Abstract

A series of Sb-doped CaCu3Ti4O12 ceramics were fabricated by the conventional solid state method, and their crystalline structures, microstructures and dielectric properties were investigated systematically. All the ceramic samples exhibited perovskite-related structures in space group Im \(\bar{3}\). The grain size decreased slightly as Sb concentration increased; whereas the dielectric permittivity of the ceramics increased slightly. The giant dielectric response was considered to be closely related with a reduction in the potential barrier height at grain boundaries (GBs). The activation energy for the dc conduction process is comparable to that for conduction at GBs, indicating that the dc conduction process is associated with the electrical response of GBs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

CaCu3Ti4O12 (CCTO) has been attracted considerable attention due to its colossal dielectric constant (ε′) of more than 104 and stable electrical response over a wide temperature range (100–600 K) [1, 2]. It is theorized to be a kind of potential materials for many electronic technological applications, such as capacitors, memories, gas sensors and filters [3]. CCTO exhibits non-ferroelectric cubic perovskite structure, and no phase or crystal structure transformation occurs below 100 K [4]. Researchers have proposed some possible mechanisms based on extrinsic or intrinsic effects to clarify the origin of unusual dielectric responses, including the local dipole moments associating with off-center displacement of Ti ions [5], the Cu deficiency model [6], the internal domains model [7], and the nanoscale disorder model [8]. The most widely accepted mechanism is the internal barrier layer capacitor (IBLC) model based on Maxwell–Wagner polarization, which states the giant dielectric permittivity should be attributed to the special electrically heterogeneous microstructure [9, 10]. It is consisting of thin insulating grain boundaries (GBs) and large n-type semiconducting grains. The changes in electric conduction of grain, domain boundaries and sample-electrode interface have a notable effect on the dielectric properties [11]. Unfortunately, to date, the comprehensive and accurate mechanism is still controversial.

It is well understood the excellent dielectric response may be derived from the different electric characteristics of grains and GBs. The semiconduction of grains is generated by the oxygen vacancies or non-stoichiometry of Ti and Cu ions as previous reported, implying a promising way to develop new dielectric materials [12, 13]. There are many investigations focusing on the influence of external element doping on CCTO ceramics because the intrinsic electric properties can be tuned. For instance, the effect of substitution of La, Bi and rare-earth element on Ca sites [14–16]; Mn, Mg, Zn on Cu sites [17–19]; Ta, Nb and W on Ti sites [20–22] have been widely studied. Besides the sintering process factors (i.e. sintering temperature and atmosphere), the microstructures and dielectric properties are also significantly influenced by doping metal ions. Unfortunately, up to date, the dielectric properties of Sb-doped CCTO ceramics have not been reported. In this work, we prepared polycrystalline CaCu3Ti4−xSbxO12 ceramics (x = 0, 0.025, 0.050) by the conventional solid state reaction method. The purpose was to discuss the role of Sb substitution on dielectric response over wide ranges of temperature and frequency, and the possible mechanism was discussed.

2 Experimental

The CaCu3Ti4−xSbxO12 ceramics, where x = 0, 0.025, 0.050, were prepared by the conventional solid state reaction method. The materials are named as CCTO, CCTSbO-1 and CCTSbO-2 respectively. CaCO3 (99.99 % purity), CuO (99 % purity), TiO2 (99.99 % purity) and Sb2O5 (99.99 % purity) were used as starting raw materials. The stoichiometric mixture of the starting raw materials was ball-milled in polytef jar with the ethanol for 24 h. The slurries were dried and then calcined at 950 °C for 10 h. Then, the calcined powders were grinded and pressed into pellets of 10 mm in diameter and ~1 mm in thickness by cooling isostatic pressing at 200 MPa for 2 min. Finally, the pellets were sintered at 1,100 °C for 8 h in muffle furnace, and then cooled to room temperature naturally.

The phase purity and lattice parameter were analyzed by X-ray diffraction (XRD) (MiniFlex-II, Rigaku). Scanning electron microscope (SEM) coupled with Energy dispersive spectroscopy (EDS) (TM3000, HITACHI) was performed to characterize the microstructures and phase formation of the sintered CaCu3Ti4−xSbxO12 ceramics. The electric and dielectric properties were measured using an Agilent 4284A LCR Meter in the frequency range of 102–106 Hz and an oscillation voltage of 1.0 V. The measurements were performed at temperatures ranging from 300 to 480 K. Prior to measurements, the ceramic samples were polished. Silver paint was coated onto both faces of the pellets, and fired at 500 °C for 1 h.

3 Results and discussion

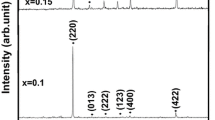

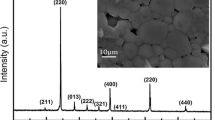

X-ray diffraction (XRD) patterns of CaCu3Ti4−xSbxO12 ceramics are shown in Fig. 1. All diffraction peaks for all of the samples confirm the pure formation of the CCTO phase. These XRD patterns can be indexed to a body-centered cubic structure in space group Im \(\bar{3}\) (JCPDS Card No.75-2188). Lattice parameters calculated from the XRD patterns using Cohen's least mean square method were found to be 7.394, 7.391 and 7.389 Å for the CCTO, CCTSbO-1 and CCTSbO-2 respectively, which are very close to the value in the literature (7.391 Å) [1]. The slight decrease in lattice parameter with the Sb5+ concentration might be ascribed to the smaller ionic radius of Sb5+ (r 6 = 0.600 Å) than Ti4+ (r 6 = 0.605 Å) [23].

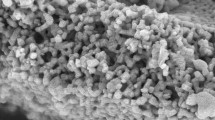

Figure 2a–c shows the surface morphologies of the sintered CaCu3Ti4−xSbxO12 ceramics. The main grain sizes of the CCTO, CCTSbO-1 and CCTSbO-2 ceramic samples were found to be about 42, 30 and 20 μm respectively, which indicates Sb5+ ions doping have a significant influence on the microstructures. For CCTO related ceramics, the presence of liquid phase plays an important role in enhancing the grain growth process [12, 20]. Smaller grains of Sb-doped CCTO ceramics may be attributed to the ability of Sb5+ to inhibit the growth rate. Figure 3a and b show EDS spectra detected at grain and GBs for the CCTSbO-2 ceramic. The Sb peak was detected in the grain region, confirming the existence of Sb inside grains. It is discovered the relative high Cu peak at the measuring point (2), indicating that CuO phase should be rich in the regions.

Figure 4 illustrates the frequency dependence of dielectric properties for pure and Sb-doped CCTO ceramics at room temperature (300 K). Giant ε’ values (~104) are exhibited in a broad frequency range, and increase with increasing Sb concentration. The dielectric losses (tan δ) at room temperature for the sintered CaCu3Ti4−xSbxO12 ceramics are also simultaneously emerged in Fig. 4. It can be seen that tan δ of the CCTO ceramic is nearly frequency-independent in the frequency range of 102–105 Hz. While the measuring frequency decreases below 103 Hz, tan δ of Sb-doped ceramics increases rapidly. The values of tan δ at 100 Hz were 0.217, 0.941 and 1.480 for CCTO, CCTSbO-1 and CCTSbO-2 respectively, revealing a relaxation process originated from reduction in the intensity of interfacial polarization at GBs [20].

Figure 5a presents the frequency dependence of ε′ at different temperatures for the CCTSbO-1 ceramic. At low temperature (<70 °C), ε′ depends slightly on frequency from 102 to 105 Hz. However, when the temperature is increasing, ε′ increases and strongly depends on frequency, especially in low-frequency range. Similar trend is observed in tan δ, as shown in Fig. 5b. The dielectric behavior of the sintered CaCu3Ti4−xSbxO12 ceramics (especially at high temperature) can be explained by Maxwell–Wagner effect, which is widely adopted to describe the dielectric relaxation behavior of materials with heterogeneous microstructures (e.g., insulating grain with semiconducting GB) [9, 10, 24]. As mentioned above, the GB region is Cu-rich. Therefore, the dielectric behavior of the sintered CaCu3Ti4−xSbxO12 ceramics coincides with this special heterogeneous microstructure.

In order to expound the electric transport mechanism of the CaCu3Ti4−xSbxO12 ceramics, the modulus spectroscopy was studied. Typical modulus approaches for the CCTSbO-2 ceramic at a few temperatures showing a broad peak are illustrated in Fig. 6. It can be seen the M″ peak shifts to the high frequency side as temperature increases, indicating a thermal activated dielectric relaxation process. The relaxation time τ is determined as τ = 1/2πf, where f is the peak frequency. Inset of Fig. 6 demonstrates the plots of In(τ) versus 1,000/T for the sintered CaCu3Ti4−xSbxO12 ceramics. The activation energies of the dielectric relaxations can be described by the following relationship [15, 17, 22]:

where τ is the dielectric relaxation time, τ 0 is the pre-exponential factor, and E a is the activation energies. The values of E a were calculated to be 0.568, 0.457 and 0.454 eV, and it is notable the E a of the CaCu3Ti4−xSbxO12 ceramics decreases significantly by substitution of Sb5+ ions.

It is apparently accepted that the IBLC effect based on Maxwell–Wagner polarization can explain the giant ε′ in CCTO-related ceramics. Generally, the related electrical properties of grain and GB in such materials are estimated by an impedance spectroscopy. The grain resistance (R g ) and GB resistance (R gb ) at particular temperatures can be determined by the diameter of two semicircular arcs at high and low frequency ranges respectively [10, 12]. Figure 7a provides the impedance complex plane plots for the sintered CaCu3Ti4−xSbxO12 ceramics at room temperature. Obviously, only a semicircular arc is observed in the measured frequency range (102–106 Hz), and the value of a nonzero intercept at high frequencies is very small, indicating the total resistance of the CaCu3Ti4−xSbxO12 ceramics is governed by R gb [24]. It is demonstrated R gb trends to decrease with increasing Sb5+ concentration, indicating Sb dopant plays an important role in regulating the dielectric properties. The impedance spectrum of the CCTSbO-1 ceramic at different measuring temperatures is presented in Fig. 7b. It is concluded from the expected diameter of a semicircular arc that the value of R gb decreases with increasing temperature, and presents 3–4 orders of magnitude larger than that of R g . In other words, the dielectric properties are mainly determined by the electrical response at GBs.

According to the IBLC effect, an equivalent circuit model has been considered to analyse the electric properties. The model contains two parallel RC elements (R g C g , R gb C gb ). The element R g C g describes the characteristics of grains, while the element R gb C gb delineates the effect caused by GBs (C gb and C g are the capacitors of GB and grain, respectively) [25]. It has been studied the giant ε′ of CCTO related ceramics is concerned with its C gb , and independent of mean grain size [26]. C gb of CCTO-related ceramics is given by \(C_{gb} = \sqrt {{{\varepsilon^{\prime}qN_{d} } \mathord{\left/ {\vphantom {{\varepsilon^{\prime}qN_{d} } {8\varPhi_{b} }}} \right. \kern-0pt} {8\varPhi_{b} }}}\), where ε′ is the relative permittivity, q is the electronic charge, N d is the charge carrier concentration in the grains, and Φ b is the potential barrier height at GBs [27]. From inset of Fig. 7a, the R g values of all CaCu3Ti4−xSbxO12 ceramics are nearly the same, signifying N d keeps constant. In absence of dc bias, Φ b is expressed as [27]

where N s is the acceptor (surface charge) concentration. The decrease in N s might cause the enhancement of C gb , and ε′ increases. It is proposed the positive charge of the supervalent cations (e.g., Nd5+, Ta5+ or W6+) in CCTO related ceramics can make compensation of the negative charge of acceptors at GBs and greatly reduce the Φ b , revealing an increase in ε′ as the Sb5+ concentration increases [28].

In the IBLC model, the complex impedance (Z *) can be used to further investigate the electric properties of GBs, which can be expressed as [10, 29],

Accordingly,

and

Figure 8 reveals the frequency dependence of the imaginary part (Z″) of Z * at different temperatures for the CCTSbO-2 ceramic. With increasing temperature, the peak position of Z″ shifts to higher frequency and the peak intensity decreases, implying a thermally activated electrical response corresponds to a decrease in the value of R gb with increasing temperature [24]. It is known that R = 2 Z″ max , where Z″ max is the maximum value of Z″. Therefore, the values of R gb at different temperatures can be calculated. As shown in the inset of Fig. 8, it is found that the GB conductivity, σ gb = 1/R gb , follows the Arrhenius law [15],

where σ 0 is the pre-exponential factor, E gb is the activation energy for conduction at GBs, k B is the Boltzmann constant and T is the absolute temperature. The values of E gb were calculated to be 0.689, 0.552 and 0.541 eV respectively, and it is consistent with a decrease in Φ b . The temperature dependence of ac conductivity of the CCTSbO-1 ceramic is shown in Fig. 9. Generally, with increasing temperature, σ ac increases and becomes more frequency independent in low frequency range. This indicates the low-frequency σ ac can be approximately equal to σ dc , especially at high temperature [20, 24]. The value of σ ac at 100 Hz was used to estimate the value of σ dc . Inset of Fig. 9 presents a plot of In(σ dc ) as a function of reciprocal temperature (1/T). It is obtained that σ dc at different temperatures follows the Arrhenius law [15, 30],

where E dc is the activation energy for the dc conduction process. The calculated E dc was 0.564 eV, which is comparable to E gb (0.552 eV), indicating the dc conduction process is closely associated with the electrical response of GBs for the CaCu3Ti4−xSbxO12 ceramics.

4 Conclusion

A series of the sintered CaCu3Ti4−xSbxO12 (x = 0, 0.025, 0.050) ceramics have been successfully fabricated by the conventional solid state method, and their microstructures, dielectric properties were investigated. It is concluded all ceramics are perovskite-related structure in space group Im \(\bar{3}\), and exhibit giant dielectric permittivity at 300 K. The impedance spectrum analysis shows R gb decreases with increasing Sb concentration, and E gb is comparable to E dc , indicating the dc conduction process is closely associated with the electrical response of GBs for the CaCu3Ti4−xSbxO12 ceramics.

References

M.A. Subramanian, D. Li, N. Duan, B.A. Reisner, A.W. Sleight, J. Solid State Chem. 151, 323 (2000)

M.A. Subramanian, A.W. Sleight, Solid State Sci. 4, 347 (2002)

S.Y. Chung, I.D. Kim, S.J.L. Kang, Nat. Mater. 3, 774 (2004)

C.C. Homes, T. Vogt, S.M. Shapiro, S. Wakimoto, A.P. Ramirez, Science 293, 673 (2001)

L. Ni, X.M. Chen, Appl. Phys. Lett. 91, 122905 (2007)

T.T. Fang, L.T. Mei, J. Am. Ceram. Soc. 90, 638 (2007)

T.T. Fang, C.P. Liu, Chem. Mater. 17, 5167 (2005)

J.C. Zheng, A.I. Frenkel, L. Wu, J. Hanson, W. Ku, E.S. Bozin, S.J.L. Billinge, Y. Zhu, Phys. Rev. B 81, 144203 (2010)

J.Q. Huang, H. Zheng, Z.H. Chen, Q. Gao, N. Ma, P.Y. Du, J. Mater. Chem. 19, 3909 (2009)

D.C. Sinclair, T.B. Adams, F.D. Morrison, A.R. West, Appl. Phys. Lett. 80, 2153 (2002)

T.B. Adams, D.C. Sinclair, A.R. West, Adv. Mater. 14, 1321 (2002)

T.B. Adams, D.C. Sinclair, A.R. West, J. Am. Ceram. Soc. 89, 3129 (2006)

J. Li, M.A. Subramanian, H.D. Rosenfeld, C.Y. Jones, B.H. Toby, A.W. Sleight, Chem. Mater. 16, 5223 (2004)

L.F. Xu, P.B. Qi, S.S. Chen, R.L. Wang, C.P. Yang, Mater. Sci. Eng., B 177, 494 (2012)

H.A. Ardakani, M. Alizadeh, R. Amini, M.R. Ghazanfari, Ceram. Int. 38, 4217 (2012)

S. Jesurani, S. Kanagesan, T. Kalaivani, K. Ashok, J. Mater. Sci.: Mater. Electron. 23, 692 (2012)

C.H. Kim, Y.H. Jang, S.J. Seo, C.H. Song, J.Y. Son, Y.S. Yang, J.H. Cho, Phys. Rev. B 85, 245210 (2012)

L. Singh, U.S. Rai, K.D. Mandal, Adv. Appl. Ceram. 111, 374 (2012)

L. Ni, X.M. Chen, Solid State Commun. 149, 379 (2009)

P. Thongbai, J. Jumpatam, T. Yamwong, S. Maensiri, J. Eur. Ceram. Soc. 32, 2423 (2012)

M.A. Sulaiman, S.D. Hutagalung, M.F. Ain, Z.A. Ahmad, J. Alloys Compd. 493, 486 (2010)

P. Thongbai, J. Jumpatam, B. Putasaeng, T. Yamwong, S. Maensiri, J. App. Phys. 112, 114115 (2012)

W.T. Hao, J.L. Zhang, Y.Q. Tan, M.L. Zhao, C.L. Wang, J. Am. Ceram. Soc. 94, 1067 (2011)

Y. Liu, W.C. Wang, J.Q. Huang, F. Tang, C. Zhu, Y.G. Cao, Ceram. Int. 39, 9201 (2013)

S.F. Shao, J.L. Zhang, P. Zheng, W.L. Zhong, C.L. Wang, J. Appl. Phys. 99, 084106 (2006)

R. Schmidt, M.C. Stennett, N.C. Hyatt, J. Pokorny, J. Prado-Gonjal, M. Li, D.C. Sinclair, J. Eur. Ceram. Soc. 32, 3313 (2012)

T.B. Adams, D.C. Sinclair, A.R. West, Phys. Rev. B 73, 094124 (2002)

S.Y. Chung, J.H. Choi, J.K. Choi, Appl. Phys. Lett. 91, 091912 (2007)

W. Somphan, N. Sangwong, T. Yamwong, P. Thongbai, J. Mater. Sci.: Mater. Electron. 23, 1229 (2012)

J.L. Zhang, P. Zheng, C.L. Wang, M.L. Zhao, J.C. Li, J.F. Wang, Appl. Phys. Lett. 87, 142901 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Chen, Q. & Zhao, X. Dielectric response of Sb-doped CaCu3Ti4O12 ceramics. J Mater Sci: Mater Electron 25, 1547–1552 (2014). https://doi.org/10.1007/s10854-014-1766-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-1766-9