Abstract

Ultrathin TiO2 anatase nanowires (NWs) were successfully prepared via a rapid and facile hydrothermal route. Consequently, the TiO2 NWs and TiO2 nanoparticles (NPs) composites electrodes were prepared with different weight ratios (25, 50 and 100 %) for a dye sensitized solar cell, and the photoelectrical performance has been systematically studied. It is observed that although the amount of absorption dye decreases, the composite solar cells exhibit a higher power conversion efficiency compared to either pure TiO2 NP or NW solar cells by rationally tuning the weight ratios. The behavior was attributed to a combination of the rapid carrier transport in NW framework and the high dye loading on P25 surface.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Dye sensitized solar cells (DSSCs) have attracted much attention because they offer the extremely inexpensive and efficient solar energy conversion [1–3]. A typical DSSC device consists of a TiO2 photoanode sensitized by a monolayer of dye molecules, a liquid electrolyte and a Pt-coated counter electrode [4]. During these components, DSSC performance is critically dependent on the characteristics of the photoanodes, which not only provide the suitable sites for dye loading but also transfer the photogenerated carriers to the contact electrode. Up to now, the cell efficiency has attained to a record value of 12.3 % in the liquid electrolyte structure and 10.1 % in the solid state ones [5, 6]. Nevertheless, the current power conversion efficiency is still low compared to the Si-based counterparts, preventing the commercialization of the solar cell [7].

In case of the anode, a number of methods were attempted to enhance the DSSC performance [8–10]. Among these methods, it is always used to optimize the structure or morphology of the photoanodes. A typical photoanode in the DSSCs is a several micro-thick film composed of nanocrystalline TiO2 NPs on a transparent conductive oxide (TCO) substrate [11–13]. P25, a type of commercial titania nanoparticles, is the most common block units due to the large specific surface area. However, such a architecture encounters a fatal weakness of the short electron diffusion length due to electron traps at the contacts between nanoparticles. For this reason, the film thickness of the photoanode is always no more than 20 μm in a NP solar cell, leading to a poor light harvesting efficiency. To obtain high performance DSSCs, it is desirable to improve the electron diffusion coefficient. For instance, the use of dispersed or arrayed 1D structure (such as rods, wires or tubes) may be a good choice. Jenning et al. [14] have estimated the electron diffusion length was over 100 μm in TiO2 nanotube (NT) cells, which are at least five times higher than that in the NPs based cells [15].

Recently, Lou et al. developed a facile sovothermal method to synthesize anatase TiO2 NWs with high yield. The as-synthesized NWs were found to exhibit more excellent photocatalytic activity than P25 [16]. Like the photocatalysts, the DSSC performance is strongly dependent on the surface area and carrier transport rate. Besides, there are a few similarities in the light-to-electricity conversion process. As a result, a higher performance is expected when the NWs are incorporated into the DSSCs as the frameworks. Nevertheless, there hasn’t any report on the solar to electricity conversion behavior of the ultrathin NWs when they are used as the photoanodes of DSSCs, to the best of our knowledge. In this work, ultrathin anatase TiO2 NWs have been synthesized through a facile hydrothermal route for applying in the field of DSSCs. The photoanodes were prepared via a doctor-blade process, where a certain amount of P25 was doped into the NW film during the preparation process in order to improve the solar cell performance. The optimized DSSCs show an excellent power conversion efficiency of nearly 6.0 %.

2 Experimental

2.1 Preparation of TiO2 single-crystal NWs

Ultrathin single-crystal rutile TiO2 NR arrays were prepared using a hydrothermal synthesis method reported previously [16]. Namely, in a typical synthesis, 0.2 g of lithium acetate dihydrate (LiAc·2H2O; Sigma-Aldrich) was dissolved in 10 mL of organic solvent containing N, N-dimethylformamide (DMF; Alfa Aesar, 99 %) and acetic acid (HAc; Merck, 100 %). After addition of 2 mL of titanium (IV) butoxide (TB; Fluka, ≥97 %), the solution was transferred into a Teflon stainless steel autoclave, and heated in an oven at 200 °C for 20 h. Finally, the resulting precipitates were collected and washed thoroughly with ethanol for several times and dried in a vacuum oven at 60 °C overnight.

2.2 Dye sensitization and DSSC assembly

For the fabrication of a dye-solar cell, the TiO2 paste was prepared according to a facile method reported in the literature [15]. Simply, the clean fluorine-doped SnO2 conducting glass (FTO, 2.2 mm thick, 15 Ω/□) was used as a current collector. 1.0 g of TiO2 dry powders (without calcination) were first dispersed into a mixture of 5.0 mL de-ionized (DI) water and 0.4 g PEG 20000, followed by a continuous stirring for 24 h. The dry powders were made up of pure P25 or a composite of P25 and NWs with different weight ratios (25, 50 and 100 %). Then, three droplets of OP emulsifier were added and further agitated for 30 min to form a paste, which was coated on the FTO glass by screen printing (0.25 cm2), dried at 100 °C for 15 min and then heated at 450 °C for 30 min. After cooling to 80 °C, the sintered films were immersed in 0.3 mM ethanolic solution of N719 at 80 °C for 2 h. Note that all the films exhibit the same thickness (~15 μm), which is controlled by the 3 M scapes. A dye-sensitized electrode together with a Pt coated FTO electrode was then assembled into a sandwich type DSSC using a 60 μm thick thermal-plastic Suryln spacer. A commercially available electrolytic solution (from Dalian Hepta Chroma) was infiltrated into the space between the electrodes by the capillary action.

2.3 Characterization

The structure, morphology and crystallinity of TiO2 NWs were examined by a high resolution transmission electron microscopy (HRTEM, JEOL-2010). The diffuse absorption spectra of the obtained TiO2 films before and after dye loading were measured on a Cary 300 UV–vis spectrophotometer with integrating sphere (Internal Varian). For device characterization, the current density versus voltage (J–V) curves of DSSCs were collected on a Keithley model 2400 digital source meter under an illumination of 60 mW cm−2 provided by a 500 W Xe lamp fitted with an AM-1.5 fitter (Beijing Trusttech). The active cell area was fixed to 0.20 cm2 by a light shading mask.

3 Results and discussion

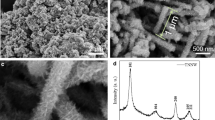

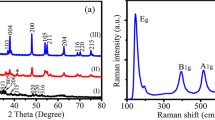

Figure 1 shows the TEM and HRTEM images of TiO2 NWs prepared via a hydrothermal route. It is clearly shown that the NWs were produced with high yield. Besides, it is also demonstrated that the NW is a single crystal, with a diameter of 20 nm and a length of hundreds of nanometers. The inter-planar distance is estimated to be 0.35 nm by measurements, corresponding to the TiO2 (101) planes. It means that the NWs grow preferentially along the [101] direction, in agreement with the description in Ref. [16].

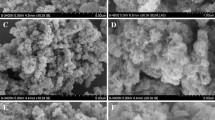

For fabricating a DSSC, a TiO2 paste composed of NWs, P25 or the composite was scribbled on a FTO substrate, followed by a post-annealing treatment to remove the organic species. As a result, the corresponding film electrodes were prepared for the dye loading and the cell assembly. Figure 2 shows the optical absorbance spectra of the NW and P25 photoanodes before and after dye loading for a comparison. For the unsensitized ones, the NW electrode show a significantly lower absorbance over the visible light range than P25, which is possibly attributed to less defects (such as oxygen vacancies) in the single-crystal structures. While for the samples undergo dye decoration, the P25 electrode exhibit the highest absorbance rate during all the samples, which should be ascribed to its abundant sites for dye anchoring. Although the dispersed NWs exhibit a high specific surface area of 67.2 g/m2 [16], it seems that there are not too many sites suitable for dye absorption. The behavior may be possibly due to a looser structure (or lighter weight) of the NW films compared with the P25 films. That is to say, it is difficult to obtain the dense structure with a large surface area when the NWs are existed in the films.

Figure 3 shows the J–V curves under illumination of DSSCs containing the TiO2 NWs, P25 and their mixtures. The open circuit voltage (V OC ), short circuit current density (J SC ), fill factor (FF) and conversion efficiency (η) are summarized in Table 1. As seen, the DSSC made with pure P25 NPs shows a η of ~3.81 %. By incorporating a certain amount (25 %) of NWs, η is increased to 5.97 %, which is mainly ascribed to a large suppression of the carrier recombination. It is well known that the photovoltaic parameters like V OC or FF are tightly correlated with the carrier transport or recombination. The faster the carriers move, the lower loss induced by the carrier recombination is. Nevertheless, increasing the amount of NWs to 50 %, a sharp drop of J SC was observed although V OC and FF remained almost unchanged, leading to a reduction of total η to 3.32 %. The behavior may be related to the reduced the specific surface area, leading to a lowered amount of dye loading. Furthermore, when the photoanode is made entirely of NWs, the DSSC exhibits a poorer power conversion efficiency of η = 0.77 %. It is also noteworthy that the degraded performance of DSSCs may be associated with a poor electrical contact between the NWs and FTO layer or the adjective NWs. Unlike the ordered arrays, not all of the NWs in the photoanodes are directly contacted to the conductive substrates, which don’t make any contribution on J SC despite loading the dye molecules. Specifically, the photo-generated electrons in a considerable part of the NWs could not travel to the external circuit.

Figure 4 compares the J–V curves measured in dark of DSSCs made with the NW, P25 and the composite electrodes. The dark current mainly results from the back transfer process occurring at the TiO2/dye/electrolyte interfaces, which typically represents the recombination between the electrons in the conduction band and the I3 − in the electrolyte [17]. As shown in these curves, the NW or NW/P25 composite solar cell shows a lower dark current and a higher onset voltage than the pure P25 one. Also, the larger the amount of NWs, the lower dark current is. It suggests that the charge recombination is suppressed a lot after compositing. As a result, a more efficient electron injection or transport is obtained, leading to the increase of V OC .

4 Conclusion

In summary, ultrathin anatase TiO2 NWs have been prepared by a simple hydrothermal route. DSSCs based on the NWs were investigated to realize the transport and light to electricity conversion mechanism underlying the structure. It was found that the pure NW electrode exhibit a low surface area and conversion efficiency. When a certain amount of P25 nanoparticles was incorporated, the derived composite electrode showed the highest power conversion efficiency of nearly 6.0 %. This indicates that the composite film is a promising electrode for high performance DSSCs, due to the rapid electron transport in it.

References

H.J. Snaith, Adv. Funct. Mater. 20, 13 (2010)

T.W. Hamann, R.A. Jensen, A.B.F. Martinson, H.V. Ryswyk, J.T. Hupp, Energy Environ. Sci. 1, 66 (2008)

M. Gräztel, Inorg. Chem. 44, 6841 (2005)

B. O’Regan, M. Gräztel, Nature 353, 737 (1991)

A. Yella, H.W. Lee, H.N. Tsao, C. Yi, A.K. Chandiran, M.K. Nazeeruddin, E.W.G. Diau, C.Y. Yeh, S.M. Zakeeruddin, M. Grätzel, Science 334, 629 (2011)

I. Chung, B. Lee, J. He, R.P.H. Chang, M.G. Kanatzidis, Nature 485, 486 (2012)

A. Shah, P. Torres, R. Tscharner, N. Wyrsch, H. Keppner, Science 285, 692 (1999)

J.M. Szeifert, D. Fattakhova-Rohlfing, D. Georgiadou, V. Kalousek, J. Rathouský, D. Kuang, S. Wenger, S.M. Zakeeruddin, M. Grätzel, Chem. Mater. 21, 1260 (2009)

Q. Miao, L. Wu, J. Cui, M. Huang, T. Ma, Adv. Mater. 23, 2764 (2011)

I. Hod, M. Shalom, Z. Tachan, S. Rűhle, A. Zaban, J. Phys. Chem. C 114, 10015 (2010)

J.A. Jeong, H.K. Kim, Sol. Energy Mater. Sol. Cells 95, 344 (2011)

B. Wang, L.L. Kerr, Sol. Energy Mater. Sol. Cells 95, 2531 (2011)

S. Li, G. Ye, G. Chen, J. Phys. Chem. C 113, 4031 (2009)

J.R. Jenning, A. Ghicov, L.M. Peter, P. Schmuki, A.B. Walker, J. Am. Chem. Soc. 130, 13364 (2008)

M.K. Nazeeruddin, F.D. Angelis, S. Fantacci, A. Selloni, G. Viscardi, P. Liska, S. Ito, B. Takeru, M. Grätzel, J. Am. Chem. Soc. 127, 16835 (2005)

H.B. Wu, H.H. Hng, X.W. Lou, Adv. Mater. 24, 2567 (2012)

W. Lee, S.H. Kang, J.Y. Kim, G.B. Kolekar, Y.E. Sung, S.H. Han, Nanotechnology 20, 335706 (2009)

Acknowledgments

This work was supported by Youth Foundation of China University of Mining and Technology No. 2009A055 and partial supported by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Gu, X., Wang, B., Zhang, Q. et al. Preparation of ultrathin TiO2 single-crystal nanowires for high performance dye sensitized solar cells. J Mater Sci: Mater Electron 24, 520–523 (2013). https://doi.org/10.1007/s10854-012-0939-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-012-0939-7