Abstract

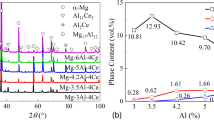

In this study, we conducted an extensive analysis and research of the microstructure, mechanical features, and fracture behaviors of Al–8Si–xMg alloy sheets under natural aging. The results reveal that while the dimensions of GP zones remained relatively unchanged with increasing Mg concentrations, their volume fraction progressively increased before reaching a plateau. It was observed that at a Mg concentration of 1.32%, numerous particles clustered areas comprising Mg2Si and Si particles were discovered. With the increase of Mg concentration in the alloy sheets, there was an initial uptick in strength, followed by a minor decline thereafter. Concurrently, the elongation consistently exhibited a reduction. The yield strength of Al–8Si alloy sheets under natural aging, incorporating varying Mg content levels, was precisely predicted. Moreover, the predicted value demonstrated strong agreement with the actual data obtained. Additionally, this research illuminated the impact of diverse strengthening mechanisms on the yield strength. Under tensile stress, the experimental alloy sheets exhibited a ductile fracture mechanism. Initially, as the Mg concentration increased, the quantity of dimples on the fracture surface remained steady, then slightly increased, while the depth of these dimples progressively became shallower and their size slightly decreased. Additionally, a rise in Mg content led to a smoother texture on the alloy sheets’ surface after undergoing tensile fracture. Secondary fractures reduced in quantity, and some secondary cracks bypassed the Si particles. Moreover, the quantity of cracked Si particles gradually grew.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

The data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Haghdadi N, Zarei-Hanzaki A, Abedi HR, Abou-Ras D, Kawasaki M, Zhilyaev AP (2016) Evolution of microstructure and mechanical properties in a hypoeutectic Al–Si–Mg alloy processed by accumulative back extrusion. Mater Sci Eng, A. 651:269–279. https://doi.org/10.1016/j.msea.2015.10.066

Liu T, Pei Z, Barton D, Thompson GB, Brewer LN (2022) Characterization of nanostructures in a high pressure die cast Al–Si–Cu alloy. Acta Mater 224:117500. https://doi.org/10.1016/j.actamat.2021.117500

Saad G, Fayek SA, Fawzy A, Soliman HN, Mohammed G (2010) Deformation characteristics of Al–4043 alloy. Mater Sci Eng, A 527(4–5):904–910. https://doi.org/10.1016/j.msea.2009.09.018

Wu Y, Liao H (2013) Corrosion behavior of extruded near eutectic Al–Si–Mg and 6063 Alloys. J Mater Sci Technol 29(4):380–386. https://doi.org/10.1016/j.jmst.2013.02.001

Mohamed AMA, Samuel FH, S.A. kahtani (2013) Microstructure, tensile properties and fracture behavior of high temperature Al–Si–Mg–Cu cast alloys. Mater Sci Eng, A 577:64–72. https://doi.org/10.1016/j.msea.2013.03.084

Wu X, Zhang H, Ma Z, Tao T, Gui J, Song W, Yang B, Zhang H (2019) Interactions between Fe-rich intermetallics and Mg-Si phase in Al–7Si–xMg alloys. J Alloys Compd 786:205–214. https://doi.org/10.1016/j.jallcom.2019.01.352

Gupta AK, Lloyd DJ, Court SA (2001) Precipitation hardening in Al–Mg–Si alloys with and without excess Si. Mater Sci Eng, A 316(1–2):11–17. https://doi.org/10.1016/S0921-5093(01)01247-3

Shen R, Wang Y, Guo B, Song M (2016) Precipitation sequence of a SiC particle reinforced Al–Mg–Si alloy composite. J Mater Eng Perform 25(11):4631–4636. https://doi.org/10.1007/s11665-016-2370-3

Rao JH, Zhang Y, Zhang K, Huang A, Davies CHJ, Wu X (2019) Multiple precipitation pathways in an Al–7Si–0 6Mg alloy fabricated by selective laser melting. Scripta Mater 160:66–69. https://doi.org/10.1016/j.scriptamat.2018.09.045

Li Z, Zhang Z, Zhou G, Zhao P, Jia Z, Poole WJ (2021) The effect of Mg and Si content on the microstructure, texture and bendability of Al–Mg–Si alloys. Mater Sci Eng, A 814:141199. https://doi.org/10.1016/J.MSEA.2021.141199

Yang H, Ji S, Yang W, Wang Y, Fan Z (2015) Effect of Mg level on the microstructure and mechanical properties of die-cast Al–Si–Cu alloys. Mater Sci Eng, A 642:340–350. https://doi.org/10.1016/j.msea.2015.07.008

Salleh MS, Omar MZ, Syarif J (2015) The effects of Mg addition on the microstructure and mechanical properties of thixoformed Al–5%Si–Cu alloys. J Alloys Compd 621:121–130. https://doi.org/10.1016/j.jallcom.2014.09.152

Hwang JY, Banerjee R, Doty HW, Kaufman MJ (2009) The effect of Mg on the structure and properties of Type 319 aluminum casting alloys. Acta Mater 57(4):1308–1317. https://doi.org/10.1016/j.actamat.2008.11.021

Yamamoto K, Takahashi M, Kamikubo Y, Sugiura Y, Iwasawa S, Nakata T, Kamado S (2020) Effect of Mg content on age-hardening response, tensile properties, and microstructures of a T5-treated thixo-cast hypoeutectic Al–Si alloy. Mater Sci Eng, A 798:140089. https://doi.org/10.1016/j.msea.2020.140089

Wang QG, Caceres CH, Griffiths JR (2003) Damage by eutectic particle cracking in aluminum casting alloys A356/357. Metall Mater Trans A 34A(12):2901–2912. https://doi.org/10.1007/s11661-003-0190-1

Wang QG, Cáceres CH (1998) The fracture mode in Al–Si–Mg casting alloys. Mater Sci Eng, A 241(1–2):72–82. https://doi.org/10.1016/S0921-5093(97)00476-0

Zhang P, Li ZM, Liu BL, Ding WJ (2017) Tensile properties and deformation behaviors of a new aluminum alloy for high pressure die casting. J Mater Sci Technol 33(4):367–378. https://doi.org/10.1016/j.jmst.2016.02.013

Huter P, Oberfrank S, Gruen F, Stauder B (2016) High- and low-cycle fatigue influence of silicon, copper, strontium and iron on hypo-eutectic Al–Si–Cu and Al–Si–Mg cast alloys used in cylinder heads. Int J Fatigue 88:142–155. https://doi.org/10.1016/j.ijfatigue.2015.09.015

Lee FT, Major JF, Samuel FH (1995) Effect of silicon particles on the fatigue crack growth characteristics of Al-12 Wt Pct Si-0.35 Wt Pct Mg-(0 to 0.02) Wt Pct Sr casting alloys. Metall Mater Trans A 26(6):1553–1570. https://doi.org/10.1007/BF02647606

Dighe MD, Gokhale AM, Horstemeyer MF (2002) Effect of loading condition and stress state on damage evolution of silicon particles in an Al–Si–Mg-base cast alloy. Metall Mater Trans A 33(3):555–565. https://doi.org/10.1007/s11661-002-0117-2

Ma K, Wen H, Hu T, Topping TD, Isheim D, Seidman DN, Lavernia EJ, Schoenung JM (2014) Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater 62:141–155. https://doi.org/10.1016/j.actamat.2013.09.042

Marioara CD, Andersen SJ, Jansen J, Zandbergen HW (2001) Atomic model for GP-zones in a 6082 Al–Mg–Si system. Acta Mater 49(2):321–328. https://doi.org/10.1016/j.actamat.2013.09.042

Deschamps A, Livet F, Bréchet Y (1998) Influence of predeformation on ageing in an Al–Zn–Mg alloy—I. Microstructure evolution and mechanical properties. Acta Mater 47(1):281–292. https://doi.org/10.1016/S1359-6454(98)00293-6

Guo MX, Zhang Y, Zhang XK, Zhang JS, Zhuang LZ (2016) Non-isothermal precipitation behaviors of Al-Mg-Si-Cu alloys with different Zn contents. Mater Sci Eng, A 669:20–32. https://doi.org/10.1016/j.msea.2016.05.060

Deschamps A, Brechet Y (1998) Influence of predeformation and ageing of an Al–Zn–Mg alloy—II Modeling of precipitation kinetics and yield stress. Acta Mater 47(1):293–305. https://doi.org/10.1016/S1359-6454(98)00296-1

Bardel D, Perez M, Nelias D, Deschamps A, Hutchinson CR, Maisonnette D, Chaise T, Garnier J, Bourlier F (2014) Coupled precipitation and yield strength modelling for non-isothermal treatments of a 6061 aluminium alloy. Acta Mater 62:129–140. https://doi.org/10.1016/j.actamat.2013.09.041

Esmaeili S, Lloyd DJ, Poole WJ (2003) A yield strength model for the Al–Mg–Si–Cu alloy AA6111. Acta Mater 51(8):2243–2257. https://doi.org/10.1016/S1359-6454(03)00028-4

Conrad H, Ramachandran S, Jung K, Narayan J (2006) Transmission electron microscopy observations on the microstructure of naturally aged Al–Mg–Si alloy AA6022 processed with an electric field. J Mater Sci 41(22):7555–7561. https://doi.org/10.1007/s10853-006-0840-y

Maisonnette D, Suery M, Nelias D, Chaudet P, Epicier T (2011) Effects of heat treatments on the microstructure and mechanical properties of a 6061 aluminium alloy. Mater Sci Eng, A 528(6):2718–2724. https://doi.org/10.1016/j.msea.2010.12.011

Liu G, Zhang GJ, Ding XD, Sun J, Chen KH (2003) Modeling the strengthening response to aging process of heat-treatable aluminum alloys containing plate/disc-or rod/needle-shaped precipitates. Mater Sci Eng, A 344(1–2):113–124. https://doi.org/10.1016/S0921-5093(02)00398-2

Nandy S, Kumar Ray K, Das D (2015) Process model to predict yield strength of AA6063 alloy. Mater Sci Eng, A 644(413):424. https://doi.org/10.1016/j.msea.2015.07.070

Chen R, Xu Q, Guo H, Xia Z, Wu Q, Liu B (2017) Modeling the precipitation kinetics and tensile properties in Al–7Si–Mg cast aluminum alloys. Mater Sci Eng, A 685:403–416. https://doi.org/10.1016/j.msea.2016.12.042

Wang X, Embury JD, Poole WJ, Esmaeili S, Lloyd DJ (2003) Precipitation strengthening of the aluminum alloy AA6111. Metall Mater Trans A 34(12):2913–2924. https://doi.org/10.1007/s11661-003-0191-0

Kucukomeroglu T (2010) Effect of equal-channel angular extrusion on mechanical and wear properties of eutectic Al–12Si alloy. Mater Des 31(2):782–789. https://doi.org/10.1016/j.matdes.2009.08.004

Liao H, Wu Y, Zhou K, Yang J (2015) Hot deformation behavior and processing map of Al–Si–Mg alloys containing different amount of silicon based on Gleebe-3500 hot compression simulation. Mater Des 65:1091–1099. https://doi.org/10.1016/j.matdes.2014.08.021

Sjölander E, Seifeddine S, Svensson IL (2011) Modelling yield strength of heat treated Al–Si–Mg casting alloys. Int J Cast Met Res 24(6):338–346. https://doi.org/10.1179/1743133611Y.0000000021

Gashti SO, Fattah-alhosseini A, Mazaheri Y, Keshavarz MK (2016) Effects of grain size and dislocation density on strain hardening behavior of ultrafine grained AA1050 processed by accumulative roll bonding. J Alloys Compd 658:854–861. https://doi.org/10.1016/j.jallcom.2015.11.032

Tian N, Wang GD, Zhou YR, Liu C, Liu K, Zhao G, Zuo L (2021) Formation of phases and microstructures in Al–8Si alloys with different mg content. Materials 14(4):762. https://doi.org/10.3390/ma14040762

Wang XJ, Hu XS, Nie KB, Deng KK, Wu K, Zheng MY (2012) Dynamic recrystallization behavior of particle reinforced Mg matrix composites fabricated by stir casting. Mater Sci Eng, A 545:38–43. https://doi.org/10.1016/j.msea.2012.02.077

Wang Z, Huang B, Qi L, Wang G, Dargusch MS (2017) Modeling of the dynamic recrystallization behavior of Csf/AZ91D magnesium matrix composites during hot compression process. J Alloys Compd 708:328–336. https://doi.org/10.1016/j.jallcom.2017.03.010

Chang H, Wang X, Hu X, Wang Y, Wu K (2014) Effects of reinforced particles on dynamic recrystalliza- tion of mg base alloys during hot extrusion. Rare Met Mater Eng 43(8):1821–1825. https://doi.org/10.1016/S1875-5372(14)60138-7

Acknowledgements

The research was financially supported by the basic scientific research projects of colleges and universities in Liaoning Province (No. XB2023007). The corresponding author would like to acknowledge the research group of Gang Zhao and Ni Tian of Northeastern University for providing experimental alloys and corresponding experimental resources.

Author information

Authors and Affiliations

Contributions

Guangdong Wang provided conceptualization, methodology, investigation, formal analysis, writing—original draft, and writing—review & editing. Yiran Zhou presented methodology, investigation, formal analysis, and resources. Jingyi Cao analyzed conceptualization, methodology, and formal analysis. Yue Tian prepared writing—review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Zhao Shen.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, G., Zhou, Y., Cao, J. et al. Tensile properties and fracture behavior of Al–8Si alloy sheets with different Mg under natural aging. J Mater Sci 59, 7368–7386 (2024). https://doi.org/10.1007/s10853-024-09604-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09604-6