were deposited on glass substrates by varying the sputtering power. The main focus is to use these doped ZnO thin films as a front contact in thin film solar cell. More than 80 % transmissions for all the ZAG films are observed, which is ideal and required transmission for polycrystalline thin film solar cell application as a front contact. From XRD and FTIR study, an increase in crystallite size is observed with an increase in the sputtering power. With increasing sputtering power the electrical properties (mobility, carrier concentration and resistivity) are also enhanced. It is found that ZAG thin films which were deposited using high sputtering power (200 and 300 W) have the resistivity of the order of 10−4 Ω cm with better optical transmittance. Thus it can be concluded that a higher deposition power is ideal for fabricating low resistive and high transmissive doped ZnO thin films of nearly 300 nm, suitable for photovoltaic application.

References

J.P. Kim, J.S. Bae, T.E. Hong, M.S. Won, J.H. Yoon, B.S. Lee, H.J. Lee, Thin Solid Films 518, 6179 (2010)

K.C. Park, D.Y. Ma, K.H. Kim, Thin Solid Films 305, 201 (1997)

X.-R. Deng, H. Deng, M. Wei, J.-J. Chen, J. Mater. Sci.: Mater. Electron. 23, 413–417 (2012)

C. Li, M. Furuta, T. Matsuda, T. Hiramatsu, H. Furuta, T. Hirao, Thin Solid Films 517, 3265 (2009)

D.-K. Kim, C.-B. Park, J. Mater. Sci.: Mater. Electron. 25, 1589–1595 (2014)

C. Guillen, J. Herrero, Vacuum 84, 924 (2010)

D.S. Ginle, C. Bright, MRS Bull. 25, 15 (2000)

S.D. Shinde, A.V. Deshmukh, S.K. Date, V.G. Sathe, K.P. Adhi, Thin Solid Films 520, 1212–1217 (2011)

C.-F. Yu, S.-H. Chen, S.-J. Sun, H. Chou, Appl. Surf. Sci. 257, 6498–6502 (2011)

W.J. Jeong, S.K. Kim, G.C. Park, Thin Solid Films 506–507, 180–183 (2006)

T. Terasako, H. Song, H. Makino, S. Shirakata, T. Yamamoto, Thin Solid Films 528, 19–25 (2013)

B.G. Choi, I.H. Kim, D.H. Kim, K.S. Lee, T.S. Lee, B. Cheong, J. Eur. Ceram. Soc. 25, 2161–2165 (2005)

L. Dghoughi, F. Ouachtari, M. Addou, B. Elidrissi, H. Erguig, A. Rmili, A. Bouaoud, Phys. B 405, 2277 (2010)

C.E. Kim, P. Moon, S. Kim, J.-M. Myoung, H.W. Jang, J. Bang, I. Yun, Thin Solid Films 518, 6304–6307 (2010)

Q. Huang, Y. Wang, S. Wang, D. Zhang, Y. Zhao, X. Zhang, Thin Solid Films 520, 5960–5964 (2012)

H. Hiramatsu, W.-S. Seo, K. Koumoto, Chem. Mater. 10, 3033–3039 (1998)

G. Sanon, R. Rip, A. Mansingh, Thin Solid Films 190, 287–301 (1990)

Z.B. Ayadi, H. Mahdhi, K. Djessas, J.L. Gauffier, L. Elmin, S. Alaya, Thin Solid Films 553, 123–126 (2014)

R. Vettumperumal, S. Kalyanaraman, R. Thangavel, J. Mol. Struct. 1059, 61–67 (2014)

F. Yakuphanoglu, S. Ilican, M. Caglar, Y. Caglar, J. Optoelectron. Adv. Mater. 92, 180 (2008)

W. Lin, R. Ma, W. Shao, B. Liu, Appl. Surf. Sci. 253, 5179 (2007)

Z. Huafu, L. Hanfa, L. Chengxin, Z. Aiping, Y. Changkun, J. Semicond. 31(8), 083005 (2010)

R.N. Gayen, K. Sarkar, S. Hussain, R. Bhar, A.K. Pal, Indian J. Pure Appl. Phys. 49, 470–477 (2011)

K.-J. Ahn, J.-H. Park, B.-K. Shin, W. Lee, G.Y. Yeom, J.-M. Myoung, Appl. Surf. Sci. 271, 216–222 (2013)

J.-H. Park, J.-B. Lim, B.-T. Lee, Semicond. Sci. Technol. 28, 065004 (2013)

J. Kang, H.W. Kim, C. Lee, J. Korean Phys. Soc. 56(2), 576–579 (2010)

T. Ghosh, M. Dutta, D. Basak, Mater. Res. Bull. 46(7), 1039–1044 (2011)

X.M. Duan, C. Stampfl, M.M.M. Biled, D.R. Mckenzie, Phys. Rev. B 79, 235 (2009)

Y.C. Lin, T.Y. Chen, L.C. Wang, S.Y. Lien, J. Electrochem. Soc. 159(6), H599–H604 (2012)

T. Matsumoto, K. Mizuguchi, T. Horii, S. Sano, T. Muranaka, Y. Nabetani, S. Hiraki, H. Furukawa, A. Fukaswa, S. Sakamoto, S. Hagihara, H. Kono, K. Kijima, O. Abe, K. Yashiro, Jpn. J. Appl. Phys. 50, 05FB13 (2011)

T. Nam, C.W. Lee, H.J. Kim, H. Kim, Appl. Surf. Sci. 295, 260–265 (2014)

T. Tohsophon, J. Hüpkes, H. Siekmann, B. Rech, M. Schultheis, N. Sirikulrat, Thin Solid Films 516, 4628–4632 (2008)

R. Menner, D. Hariskos, V. Linss, M. Powalla, Thin Solid Films 519, 7541 (2011)

Acknowledgments

The authors would like to thanks Defence Research and Development Organization, DRDO for financial support through Grant ERIP/ER/0903813/M/01 and Department of Science and Technology, DST for financial support through Grant no. DST/TM/SERI/2K11/42.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, C.A., Mangal, S. & Singh, U.P. Impact of sputtering power on the properties of Al and Ga co-sputtered ZnO thin films. J Mater Sci: Mater Electron 26, 4280–4284 (2015). https://doi.org/10.1007/s10854-015-2979-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2979-2