Abstract

Lead-free piezoelectric ceramics (1 − x)Bi0.5Na0.5TiO3–xBaNb2O6 (BNT–BN100x), a new member of the BNT-based group, was prepared by conventional solid state reaction. X-ray diffraction showed that BaNb2O6 (BN) diffused into the lattice of Bi0.5Na0.5TiO3 to form a solid solution with perovskite-type structure. The temperature dependence of dielectric constant εr revealed that the solid solution underwent two phase transitions from ferroelectric to anti-ferroelectric and anti-ferroelectric to paraelectric. Both the transition temperature T d and T m were shifted to lower with the increasing content of BaNb2O6. The temperature dependence of dielectric constant at different frequency revealed that the solid solution exhibited obviously dielectric relaxation characteristics. The sample with x = 0.6 mol% exhibited excellent electrical properties, piezoelectric constant d 33 = 94 pC/N; electromechanical coupling factor k p = 0.185. The results showed that BNT–BN100x ceramics were good candidates for use as lead-free piezoelectric ceramics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Lead oxide based ferroelectrics, represented by lead zirconate titanate, Pb(Zr, Ti)O3 (PZT) are widely used for piezoelectric actuators, sensors and transducers due to their excellent piezoelectric properties. However, the toxicity of lead oxide and its high vapor pressure during processing demand alternative environmentally friendly materials to replace PZT based ceramics.

Bismuth sodium titanate, Bi0.5Na0.5TiO3 (abbreviate as BNT), discovered by Smolensky et al. in 1960, is one of important lead-free piezoelectric materials with perovskite structure [1]. As BNT shows a strong ferroelectricity with a large remnant polarization Pr = 38 μC/cm2 and high Curie temperature T c = 320 °C, it has been considered to be a promising candidate of lead-free piezoelectric materials to replace the widely used piezoelectric ceramics. However, this ceramic has drawbacks such as high conductivity and large coercive field, to cause problems in poling process. As a result of those, a lot of work to modify and improve piezoelectric properties of BNT ceramics, have been done by substitution of BaTiO3, K0.5Bi0.5TiO3, NaNbO3, etc. [2–6]. However, a BNT composition modified with BaNb2O6 (abbreviate as BN) has not been reported. Recently, BaNb2O6-based compounds are receiving great attention as a new ferroelectric tungsten bronze niobate materials [7]. It is hoped that BN can diffuse into BNT grains to enhance the properties of BNT ceramics.

The aim of this study is to investigate the dielectric and piezoelectric properties of (1 − x)Bi0.5Na0.5TiO3–xBaNb2O6 (abbreviate as BNT–BN100x) system as a new member of BNT based group. The effect of incorporated BN amounts up to 1.4 mol% on the electrical properties of the BNT system has been examined.

2 Experiment

A conventional ceramic fabrication technique was adopted to prepare BNT–BN100x ceramics with x = 0, 0.2, 0.6, 1.0 and 1.4. Reagent grade oxide or carbonate powders of Bi2O3, TiO2, Nb2O5, BaCO3 and Na2CO3 were used as starting materials. The powders were ball-milled for 12 h and calcined at 900 °C for 2 h. After calcinations, the mixture was ball-milled for 24 h, dried and granulated with PVA as a binder. The granulated powders were pressed into disc with diameter 18 mm and thickness 1.2 mm. The compacted discs were sintered at 1190 °C for 2 h in air. Silver paste was fired on both faces of the discs at 650 °C as electrodes. The specimen for measurement of piezoelectric properties was poled in silicon oil at 80 °C under 3–4 kv/mm for 15 min.

X-ray diffraction patterns were taken on a Bruker D8-Advance X-ray diffractometer with Cu Kα radiation (λ = 1.5418 Å) and graphite monochrometer. Piezoelectric properties were measured using a precision impedance analyzer (Agilent 4294A) by resonant and anti-resonant method. Piezoelectric constant d 33 was measured by means of a quasi-static d 33 meter (ZJ-3A) based on the Berlincourt method at 110 Hz. The temperature dependence of dielectric constant was investigated using LCR meter (TH2818) in the temperature range 20–410 °C.

3 Result and discussion

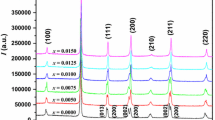

Figure 1 shows the X-ray diffraction patterns of BNT–BN100x ceramics in the 2θ range of 20–80°. It can be seen from Fig. 1 that a solid solution with perovskite-type structure has been formed for all samples and without any detectable impurity phases. The lattice and angle parameter were indexed to be a rhombohedral symmetry structure, implying that BN diffused into the BNT lattice and does not cause an obvious change in the phase structure.

The temperature dependence of dielectric constant εr at 1 kHz between room temperature and 410 °C of BNT–BN100x samples is shown in Fig. 2. From the curves, it can be evidently seen that there are two anomaly dielectric peaks with the increasing temperature, corresponding to the phase transition of ferroelectric–anti-ferroelectric and anti-ferroelectric–paraelectric which is consistent with the previous reports of NBT, NBT-NN, NBT-PT lead-free ceramics system [7–11]. Here, the transition temperature corresponding to the phase transition of ferroelectric to anti-ferroelectric phase is called the transition temperature (T d) and the temperature corresponding to maximum value of dielectric constant is named as maximum temperature (T m). It was found that the εr-temperature cures of the compositions exhibit strong dielectric dispersion with the increasing temperature. This phenomenon could be a result of the diffuse phase transition because BNT–BN system is a typical ABO3 structure with A site and B site complex ions. It also can be found that both transition temperature (T d) and maximum temperature(T m) of the ceramics obviously decrease with the increasing content of BN. Transition temperature (T d) and maximum temperature (T m) are correlated with the stabilization of domains and coupling degree of oxygen octahedron. When Nb5+ ions substituted Ti4+ ions in the A site of ABO3 perovskite structure unit cell, it would create A-site vaccines, and deteriorated stabilization of domain and the coupling degree of oxygen octahedron and lead to the decreasing T d and T m.

The temperature dependence of dielectric constant of BNT–BN100x samples with x = 0.2, 1.4 under various frequencies is shown in Fig. 3. Judged from these curves, the ferroelectric to anti-ferroelectric phase transition has obviously relaxor characteristics, i.e. both dielectric constant and phase transition temperature (T d), are strongly measurement-frequency dependent: the higher the frequency, the lower the dielectric constant value, and the higher phase transition temperature (T d). The relaxor behavior can be induced by many reasons such as the merging of micropolar regions into macropolar regions [12], local compositional fluctuation [13], superparaelectric [14] and dipolar glass model [15]. In the solid solution of BNT–BN100x, Ba2+, Na+, Bi3+ ions co-occupy the A-site of ABO3 perovskite structure, Ti4+, Nb5+ ions co-occupy the B-site, therefore the cations disorder in perovskike unit cell should be one of the reason for the appearance of relaxor state.

Figure 4a shows the piezoelectric constant d 33 and the electromechanical coupling factor k p of BNT–BN100x ceramics. The piezoelectric constant d 33 and the electromechanical coupling factor k p increased rapidly with the increasing content of BN, showed the maximum value of 94 pC/N and 0.185 at x = 0.6, respectively, then decreasing rapidly with the increasing content of BN.

Figure 4b shows the dissipation factor tanδ and mechanical quality factor Q m of BNT–BN100x ceramics. Mechanical quality factor Q m decreased rapidly with increasing amount of BN. Dissipation factor tanδ increased rapidly with increasing amount of BN, approached maximum value (tanδ = 4.5%) at x = 0.6 and slightly changed when x higher than 0.6. BN seem to be as soft dopant caused the electrical properties change of the ceramics. Nb5+ and Ba2+ have effective ionic radius of 0.69 Å, 1.34 Å, which is very close to that of Ti4+ (0.68 Å) and (Bi0.5Na0.5)2+ (1.12 Å), respectively. According to the principle of crystal chemistry, Nb5+ is most likely to go into B-site in perovskite system substituting Ti4+ and Ba2+ go into B-site substituting (Bi0.5Na0.5)2+. As Nb5+ substitute Ti4+, the charge compensation will occur by creation of A site vacancies, which benefits the reorientation of domains during the polarization process. When Ba2+ substituting (Bi0.5Na0.5)2+, it will cause deformation of lattice, which also facilitates the domain movement. These may be the explanation for the increase of d 33, k p and tanδ.

4 Conclusion

Lead-free piezoelectric ceramics Bi0.5Na0.5TiO3–BaNb2O6, a new member of the BNT-based group, has been successfully synthesized by using conventional ceramics technique. All compositions experience two phase transitions: from ferroelectric to anti-ferroelectric and from anti-ferroelectric to paraelectric. Both transitions temperature T d and T m are lowered due to introduction of BN. Ferroelectric to anti-ferroelectric phase transition has obviously relaxor characteristics. Piezoelectric properties have relatively high value around 0.6 mol% BN: piezoelectric constant d 33 = 94 pC/N; electromechanical coupling factor k p = 0.185.

References

G.A. Smolenski, V.A. Isupy, A.I. Aganovskaya, J. Sov. Phys. Solid State 2, 2651 (1961)

T. Takenaka, K. Sakata, Ferroelectrics 95, 153 (l989)

Y.M. Li, W. Chen, J. Zhou, Ceram. Int. 31, 139 (2005)

Y.M. Li, W. Chen, J. Zhou, Mater. Sci. Eng. B 112, 5 (2004)

T. Takenaka, K. Maruyama, K. Sakata, Jpn. J. Appl. Phys. 30, 2236 (1991)

A. Sasaki, T. Chiba, Y. Mamiya, E. Otsuki, Jpn. J. Appl. Phys. 38, 5564 (1999)

W. Sakamoto, M. Mizuno, J. Alloys Comp. 408–412, 538 (2006)

S. Said, J. Mercrio, J. Eur. Ceram. Soc. 21, 1333 (2001)

T. Takenaka, T. Okuda, K. Takegahara, Ferroelectrics 196, 175 (1997)

K. Sakata, T. Takenaka, Y. Naitou, Ferroelectrics 131, 219 (1992)

Y.M. Li, W. Chen, J. Zhou, Ceram. Int. 31, 139 (2005)

X. Yao, Z.L. Chen, I.E. Cross, J. Appl. Phys. 51(8), 4356 (1980)

N. Setter, L.E. Cross, J. Appl. Phys. 54(6), 3399 (1983)

I.E. Cross, Ferroelectrics 76, 241 (1987)

D. Viehland, S.J. Jang, L.E. Cross, M. Wutting, J. Appl. Phys. 68, 2916 (1990)

Acknowledgments

I am grateful to Dr Y. Luo for his pioneer work and helpful discussion. I would like to thank Mr J. Chen for the technical supports and valuable suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, C., Liu, X. Dielectric and piezoelectric properties of Bi0.5Na0.5TiO3–BaNb2O6 lead-free piezoelectric ceramics. J Mater Sci: Mater Electron 19, 29–32 (2008). https://doi.org/10.1007/s10854-007-9223-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-007-9223-7