Abstract

High dielectric constant and low loss ceramics in the system Ba4LaTiNb3−x Ta x O15 (x = 0–3) have been prepared by conventional solid-state ceramic route. Ba4LaTiNb3−x Ta x O15 solid solutions adopted A5B4O15 cation-deficient hexagonal perovskite structure for all compositions. The materials were characterized at microwave frequencies. They show a linear variation of dielectric properties with the value of x. Their dielectric constant varies from 53.1 to 42.3, quality factor Qu × f from 18,790 to 28,070 GHz and temperature variation of resonant frequency from +94.3 to +33.1 ppm/°C as the value of x increases.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The recent advances in the telecommunication systems have led to an increasing attention on microwave ceramic dielectric resonators (DRs) [1]. DRs are extensively used in microwave devices like filters, oscillators and Dielectric Resonator Antennas. To meet the requirements for use in such wide applications, the materials should possess stringent properties like (a) high dielectric constant (εr) for miniaturization, (b) high unloaded quality factor (Qu) or low dielectric loss for better selectivity and (c) low temperature coefficient of resonant frequency (τf) for frequency stability. Although several materials such as Ba(Zn1/3Ta2/3)O3, BaTi4O9, Ba2Ti9O20, (Zr, Sn)TiO4, and Ba6−3x Re8 + 2x Ti18O54 (Re = Nd, Sm, La) systems have been reported for practical applications [1–2], active research is still going on for new ceramics due to the great demand for a variety of materials with varying dielectric constants [3–9].

Recently Sebastian and Vineis et al. reported the microwave dielectric properties of some A5B4O15 type cation-deficient hexagonal perovskites such as Ba5Nb4O15, Ba5−x Sr x Nb4O15, and MLa4Ti4O15 (M = Ba, Sr and Ca) [10–15]. More recently, we also investigated the microwave dielectric properties of A site and B sites co-substituted Ba5Nb4O15 ceramics such as Ba4LaMNb3O15 (M = Ti, Sn), Ba3Ln2Ti2Nb2O15 and Ba2Ln3Ti3NbO15 (Ln = La, Nd) [16–18]. Among those compounds, Ba4LaTiNb3O15 was characterized by high dielectric constant of 52, high quality factors with Qu × f of 15,652 GHz, but its τ f value (+93 ppm °C−1) is too large and precludes its application as DRs [16]. Since many studies have reported that the substitutions of Nb with Ta to form solid solutions might reduce the value of τ f and improve the properties of microwave dielectric ceramics such as Ca5Nb2−x Ta x TiO12, GdTiNb1−x Ta x O6 A5Nb x Ta4−x O15 (A = Ba, Sr) and Mg4Nb2−x Ta x O9 [14, 19–21]. In the present study, the preparation, characterization and microwave dielectric properties of Ba4LaTiNb3−x Ta x O15 (x = 0–3) ceramics were investigated.

2 Experimental

The ceramic resonators in the system Ba4LaTiNb3−x Ta x O15 (x = 0, 1, 2 and 3) were prepared by the conventional solid-state ceramic route. High purity raw powders BaCO3 (99.9%), La2O3 (99.99%), TiO2 (>99.95%), Ta2O5 (99.9%) and Nb2O5 (99.9%) were used as the starting materials. Stoichiometric amounts of the powders were weighed and ball milled using zirconia balls in plastic containers. Ba4LaTiNb3−x Ta x O15 was calcined at 1,300 °C for 8 h. The calcined powders were ground well and mixed with 5 wt.% solution of PVA as the binder. The powders were then uniaxially pressed into cylindrical disks with 11 mm diameter and 7 mm height under a pressure of 300 MPa. The samples were fired at 600 °C for 2 h to remove the organic binder and then sintered in the range 1,400–1,520 °C for different durations. The sintered sample was typically annealed at 1380 °C for 2 h to minimize the reduction of titanium ions.

The sintered samples were well polished and their bulk density was calculated by Archimedes method. The crystal structure and phase purity of the samples were studied using a Rigaku D/MAX-RB X-ray diffractometer using CuKα radiation (λ = 0.154060 nm). The surface morphology of the samples was examined using a JSM-6380LV scanning electron microscope (SEM). The microwave dielectric properties were measured using an Agilent 8722ET network analyzer. The dielectric constant was measured by the dielectric post resonator method suggested by Hakki and Coleman and modified by Courtney [22, 23]. The resonator was placed between two gold-coated copper metallic plates, and microwave energy was coupled through E-field probes to excite various resonant modes. Among the various resonant modes, the TE011 mode was selected for the measurements. The τ f was measured by noting the temperature variation of the TE011 resonance in the temperature range 15–85 °C.

3 Results and discussion

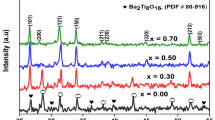

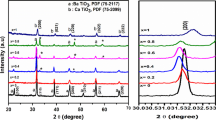

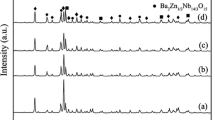

The room temperature XRD patterns recorded for the Ba4LaTiNb3−x Ta x O15 (x = 0–3) ceramics using CuKα radiation are shown in Fig. 1. The patterns are similar and match with JCPDS file No.56-400 of Ba4LaTiNb3O15. All of the peaks were indexed and there was no evidence of any second phases(s) present. The system Ba4LaTiNb3−x Ta x O15 crystallizes in a cation-deficient hexagonal A5B4O15 perovskite structure where the large Ba and La ions occupy the A sites with coordination numbers of 12, and Ti and Nb/Ta ions occupy the B sites with coordination numbers of 6 [16]. The solid solutions of Ba4LaTiNb3−x Ta x O15 are easily formed for all x values since the Shannon’s effective ionic radii (0.64 Å) [24] and charge are the same for Nb5+ and Ta5+ ions.

Figure 2 demonstrates the relative density of Ba4LaTiNb3−x Ta x O15 ceramics as a function of sintering temperature, through which the optimized sintering temperature of the solid solutions can be determined at 1,440, 1,480, 1,500 and 1,520 °C for the compositions of x = 0, 1, 2 and 3, respectively. It clearly reveals that the maximum densities for all the samples could reach >95% of the theoretical X-ray density. The microstructure of the ceramics with maximum densities was characterized using SEM and no apparent difference with composition was observed. Figure 3 shows the typical SEM micrographs of the surface recorded for two end members Ba4LaTiNb3O15 and Ba4LaTiTa3O15. The both ceramics have a close microstructure with low porosity, and the packed plate-like grains are in the size range of 2–12 μm for both ceramics.

Under optimum sintering conditions, the microwave dielectric properties of the solid solution phases Ba4LaTiNb3−x Ta x O15 (x = 0, 1, 2 and 3) are given in Table 1. Ba4LaTiTa3O15 and Ba4LaTiNb3O15 both show high quality factors with Qu × f values of 28,070 and 18,790 GHz. Ba4LaTiTa3O15 has a comparatively lower ε r of 42.3 and τ f of + 33.1 ppm/°C than Ba4LaTiNb3O15, which has ε r of 53.1 and τ f of +94.3 ppm/°C. The influence of Ta substitution for Nb on the dielectric constants and quality factors as a function of compositions x are shown in Fig. 4. The dielectric constant linearly decreased as x increased while the unloaded quality factors Qu × f increased with the value of x. This result is similar to those of Ca5Nb2−x Ta x TiO12 (x = 0–2) [19] and Mg4Nb2−x Ta x O9 (x = 0–2) [21]. Ratheesh et al. [25] has suggested larger short-range interaction parameter in O–Ta–O bond as the cause of lower dielectric constant and lower dielectric loss for tantalum compounds than the niobium compounds. The temperature coefficients of resonant frequency (τf) also linearly decreased with increasing Ta content from x = 0 to x = 3 (see Fig. 5), which is similar to those of Ca5Nb2−x Ta x TiO12 (x = 0–2) [19] and Ba5Nb x Ta4−x O15 (x = 0–4) [14].

4 Conclusions

The Ba4LaTiNb3−x Ta x O15 (x = 0–3) has been prepared as single-phase materials by the conventional solid-state ceramic route. The optimum sintering temperature of Ba4LaTiNb3−x Ta x O15 ceramics increased with increasing x values and ranged from 1,440 to 1,520 °C. The microwave dielectric properties of Ba4LaTiNb3−x Ta x O15 ceramics show a linear variation between that of the end members for all compositions. These ceramics exhibit high ε r ranged from 53.1 to 42.3, low τf value from +93.4 to +33.1 ppm/°C, and high quality factor with Qu × f value from 18,790 to 28,070 GHz with increasing x values.

References

W. Wersing, Curr. Opin. Solid State Mater. Sci. 1, 715 (1996)

R. Ubic, I.M. Reaney, W.E. Lee, Int. Mater. Rev. 43, 205 (1998)

M.T. Sebastian, J. Mat. Sci: Mater. Electron 10, 475 (1999)

S. Solomon, M. Kumar, K.P. Surendran, M.T. Sebastian, P. Mohanan, Mater. Chem. Phys. 67, 291 (2001)

T. Okawa, K. Kiuchi, H. Okabe, H. Ohsato, Jpn. J. Appl. Phys. Part 1 40, 5779 (2001)

L. Fang, L. Chen, Hui Zhang, X.K. Hong, C.L. Diao, J. Mat. Sci: Mater. Electron. 16, 149 (2005)

R. Ratheesh, M.T. Sebastian, P. Mohanan, J. Harnett, R.E. Woode, D.G. Blair, Mater. Lett. 45, 279 (2000)

H. Zhang, L. Fang, R. Dronskowski, P. Mueller, R.Z. Yuan, J. Solid State Chem. 177, 4007 (2004)

L. Fang, H. Zhang, L. Chen, R.Z. Yuan, R. Dronskowski, J. Mat. Sci: Mater. Electron. 16, 43 (2005)

C. Veneis, P.K. Davies, T. Negas, S. Bell, Mater. Res., Bull. 31, 431 (1996)

H. Sreemoolanadhan, M.T. Sebastian, P. Mohanan, Mater. Res. Bull. 30, 653 (1995)

I.N. Jawahar, N.I. Santha, M.T. Sebastian, J. Mater. Res. 17, 3084 (2002)

S. Kamba, J. Petzelt, E. Buixaderas, D. Haubrich, P. Vanek, P. Kuzel, I.N. Jawahar, M.T. Sebastian, P. Mohanan, J. Appl.Phys. 89, 3900 (2001)

I.N. Jawahar, M.T. Sebastian, P. Mohanan, Mater. Sci. Eng. B106, 207 (2004)

I.N. Jawahar, P. Mohanan, M.T. Sebastian, Mater. Lett. 57, 4043 (2003)

L. Fang, H. Zhang, X.K. Hong, F.C. Meng, J.F. Yang, T.H. Huang. Mater. Lett. 58, 3884 (2004)

L. Fang, C.L. Diao, H. Zhang, R.Z. Yuan, R. Dronskowski, H.X. Liu, J. Mat. Sci: Mater. Electron. 15, 803 (2004)

L. Fang, H. Zhang, T.H. Huang, R.Z. Yuan, R. Dronskowski, Mater. Res. Bull. 39, 1649 (2004)

P.V. Bijumon, P. Mohanan, M.T. Sebastian, Materials Letters, 57, 1380 (2003)

K.P. Surendran, P. Mohanan, M.T. Sebastian, J. Eur. Ceram. Soc. 23, 2489 (2003)

H. Ogawa, A. Kan, S. Ishihara, Y. Higashid, J. Eur. Ceram. Soc. 23, 2485 (2003)

B. W. Hakki P.D. Coleman, IRE Trans. Microw. Theory Tech. MIT-8, 402 (1960)

W.E. Courtney, IEEE Trans. Microw. Theory Tech. MIT-8, 476 (1970)

R.D. Shannon, J. Appl. Phys. 73, 348 (1993)

R. Ratheesh, M. Wohlecke, B. Berge, T. Wahlbrink, H. Haeuseler, E. Ruhi, R. Blachnik, P. Balan, N. Santha, M.T. Sebastian, J. Appl. Phys. 88, 2813 (2000)

Acknowledgments

This work was partially supported by Natural Science Foundation of China (NSFC No.20571059 and No.50572078), the Project-sponsored by SRF for ROCS, SEM. This work was also financially supported by ICDD Grant-in-Aid project under Grant No.05–005 and 06–006, and Program for New Century Excellent Talents in University (NCET-06–0656), Ministry of Education, China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gui, D., Zhang, H., Fang, L. et al. Microwave dielectric properties of Ba4LaTiNb3−x Ta x O15 ceramics. J Mater Sci: Mater Electron 19, 543–546 (2008). https://doi.org/10.1007/s10854-007-9383-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-007-9383-5