Abstract

Thin films of Zinc Sulfide (ZnS) are prepared by Chemical Bath Deposition Technique using aqueous solution of Zinc acetate (Zn (CH3COO)2) and thiourea on glass Substrates. The Structural, Surface morphology and Optical properties of these films are investigated. The crystallinity of the thin films was characterized by means of X-ray diffraction and they all turned out to be polycrystalline. SEM studies gives the average grain size to be small (08–130 nm) with an uneven surface feature. From FTIR analysis, films show an optical transmittance more than 70% in the visible range. Optical band gap found from the absorption study is about 3.7 eV. The physical conditions were kept identical while growing all the samples. The investigation of the effect of the synthesis method on the grain size and the effect of grain size on the properties of semiconductor is under consideration.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Zinc Sulfide (ZnS) thin film is a promising material for its use in various application devices. In opto-electronics, it can be used as light emitting diode in the blue to ultraviolet spectral region due to its wide band gap of 3.7 eV at room temperature [1]. In the area of optics, ZnS can be used as a reflector and dielectric filter because of its high refractive index (2.35) and its high transmittance in the visible range [2, 3]. Several techniques such as molecular beam epitaxy [4], H2 plasma chemical sputtering [5], MOCVD [6] and MOVPE [7] have been used to produce ZnS thin films with adequate properties (high crystallinity, low resistivity and high transmittance). However, Chemical Bath Deposition (CBD) appears as an interesting technique for preparing ZnS thin films, Since CBD is one of the most convenient, reliable, simplest, inexpensive method and useful for large area industrial applications as well as preparation of thin films at close to room temperature [8, 9]. The technique of CBD involves the controlled precipitation from solution of a compound on a suitable substrate. The technique offers many advantages over the more established vapor phase synthetic routes to semiconductor materials, such as CVD, MBE and Spray Pyrolysis. Factors such as control of film thickness and deposition rate by varying the solution pH, temperature and reagent concentration are allied with the ability of CBD to coat large areas, in a reproducible and low cost process. Another advantage of CBD method with respect to other methods is that the films can be deposited on different kinds, shapes and sizes of substrates [10].

In the present work we report on the preparation of the Zinc based binary and ternary II–VI compound semiconductor ZnS thin films having a nanometer grain size by using Chemical Bath Deposition (CBD) Technique. Structural, Morphological and optical properties of as deposited ZnS thin films were investigated by XRD, SEM, FTIR and UV–VIS Spectrophotometer.

2 Experimental

Thin films of ZnS were deposited from a solution of analytical grade with purity over 99.9% of Zn (CH3COO) 2 (Zinc Acetate) a Zn++ ion source and Thiourea a S− ion source in an alkaline solution of Ammonia. The bath pH was optimised between 10 ± 0.5 by the addition of ammonia solution. Commercial glass slides used as substrates were cleaned in acetone and methanol ultrasonically and finally again washed with methanol ultrasonically before use. After cleaning the Substrate were mounted on a glass holder and were immersed in the solution. The solution was continuously stirred at a constant speed during the film deposition with the help of AC motor. The bath temperature was raised to a maximum of 70 ± 2 °C from room temperature using temperature controller. After the deposition, the ZnS films were washed with methanol ultrasonically to remove the loosely adhered ZnS particles on the film and finally dried in air. The crystallographic structure of films was analyzed with a diffractometer (XPERT-PRO) by using Cu-Kλ lines (λ = 1.54 Å). The average grain size in the deposited films was obtained from a Debye–Scherrer’s formula. IR spectra of representative sample were recorded with the FTIR-8400S (SHIMADZU, Japan).The absorbance vs. the wavelength was recorded with the UV–VIS spectrometer (Perkin Elmer: Lambda 35) in the wavelength range 200–800 nm.

3 Results and discussion

All the measurements were done at room temperature for the films deposited by chemical route. The thickness of the films was measured by the micro-weighing method.

3.1 XRD studies

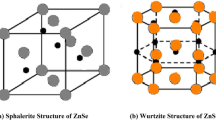

The X-ray diffractogram of ZnS films show broadened diffraction profiles, Fig. 1 shows the XRD patterns of ZnS nanoparticles showing reflections from (002), (103) planes, indicating the formation of ZnS nanoparticles having hexagonal structure with cell parameters a = 3.800 and c = 6.230. The grain size of the nanocrystalline films is estimated using the Scherrer formula [11],

where K is a constant taken to be 0.94, λ the wavelength of X-ray used (λ = 1.54 Å) and β2θ the full width at half maximum. The peak broadening in the XRD patterns clearly indicates the formation of ZnS nanocrystal of very small size. The grain sizes were found to be within the range of 08–130 nm.

3.2 SEM analysis

Scanning electron microscopy is a convenient technique to study the microstructure of thin films. Figure 2 shows the surface morphology of ZnS thin films deposited at 345 K temperature observed by SEM. From the micrographs, it is observed that the ‘as-deposited’ films are not uniform throughout all the regions. But the films are without any void, pinhole or cracks and that they cover the substrates well. From the figure, we clearly observe the small nanosized grains engaged in a fibrous- like structure, which clearly indicates the nanocrystalline nature along with some amorphous phase of ZnS thin films.

3.3 IR spectra

IR spectra and Transmittance Vs. Wavelength of ZnS thin films is presented in Fig. 3. The IR frequencies along with the vibrational assignments of ZnS films are given in Table 1. The band at 3,356.25 cm−1 is due to O–H stretching vibrations of water molecules. The band at 2,746.44 cm−1 is due to C–H stretching vibrations (Tang et al 2005).The stretching at 2,195.07 cm−1, due to N = N vibrations. At 694.36 cm−1 and 705.8 cm−1, there are medium to strong bands which have been assigned to ZnS stretching [11–13].

3.4 Absorption studies

The UV absorption spectra of ZnS thin films taken at room temperature are shown in Fig. 4a. From the spectrograph the absorption edge of the samples are found to occur in the range 250–400 nm for nanocrystalline films. Absorption spectrum shows a clear shift to the lower wavelength side at ~500 nm. This blue shift of the absorption edge indicates decrease of the crystallite sizes of the samples. ZnS is a typical direct band gap semiconductor. According to Tauc relation, the absorption coefficient for direct band material is given by (Tauc 1974; Sharma et al 1992)

where α is the absorption coefficient, c a constant, hν the photon energy and Eg the band gap. The spectrographs were studied using the standard relation. A graph between hν vs (α hν)2 is plotted and shown in Fig. 4b. The extrapolation of straight line to (α hν)2 = 0 axis gives the value of the energy band gap of film materials. The band gap of the films are determined from the plots which are found to be within 3.5–4 eV. The band gap increases with the decrease of crystallite size. The increment in band gap is approximately inversely proportional to the square of the crystallite size based on the effective mass approximation (Brus 1986).

4 Conclusion

Thin films of ZnS prepared by CBD technique are found to be nanocrystalline. The crystallite sizes measured by XRD studies are found to be within 08–130 nm. XRD shows that samples are of hexagonal phase which is important for device performance. SEM studies showed presence of long tubes and irregular distributions of particles. FTIR spectroscopy showed that the bonding peaks and the percentage transmittance, the films were found to have high transmittance in the range between 60 and 75% in the UV–VISNIR regions; hence, they could be effective as thermal control window coatings for cold climates and antireflection coatings. The UV absorption studies on films clearly show an increase in band gap with reduction in particle size as compared to bulk materials, and this fact supports the formation of nanocrystallites in these films.

References

E. Monroy, F. Omnes, F. Calle, Semicond. Sci. Technol. 18, 33–51 (2003)

R.N. Bhargava, D. Gallagher, X. Hong, D. Nurmikko, Phys. Rev. Lett. 72, 416–419 (1994)

W. Park, J.S. King, C.W. Ne, C. Liddell, C. Summers, Phys. Status Solid 229, 949–960 (2002)

V. Kishore, N.S. Saxena, V.K. Saraswat, K.B. Sharma, T.P. Sharma, J. Optoelectron. Adv. Mat. 8, 1641–1642 (2006)

A.F. Cattell, A.G. Cullis, Thin Solid Films 92, 211–217 (1982)

Z. Porada, E.S. Osiowska, Thin Solid Films 145, 75–79 (1986)

Z. Wang, L. Daemen, Y. Zhao, C.S. Zha, R.T. Downs, X. Wang, Z.L. Wang, R.J. Hemley, Nat. Mat. 4, 1522 (2005)

Y.S. Kim, S.J. Yun, App. Sur. Sci. 229, 105–111 (2004)

B.S. Rema Devi, R. Raveendran, A.V. Vaidyan, Pramana Ind. Acad. Sci. 68, 679–687 (2007)

J.P. Borah, K.C. Sarma, Acta. Physica. Polonica. A 114, 586 (2008)

N. Karar, S. Raj, F. Singh et al., J. Cryst. Growth 268, 585–589 (2004)

R.K. Rana, L. zhang, J.C. Yu, Y. Mastai, A. Gedanken, Langmuir 19, 5904–5911 (2003)

M. Rabah, B. Abbar, Y. Al-Douri, B. Bouhafs, B. Sahraoui, Mater. Sci. Eng. 100, 163–171 (2003)

Acknowledgments

The authors would like to acknowledge Head, DME, VNIT, NAGPUR, INDIA for providing XRD and SEM facilities. We would also like to acknowledge Head of Instrumentation Cell, SGBAMU, AMRAVATI. INDIA for FTIR & UV–VIS facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kawar, S.S., Pawar, B.H. Nanocrystalline grain size in ZnS thin films deposited by chemical bath technique. J Mater Sci: Mater Electron 21, 906–909 (2010). https://doi.org/10.1007/s10854-009-0016-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-009-0016-z