Abstract

CdSe/ZnS core–shell structured nano-crystal quantum dots (QDs) are ideal candidates for light-emission applications due to their high quantum efficiency, narrow-band, and particle-size-tunable photoluminescence. In particular, their small size results in the quantum confinement of semiconductor nano-crystals, which widens their energy gaps. In general, high resolution imaging analyses of QDs using a transmission electron microscope are very difficult due to their significantly small size. Successful imaging depends on the capabilities of TEM equipment and the contrast of the QDs sample relative to the supporting film. In this work, all imaging analyses were performed on a TEM equipped with a probe Cs corrector. The samples for observing QDs were prepared by drying each QDs solution on a lacey carbon Cu (300 mesh) grid previously coated with an ultra-thin graphene monolayer (thickness = 0.3 nm), due to the need to minimize the effect of the supported film.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

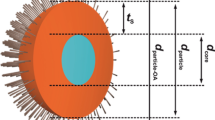

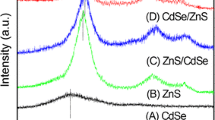

Chemically synthesized semiconductor nano-crystals (colloidal quantum dots) are small molecular clusters of which the size varies from 1 to 10 nm in diameter. They exhibit unique optical properties arising from the three-dimensional quantum confinement of carriers that differ somewhat from those of bulk crystals [1–3]. Quantum confinement leads to the formation of discrete and blue-shifted absorption bands and an increase of oscillator strength, due to an electron–hole overlap, giving enhanced emission efficiency and optical nonlinearity. In addition, the emission wavelengths can be changed by simply controlling the nanocrystal size [1–3]. Their size-tunable optical properties are of major interest for lighting and solar cell applications and for replacement of fluorescent dyes in biological imaging [4, 5]. QDs with emissions in the spectral range from 525 to 535 nm are of special interest for application in green LEDs and white-light generation. Of all QDs in the spectral range, CdSe/ZnS core–shell structured nano-crystals are among the promising candidates [6]. In general, a high band gap inorganic material coating over the QD core has been proven to enhance the quantum yield (QY) by passivating the surface nonradiative recombination sites. Typically, II–VI semiconductor QDs are covered with a high band gap ZnS shell, which was initially developed by Hines and Guyot-Sionnest [7]. This ZnS shell covering method has been widely used to achieve narrow-size particle distribution and enhance QY.

Transmission electron microscope (TEM) equipment has opened a wide range of opportunities for structural characterization of materials due to its excellent spatial resolution and various capabilities. Nonetheless, sample preparation for observing the TEM has become a limiting factor in many fields. TEM imaging relies on the difference between the electron densities of the sample and the surrounding substrate/matrix. Successful imaging of nano-particles depends on the contrast of the QDs sample relative to the supporting film. In this work, samples for observing CdSe/ZnS core–shell QDs were prepared by drying each QDs solution on a lacey carbon Cu (300 mesh) grid previously coated with a graphene monolayer (thickness = 0.3 nm), due to the need to minimize the effect of the supported film. All imaging analyses were performed on TEM equipped with a probe Cs corrector.

2 Experimental procedure

In a typical synthesis, a Se stock solution was prepared by dissolving 80 mg of Se powder in 2 mL trioctylphosphine (TOP). The obtained solution was further diluted with 2 mL octadecen (ODE). Meanwhile, a suspension of 12.5 mg CdO, 0.25 mL oleic acid (OA), 2 mL oleylamine (OLA), and 1.75 mL ODE was heated at 150 °C with stirring to prepare a clear yellow cadmium precursor solution. Before being drawn into the syringes, the two stock solutions were thoroughly degassed. Then, single-molecular zinc diethyl dithiocarbamate (ZDC) (0.5 mmol) dissolved in TOP (2 mL), and OLA (2 mL) were chosen as the S and Zn sources, respectively. During the operation, equal-volume solutions of CdSe and ZnS precursors were delivered by a syringe pump under the same flow rate; after being mixed by a convective micro-mixer, two stock solutions were poured into a heated capillary for the overcoating process.

A TEM specimen was prepared by drying each QDs solution on a lacey carbon Cu (300 mesh) grid previously coated with a graphene monolayer (thickness = 0.3 nm). The prepared TEM specimen was a Titan G2 (FEI) microscope operating at 300 kV equipped with a probe Cs corrector. A fast Fourier transform (FFT) simulation and a strain analysis with the HR-TEM images were performed in a DigitalMicrograph (Gatan) environment. This is a geometrical phase method designed and developed by Hytch [8]. This method involves filtering the image with an asymmetric filter at a Bragg spot of the Fourier transform simulation of the HR-TEM lattice image and performing an inverse Fourier transform simulation. This method can provide useful information on the local displacement of interesting region in a given direction.

3 Results and discussion

For successful imaging of nano-crystals, the characterization of a direct transfer TEM copper grid previously coated with a graphene monolayer was performed on the TEM [9]. Figure 1 shows the graphene grid at different magnifications, and the macroscopic graphene film coverage is shown in Fig. 1a. Darker edge regions in this image show where the graphene has bonded to the amorphous-carbon (a-C) support, while the graphene film covers a hole in the a-C. Figure 1b shows a higher magnification TEM image and typical top view of the suspended graphene with clean regions separated by scattered organic materials covering the highly reactive graphene surface. This image shows that the graphene membrane is a distinctive hexagonal structure and has a single layer thickness (0.3 nm). Therefore, we were able to prepare an ultra-thin graphene membrane TEM grid to obtain high quality HR-TEM/STEM images of the CdSe/ZnS QDs.

The nano-structure of the CdSe/ZnS core–shell QDs was observed from conventional HR-TEM and HR-STEM modes as shown in Fig. 1. The QDs were assembled on the lacey carbon Cu (300 mesh) grid with the graphene monolayer, so we could obtain high quality HR-TEM and STEM HAADF images of the QDs. Figure 2a and c shows that the size distribution of the green colored QDs is concentrated in the range of 5–7 nm. Observation of the QDs using a probe Cs-corrected HR-STEM was surprisingly successful in revealing the atomic arrangements. This is shown in Fig. 2d, where several QDs are seen in atomic scale. The QDs were not observed until the spherical aberration was corrected using the Zemlin tableau method and a beam tilt of ~18 mrad or higher.

Figure 3a, b shows the higher magnified HR-STEM HAADF image and its reconstructed image of CdSe/ZnS QDs, respectively. The FFT pattern at the right corner in Fig. 3a shows that the crystal quality of QDs is good, and that the FFT pattern on Fig. 3b shows a simulated mask of the reconstructed image. We could clearly identify the atomic arrangement from this image. The FFT pattern analysis of each QD was performed to understand the crystal structure and the direction vector of the electron beam (zone-axis). The zone axis of one was found to be the [0001] direction of a Wurtzite structure and the other was \( [1\bar{2}1\bar{3}] \)of the same structure. As a result, we could identify that the crystal structures of the CdSe/ZnS core–shell QDs were Wurtzite structures.

Generally, distinguishing the interface between CdSe core and ZnS shell is very difficult in TEM imaging due to the small mass of QDs, even if the elemental (Z) contrast of the HAADF image is able to distinguish multi-layers. Figure 4 shows a STEM HAADF image, where Fig. 4a shows CdSe/ZnS core–shell QDs and Fig. 4b–d shows their intensity profiles. The interface between the CdSe core and the ZnS shell could not be identified from the raw STEM HAADF image; however, the intensity profiles of HAADF Z-contrast indirectly reveal the interface between the core and shell from the curves of their graph. While we hoped to obtain an energy dispersive spectroscopy (EDS) line scan profile of the CdSe/ZnS core–shell QD, this was not possible due to the very small QDs sizes. The EDS result only shows the Cd and Se components of the core and the Zn and S components of the shell simultaneously.

The lattice mismatch between CdSe and ZnS is 14 %; that is, the registry of Cd and Se atoms in the CdSe lattice is offset from the arrangement of the Zn and S atoms in the ZnS lattice by 14 %. As a result, if we analyzed how to use these lattice differences, we would be able to distinguish between the CdSe core and the ZnS shell. A strain simulation of QD with an HR-STEM image is carried out using the dedicated software, the GPA phase, which was developed in the DigitalMicrograph (Gatan) environment. Strain mapping is defined as a numerical image processing technique that measures the local shifts of an image due to lattice distortion [10]. The scale-bar under the figures shows the quantity (%) of lattice distortions, which is indicated by various colors corresponding to the degree of local strain. Figure 5a shows an HR-STEM image of the QD, while Fig. 5b, c shows the simulated strain mapping images of the εxx and εyy components, respectively. The \( [1\bar{1}01] \) and \( [10\bar{1}0] \) spots were used for strain for the εxx and εyy components, respectively. From the result of the CdSe core region, both the εxx and the εyy components show green colors due to the large and referenced region, while the shell ZnS region shows blue and yellow colors corresponding to the high strain appearing mainly near the outline. This indicates the existence of more residual strain due to the lattice mismatch of elemental components. From these strain analyses, it is revealed that considerable residual strain was generated mainly at the interface between the CdSe core and the ZnS shell, therefore making it possible to distinguish the core and the shell.

4 Conclusions

We have attempted to obtain high resolution TEM/STEM images of CdSe/ZnS core–shell QDs using TEM by directly observing the atomic arrangement and analyzing the core–shell micro-structure. Through samples prepared on a lacey carbon Cu (300 mesh) grid coated with an ultra-thin graphene monolayer due to the need to minimize the effect of the supported film, and using a high performance TEM equipped with a probe Cs corrector, we were able to obtain high quality TEM/STEM results. The FFT pattern analysis using HR-STEM images showed that the crystal structures of CdSe/ZnS QDs have a Wurtzite structure. Furthermore, we could clearly distinguish the interface between the CdSe core and the ZnS shell from the intensity profiles of HAADF Z-contrast and the GPA strain analysis.

References

L.E. Brus, J. Chem. Phys. 80, 4403 (1984)

A. Henglein, Chem. Rev. 89, 1861 (1989)

C. Burda, X. Chen, R. Narayanan, M.A. El-Sayed, Chem. Rev. 105, 1025 (2005)

G. Jacob, L.C. Barbosa, C.L. Cesar, in Proceeding of the SPIE 5734, 124 (2005)

B. Ballou, B.C. Lagerholm, L.A. Ernst, A.S. Waggoner, Bioconjugate Chem. 15, 79 (2004)

W. Luan, H. Yang, T. Shan-Tung, Nanoscale Res. Lett. 3, 134–135 (2008)

M.A. Hines, P. Guyot-Sionnest, J. Phys. Chem. 100, 468–471 (1996)

M.J. Hytch, E. Snoeck, R. Kilaas, Ultramicroscopy 74, 131 (1998)

W. Regan, N. Alem, B. Alemán, Appl. Phys. Lett. 96, 113102 (2010)

H.Y. Shin, S.K. Kwon, Y.I. Chang, M.J. Cho, K.H. Park, J. Korean Phys. Soc. 53, 3402 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shin, H., Jang, D., Jang, Y. et al. High resolution imaging analysis of CdSe/ZnS core–shell quantum dots (QDs) using Cs-corrected HR-TEM/STEM. J Mater Sci: Mater Electron 24, 3744–3748 (2013). https://doi.org/10.1007/s10854-013-1312-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-013-1312-1