Abstract

This study reports the effect of annealing time (15 min, 1.5 and 3 h) and temperature (850, 860 and 870 °C) on the structural and superconducting properties of thin films by means of scanning electron microscopy (SEM), X-Ray analysis (XRD), electron dispersive X-Ray (EDX), resistivity and transport critical current density (Jc) measurements. Zero resistivity transition temperatures (Tc) of the films produced are estimated from the dc resistivity measurements. In addition, the phase and lattice parameters are determined from XRD patterns when the microstructure, surface morphology and element composition analyses of the samples are investigated by SEM and EDX measurements, respectively. The results indicate that Tc values of the films obtained are observed to be in a range of 23–102 K. The Tc of the film annealed at 870 °C for 3 h is found to be the smallest (23 K) while the film annealed at 860 °C for 3 h is noted to obtain the maximum Tc value (102 K). On the other hand, the maximum (minimum) Jc is found to be about 2068 A/cm2 (20 A/cm2) for the film annealed at 860 °C for 3 h (870 for 3 h). Moreover, according to the refinement of cell parameters done by considering the structural modulation, the greatest Bi-2223 phase fraction is noticed to belong to the film annealed at 860 °C for 3 h. Furthermore, SEM measurements show that the best surface morphology, largest grain size and grain connectivity are observed for that film. Based on these results, Tc and Jc values of the samples studied are found to depend strongly on the microstructure. As for EDX results, the elements used for the preparation of samples are observed to distribute homogeneously. The aim of this study is not only to investigate the changes of structural and superconducting properties of the films produced in the varied time and temperature but also to determine the best ambient for the film fabrication and show the feasibility of obtaining Bi-2223 film with tailored structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the discovery of Bi–Sr–Ca–Cu–O (BSCCO) high-temperature superconductor (HTSC) materials [1, 2] of the general formula Bi2Sr2Can−1CunOy (n = 1, 2 and 3), researchers have tried to improve their superconducting, mechanical, structural and flux pinning properties to make them suitable for high temperature and magnetic field applications [3–5]. Bi-based thin films are also the most promising materials for potential technological (especially microelectronics devices) and industrial applications [6–12] because of the their remarkable smaller power losses, high current and magnetic field carrying capacity, optical and electronic properties [13–15]. The BSCCO system composed of a layered structure has three different phases with respect to its chemical compositions, the Bi-2201 phase (n = 1, Tc ≈ 20 K), Bi-2212 phase (n = 2, Tc ≈ 85 K) and Bi-2223 phase (n = 3, T ≈ 110 K) [16]. In these series, the Bi-2223 phase is the most attractive owing to the highest critical temperature (Tc) of about 110 K [17, 18]; however, the preparation of the high Tc-phase (2223) for both the thin film is very difficult task due to the formation of regular grain orientation distribution, the high complexity of the reaction and the appearance of numerous phases as (Bi, Pb)-2212 and Ca2PbO4 during the phase formation [19]. The preparation conditions such as the operational procedure, annealing ambient (time, temperature, atmosphere and pressure), composition, heat-treatment method, type and quantity of the dopant also affect the high Tc-phase formation. In particular, the annealing ambient plays a very significant role on the phase fabrication of the high-Tc cuprate superconductors due to the electron–phonon anharmonicity [20]. In this respect, it is necessary to produce the superconductors with higher Tc in the form of high quality thin films on a suitable substrate under convenient ambient conditions for numerous technological applications such as microwave integrated circuits, high-frequency devices, magnetic shielding devices and resonators [10]. In order to prepare high quality thin film superconductors, several techniques such as molecular beam epitaxy [21], laser ablation [22], the excimer laser etching [23], coevaporation [24], in situ single chamber arc sputtering [25], ion beam sputtering [26], chemical vapor deposition [27] and magnetron sputtering [28] have been experienced. The conventional sputtering methods, among others, are the most preferred technique owing to the reproducible deposition of the films accomplished quite easily compared to the other methods.

In the present work, we report the effect of the various annealing temperature and time on the microstructure and transport properties of the thin films fabricated by DC sputtering method by X-Ray analysis (XRD), scanning electron microscopy (SEM), electron dispersive X-Ray (EDX), resistivity and critical current density (Jc) measurements. It is found that the sample annealed at 860 °C for 3 h obtains the highest transition temperature (102 K) and critical current density (2068 A/cm2) among the films produced while the smallest values are noted for the sample annealed 870 °C for 3 h. The greatest Bi-2223 phase fraction also belongs to the film annealed at 860 °C for 3 h. Moreover, SEM measurements indicate that the best surface morphology, grain size and grain connectivity are observed for that film. According to the results, Tc and Jc values of the films prepared are found to depend strongly on the microstructure. From EDX results, the elements used for the preparation of samples are observed to distribute homogeneously.

2 Experimental details

In this study, the superconducting thin films are produced by DC magnetron reactive sputtering method at 100 W. The starting materials are commercially available powders of PbO, SrCO3, Bi2O3, CaCO3, (Alfa Aesar Co Ltd. 99.99% purity). Superconducting Bi2Pb1Sr2Ca2.2Cu3.2Oy material for the target is prepared by the standard solid–state reaction method [29, 30]. These oxides and carbonates weighted in stoichiometric proportion are mixed in a grinding machine for 24 h with a rotation speed of 2000 rpm in 10 min in a medium of atmospheric air. Then, the homogeneous mixture of powders is subjected to the calcination process in air at 800 °C for 12 h (5 K per minute heating rate). The final material calcined is reground and pressed into cylindrical bar of 25 × 25 × 5 mm3 at 225 MPa. The target prepared is placed on the DC gun in the sputtering system. MgO(100) single crystal substrates with dimensions of 10 × 10 × 5 mm3 used for production of the thin films are cleaned. The cleaning process of MgO substrates includes two stages: waiting in acetone and alcohol under ultrasound for 10 min, respectively. Therefore, the crystal substrates are ready for sputtering process. The distance between the target and substrate is adjusted to be about 40 mm. The chamber is evacuated with the aid of rotary and turbo pump down to 6.33 × 10−9 bars, then 100 W DC power is applied between the target and plate for 3 h. Nevertheless, the pressure is noticed to be nearly 5.04 × 10−6 bars during film sputtering process. The annealing process of the films is carried out using various time (15 m, 1.5 h and 3 h) and temperature (850, 860 and 870 °C). The films will be herein after denoted as Bi-1, Bi-2, Bi-3, Bi-4, Bi-5, Bi-6, Bi-7, Bi-8, and Bi-9, respectively.

The dc resistivity measurements are performed on the sample with the four-probe method. Both voltage and current contacts are made with silver paint to minimize the contact resistance. The temperature (20–120 K) dependence of resistivity of the samples is measured by running 1 mA dc current through the sample in the He gas contact cryocooler from CRYO Industries. A Keithley 220 programmable current source and a Keithley 2182A nano-voltmeter are used in the resistivity measurements. Additionally, the transport critical current of the samples in self-field is measured by the same system at 4.2 K in zero field using four-probe method. A programmable temperature controller (Lakeshore 340) is used for the accurate monitoring of the temperature with a stability and accuracy of ±0.01 K. The current applied parallel to the direction of pressed surface is ramped at a constant rate (10 mA/s) for the entire sample. The critical current (Ic) values of the samples are defined with the criterion of 1 μV/cm. The Jc values are calculated from the Ic and the total cross-sectional area (width 5 mm × thickness 1 μm) of the samples studied. All the data taken are recorded using the Labview computer software. Moreover, the phase compositions of the samples prepared are characterized by XRD investigation by using a Jeol Multiflex XRD with Cu Kα radiation (λ = 1.5418 Å) in the range 2θ = 3–60° at a scan speed of 3°/min and a step increment of 0.02° at room temperature. Phase purity and lattice parameters are deduced from the XRD patterns. The accuracy in determining the lattice parameters (a and c) is found to be ±0.0001 Å. Additionally, the average sizes of the crystal of the samples produced are estimated by the Scherrer–Warren approach [31, 32] owing to the broadening nature of the XRD peaks. Besides, the grain size, grain connectivity and surface morphology of the sample are examined via a Jeol scanning electron microscope (SEM) JEOL 6390-LV, operated at 20 kV, with a resolution power of 3 nm. The elemental compositions (in the percent) and distributions (homogeneously or not) of the samples studied are also examined by means of an Oxford X-ray micro-probe analysis connected to SEM (EDX).

3 Results and discussion

3.1 Electrical resistivity measurements

The R-T plots of the samples studied in the temperature range 20–120 K are shown in Fig. 1. It is clearly visible that all the samples show metallic behaviour above the Tc value and the Bi-6 sample is less resistive than the other samples. The room temperature (at 300 K) resistivity of the samples are listed in Table 1. The resistivity is found to be about 1.2 mmΩ cm (minimum) for Bi-6 and 168.6 mΩ cm (maximum) for Bi-8 sample, respectively. The resistivity values of the films annealed at 850 °C are found to be close to each other. Furthermore, the zero resistivity transition temperatures (R = 0 Ω) obtained from the dc resistivity measurements of the films are given in Fig. 2.

The critical transition temperatures (Tc) of the films studied in this work are observed to be in a range of 23–102 K. The Bi-6 obtains the maximum Tc value of 102 K; on the other hand, the minimum Tc is noted to be about 23 K for the Bi-9 film. Moreover, the Tc values of the films prepared at 850 °C do not change considerably with the increase of the annealing time while that of the samples annealed at 870 °C degrade with the increase in the time (see Fig. 2). In addition, the variations of ΔTc (T onsetc − T offsetc ) are illustrated in Table 1, indicating that the annealing time and temperature affect dramatically on the broadening of the resistive transition of the samples. It is visible from the table the minimum ΔTc is observed to be about 5.5 K for the Bi-8 film while the maximum ΔTc is obtained to be about 63 K for the Bi-9 sample. This phenomenon can be explained by the presence of impurities and weak links between the superconducting grains and grain misorientations [33], which will be supported by the SEM measurements. Based on the results,

-

The critical transition temperatures of the films annealed at 850 °C are found to be close to each other.

-

The Tc values of the samples annealed at 860 °C are noticed to be changeable and the Tc is observed to enhance with the increase in the annealing time.

-

The Tc is found to decrease with the increase of the time for the samples produced at 870 °C.

-

The maximum variation between T onsetc and T offsetc values is noted to be 60 K for the sample annealed at 870 °C for 3 h.

-

The minimum ΔTc (5.5 K) is observed for the film annealed at 870 °C for 1.5 h.

-

For the Bi-2223 thin film fabrication, the best ambient is determined to be 860 °C (for the annealing temperature) and 3 h (for the annealing time), respectively.

3.2 XRD analyses

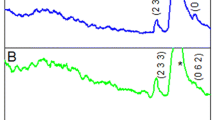

Figure 3a, b indicates the X-ray diffraction patterns between 3° and 60° for the thin films annealed in different conditions. The (Bi, Pb)-2223 peaks are presented by H (hkl) Miller indices while the peaks of (Bi, Pb)-2212 phase are shown by L (hkl) Miller indices given in the diagrams. All the samples studied in this work exhibit the polycrystalline superconducting phase. It is observed that the Bi-6 sample illustrates the highest peak intensities belonging to (Bi, Pb)-2223 phase while the (Bi, Pb)-2212 phase is found to be denser than other phase in the Bi-9 sample. In other words, not only are (0 0 l) peaks dominant features in the Bi-6 film, but also the Bi-2223 phase is more dominant than the Bi-2212 phase. Based on the results, the best ambient is determined to be 860 °C for 3 h to obtain the formation of (Bi, Pb)-2223 phase. The relative percentages of (Bi, Pb)-2223 and (Bi, Pb)-2212 phases computed by using the following relations (1) and (2) are tabulated in Table 2.

and

where I gives the peak intensity of the present phase. Moreover, the lattice parameters a and c are calculated using the least square method through d value and (hkl) planes for tetragonal unit cell structure. Their variations as a function of the annealing time are also depicted in Table 2. As seen from the table, the lattice constant, a, of all the samples prepared is found to be close to each other while the largest lattice constant, c, is obtained for the Bi-6 sample. In addition, Fig. 3b depicts the XRD graphs of Bi-6 and Bi-9 sample. As seen from the figure, some peak intensities such as (00 12)H, (016)H, and (119)H decrease dramatically whereas the other peak intensities including (002)H, (008)H, (016)H, (00 10 )H,(115)H, (00 14)H, (00 16)H and (02 12)H disappear completely. However, (006)L, (02 10)L, (115)L, (135)L and (22 10)L peaks start to appear entirely. Based on the results, the annealing ambient of Bi-6 is determined to be optimum to obtain the Bi-2223 phase. These findings are also ascertained by both the resistivity and SEM measurements. Besides, the broadening nature of the XRD peaks provides that the particle sizes of the samples are found to be within the nanometer scale [34–37] by using the Scherrer–Warren equation. According to the equation, in broadening region the average size of a crystal is defined as;

where d is the thickness of the crystal, λ is the wavelength, B is the fullwidth half maximum (FWHM) of the Bragg peak corrected using the corresponding peak in micron-sized powder and θB is the Bragg angle. Moreover,

where Bs is the halfwidth of the standard material in radians. The calculations indicate that the largest grain size is obtained for the Bi-6 sample (Table 2).

3.3 Hole-carrier concentration calculation

The hole-carrier concentrations per Cu ion, P, are calculated by means of the following relation [30]:

where \( {\text{T}}_{\text{c}}^{\max } \)is taken as 85 K for Bi-2212 phase [38] and 110 K for (Bi, Pb)-2223 phase [39] and Tc values are deduced form Fig. 1. Figure 4a illustrates the linear-like relationship between the superconducting transition temperature and hole-carrier concentrations, confirming the effect of the carrier concentrations on the superconducting materials. Figure 4b also depicts the change of P as a function of the annealing time and temperature. The hole-carrier concentration of the Bi-6 sample obtaining the highest critical temperature is observed to be greater than the others (Table 1).

3.4 SEM analyses

The surface morphology images of the samples produced are performed by SEM. Figure 5a–i indicates the SEM images of the fractured surface of all the films. As seen from the figure, the granular morphology of some samples consists primly from flaky layers of large platelet-like structure with random alignment distribution, which reveals the layered growth mechanism, typical of (Bi, Pb)-2223 phase formation [40–43]. However, with the change of the annealing time and temperature, the platelet grains linked well in the samples can be degraded due to the random orientation, weak links between the grains, the increase in the partial melting, level of impurities, voids, and porosity associated with formation of a smaller plat-like grains (the basic characteristics of (Bi, Pb)-2212 phase formation) [29]. It is visible that SEM photograph of the Bi-6 sample obtaining leafy appearance [44–47] presents a broad grain size distribution and the best crystallinity in comparison with the others (Fig. 5f). Additionally, the surface of the sample is more uniform with better alignment of grains. On the other hand, the Bi-9 sample has the worst appearance among these samples and there are voids and signs of partial melting on the micrograph of the sample. Using the image processing, the average grain sizes are also obtained to be about 520 and 350 nm for the Bi-6 and Bi-9 samples, respectively. According to the results of the SEM measurements, the Bi-6 sample has the largest average crystallite size, the best surface morphology and grain connectivity. In conclusion, we examine that how the annealing ambient affects the structural properties of the films studied.

3.5 EDX analyses

The elemental composition analyses of the samples are analytically investigated with the aid of the EDX. Figure 6 presents Bi, Sr, Ca, Cu and O element composition mappings taken on the surface of all the samples produced in this work. As can be seen from the figure, the elements used for the preparation of samples are observed to distribute homogeneously (Fig. 6), revealing that all the elements are observed to incorporate into the crystalline structure of the samples studied. However, Pb and Cu elements of the Bi-6 sample are found to be more than that of the other samples (Table 3), which confirms the superconducting properties of the sample are more superior to the other ones. Moreover, the oxygen element in the samples studied is observed to be variable and the maximum oxygen content is obtained for the Bi-3 sample. Hence, it is concluded that the superconducting properties such as Tc and Jc do not depend strongly on the oxygen content in the system.

3.6 Transport critical current density

There are several methods [48, 49] to explain the pinning mechanism in a thin film. One of them is to measure the critical current density (Jc). Figure 7a shows the role of the annealing ambient on the self field critical current density of the thin films prepared in the present work. As seen from the figure, Jc values of the films are found to be in a range of 59–2,068 A/cm2 at 4.2 K (in liquid hydrogen). Here, while the smallest Jc is observed for the Bi-9 sample, the maximum Jc is obtained for the Bi-6 sample. Moreover, there is a sharply decrease in the Jc of the films annealed at 850 and 860 °C for 1.5 h whereas that of the film annealed 870 °C for 1.5 slightly increases. This dramatic change in Jc values is attributed to the increase of the increased weak links between the superconducting grains, porosity, secondary phases, grain boundaries resistance and de-orientation of (Bi, Pb)-2223 grains. Figure 7b also illustrates the critical current density versus critical translation temperature. One can see from the figure, the films produced at 860 °C obtain higher critical temperature and critical current density than others. It is concluded that the highest annealing temperature and time (870 K for 3 h) studied in this work degrades the superconducting properties of the thin film while the best ambient is noted to be 860 °C for 3 h for the formation of (Bi, Pb)-2223 phase, supporting the results of the structural observations.

4 Conclusion

In this study, it is analyzed that how the different annealing time (15 min, 1.5 and 3 h) and temperature (850, 860 and 870 °C) affect the structural and superconducting properties of the Bi-based superconductor thin films by means of the SEM, XRD, EDX, R-T and I–V measurements. The results show that the zero resistivity transition temperatures estimated from the dc resistivity measurements are obtained to change from 23 to 102 K when transport critical current densities of the films studied are observed in the range from 20 until 2068 A/cm2. The maximum value of both measurements is noted for the film annealed at 860 °C for 3 h. Moreover, according to the phase and lattice parameters determined from XRD measurements, the film annealed at 860 °C for 3 h is noticed to obtain the greatest Bi-2223 phase fraction. Likewise, SEM images point out that the best surface morphology, largest grain size and grain connectivity are observed for that film. Based on these results, Tc and Jc values of the samples studied are found to depend strongly on the microstructure. Additionally, it is visible form the EDS investigations, all the elements used for the preparation of samples are observed to distribute homogeneously. To sum up, the aim of this study is to not only examine the role of annealing time and temperature on structural and superconducting properties of the thin films but determine the best ambient for the superconducting film fabrication and show the feasibility of obtaining Bi-2223 films with tailored structures in the ambient, as well.

References

H. Maeda, Y. Tanaka, M. Fukutomi, T. Asano, Jpn. J. Appl. Phys. Lett 27, L209 (1988)

J.M. Tarascon, Y. Lepage, L.H. Greene, B.G. Bagley, P. Barboux, D.M. Hwang, G.W. Hull, W.R. Makinnon, M. Giroud, Phys. Rev. B 38, 2504 (1988)

N. Ghazanfari, A. Kilic, A. Gencer, H. Ozkana, Solid State Commun. 144, 210 (2007)

T. Makise, S. Uchida, S. Horii, J. Shimoyama, K. Kishio, Physica C 460–462, 772 (2007)

G. Yildirim, Y. Zalaoglu, M. Akdogan, S. P. Altintas, A. Varilci, C. Terzioglu, J. Supercond, Nov. Magn. (2011) doi:10.1007/s10948-011-1174-9

A. Tsukamoto, K. Imagawa, M. Hiratani, K. Kanehori, K. Takagi, Jpn. J. Appl. Phys. 30, L830 (1991)

A.N. Jannah, S.A. Halim, H. Abdullah, Eur. J. Sci. Res. 29, 438 (2009)

V. Hakuraku, Z. Mori, S. Oku, Supercond. Sci. Technol. 6, 408 (1993)

G. Yildirim, M. Akdogan, S.P. Altintas, M. Erdem, C. Terzioglu, A. Varilci, Physica B 406, 1853 (2011)

M.A. Aksan, M.E. Yakinci, A. Guldeste, Thin Solid Films 515, 8022 (2007)

H. Martinez, A. Marino, J.E. Rodriguez, Physica C 408–410, 568 (2004)

M.A. Aksan, S. Altin, M.E. Yakinci, A. Guldeste, Y. Balci, Mater. Sci. Tech. Lond 27, 314 (2011)

M. Runde, IEEE T. Appl. Supercond. 5, 813 (1995)

A. Godeke, D. Cheng, D.R. Dietderich, C.D. English, H. Felice, C.R. Hannaford, S.O. Prestemon, G. Sabbi, R.M. Scanlan, Y. Hikichi, J. Nishioka, T. Hasegawa, IEEE T. Appl. Supercond. 18, 516 (2008)

H. Miao, M. Meinesz, B. Czabai, J. Parrell, S. Hong, AIP Conf. Proc. 986, 423 (2008)

S.E. Mousavi Ghahfarokhi, M. Zargar Shoushtari, Physica B 405, 4643 (2010)

K.A. Sarkar, I. Maartense, T.L. Peterson, B. Kumar, J. Appl. Phys. 66, 3717 (1989)

C.K. Rhee, C.J. Kim, H.G. Lee, I.H. Kuk, J.M. Lee, I.S. Chang, C.S. Rim, P.S. Han, S.I. Pyun, D.Y. Won, Jpn. J. Appl. Phys. 28, L1137 (1989)

E. Giannini, E. Bellingeri, R. Passerini, R. Flükiger, Physica C 315, 185 (1999)

I.V. Kityk, J. Phys. Condensd. Mat. 6, 4119 (1994)

H. El Alami, I. Rannou, C.D. Cavellin, Physica C 406, 131 (2004)

A.M. Saleh, M.M. Abu-Samreh, M.H. Soliman, A.A. Leghrouz, R.M.L. Ketaneh, S. Darwish, M.I. Abu Taha, Thin Solid Films 468, 93 (2004)

Y. Hakuraku, Y. Shimada, M. Itoh, Supercond. Sci. Technol. 10, 325 (1997)

M. Sugano, K. Osamura, W. Prusseit, R. Semerad, K. Itoh, T. Kiyoshi, Supercond. Sci. Technol. 18, 369 (2005)

M.E. Yakinci, Y. Balci, M.A. Aksan, Y. Aydogdu, H. Ates, J. Low, Temp. Phys. 117, 645 (1999)

Y. Iijima, K. Kakimoto, Y. Sutoh, S. Ajimura, T. Saito, Supercond. Sci. Technol. 17, S264 (2004)

A. Kursumovic, R.I. Tomov, R. Huhne, J.L. MacManus-Driscoll, B.A. Glowacki, J.E. Evetts, Supercond. Sci. Technol. 17, 1215 (2004)

G. Leroy, J. Gest, L.K.J. Vandamme, J.C. Carru, Physica C 425, 27 (2005)

J.S. Moodera, R. Meservey, J.E. Tkaczyk, C.X. Hao, G.A. Gibson, P.M. Tedrow, Phys. Rev. B 37, 619 (1988)

B.F. Azzouz, A. M’chirgui, B. Yangui, C. Boulesteix, B.M. Salem, Physica C 356, 83 (2001)

B.D. Cullity, Element of X-ray Diffraction, 3rd edn. (Addition-Wesley, Reading MA, 2001), pp. 80–90

E. Yucel, C. Terzioglu, A. Varilci, I. Belenli, J. Mater. Sci.-Mater. El. doi:10.1007/s10854-010-0274-9

A. Ianculescu, M. Gartner, B. Despax, V. Bley, Th. Leby, R. Gavrila, M. Modreanu, Appl. Surf. Sci. 253, 344 (1996)

J. Economy, R. Anderson, Inorg. Chem. 5, 989 (1966)

L. Shi, Y. Gu, L. Chen, Z. Yang, J. Ma, Y. Qitan, Mater. Lett. 58, 3301 (2004)

E. Budak, C. Bozkurt, Physica B 405, 4702 (2010)

J. Jiang, Mater. Lett. 61, 3239 (2007)

T. Kucukomeroglu, E. Bacaksiz, C. Terzioglu, A. Varilci, Thin Solid Films 516, 2913 (2008)

M.R. Persland, J.L. Tallon, R.G. Buckley, R.S. Liu, N.E. Floer, Physica C 176, 95 (1991)

M. Akdogan, C. Terzioglu, A. Varilci, I. Belenli, Physica B 405, 4010 (2010)

O. Ozturk, D. Yegen, M. Yilmazlar, A. Varilci, C. Terzioglu, Physica C 451, 113 (2007)

M. Erdem, O. Ozturk, E. Yucel, S.P. Altintas, A. Varilci, C. Terzioglu, I. Belenli, Physica B 406, 705 (2011)

C. Terzioglu, M. Yilmazlar, O. Ozturk, E. Yanmaz, Physica C 423, 119 (2005)

M.A. Aksan, M.E. Yakinci, K. Kadowaki, J. Supercond. Nov. Magn. 23, 371 (2010)

O. Bilgili, Y. Selamet, K. Kocabas, J. Supercond. Nov. Magn. 21, 439 (2008)

M.T. Malachevsky, C.A. Dovidio, Supercond. Sci. Technol. 18, 289 (2005)

H.J. Lim, J.G. Byrne, Physica B 229, 294 (1997)

A. Tampieri, G. Celotti, S. Lesca, G. Bezzi, T.M.G. La Torretta, G. Magnani, J. Eur. Ceram. Soc. 20, 119 (2000)

A. Biju, R.P. Aloysius, U. Syamaprasad, Supercond. Sci. Technol. 18, 1454 (2005)

Acknowledgments

This study is dedicated to Izzet Baysal on the occasion of his 11th death anniversary.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yildirim, G., Varilci, A., Akdogan, M. et al. Role of annealing time and temperature on structural and superconducting properties of (Bi, Pb)-2223 thin films produced by sputtering. J Mater Sci: Mater Electron 23, 928–935 (2012). https://doi.org/10.1007/s10854-011-0522-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-011-0522-7