Abstract

ZnO films were deposited on Al2O3 substrates by metalorganic chemical vapor deposition (MOCVD) at temperatures of 400, 450 and 500 °C. The photoconductivity of the films has been analyzed for ultraviolet detector application. The changes in photoresponse and current–voltage (I–V) are correlated with the deposition temperatures and microcrystalline structures. The study suggested that the photoresponse originating from bulk- and surface-related processes. For a film deposited at 400 °C, a 1 ms fast rising time and a 5 ms fall time were observed. The photoresponsivity is ∼24 A/W with a 3 V bias.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

ZnO, which has a wurtzite crystal structure, is a promising material for semiconductor photonic devices operating in the ultraviolet (UV) region due to its wide bandgap (3.37 eV at 300 K) and large exciton binding energy (∼60 meV). It is also a promising material for UV detection. It is, however, very important to obtain high quality ZnO films in order to effectively utilize its optical and electronic properties. Over the years, various growth techniques have been used, such as molecular beam epitaxy (MBE) [1], radio frequency magnetron sputtering [2], pulsed laser deposition (PLD) and metalorganic vapor deposition (MOCVD) [3, 4], etc. Optical and electronic properties of ZnO films have also been extensively investigated [5–8]. However, limited work has focused on ZnO-based UV photodetector applications.

UV photoresponse in ZnO was first observed by Mollow in 1940s [9]. Since then, the photoresponse of ZnO in the UV region was investigated by many groups in the forms of single crystals, poly and single crystalline films as well as nanowires [10–12]. However, a slow photoresponse has been observed. The typical rise and recovery times were obtained ranging from microseconds to hours. Many factors, such as the thickness of the film, grain size, post-deposition thermal treatment, doping effects and film structure, were found to be responsible for photoresponse characteristics. It is argued that the growth temperature is one of the most important parameters that determine the quality of epitaxial film which, in turn, affect optical and electronic properties. On the other hand, there have been a few reports to study the temperature dependent effects on structural, optical and electrical properties of ZnO epitaxial films grown by MOCVD [13, 14].

As a photodetector, Si-based materials have been developed for a long time. Comparing Si-based photodetector, wide bandgap semiconductor, such as GaN-based photodetector, can be used in UV region. These UV detectors do not require bulky band filters to block the visible radiation and can be used at high temperature and caustic environments as well. However, the fabrication of GaN requires very expensive epitaxial growth techniques.

ZnO, on the other hand, has the similar crystal structure and bandgap as GaN. It may be a nice alternative material for UV photodetector fabrication. Some theory and experiments have been suggested that photoresponse of ZnO is primarily governed by desorption and adsorption of oxygen. Based on their findings, the overall photoresponse can be divided into two separate processes: one is a bulk material related process that is a fast and reproducible. The other is surface related process which is slow. The later can be explained in following way: first, an electron can be trapped by oxygen to form a chemically adsorbed surface state,

Upon UV excitation, O −2 species can become neutral by capturing a photogenerated hole,

The freed electrons during the photodesorption process will be contributed to the increase of the photoconductivity. The bulk-related process is the exciton generation by absorption of high-energy photons.

In order to fabricate high quality ZnO films and improve the properties of photoconduction of the film, efforts were made to examine the photocurrent of ZnO film grown by MOCVD as a function of deposition temperatures. The samples were deposited at three temperatures of 400, 450 and 450 °C. The photoluminescence (PL), photoresponse spectra and photoresponsivity were measured.

2 Experimental

The detailed MOCVD growth processes of the ZnO films have been reported previously [15, 16]. Briefly, oxygen gas and diethyl zinc (Zn(C2H5)2, DEZn) were used as precursors and nitrogen as a carrier gas for the DEZn. As-polished Al2O3 (0001) substrates were cleaned in organic solutions before mounted into the growth chamber. Oxygen gas was introduced into the growth chamber and the pressure inside the chamber was controlled to be ∼10 Torr by using a conductance valve and a turbo molecular pump. The substrate was first heated to a growth temperature. Then, DEZn was introduced into the chamber. During the growth, the flow rates of O2 and N2 were set to be 30 sccm and 5 sccm, respectively. The temperature of DEZn was kept at 5 °C.

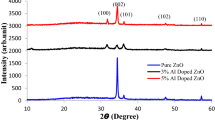

Surface morphologies were characterized by a scanning electron microscope (SEM). The result was shown in Fig. 1. From the SEM micrograph, the surface morphology changes with the growth temperature significantly. The porous structure was found for a film deposited at 400 °C.

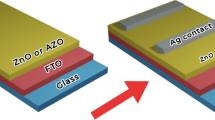

A UV photodetector was fabricated with metal-semiconductor-metal (MSM) structure, which was shown as Fig. 2. The thickness of a ZnO film used for the detector fabrication was about 1 μm. Two Pt/Au electrodes with a thickness of 30 nm were deposited on the as-grown film. The separation between the two electrodes was ∼1 mm. The measured resistance between two electrodes for the samples deposited at 400 (S1), 450 (S2) and 500 (S3) is 200, 120 and 89 kΩ. I–V curves for these samples in the dark were recorded by changing the bias across the junction using a Keithley source meter. The results show that an Ohmic contact was obtained for all MSM structures as illustrated in Fig. 3. The inset in Fig. 3 shows the dark current and photocurrent illuminated with a 325 nm laser with a power 5 mW/cm2 of S1. To obtain a photocurrent spectrum, a 1,000 W xenon lamp was first dispersed by a monochromater, then passed through a slit and finally focused by a cylinder lens (f = 300 mm) on to the detector structure. The spot size was adjusted to the same size as the detector window between the electrodes. The power density of the incident photons was measure by Keithley 3350 interfaced with a computer. For photoresponse and PL measurements of the samples, a He–Cd laser (325 nm) was used as an excitation source. The changes of photocurrent were recorded by an oscilloscope (TDS 3054). All measurements were carried out at room temperature.

The photoresponses of the samples under the continuous illumination of 325 nm He–Cd laser was shown in Fig. 4. The bias voltage is 3 V and the optical power density is 2 mW/cm2. The rise and decay curves contain a fast and a slow processes. They correspond to the bulk and surface-related photoresponses, as presented earlier. In the case of sample S1, the UV intensity-dependent photoresponse was measured and shown in Fig. 5a. As optical power density increases, the rise time becomes faster. Figure 5b shows the photoresponse with the laser power of 25 mW/cm2. The decay can be fitted by bi-exponential. The fast and slow process is about 45 s and 900 s, respectively.

Photoresponse spectrum was also measured for S1 and shown in Fig. 6. The wavelength range was measured from 300 nm to 500 nm. A sharp cutoff wavelength at about 370 nm was observed. By comparing photoresponse spectrum and PL spectrum, as an insert in Fig. 6, we can conclude that the sudden drop-off in photoresponse curve is due to excitonic excitation at bandgap Eg = 3.37 eV.

It is known that the photocurrent in the semiconductor UV detector can be express as

where G is the photoconductive gain (number of electrons detected per incident photon) and P is the incident power. The photodetector responsivity is defined as

For a classical mode of UV detector,

where τ and t tr are the excess carrier lifetime and transit time of electrons between two electrodes, respectively. η is the quantum efficiency. The t tr can be expressed as

where μe and V b is electron mobility and bias voltage, respectively. L is the distance between the contacts. Thus,

Clearly, photocurrent should linearly be dependent on the bias voltage. For the three samples deposited temperatures of 400, 450 and 500 °C, the photoresponsivity was measured at 325 nm and shown in Fig. 7. A value of 24 A/W was obtained for the film deposition temperature at 400 °C. The quantum efficiency is found to be ∼20%. For the films deposited at high temperatures, the responsivity is low. The reason may come from the structure changes of the films. The porous structure enhances the surface effect, which increases the photoresponsivity.

3 Conclusion

The high quality ZnO films were deposited on sapphire substrates by metalorganic chemical vapor deposition at three different temperatures. Simple UV photodetectors with a MSM structure were fabricated for all samples. The highest photoresponsivity among the three temperature grown samples was measured ∼24 A/W at bias 3 V for the film deposited at 400 °C. The rise and fall times are ∼1 and 45 s, respectively.

References

Y. Segawa, A. Ohtomo, M. Kawasaki, H. Koinuma, Z.K. Tang, P. Yu, G.K.L. Wong, Phys. Stat. Sol. (b) 202, 669 (1997). doi:10.1002/1521-3951(199708)202:2<669::AID-PSSB669>3.0.CO;2-T

H. Nanto, T. Minami, S. Takata, Phys. Stat. Sol. A 65, k131 (1981). doi:10.1002/pssa.2210650252

R.D. Vispute, V. Talyansky, S. Choopun, R.P. Sharma, T. Venkatesan, M. He, X. Tang, J.B. Halpern, M.G. Spencer, Y.X. Li, K.A. Jones, Appl. Phys. Lett. 73, 348 (1998). doi:10.1063/1.121830

S.Y. Myong, S.J. Baik, C.H. Lee, W.Y. Cho, K.S. Lim, Jpn. J. Appl. Phys. 36, L1087 (1997). doi:10.1143/JJAP.36.L1078

S.C. Jain, M. Willander, J. Narayan, R. Van Overstraeten, J. Appl. Phys. 87, 965 (2000). doi:10.1063/1.371971

H. Cao, Y.G. Zhao, H.C. Ong, S.T. Ho, J.Y. Dai, J.Y. Wu, R.P.H. Chang, Appl. Phys. Lett. 73, 3656 (1998). doi:10.1063/1.122853

M.H. Huang, S. Mao, H. Feick, H. Yan, Y. Wu, H. Kind, E. Weber, R. Russo, P. Yang, Science 292, 1897 (2001). Medline. doi:10.1126/science.1060367

B.P. Zhang, N.T. Binh, K. Wakatsuki, N. Usami, Y. Segawa, Appl. Phys. A 79, 1711 (2004)

E. Mollwo, in Photoconductivity Conference, ed. by R.G. Breckenridge, et al. (Wiley, New York, 1954), p. 509

S. Liang, H. Sheng, et al. J. Crystal Growth. 225, 110 (2001). doi:10.1016/S0022-0248(01)00830-2

C.H. Seager, S.M. Myers, J. Appl. Phys. 94, 2888 (2003). doi:10.1063/1.1595147

T. Koida, S.F. Chichibu, A. Uedono, A. Tsukazaki, M. Kawasaki, T. Sota, Y. Segawa, H. Koinuma, Appl. Phys. Lett. 82, 532 (2003). doi:10.1063/1.1540220

B.P. Zhang, N.T. Binh, N. Usami, Y. Segawa, Thin Solid Films 449, 12 (2004). doi:10.1016/S0040-6090(03)01466-4

B.P. Zhang, N.T. Binh, K. Wakatsuki, N. Usami, Y. Segawa, Appl. Phys. A 79, 1711 (2004)

C.Y. Liu, B.P. Zhang, N.T. Binh, Y. Segawa, J. Cryst. Growth 290(2), 314 (2006)

C.Y. Liu, B.P. Zhang, N.T. Binh, K. Wakatsuki, Y. Segawa, Physica B 381, 20 (2006). doi:10.1016/j.physb.2005.11.172

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, C.Y., Zhang, B.P., Lu, Z.W. et al. Fabrication and characterization of ZnO film based UV photodetector. J Mater Sci: Mater Electron 20, 197–201 (2009). https://doi.org/10.1007/s10854-008-9698-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-008-9698-x