Abstract

Indium vanadate (InVO4) nanoribbons were irradiated with various doses of gamma ray irradiation. The results revealed that the crystal structure remained unchanged after irradiation while the UV–Vis spectra underwent a red-shift with increasing irradiation dose. In addition, gamma ray irradiation enhanced the sensibility of InVO4-based sensors for ammonia testing. The improved properties of InVO4-nanobased sensors exposed to irradiation might be ascribed to the defects introduced by gamma ray, making gamma ray irradiation a good approach for material modification.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Gamma ray irradiation has been intensively studied recently in the following aspects: Firstly, it is applied in initiating polymerizations by the radiolysis of monomers and the generation of radicals on polymer surfaces [1–3]. Secondly, it could be used to prepare noble metals [4], bimetallic particles [5] and core–shell nanoparticles [6] by reduction of metal ions without any chemical Reducing agents [7]. Thirdly, gamma ray irradiation has also been employed to controllably introduce point defects and gain insight into the nature of intrinsic defects and their effect on optical and electrical properties of target materials [8, 9].

For instance, Skakalova et al. [10] found that gamma ray irradiation could create defects in carbon nanotube paper (CNT-paper), and increase Young modulus and electrical conductivity of CNT-paper at a certain defects concentration. Furthermore, the electron mobility of n-GaN decreased after exposure to gamma ray irradiation owning to the introduction of defects, which act as scattering centers [11].

Indium vanadate (InVO4) is a good candidate for gas sensor [12], electrochemical [13] and photoelectrochemical [14] analysis and photocatalyst [15] thanks to its surface property and excellent photocatalytic capability, which are both sensitive to defects. As gamma ray might induce point defects, it might enhance the gas sensing of InVO4-based sensors after the irradiation.

In this work, different doses of irradiation were carried out on InVO4 nanoribbons. The increase of irradiation dose brought about little change in the crystal structure of InVO4 nanoribbons, but led to red-shift in UV–Vis spectra and higher gas sensitivity, which might be attributed to more defects induced by gamma ray irradiation.

2 Materials and methods

2.1 Preparation of InVO4 nanoribbons

InCl3·4H2O, NH4VO3, NH4OH were purchased from Sinopharm Chemical Reagent Co. Ltd. (Shanghai, China) and used directly without further purification.

The synthesis process was as follows: 1 mmol InCl3·4H2O and 1 mmol NH4VO3 were added into 35 mL diluted ammonia solution (pH = 8). After stirring for 30 min, the solution was transferred into a 50 mL Teflon-lined autoclave, sealed and maintained at 150 °C for 15 h, and then cooled to room temperature naturally. The precipitate was filtered, washed with distilled water for several times, and then dried under vacuum at 60 °C for 8 h.

2.2 Process of gamma ray irradiation

InVO4 sample was divided into 5 equal parts and then irradiated with gamma ray with the doses of 0, 100, 200, 300, 400 kGy, respectively. The irradiation process was conducted at room temperature.

Gamma ray irradiation treatments were carried out under ambient conditions of approximately 25 °C and 60 % relative humidity (RH) by the Irradiation Technology Research Institute of Soochow University using a cobalt-60 source, which emits 1.17 and 1.33 MeV gamma ray. The total dose received by the samples was recorded by a dose meter.

2.3 Fabrication of InVO4-based gas sensors

The irradiated InVO4 nanoribbons (15 mg) were dispersed into distilled water (1 mL) separately, and formed into slurry, then coated on ceramic tube-like substrates. The as-fabricated devices were dried at 60 °C under vacuum for 24 h.

2.4 Process of gas sensing

The gas sensing was conducted using a computer-controlled gas sensing system (WS-30A, Han Wei Electronics Co. Ltd., China). A certain amount of NH4OH was injected onto the heating substrate inside the chamber and then evaporated into gas so as to fill the container evenly. The gas sensitivity of the sensor in this paper was defined as S = (R − R0)/R0 × 100 %, where R and R0 were the resistance in the test gas and air, respectively. NH4OH sensing was measured at 20 % RH.

2.5 Characterization

The as-prepared products were characterized by X-ray diffraction (XRD, a Philips X’pert PRO MPD diffractometer) with Cu Ka radiation (λ = 0.15406 nm). A scanning rate of 0.05° s−1 was applied to record the patterns in the 2θ range of 10–65°. Scanning electron microscopy (SEM) images were taken on a FEI-quanta 200 scanning electron microscope with accelerating voltage of 30 kV. UV–Vis absorption spectra were recorded by a Perkin Elmer Lambda 750 UV–Vis-near-infrared spectrophotometer.

3 Results and discussion

3.1 XRD patterns of InVO4 samples

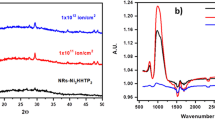

The XRD patterns of pristine InVO4 and irradiated InVO4 nanoribbons are shown in Fig. 1. All the patterns are consistent with the standard XRD data for the orthorhombic phase of InVO4 (JCPDS 48-0898), indicating that increased irradiation dose had little impact on InVO4 crystal structure.

3.2 SEM images of InVO4 samples

The SEM images of the pristine and 400 kGy irradiated InVO4 nanoribbons are shown in Fig. 2a, b, respectively. The width of InVO4 nanoribbons ranges from 50 to 150 nm. After gamma ray irradiation, the morphology of InVO4 nanoribbons does not show obvious changes.

3.3 UV–Vis adsorption spectra of InVO4 samples

The UV–Vis adsorption spectra of pristine InVO4 and irradiated InVO4 nanoribbon are displayed in Fig. 3. After gamma ray irradiation, two prominent differences have been observed. Firstly, the absorption intensities increase along with the increasing irradiation dose; secondly, the absorption peaks have red-shifted from 413 to 424 nm with the increase of irradiation dose. Both differences demonstrate that gamma ray irradiation induces the increase of defects in the InVO4 nanoribbons.

3.4 Gas sensing measurements

In our previous work, InVO4 nanoribbons were found to be a good ammonia sensor with excellent sensibility and recovery capability. Therefore, the irradiated InVO4-based sensors were employed to test ammonia so as to study the effect of irradiation on InVO4 sensing property.

InVO4 samples with different irradiation doses but same amount were fabricated into gas sensors being tested in one chamber. As shown in Fig. 4, the upper curves in each pattern indicate the changes of sensibilities with the increased gas concentration, while the lower curves are the amounts of ammonia injected into the chamber. The 5 samples all had response to a low gas concentration (20 ppm), and enjoyed a wide detection range (20–1,880 ppm).

Figure 5 demonstrated the sensibilities of these 5 samples under the same detecting condition. The curves from the bottom to top correspond to 0, 100, 200, 300, 400 kGy irradiation, respectively. Obviously, exposure to a relatively low irradiation dose didn’t cause significant sensitivity difference. Sample sensitivities improved remarkably with the irradiation doses above 200 kGy, and reached maximum value at the highest irradiation dose (400 kGy).

The mechanism for gas-sensing of InVO4-based sensors was as follows: When the nanoribbons exposed to air, oxygen and water were adsorbed on their surface. Oxygen and water molecules would extract electrons from the conduction band and form O2 −. The negative charges on the surface of InVO4 ribbons would lead to accumulation of excess holes in the valence band of InVO4. The excess holes from surface adsorption should have been enough to fully compensate the electrons in nanoribbons, and enable InVO4 surface to display p-type character. Therefore, when the sensor is exposed to a reducing gas, its resistance increases [14, 16, 17].

Why gamma ray irradiation could enhance the sensitivity of InVO4 nanoribbon-based gas sensor? It may be explained as follows: First, gamma ray has high energy, which may produce more defects in irradiated InVO4 nanoribbons, as shown the increasing absorptions in Fig. 3. And these defects will extract more electrons from the conduction band and lead to accumulation of more holes in the valence band of InVO4. So the resistance in air (R0) of high-dose irradiated InVO4-based sensor is lower than that of low-dose irradiated one. Secondly, the sensitivity of a gas sensor is inversely proportional to the initial resistance by the definition (S = (R − R0)/R0 × 100 %). Therefore, the high-dose irradiated InVO4-based sensor had a larger sensitivity than the low-dose irradiated one when exposing to the ammonia gas.

4 Conclusions

In summary, InVO4 nanoribbons obtained via hydrothermal process were divided into 5 equal parts, and exposed to different gamma ray irradiation doses (0, 100, 200, 300 and 400 kGy). XRD results of these samples indicated that there was no structure changing of InVO4 nanoribbons under gamma ray irradiation. However, increased gamma ray irradiation dose resulted in red shift in UV–Vis spectra, as well as improved ammonia sensing property of InVO4-based sensors. These changes in InVO4 properties might originate from the defects introduced by gamma ray irradiation. Therefore, gamma ray irradiation may be taken as an efficient method to improve the photocatalytic capability and gas sensing property of InVO4 or other materials.

References

H.X. Xu, X.B. Wang, Y.F. Zhang, S.Y. Liu, Chem. Mater. 18, 2929 (2006)

M.M. Nasef, J. Appl. Polym. Sci. 77, 1003 (2000)

C.S. Pande, N. Gupta, J. Appl. Polym. Sci. 71, 2163 (1999)

X.J. Zhang, D.G. Zhang, X.M. Ni, J. Chen, H.G. Zheng, Mater. Res. Bull. 8, 2421 (2008)

Y.J. Zhu, Y.T. Qian, Y.F. Cao, Mater. Sci. Eng., B 57, 247 (1999)

A. Henglein, Langmuir 17, 2329 (2001)

S.D. Oh, B.K. So, S.H. Choi, A. Gopalan, K.P. Lee, K.R. Yoon, I.S. Choi, Mater. Lett. 59, 1121 (2005)

A.G. Bishay, S. El-Gamal, J. Mater. Sci. Mater. Electron. 24, 2619 (2013)

D.C. Look, D.C. Reynolds, J.W. Hemsky, J.L. Sizelove, R.L. Jones, R.J. Molnar, Phys. Rev. Lett. 79, 2273 (1997)

V. Skakalova, U. Dettlaff-Weglikowska, S. Roth, Diam. Relat. Mater. 13, 296 (2004)

V.V. Emtsev, V.Y. Davydov, V.V. Kozlovskii, V.V. Lundin, D.S. Poloskin, A.N. Smirnov, N.M. Schmidt, A.S. Usikov, J. Aderhold, H. Klausing, D. Mistele, T. Rotter, J. Stemmer, O. Semchinova, J. Graul, Semicond. Sci. Technol. 15, 73 (2000)

S.S. Liu, F. Hu, J. Zhang, H.X. Tang, M.W. Shao, ACS Appl. Mater. Int. 5, 3208 (2013)

Y. Wang, G.Z. Cao, J. Mater. Chem. 17, 894 (2007)

C.S. Enache, D. Lloyd, M.R. Damen, J. Schoonman, R.V. de Krol, J. Phys. Chem. C 113, 19351 (2009)

J.F. Shen, X.F. Li, W.S. Huang, N. Li, M.X. Ye, Mater. Res. Bull. 9, 3112 (2013)

J.S. Jie, W.J. Zhang, K.Q. Peng, G.D. Yuan, C.S. Lee, S.T. Lee, Adv. Funct. Mater. 18, 3251 (2008)

D.E. Williams, P.T. Moseley, J. Mater. Chem. 1, 809 (1991)

Acknowledgments

The financial supports from Natural Science Foundation of China (No. 21071106), the National Basic Research Program of China (973 Program) (No. 2012CB932900) and Specialized Research Fund for the Doctoral Program of Higher Education (20103201110016) are acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yin, K., Liu, S., Cai, Q. et al. The enhanced ammonia gas-sensing activity of gamma ray irradiated indium vanadate nanoribbons. J Mater Sci: Mater Electron 25, 419–422 (2014). https://doi.org/10.1007/s10854-013-1604-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1604-5