Abstract

BaTi4O9 film was prepared on Pt/Ti/SiO2/Si substrate by laser chemical vapor deposition. The microstructure and dielectric properties were investigated. The single-phase BaTi4O9 film with random orientation was obtained. The surface consisted of round and rectangular grains, and the cross-section was columnar microstructure. The deposition rate (R dep) was 135 μm h−1. The dielectric constant (ε r) and loss (tanδ) were 35 and 0.01, respectively, at 1 MHz. With increasing temperature, ε r increased and showed a broad peak around 736 K, which indicated there might be a phase transition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

BaTi4O9 has potential application in dynamic random access memory and wireless- communication systems due to excellent microwave dielectric properties with high dielectric constant (ε r) value of 36–38, high-quality factor of 3,500–5,000 at 6–10 GHz and good thermal stability [1–4]. It was widely investigated as ceramics and single crystal [5–8]. However, due to the demand of miniaturization, it should be applied in electronic devices as thin or thick film forms. Sun et al. prepared BaTi4O9 films by RF magnetron sputtering at low deposition rate (R dep = 0.18 μm h−1) and investigated the effect of frequency on dielectric properties of the films [9, 10]. To the best of our knowledge, there was no paper reported on the temperature dependence of dielectric properties of BaTi4O9.

Laser chemical vapor deposition (LCVD) is considered to be a promising process to prepare high-quality films at high R dep, and there is also no report about preparation of BaTi4O9 film by LCVD. We have reported the preparation of yttria stabilized zirconia, TiO2 and CeO2 films by LCVD at high R dep [11–15]. In this study, we prepared BaTi4O9 film on Pt/Ti/SiO2/Si substrate by LCVD and investigated the effect of frequency and temperature on dielectric properties of BaTi4O9 film.

2 Experimental

BaTi4O9 film was prepared on Pt/Ti/SiO2/Si substrate by LCVD with a continuous-wave Nd:YAG laser (wavelength: 1,064 nm). Figure 1 is the schematic diagram of the LCVD apparatus. The substrate was heated on a hot stage at a pre-heating temperature (T pre) of 773 K. A thermocouple was inserted at the bottom side of the substrate to measure the deposition temperature (T dep = 1,050 K). A laser beam 14 mm in diameter was introduced through a quartz window to irradiate the whole substrate. The laser power (P L) was 93 W. The barium dipivaloylmethanate (Ba(DPM)2) and titanium diisopropoxy-dipivaloylmethanate (Ti(Oi–Pr)2(DPM)2) precursors were heated at 563 and 451 K, respectively, and their vapors were carried into the chamber with Ar gas. O2 gas was separately introduced into the chamber through a double-tube gas nozzle. The total pressure (P tot) in the CVD chamber was held at 400 Pa. The deposition was conducted for 600 s. Details of the deposition conditions are listed in Table 1.

The crystal structure was analyzed by X-ray diffraction (XRD, Rigaku RAD–2C) using CuKα X-ray radiation. The surface and cross sectional microstructures were observed by a scanning electron microscope (SEM, Hitachi S-3100H). The dielectric properties were measured by an impedance spectroscope (Hewlett-Packard HP4194). These results were obtained using an ac driving voltage of 10 mV and a frequency range of 100 Hz–1 MHz.

3 Results and discussions

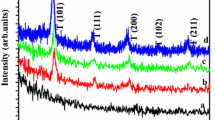

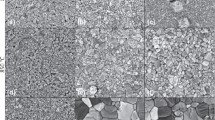

Figure 2 shows the XRD result of BaTi4O9 film. The XRD pattern was indexed to the orthorhombic phase (JCPDS 34–0070). The single-phase BaTi4O9 film was obtained with random orientation. The microstructures of BaTi4O9 film are shown in Fig. 3. The film prepared at high T dep by CVD method will show its natural structure [16]. BaTi4O9 compound had orthorhombic crystal structure (a = 0.6294 nm, b = 1.45324 nm and c = 0.37972 nm). The surface of BaTi4O9 film consisted of round and rectangular grains as shown in Fig. 3a due to its orthorhombic structure. Figure 3b shows that BaTi4O9 film has a columnar texture, and the microstructure of columnar grains near the substrate interface consisted of fine grains which grew into larger columnar grains, as commonly observed in conventional CVD [16]. According to Fig. 3b, the film thickness was about 22.5 μm, which indicated that the R dep was 135 μm h−1. The R dep was more than 1,000 times higher than that reported of BaTi4O9 film prepared by rf magnetron sputtering [9, 10]. The high R dep is advantageous to practical production. A magnified image of the upper part of Fig. 3b is displayed in Fig. 3c. The grains were regularly arranged along the perpendicular direction to the substrate.

Figure 4 demonstrates the dielectric properties of BaTi4O9 film measured at 300 K. At 100 Hz, ε r and dielectric loss (tanδ) were 46 and 0.15, respectively. With increasing frequency, both ε r and tanδ decreased and were kept constant at high frequency. In the film, there are many kinds of polarization (such as defect dipole polarization, ion polarization, electronic polarization, etc.) contributing to the value of ε r. When the frequency is low, all kinds of polarization can keep up with reversal of external electric field, ε r is large. With increasing frequency, the other polarization can not gradually keep up with reversal of external electric field, which contributes to the decrease of ε r [17]. At high frequency, ε r and tanδ should be the intrinsic value of BaTi4O9 film. The ε r and tanδ were 35 and 0.01, respectively, at 1 MHz. Table 2 lists ε r values of BaTi4O9 single crystal, ceramics and films. The ε r value in this work was good agreement with that reported in the literature.

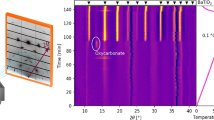

Figure 5 displays the effect of temperature on dielectric properties of BaTi4O9 film measured at 1 MHz. With increasing temperature, ε r slightly increased and showed a broad peak around 736 K, which indicated there might be a phase transition. In the future work, further research should be done to explain this peak. At 300–700 K, tanδ was almost constant. BaTi4O9 film showed good thermal stability at dielectric properties for a wide temperature ranging from 300 to 600 K. When temperature was beyond 800 K, ε r and tanδ increased abruptly due to heat activation.

4 Conclusions

The single-phase BaTi4O9 film was prepared on Pt/Ti/SiO2/Si substrate by LCVD at high R dep (135 μm h−1). The surface consisted of round and rectangular grains, and the cross-section was columnar microstructure. The ε r and tanδ were 35 and 0.01, respectively, at 1 MHz. With increasing temperature, ε r increased and showed a broad peak around 736 K, which indicated there might be a phase transition. These results indicated the BaTi4O9 film prepared by LCVD had potential use in electric devices.

References

H.M. O’Bryan, J. Thomson, J.K. Plourde, J. Am. Ceram. Soc. 57, 450 (1974)

I. Tanaka, H. Kojima, J. Mater. Sci. 24, 959 (1989)

T. Negas, G. Yeager, S. Bell, N. Coats, I. Minis, J. Am. Ceram. Soc. 72, 80 (1993)

J.H. Choy, Y.S. Han, J.H. Sohn, M. Itoh, J. Am. Ceram. Soc. 78, 1169 (1995)

I. Tanaka, H. Kojima, F. Sudo, J. Cryst. Growth 76, 311 (1986)

M. Cernea, E. Chirtop, D. Neacsu, I. Pasuk, S. Iordanescu, J. Am. Ceram. Soc. 85, 499 (2002)

F. Li, L.Q. Weng, G.Y. Xu, S.H. Song, J. Yu, Mater. Lett. 59, 2973 (2005)

X. Huang, F. Wang, Y. Song, Jpn. J. Appl. Phys. 45, 868 (2006)

H.J. Sun, B.Y. Jang, Y.H. Jung, S.J. Lee, S. Nahm, Jpn. J. Appl. Phys. 43, 628 (2004)

B.Y. Jang, B.J. Kim, S.J. Lee, K.J. Lee, S. Nahm, H.J. Sun, H.J. Lee, Appl. Phys. Lett. 87, 112902 (2005)

T. Kimura, T. Goto, Mater. Trans. 44, 421 (2003)

T. Goto, Solid State Ionics 172, 225 (2004)

T. Goto, T. Kimura, Thin Solid Films 515, 46 (2006)

T. Goto, R. Banal, T. Kimura, Surf. Coat. Technol. 201, 5776 (2007)

P. Zhao, A. Ito, R. Tu, T. Goto, Appl. Surf. Sci. 256, 6395 (2010)

W.A. Bryant, J. Mater. Sci. 12, 1285 (1977)

D. Guo, C. Wang, Q. Shen, L. Zhang, M. Li, J. Liu, Appl. Phys. A 97, 877 (2009)

Acknowledgments

This work was supported in part by Global COE Program of the Materials Integration, Tohoku University, and by the International Science and Technology Cooperation Program of China (Grant No. 2009DFB50470).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, D., Goto, T., Wang, C. et al. High-speed preparation and dielectric properties of BaTi4O9 film by laser chemical vapor deposition. J Mater Sci: Mater Electron 23, 897–900 (2012). https://doi.org/10.1007/s10854-011-0517-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-011-0517-4