Abstract

Magnetic porous manganese ferrite nanoparticles (MnxFe3-xO4) with diverse ingredient Mn/Fe mole ratios were synthesized to degrade sulfamethoxazole (SMX) antibiotic residues involving peroxymonosulfate (PMS) dissociation to produce free radical SO4•−, •OH and singlet oxygen 1O2 in the absence of heat and light. With the increase in proportion of manganese, the degradation efficiency of SMX increased from 19 to 70% in 30 min. The removal efficiency of SMX increased following the concentration increase of PMS (from 1 ~ 10 mM). After 60 min, the total organic carbon went down by 20%, and the concentration of NH4+ and NO3− accumulated obviously simultaneously. EPR study and chemical probe method, depending on scavenging revealed that SO4•−, •OH and 1O2 were generated and contributed to the degradation system. Based on the capture of eleven decomposition by-products by LC/MS, two different degradation pathways of SMX were determined, mainly consisting of cleavage of the S–N bond, hydroxylation of benzene and heterocyclic ring, oxidation of amino group and ring-opening cleavage processes. The nanoparticle reuse tests showed that the porous magnetic manganese ferrite nanoparticles could still maintain a high degradation efficiency after five oxidative degradation reactions. The magnetic porous manganese ferrite nanocrystals could activate the PMS to oxidize SMX antibiotic residue without additional energy.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Antibiotic environmental residues accelerate the development and spread of bacterial resistance and have become a global environmental health problem [1, 2]. They are mercilessly discharged into rivers and lakes by human beings and further into surface water, which brings about that the quality of water needed in daily life cannot be effectively guaranteed [3, 4]. It has been reported that various types of antibiotics, such as sulfonamides, β-lactamides, macrolides and quinolones, have been detected in the effluent of urban sewage treatment plants [5]. The world health organization (WHO) has identified bacterial resistance as the most serious problem facing humanity in the twenty-first century and proposed a global action plan to control antibiotic resistance in 2015 [5, 6]. Besides, sulfamethoxazole (N1-(5-methylisoxazol-3-yl)-4-aminobenzene-1-sulfonamide, SMX) is a frequently used sulfonamide antibiotic, mainly used for urinary tract infection, respiratory system infection, intestinal infection, biliary tract infection and local soft tissue or wound infection caused by sensitive bacteria. Drug abuse for humans and animals leads to excessive residue of SMX in wastewater and surface water, which leads to resistance genes in human body [7,8,9]. Residual antibiotics have a bullheaded inhibitory effect on microorganisms; therefore, traditional biochemical treatments cannot achieve the desired treatment effect. It is urgent to exploit effective methods to deal with antibiotic residues in the water environment.

Advanced oxidation processes (AOPs) are currently recognized as one of the most effective treatment methods for degrading toxic pollutants, which can replace the traditional process, and have been widely used in dyes [10], drugs, pesticides and other refractory organic organics [11,12,13,14]. Persulfates are a stable oxidant, which is convenient for storage and transportation, and it lays a foundation for the practical application of persulfate advanced oxidation process [15,16,17]. Peroxymonosulfate (PMS) and persulfate (PS) are two different persulfates that can provide free radicals SO4•−, •OH, and singlet oxygen 1O2; thereinto PMS is more likely to be activated. The stability and a redox potential of 2.5–3.1 V of SO4•− are slightly better than that of hydroxyl radicals (•OH with 1.8–2.7 V) and 1O2 (2.2 V) [18,19,20,21]. What is more to be expected is its positive oxidation and independence of pH value. Therefore, the development of practical methods for PMS activation is urgent. At present, the activation methods of PMS mainly include thermal activation, alkali activation, ultrasonic activation, and transition metal ions activation [22,23,24]. The transition metal ions activation method is concerned for its simple operation and strong practicability [25,26,27,28]. Recently, a great deal of transition metal oxides and bimetallic oxide catalysts have been synthesized and applied [29]. Magnetic crystal MFe2O4 (M = Co, Mn, Cu, Ni, etc.) has been found to have excellent catalytic properties and has been applied in such as the degradation and removal of organic pollutants in water [30, 31]. However, most of the metal oxides nano-sized catalysts have some shortcomings in the application of water purification, for instance, the difficulty of separation and the help of external energy [32, 33]. Recently, among the many nano-metal composites, iron-based bimetallic oxides have been widely used in the degradation and removal of organic pollutants in water due to their strong magnetics [34,35,36]. Cobalt is the best of all transition metals for PMS activation; nevertheless, cobalt has shortcoming in practical water purification applications on account of its recognized carcinogenicity, high price and difficulty to recycle. So some researches turned to transition metal manganese which can also high efficient activate PMS in many degradation processes [37, 38]; however, the effect of manganese in bimetallic oxides on the catalyst performance is worth further study.

Inspired by most of the researches, magnetic bimetallic oxide porous manganese ferrite nanoparticles (MnxFe3-xO4) were synthesized with a simple hydrothermal method and applied to activate PMS for the degradation of SMX in this work. The porous structure of the prepared porous MnxFe3-xO4 was increased, and the activity of the catalyst was improved by calcining at high temperature. The reactive activation of MnxFe3-xO4 was compared with that other different Mn/Fe stoichiometric ratios catalysts and investigated under a variety of external conditions. The mineralization of SMX was determined by simultaneously observing the total organic carbon (TOC) detection and the formation of ammonia nitrogen. Free radical quenching experiments combined with EPR tests proved the generation of two kinds of free radicals, SO4•− and •OH, and singlet oxygen 1O2 with the loadings of catalyst and concentrations of PMS in the degradation process and revealed their relative concentration changes (SO4•− and •OH, and 1O2) under crescent conditions. The possibility of reusing of catalyst MnxFe3-xO4 was verified by measuring the concentration of iron and manganese ions in the solution after the reaction. Finally, the degradation pathways of sulfamethoxazole by magnetic porous manganese ferrite nanoparticles (MnxFe3-xO4) were determined according to the composition of the reaction products in the degradation system.

Materials and methods

Chemicals and reagents

PMS (Oxone [KHSO5·0.5 KHSO4·0.5 K2SO4, molecular weight: 307.38 g/mol)] was purchased from Sigma-Aldrich. FeCl3•6H2O, MnCl2•4H2O, sodium acetate anhydrous NaN3 are purchased from China National Medicines Corporation Ltd. Sulfamethoxazole (SMX, 99%), ethylene glycol, polyethylene glycol (PEG) with 1000 MW, ethyl alcohol, methanol, tert-butanol, NaN3, 5,5-dimethyl-1-pyrroline N-oxide (DMPO, 99%), 4-amino-2,2,6,6-tetramethylpiperidine (TEPM, 99%) are purchased from Aladdin. A certain concentration of PMS solution was prepared in advance for later dilution for degradation experiments. All other chemicals and reagents are not processed before use after purchase.

Synthesis of MnxFe3-xO4 catalysts

MnxFe3-xO4 was prepared by modified hydrothermal method and then calcined. FeCl3•6H2O and MnCl2∙4H2O provide raw material sources of copper and iron. Manganese (II) and iron (III) with different molar ratios (0.1:2.9, 0.5:2.5, 0.7:2.3, 1.0:2.0, and 1.5:1.5) (abbreviated to MnxFe3-xO4 in the following article) are dissolved in 80 mL of ethylene glycol, and when they were completely dissolved, add 6.0 g sodium acetate anhydrous and 3.0 g PEG 1000 to the solution. Closely followed by 45 min of forceful stirring, the solution was poured into 100 mL Teflon-lined stainless steel autoclave at 200 °C for 8 h in oven. The resulting black—brown solid was dried in oven at 60 °C for 6 h after washed alternately with ethanol and water three times each using sucked out with a magnet, as reported in previous work of our research group [39]. The catalyst MnxFe3-xO4 spherical spinel was obtained by calcining at 450 °C in a muffle furnace for 3 h at the rate of 3 °C/min.

Characterization of MnxFe3-xO4 catalysts

The surface morphology and microstructure of obtained powder were observed by a field-emission scanning electron microscopy (SEM, FEI Quanta 200 FEG) and transmission electron microscopy (TEM, JEOL JEM-2010). The EDS pattern was analyzed with ZEISS Auriga SEM/FIB Crossbeam System. Fourier transform infrared (FTIR) spectrometer in KBr pellets on a Thermo Nicolet Nexus-870 spectrophotometer was used to support the composition information of catalysts. Magnetite properties of the eventual products were measured using superconducting quantum interference device (Quantum Design MPMS XL5) in 300 K. Thermo-gravimetric analysis (TGA, SDT Q600) was characterized only in detecting the thermal stability of the catalysts. XRD analysis was performed using a PANalytical X'Pert instrument with a Cu Ka radiation. X-ray photoelectron spectroscopy (XPS, Thermo-VG Scientific ESCALAB 250) was used to investigate the catalysts before and after degradation.

Degradation experiments

All degradation experimental systems were completed containing MnxFe3-xO4 placed into a shaker with a speed of 200 rpm at room temperature (25 ± 2 °C) in 250-mL conical flask covered with tin foil to avoid light with SMX initial concentration 20 mg/L at pH 7.0 (by adjusting with 1.0 M NaOH and 1.0 M HCl). To explore the activity of five different catalysts, 0.20 g/L MnxFe3-xO4 were added separately into degradation systems under the same conditions after adding 60 mL SMX (initial concentration of 50 mM) and 20 mL PMS (initial concentration of 30 mM) in succession. In addition, a certain volume of SMX and PMS were added to dilute the concentration to 20 mg/L and 1–10 mM (1, 2, 4, 10 mM), and different amounts of catalysts (0.01–0.50 g/L Mn1.5Fe1.5O4) were added to start the degradation experiment. The stability and repeatability of the MnxFe3-xO4 were observed by six cycle degradation experiments under the same above experimental conditions. All the experimental data of SMX degradation experiment were the average of three times by UV–Vis spectrophotometer (Fig. S1), and the error of experiments was reflected in the error bar of data graphs.

Kinetics were analyzed using the pseudo-first-order and pseudo-second-order model using Eqs. 1 and 2 [40]

where C0 express initial concentration, and Ct is the concentration at time t min of SMX (mg/g) in the MnxFe3-xO4/PMS system. k1 (min−1) and k2 (g/mg min) are the pseudo first-order and pseudo second-order rate constants.

Degradation of sulfamethoxazole in real water samples was a formidable challenge; thus, the volume of the experimental system was designed to 1 L. A small Fenton tower device was structured with simulated actual water samples (0.20 g/L Mn1.5Fe1.5O4, 20 mg/L SMX, 4.0 mM PMS, pH = 7.0, 10 mg/L Na+/Mg2+ and 30 mg/L NO3_).

Analytical methods

Inductively coupled plasma atomic emission spectrometer (ICP PERKINELMER Optima 7300 DV) was used to measure the concentration of Mn and Fe ions in the reaction solution. In order to study and discuss conceivable degradation pathways, Agilent 6540 UHD accurate-mass quadrupole time-of-flight tandem mass spectrometer (Q-TOF-MS) with an electrospray ionization source was used to detect the mass of products and by-products generated in the degradation process of SMX. The mineralization of SMX was analyzed by detecting NH4+ (ammonia nitrogen) and TOC after degradation using MnxFe3-xO4/PMS [41].

The decrease of TOC in degradation system represents the mineralization of SMX, and the calculation method of mineralization degree is as follows Eq. 3:

where TOCt and TOC0 represent total organic carbon concentration after t minutes and initial organic carbon content of SMX.

Quenching experiments and EPR experiments

In order to analyze the production and predominance of free radicals SO4•−, •OH and non-free radical 1O2 in MnxFe3-xO4/PMS degradation system, three quenching agents, methanol (MeOH), tert-butyl alcohol (TBA) and NaN3 were added to the reaction system for comparison experiments. Previous studies reported that the quenching ability of MeOH to SO4•−, •OH was basically the similar, and TBA could quench •OH, and NaN3 quench 1O2 efficiently with the rate constants kMeOH, SO4•−, kMeOH, •OH, kTBA, •OH and kNaN3, 1O2 shown in Table 1. Thereinto concentrations of MeOH and TBA were 100 mM and NaN3 was 20 mM, and other experimental conditions are controlled as the best conditions of the above research. The types of free radicals SO4•−, •OH and singlet oxygen 1O2 were proved by EPR (electron paramagnetic resonance) test using a spin-trapping agents DMPO and TEMP respectively by EPR (EMX 10/12, Bruker, Germany) at a resonance frequency of 9.39 GHz, microwave power of 5.02 mW, modulation amplitude of 0.30 G, receiver gain of 1.0 ×104/2.0 ×104, and regulatory sweep width, time constant and sweep time. Pre-weighed catalyst and a certain volume of PMS and SMX were added to 15-mL centrifugal tube, and capture agents DMPO (100 mM) and TEMP (100 mM) were added at the end. The relative strengths of SO4•−, •OH and 1O2 were detected under different loadings of catalysts (0.01–0.50 g/L Mn1.5Fe1.5O4) and concentrations of PMS (1–10 mM).

Results and discussion

Characterization of MnxFe3-xO4 nanoparticles

All five MnxFe3-xO4 catalysts range in size by SEM and TEM from 500 to 600 nm with stable solid spherical structures. It was obvious that a mass of pores were formed on the surface of the catalyst after calcination at 450 °C (Fig. 1a and b), and they are favorable for the catalyst to contact with SMX to be degraded. However, the material size remains essentially unchanged before and after calcination. After calcination in high temperature, the internal structure of the material becomes less granular and more stable reflected in TEM (Fig. 1c) and HRTEM (Fig. 1d), the lattice spacing of 0.296 nm corresponds to the (220) planes of MnxFe3-xO4, consistent with the previous reports, which is beneficial to the degradation and multiple utilization of SMX. The EDS results confirm that the catalysts contain Mn, Fe, O and a small amount of C and the manganese relative amount in MnxFe3-xO4 increased with the increase of the Mn/Fe stoichiometry ratios (Table 2).

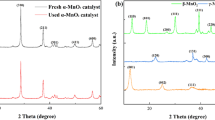

The observed field dependence the MnxFe3-xO4 catalysts agrees well with the reported room temperature superparamagnetic behavior of MnFe2O4 nanoparticle. The saturation magnetization of the MnxFe3-xO4 catalysts shown in Fig. 2a ranges from 57.53 to 62.79 emu/g. Among them, the catalyst with the strongest magnetic is Mn1.5Fe1.5O4. Superparamagnetic characteristics are beneficial for separation applications in water environments [42]. The XRD diffraction data of the synthesized catalysts MnxFe3-xO4 showed that they belong to the nanocrystal structure (Fig. 2b). The diffraction peaks were absolutely matched against the diffraction files of the JCPDS card No. 65–3107 indexed to synthetic spinel crystalline structure Fe3O4. And the peaks were at 18.34°, 30.28°, 35.7°, 43.39°, 54.05°, 57.41°, and 62.96° correspond to crystal planes (111), (220), (311), (400), (422), (511), and (440), respectively. The peak observed at 33.15° of Mn0.1Fe2.9O4, Mn0.5Fe2.5O4 and Mn0.7Fe2.3O4 was assigned to little α-Fe2O3 produced during the synthesis process, which correspond to crystal planes (104) (JCPDS NO. 33-0664) [43, 44]

In FTIR spectra (Fig. S2a) of MnxFe3-xO4, metal oxide characteristic peak signals of catalysts are less than 1000 cm−1, and the peaks at 438 and 578 cm−1 are corresponded to the stretching vibrations of Fe–O and Mn–O in the apparent spinel structure. The two high intensity peaks 3440 and 1644 cm−1 are recognized as hydroxyl groups. The spinel structure of all catalysts natures were confirmed once again. Fig. S2b showed N2 adsorption–desorption isotherm and pore size distribution (inset) of MnxFe3-xO4. Compared with other MFe2O4 (M = Cu, Mn) prepared by predecessors [45, 46], the MnxFe3-xO4 possessed a higher specific surface area (47.55 m2/g). The average pore diameter was 6.66 nm suggesting the mesoporous structure of catalysts. The larger specific surface area facilitated the affinity between the active sites on the catalysts surface and the corresponding substances to be activated.

TGA analysis was performed to investigate the MnxFe3-xO4 catalysts pyrolysis process, and the results were exhibited in the Fig. S3. The first mass loss (2.910%) processes that occurred between room temperature and 165.33 °C was assuredly derived from the weight of physically adsorbed water; next, the second mass losses (5.728%) in the range from 165.33 to 449.87 °C belonged to surface hydroxyl group namely chemisorption water. It followed that the structures and properties of the MnxFe3-xO4 catalysts were stable, which were conducive to the following long-term degradation experiments.

The XPS shows the elemental composition of the catalysts MnxFe3-xO4. The four predominant peaks on behalf of the Mn2p, Fe2p, O1s and C1s are clearly observed at about binding energy of 641.61, 711.26, 531.26 and 285.51 eV, respectively, in the spectrogram (Fig. 3a). Figure 3d displays XPS data of the C1s core level peak. The peak consists of three components assigned to O–C = O, C–O, and C–C bonds at 288.90 eV (I), 286.30 eV (II), ∼284.80 eV (III), respectively. These peaks were very intense in the MnFeO4 sample. The C1s peak shape is characteristic of iron carbonate, FeCO3 [47]. The C1s peak is less intense in the other three samples of cobalt ferrites [41, 48]. The XPS spectra of Mn2p as Fig. 3b of MnxFe3-xO4 showed the same form and binding energies and peaks of increasing strength are also consistent with the five catalysts with the relative increase of Mn dosage in the raw materials. The peak at 642.8 and 653.8 eV assigned to Mn2p3/2 and Mn2p1/2 [49], and the peak of Mn2p is not obvious due to the relatively low dosage in Mn0.1Fe2.9O4. Figure 3e shows that Mn2+ existed on the surface of preparative catalysts unused [49, 50]. Figure 3c shows the XPS spectra of Fe2p, and it behaved differently from Mn2p, the peak area of Fe changed negligibly consistent with Fe2p1/2 and Fe2p2/3 in the binding energies of 724.8 and 710.8 eV with the change of Mn/Fe stoichiometric. The peak of 710.7 eV was assigned to Fe2+ possibly derived from manganese ferrite or iron carbonates; furthermore, the peak with higher binding energy abound 712.1 eV had been assigned to Fe3+ from ferric oxide (Fig. 3f) [50, 51].

Degradation of SMX using MnxFe3-xO4/PMS

Effect of Mn/Fe stoichiometric ratio

The degradation degree of SMX was an important index to judge the activity of catalysts MnxFe3-xO4 (with different Mn/Fe molar ratios, 0.1:2.9, 0.5:2.5, 0.7:2.3, 1.0:2.0, and 1.5:1.5)/PMS. Figure 4a demonstrated SMX was hardly degraded in the reaction system with no catalyst as only existence of PMS under experimental conditions: 4 mM PMS, C0 of SMX 20 mg/L, and 7.0 pH value. Moreover, the SMX was mostly degraded at a certain time after the subsequent addition of constant concentration PMS (4 mM) in the degradation system in which there was no degradation with only catalyst. PMS naturally occurred as an oxidant in degradation systems. At the same time, it was observed that the degradation results of five catalysts with the same mass (MnxFe3-xO4 0.20 g/L) were completely different. The degradation efficiency of catalysts MnxFe3-xO4 also increased gradually with the increase of Mn/Fe relative stoichiometric ratio. In other words, removal efficiency of five catalysts was: Mn1.5Fe1.5O4 (with a removal rate of 70%) > MnFe2O4 > Mn0.7Fe2.3O4 > Mn0.5Fe2.5O4 > Mn0.1Fe2.9O4. Under the approximate reference conditions, the removal efficiency for SMX degradation of the porous Mn1.5Fe1.5O4 catalyst was higher than that of most of the catalysts reported previously (Table S1).

Effect of initial conditions on degradation of SMX by MnxFe3-xO4: a different molar ratios:0.1:2.9, 0.5:2.5, 0.7:2.3, 1.0:2.0, 1.0:1.0, b catalyst loadings, c catalyst concentrations of PMS, d–f pseudo-second-order kinetic models fitting. Other experimental parameters: C0 = 20 mg/L, pH = 7.0, (a) 0.20 g/L MnxFe3-xO4, 4 mM PMS, (b) 4.0 mM PMS, (c) 0.20 g/L Mn1.5Fe1.5O4

And the degradation processes of catalysts conformed to pseudo-second-order kinetic models (Fig. 4d). In addition, it could be observed that in the catalysts and PMS system, SMX degraded rapidly in the initial 20 min, and then, the degradation efficiency of tended to be stable without obvious change. This behavior has been shown in many semblable catalytic studies. This phenomenon was caused by the commonly perceive catalyst “surface poisoning.” In order to observe the best degradation efficiency under the influence of subsequent diverse experimental conditions, Mn1.5Fe1.5O4 was examined with the best degradation rate (70%) of degradation of SMX among five catalysts. Another problem that we should pay attention to is that in the catalyst and PMS degradation of SMX system, there may be slight changes in the pH of the solution caused by the mixture of two solutions (SMX and PMS), and we did not consider the influence on the experiment, which is more conducive to the different test conditions existing in our actual water samples.

Effect of MnxFe3-xO4 loadings and concentrations of PMS

Considering that degradation experiments may be affected by many environmental factors, the influences of different loadings of Mn1.5Fe1.5O4 and PMS at different concentrations on SMX degradation were described in Fig. 4b and c. On the one hand, the degradation was observed for 300 min at 20 mg/L initial concentration of SMX, 4 mM PMS and pH = 7.0. The removal rate of SMX increased gradually from 37 to 70% (with catalyst loadings from 0.01 to 0.50 g/L) with the pseudo-second order reaction rate constants (kobs) increased from 0.0246 to 0.1201 min−1 (Fig. 4e); nevertheless, when the catalysts loading increased to the 0.50 g/L, the degradation rate of SMX decreased compared with the previous maximum removal rate. It might be well understood that when the loadings of the catalyst Mn1.5Fe1.5O4 was increased, it could promote the activation of PMS to produce more strong oxidizing substances and increase the degradation of SMX. While, when the loading exceeded a certain amount, the exposed surface of catalyst activated PMS was reduced because of the inherent agglomeration of the nanomaterial; therefore, the degradation of SMX was relatively stable or even reduced.

In the same way, similar to general perception, the increase of concentration of PMS was beneficial to the degradation of SMX. It was also intuitive to analyze the effect of PMS concentration on the removal of SMX by kobs increasing from 0.0031 to 0.0110 min−1 with an 0.20 g/L Mn1.5Fe1.5O4, 20 mg/L initial concentration of SMX (1.0, 2.0, and 4.0 mM), and pH = 7.0. Certainly, it was also apparent that the concentration of PMS further increased to 10 mM did not cause the degradation of SMX to increase continuously but remained substantially constant with kobs = 0.011 min−1 (Fig. 4f). It signified that when PMS exceeded a certain concentration, the loadings of MnxFe3-xO4 was the main factor affecting degradation.

Effect of solution pH in MnxFe3-xO4/PMS system

For field of environmental remediation, the influence of pH value is very important. Hence, the effect of solution pH ranges from 3 to 11 in MnxFe3-xO4/PMS system of SMX degradation was investigated. As shown in Fig. 5, degradation efficiency was seriously negative affected in excessively acidic and alkaline solution. Effect of solution pH mainly depended on deprotonation of oxidant and surface charges of MnxFe3-xO4 [52]. When the pH was adjusted to 3, the oxidant PMS tended to break down to produce SO42− rather than SO4•−. And at pH of 11, the production of SO5•− was reduced due to the deprotonation of PMS and it was not conducive to the affinity of negative groups HSO5−, SO52− on the surface of MnxFe3-xO4 with negatively charged. Although the degradation efficiency of the catalysts was outstanding at a pH of 9, in order to make the catalysts better suited to the mild water environment, other parameters affecting of SMX degradation were selected under neutral condition (pH = 7).

Free radical quenching and EPR studies

It is well known that the types of oxidants that may occurred in the activation of PMS by catalysts MnxFe3-xO4 include free-radical SO4•−, •OH or singlet oxygen 1O2. As shown in the Fig. 6, after adding of MeOH, TBA and NaN3, the removal efficiency declined to 40%, 50% and 14%, respectively. These results showed that both SO4•−, •OH and 1O2 contributed to the degradation of SMX and 1O2 probably played a leading role. Because Eqs. 12 and 13 showed that •OH was produced from SO4•− and H2O/OH−, the main responsibility for degradation of SMX is SO4•−. For 1O2, the self-decomposition of PMS and the promotion of the catalysts were not drastic, but the presence of plentiful hydroxyl groups accelerated the decomposition of PMS to 1O2.

EPR experiments further verified the existence of three oxidants in the PMS activation process. The EPR provided a good explanation for the experiments to explore the influence of catalyst loadings and the different concentrations of PMS on degradation. Figure 7a and b shows that the signals of DMPO- SO4•− and DMPO-•OH occurred in the activation of PMS by catalyst Mn1.5Fe1.5O4, assigned according to their hyperfine splitting constants (DMPO-SO4•−: aN = 13.2 G, aH = 9.6 G, aH = 1.48 G, and aH = 0.98 G; DMPO-•OH: aH = aN = 14.9 G) [53, 54]. And Fig. 7c and d described PMS activation also formed TEMP-1O2 signals with the hyperfine splitting constants (TEMP-1O2: aN = 16.9 G) [55]. Results displayed that the peak intensity of EPR also increased gradually and remained invariable consistent followed aggrandizement of catalyst loadings or enhancement of concentration of PMS in accord with the degradation trend of SMX. AS shown in Fig. 7a and c, the peak intensity of EPR enlarged by four-fold. With the catalyst loadings increased from 0.01 to 0.20 g/L, what’s even more remarkable was that when catalyst loading was 0.50 g/L, the peak intensity increased nine-fold. Moreover, Fig. 7b and d shows that as the PMS concentration increased from 1 to 10 mM, the peak intensity of PMS also enlarged, but it was obvious that the effect was not as significant as on the catalyst loadings. In general, the analysis of quenching experiments and EPR indicated that catalysts MnxFe3-xO4 promoted the activation of PMS to produce free-radical SO4•−, •OH and singlet oxygen 1O2 participating in the degradation of SMX.

EPR of free-radical SO4•−, OH• of a Mn1.5Fe1.5O4 loadings, b concentrations of PMS, and singlet oxygen of 1O2c Mn1.5Fe1.5O4 loadings, d concentrations of PMS generated in the PMS/ Mn1.5Fe1.5O4 system. Experiment conditions: C0 = 20 mg/L, pH = 7.0, a, c 0.01, 0.05, 0.10, 0.20, 0.50 g/L Mn1.5Fe1.5O4, 4 mM PMS, b, d 0.20 g/L Mn1.5Fe1.5O4, 1, 2, 4, 10 mM PMS. Sulfate radicals (DMPO-SO4•−: (●), hydroxyl radicals (DMPO-OH•: (◊) and (TMPO-1O2: (*) are denoted

Activation mechanism of PMS on catalysts MnxFe3-xO4

It is well-known that free-radical SO4•−, •OH were main products by the transition metals activation of PMS mentioned in previous studies. However, in the degradation experiments, the role of transition metals Mn and Fe ions mainly served as activator for PMS, and the degradation of SMX was mainly dependent on not only strong oxidizing free-radical SO4•−, •OH but singlet oxygen 1O2 produced by the activation process. And evidence of Mn and Fe ions participating in the activation were proved by the XPS spectra of the two metals before and after the degradation. Figure 3e displayed that Mn3+ (642.4 eV) accounted for 61.0% of Mn species. The deconvolution peaks of Fe2p were slightly shifted and dramatical increases of strength because of electron transfer. There were conspicuous changes in the peak area proportions of Fe3+ (712.1, 725.5 eV) and Fe2+ (710.5, 723.9 eV) in terms of the deconvolution peaks of Fe2p1/2 and Fe2p3/2 envelops after degradation as shown in Fig. 3f. It was verified that the transition metal Mn and Fe on the surface of the catalysts participated in the process of activating PMS to produce strong oxidizing substances for redox nature as illustrated in following Fig. 8 [49]. Also, the transition metals ion M2+ activated the hydrogen sulfate radical to produce SO4•− and SO5•− as shown in Eqs. 4 and 5. Equation 6 described the decomposition of PMS to produce 1O2, and the addition of Mn/Fe also increased decomposition rate. The free radicals SO4•−, •OH (Eqs. 4–13) and singlet oxygen 1O2 (Eq. 6) served as oxidants in the degradation system of SMX, which ultimately oxidized to degrade the SMX into CO2, H2O and by-products (Eq. 14).

where M stands for transition metals Mn and Fe. Both M3+metal ions in the catalysts played a certain role in activating PMS. The addition of Mn caused the acceleration of activation, and the removal efficiency increased with the enlargement of the relative stoichiometry of Mn, which also indicates that this understanding is reasonable.

Among the many equations (Eqs. 4 to 14), considering the redox potential of HSO5−/SO4•− (2.5 − 3.1 V) and HSO5−/SO5•− (1.1 V) and according to the reduction potential of the reduction of Fe3+ (0.77 V), we concluded that the regeneration of Fe2+ was the main rate limiting step.

To explore whether Fe is involved in activating PMS in addition to providing magnetic properties during the degradation process, we added a new control group for the SMX degradation of Fe3O4/PMS. The XRD, surface morphology and the reference experimental were shown in Fig. S4a. Obviously, when Fe3O4 without Mn was added into the degradation system (Fig. S4b), SMX was almost not degraded and the SMX removal rate increased significantly with addition of Mn. Because the redox cycle between Mn3+/Mn2+ was thermodynamically favorable, we speculate Mn is the main active site on the catalyst surface combined with the performance of Fe3O4 in the degradation system. On the other hand, it is reported that the stability of complex between Fe and ligand is generally considered to be better than that of Mn and the modification of the stronger coordination environment between Fe and PMS increases the probability of producing free radicals. Therefore, we assumed that the synergistic effect between Fe and Mn was a decisive factor for activation of PMS.

Mineralization of SMX

The mineralization products of C and N in the system were explained by investigation of TOC, NH4+ and nitrate nitrogen (NO3−) in SMX solution after degradation. It had been reported that the nitrogen on the amino group was generally converted into NH4+, and the nitrogen-containing heterocyclic ring of isoxazole was mostly converted into NH4+ and NO3− [56]. Figure 9 presented the conversion degrees of TOC, NH4+ and NO3−. Negligible TOC were reduced only 25% within 20 min and remained invariable for the following 2 h in the degradation of SMX system using PMS activated by MnxFe3-xO4 catalysts. It followed that the further mineralization of SMX required a longer reaction time. After 20 min of degradation, 0.69 mg/L NH4+ and 0.54 mg/L NO3− were detected, which was also synchronous with degradation of 70% SMX. In theory, few nitrite ions (NO2−) were released considering that NO2− was unstable in solution easily oxidized to NO3−. In general, SMX was mainly mineralized into ammonia nitrogen, nitrate nitrogen and trace amounts of nitrite in degradation systems.

Possible by-products and pathways for degradation of SMX

During the integrated degradation, target antibiotic SMX was subjected to different levels of hydroxylation, elimination of sulfonate group, oxidation of amino group and ring-opening cleavage mainly through the different attacks of free-radical SO4•−, •OH and singlet oxygen 1O2.

Figure 10 demonstrated the SMX intermediates and the feasible two degradation pathways by LC–MS spectrogram (Fig. S5) during the degradation of antibiotic by PMS activated by MnxFe3-xO4. The appearance of the product with an m/z of 254 described the unreacted SMX molecules during degradation. The degradation pathway analysis mainly was owing to the first difference molecular sites to attack. Pathway I: As stated in previous reports, cleavage of S–N bond occurred easily in SMX [57], the cleavage of S–N bond resulted in SMX molecular resolved into product 1 (m/z of 156) and product 2 (m/z of 99). Certainly, product 1 quickly converted to product 3 sulfanilic acid with m/z of 212. And then, sulfanilic acid naturally oxidized to hydroxyl sulfanilic acid. Subsequently, further decomposition of hydroxyl sulfanilic acid occurred to generate product 4 (m/z of 108) and following product 5 (m/z of 93), product 6 (m/z of 95) on account of the release of sulfonate group. Once again, the amino group on heterocyclic ring of product 2 was also oxidized to product 7 (m/z of 100) (the hydroxylation of benzene ring) which was cracked with ring-opening, and all products finally mineralized into CO2, H2O, NH4+, NO3− and mineral acids. Pathway II: Considering that hydroxylation might occur on heterocycle of SMX, the molecular structure of SMX could be reorganized to form derivatives. In consequence, heterocycle of SMX was oxidized and molecule cleaved to product 8 (m/z of 215) by structure reengineering with the subsequent hydroxylation – deamination (product 9 with m/z of 233) [58]. Product 10 (m/z of 192) and product 11 (m/z of 143) were generated resulting from cleavage of S–N bond and oxidation of amino group. Finally, the resulting simple molecules like benzene, phenol and so on were mineralized into CO2, H2O, NH4+, NO3− and mineral acids by ring-opening under the oxidation of attacks of free-radical SO4•−, •OH and singlet oxygen 1O2.

Stability and reusability of MnxFe3-xO4

For environmental pollution governance, the choice of catalysts is particularly significance in excellent stability and reusability. On the one hand, the residual concentrations of Mn and Fe ions in the collected solution after degradation were detected by ICP-MS. The data showed that the concentrations of Mn and Fe ions in the solution after 1 h and 4 h degradation only were 0.063, 0.869, 0.091, and 1.076 μg/mL, respectively, 9 (Table 3). On the other hand, the analysis about FTIR of catalysts collected in the degradation system in Fig. 11a revealed that catalyst structure had not changed substantially after degradation. The degradation degree during the five cycle degradation experiments indicated a gradually decreasing trend, but the overall degradation rate remained relatively high as shown in Fig. 11b. The loss of metal ions might be responsible for activation of PMS generating oxidizing substances and the production of some “toxic” substances probably were the leading causes in multiple degradation systems.

Scale-up experiment test

As shown in the Fig. S6, the Mn1.5Fe1.5O4/PMS system still maintained a certain degradation performance in simulated actual water samples. The degradation efficiency reached 45% after 60 min in the water environment with overloaded interfering ions concentration. Therefore, it was speculated that the catalyst would make an excellent candidate in the actual water sample.

Conclusion

The magnetic porous manganese ferrite nanoparticles(MnxFe3-xO4) catalysts were prepared by a common hydrothermal method followed by calcining at a certain temperature according to different Mn/Fe stoichiometry. In this study, a deep insight and analysis in activation PMS using MnxFe3-xO4 for degradation of SMX antibiotics were presented. The Mn1.5Fe1.5O4 showed great degradation degree (70%) of SMX after 10 min with 4 mM PMS for 20 mg/L initial concentration at pH 7.0 of SMX. SMX was mainly degraded into CO2, H2O, NH4+, NO3− and mineral acids, and the TOC was reduced by 20%. Mn and Fe ions in the activation of PMS promoted each other and participated jointly in the activation, and the verification of EPR and quenching experiments revealed activation produced strong oxidizing substances free-radical SO4•−, •OH and singlet oxygen 1O2 involved in degradation of SMX. Two possible degradation pathways of SMX in degradation system were deduced by LC–MS analysis of intermediate including: (I) cleavage of the S–N bond; (II) hydroxylation of benzene and heterocyclic ring; (III) disappearance of sulfonate group; (IV) oxidation of amino group; (V) ring-opening cleavage. Finally, the MnxFe3-xO4 catalysts showed good stability and reuse performance after five cycle experiments. The magnetic MnxFe3-xO4 catalysts have inestimable potential in environmental repair and pollutants degradation due to their excellent stability and reuse performance.

References

Wang J, Liu W, Zhong D, Ma Y, Ma Q, Wang Z, Pan J (2019) Fabrication of bismuth titanate nanosheets with tunable crystal facets for photocatalytic degradation of antibiotic. J Mater Sci 54:13740–13752. https://doi.org/10.1007/s10853-019-03882-1

Zhang R, Han Q, Li Y, Zhang T, Liu Y, Zeng K, Zhao C (2019) Fabrication and characterization of high efficient Z-scheme photocatalyst Bi2MoO6/reduced graphene oxide/BiOBr for the degradation of organic dye and antibiotic under visible-light irradiation. J Mater Sci 54:14157–14170. https://doi.org/10.1007/s10853-019-03883-0

Vaizoğullar Aİ (2020) An effective photocatalytic and photoelectrochemical performance of β/γ-MnS/CdS composite photocatalyst for degradation of flumequine and oxytetracycline antibiotics under visible light irradiation. J Mater Sci 55:4005–4016. https://doi.org/10.1007/s10853-019-04299-6

Zhao R, Sun X, Jin Y, Han J, Wang L, Liu F (2019) Au/Pd/g-C3N4 nanocomposites for photocatalytic degradation of tetracycline hydrochloride. J Mater Sci 54:5445–5456. https://doi.org/10.1007/s10853-018-03278-7

Zhang H, Liu P, Feng Y, Yang F (2013) Fate of antibiotics during wastewater treatment and antibiotic distribution in the effluent-receiving waters of the yellow Sea. Northern China. Mar Pollut Bull 73:282–290

Du J, Zhao H, Liu S, Xie H, Wang Y, Chen J (2017) Antibiotics in the coastal water of the South Yellow Sea in China: occurrence, distribution and ecological risks. Sci Total Environ 595:521–527

Ao X, Liu W (2017) Degradation of sulfamethoxazole by medium pressure UV and oxidants: peroxymonosulfate, persulfate, and hydrogen peroxide. Chem Eng J 313:629–637

Yang Y, Lu X, Jiang J et al (2017) Degradation of sulfamethoxazole by UV, UV/H2O2 and UV/persulfate (PDS): formation of oxidation products and effect of bicarbonate. Water Res 118:196–207

Zhu W, Sun F, Goei R, Zhou Y (2017) Facile fabrication of RGO-WO3 composites for effective visible light photocatalytic degradation of sulfamethoxazole. Appl Catal B-Environ 207:93–102

Ye P, Wu D, Wang M, Wei Y, Xu A, Li X (2018) Coating magnetic CuFe2O4 nanoparticles with OMS-2 for enhanced degradation of organic pollutants via peroxymonosulfate activation. Appl Surf Sci 428:131–139

Tan C, Dong Y, Fu D, Gao N, Ma J, Liu X (2018) Chloramphenicol removal by zero valent iron activated peroxymonosulfate system: Kinetics and mechanism of radical generation. Chem Eng J 334:1006–1015

Xing M, Xu W, Dong C, Bai Y, Zeng J, Zhou Y, Zhang J, Yin Y (2018) Metal sulfides as excellent Co-catalysts for H2O2 decomposition in advanced oxidation processes. Chem 4:1359–1372

Yao Y, Lu F, Zhu Y, Wei F, Liu X, Lian C, Wang S (2015) Magnetic core–shell CuFe2O4@C3N4 hybrids for visible light photocatalysis of Orange II. J Hazard Mater 297:224–233

Zhang C, Ou Y, Lei W-X, Wan L-S, Ji J, Xu Z-K (2016) CuSO4/H2O2-induced rapid deposition of polydopamine coatings with high uniformity and enhanced stability. Angew Chem 128:3106–3109

Naim S, Ghauch A (2016) Ranitidine abatement in chemically activated persulfate systems: Assessment of industrial iron waste for sustainable applications. Chem Eng J 288:276–288

Qi C, Liu X, Ma J, Lin C, Li X, Zhang H (2016) Activation of peroxymonosulfate by base: implications for the degradation of organic pollutants. Chemosphere 151:280–288

Tsitonaki A, Petri B, Crimi M, MosbÆK H, Siegrist RL, Bjerg PL (2010) In situ chemical oxidation of contaminated soil and groundwater using persulfate: a review. Crit Rev Env Sci Technol 40:55–91

Anipsitakis GP, Dionysiou DD (2004) Radical generation by the interaction of transition metals with common oxidants. Environ Sci Technol 38:3705–3712

Ball DL, Edwards JO (1956) The kinetics and mechanism of the decomposition of caro's acid I. J Am Chem Soc 78:1125–1129

Ji Y, Fan Y, Liu K, Kong D, Lu J (2015) Thermo activated persulfate oxidation of antibiotic sulfamethoxazole and structurally related compounds. Water Res 87:1–9

Matzek LW, Carter KE (2016) Activated persulfate for organic chemical degradation: a review. Chemosphere 151:178–188

Li X, Yu J, Li G et al (2018) TiO2 nanodots anchored on nitrogen-doped carbon nanotubes encapsulated cobalt nanoparticles as photocatalysts with photo-enhanced catalytic activity towards the pollutant removal. J Colloid Interface Sci 526:158–166

Lin K-YA, Lai H-K, Tong S (2018) One-step prepared cobalt-based nanosheet as an efficient heterogeneous catalyst for activating peroxymonosulfate to degrade caffeine in water. J Colloid Interface Sci 514:272–280

Zeng H, Zhang W, Deng L et al (2018) Degradation of dyes by peroxymonosulfate activated by ternary CoFeNi-layered double hydroxide: catalytic performance, mechanism and kinetic modeling. J Colloid Interface Sci 515:92–100

Chen F, Cao Y, Jia D (2013) A facile route for the synthesis of ZnS rods with excellent photocatalytic activity. Chem Eng J 234:223–231

De Luca A, Dantas RF, Esplugas S (2014) Assessment of iron chelates efficiency for photo-Fenton at neutral pH. Water Res 61:232–242

Rajabi HR, Khani O, Shamsipur M, Vatanpour V (2013) High-performance pure and Fe3+ ion doped ZnS quantum dots as green nanophotocatalysts for the removal of malachite green under UV-light irradiation. J Hazard Mater 250–251:370–378

Yang Q, Choi H, Chen Y, Dionysiou DD (2008) Heterogeneous activation of peroxymonosulfate by supported cobalt catalysts for the degradation of 2,4-dichlorophenol in water: The effect of support, cobalt precursor, and UV radiation. Appl Catal B-Environ 77:300–307

Hu Y, Chen K, Li Y-L et al (2019) Morphology-tunable WMoO nanowire catalysts for the extremely efficient elimination of tetracycline: kinetics, mechanisms and intermediates. Nanoscale 11:1047–1057

Anipsitakis GP, Dionysiou DD (2003) Degradation of organic contaminants in water with sulfate radicals generated by the conjunction of peroxymonosulfate with cobalt. Environ Sci Technol 37:4790–4797

Lu LT, Dung NT, Tung LD, Thanh CT, Quy OK, Chuc NV, Maenosono S, Thanh NTK (2015) Synthesis of magnetic cobalt ferrite nanoparticles with controlled morphology, monodispersity and composition: the influence of solvent, surfactant, reductant and synthetic conditions. Nanoscale 7:19596–19610

Shen J, Lu Y, Liu J-K, Yang X-H (2016) Design and preparation of easily recycled Ag2WO4@ZnO@Fe3O4 ternary nanocomposites and their highly efficient degradation of antibiotics. J Mater Sci 51:7793–7802. https://doi.org/10.1007/s10853-016-0063-9

Wu K, Qin Z, Zhang X, Guo R, Ren X, Pu X (2020) Z-scheme BiOCl/Bi–Bi2O3 heterojunction with oxygen vacancy for excellent degradation performance of antibiotics and dyes. J Mater Sci 55:4017–4029. https://doi.org/10.1007/s10853-019-04300-2

Duan X, Su C, Miao J, Zhong Y, Shao Z, Wang S, Sun H (2018) Insights into perovskite-catalyzed peroxymonosulfate activation: Maneuverable cobalt sites for promoted evolution of sulfate radicals. Appl Catal B-Environ 220:626–634

Yao Y, Cai Y, Wu G, Wei F, Li X, Chen H, Wang S (2015) Sulfate radicals induced from peroxymonosulfate by cobalt manganese oxides (CoxMn3−xO4) for Fenton-Like reaction in water. J Hazard Mater 296:128–137

Zhang T, Zhu H, Croué J-P (2013) Production of sulfate radical from peroxymonosulfate induced by a magnetically separable CuFe2O4 spinel in water: efficiency, stability, and mechanism. Environ Sci Technol 47:2784–2791

Sun B, Guan X, Fang J, Tratnyek PG (2015) Activation of manganese oxidants with bisulfite for enhanced oxidation of organic contaminants: the Involvement of Mn(III). Environ Sci Technol 49:12414–12421

Sundar M, Easwaramoorthy D, Kutti Rani S, Mohammed Bilal I (2008) Mn(II) catalysed decomposition of peroxomonosulphate—kinetic and mechanistic study. Catal Commun 9:2340–2344

Xu W-H, Wang L, Wang J, Sheng G-P, Liu J-H, Yu H-Q, Huang X-J (2013) Superparamagnetic mesoporous ferrite nanocrystal clusters for efficient removal of arsenite from water. CrystEngComm 15:7895–7903

Li Y, He J, Zhang K et al (2019) Super rapid removal of copper, cadmium and lead ions from water by NTA-silica gel. RSC Adv 9:397–407

Al-Anazi A, Abdelraheem WH, Han C et al (2018) Cobalt ferrite nanoparticles with controlled composition-peroxymonosulfate mediated degradation of 2-phenylbenzimidazole-5-sulfonic acid. Appl Catal B-Environ 221:266–279

Zhang S, Zhao X, Niu H, Shi Y, Cai Y, Jiang G (2009) Superparamagnetic Fe3O4 nanoparticles as catalysts for the catalytic oxidation of phenolic and aniline compounds. J Hazard Mater 167:560–566

Wang B, Sun J, Abbas M, Liu Y, Kong F, Xiao H, Chen J (2017) A Novel hydrothermal approach for the synthesis of flower-Like Fe2O3/Fe foam Nanocrystals and their superior performance in fisher-tropsch synthesis. Catal Lett 147:1153–1161

Zhu H, Yang D, Zhu L, Yang H, Jin D, Yao K (2007) A facile two-step hydrothermal route for the synthesis of γ-Fe2O3 nanocrystals and their magnetic properties. J Mater Sci 42:9205–9209. https://doi.org/10.1007/s10853-007-1887-0

Fu Y, Chen Q, He M, Wan Y, Sun X, Xia H, Wang X (2012) Copper ferrite-graphene hybrid: a multifunctional heteroarchitecture for photocatalysis and energy storage. Ind Eng Chem Res 51:11700–11709

Wang Z, Ma H, Zhang C, Feng J, Pu S, Ren Y, Wang Y (2018) Enhanced catalytic ozonation treatment of dibutyl phthalate enabled by porous magnetic Ag-doped ferrospinel MnFe2O4 materials: Performance and mechanism. Chem Eng J 354:42–52

Descostes M, Mercier F, Thromat N, Beaucaire C, Gautier-Soyer M (2000) Use of XPS in the determination of chemical environment and oxidation state of iron and sulfur samples: constitution of a data basis in binding energies for Fe and S reference compounds and applications to the evidence of surface species of an oxidized pyrite in a carbonate medium. Appl Surf Sci 165:288–302

Zhou Y, Xiao B, Liu S-Q et al (2016) Photo-Fenton degradation of ammonia via a manganese–iron double-active component catalyst of graphene–manganese ferrite under visible light. Chem Eng J 283:266–275

Wang G, Zhao D, Kou F, Ouyang Q, Chen J, Fang Z (2018) Removal of norfloxacin by surface Fenton system (MnFe2O4/H2O2): Kinetics, mechanism and degradation pathway. Chem Eng J 351:747–755

Tan C, Gao N, Fu D, Deng J, Deng L (2017) Efficient degradation of paracetamol with nanoscaled magnetic CoFe2O4 and MnFe2O4 as a heterogeneous catalyst of peroxymonosulfate. Sep Purif Technol 175:47–57

Su Y, Jiang H, Zhu Y, Yang X, Shen J, Zou W, Chen J, Li C (2014) Enriched graphitic N-doped carbon-supported Fe3O4 nanoparticles as efficient electrocatalysts for oxygen reduction reaction. J Mater Chem A 2:7281–7287

Guan Y-H, Ma J, Ren Y-M, Liu Y-L, Xiao J-Y, Lin L-q, Zhang C (2013) Efficient degradation of atrazine by magnetic porous copper ferrite catalyzed peroxymonosulfate oxidation via the formation of hydroxyl and sulfate radicals. Water Res 47:5431–5438

Li L, Abe Y, Kanagawa K, Usui N, Imai K, Mashino T, Mochizuki M, Miyata N (2004) Distinguishing the 5,5-dimethyl-1-pyrroline N-oxide (DMPO)-OH radical quenching effect from the hydroxyl radical scavenging effect in the ESR spin-trapping method. Anal Chim Acta 512:121–124

Zhou Y, Wang X, Zhu C, Dionysiou DD, Zhao G, Fang G, Zhou D (2018) New insight into the mechanism of peroxymonosulfate activation by sulfur-containing minerals: role of sulfur conversion in sulfate radical generation. Water Res 142:208–216

Moan J, Wold E (1979) Detection of singlet oxygen production by ESR. Nature 279:450–451

Nohara K, Hidaka H, Pelizzetti E, Serpone N (1996) Dependence on chemical structure of the production of NH4+and/or NO3−3ions during the photocatalyzed oxidation of nitrogen-containing substances at the titania/water interface. Catal Lett 36:115–118

Deng Y, Mao Y, Li B, Yang C, Zhang T (2016) Aerobic degradation of sulfadiazine by arthrobacter spp: kinetics, pathways, and genomic characterization. Environ Sci Technol 50:9566–9575

Liu Y, Fan Q, Wang J (2018) Zn-Fe-CNTs catalytic in situ generation of H2O2 for Fenton-like degradation of sulfamethoxazole. J Hazard Mater 342:166–176

Acknowledgements

This work was supported by the State Key Research Development Program of China (2019YFC0408500), the Natural Science Foundation of China (2196182 and 61873253), the Science and Technology Major Projects of Anhui Province (18030801104), and China Postdoctoral Science Foundation (2019M652227). A portion of this work was performed on the Steady High Magnetic Field Facilities, High Magnetic Field Laboratory, CAS.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, Y., He, J., Zhang, K. et al. Oxidative degradation of sulfamethoxazole antibiotic catalyzed by porous magnetic manganese ferrite nanoparticles: mechanism and by-products identification. J Mater Sci 55, 13767–13784 (2020). https://doi.org/10.1007/s10853-020-05000-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05000-y