Abstract

Cerium-based CeMO3 (M = Co, Ni, Cu) perovskites were efficiently synthesized by electrospinning process. The structures, morphologies, elemental compositions, and valence states of CeMO3 perovskites were manifested in detail using X-ray diffraction analysis, Raman spectroscopic analysis, UV–vis diffuse reflectance spectroscopy, scanning electron microscope, transmission electron microscope, energy-dispersive X-ray spectroscopy, and X-ray photoelectron spectroscopy, respectively. The tolerance factor (t) was accurately calculated to confirm the perovskite structure stability. The electrochemical properties of CeMO3 perovskites were investigated, and the specific capacitances of CeCoO3, CeNiO3, and CeCuO3 perovskites are 128, 189, and 117 F g−1 at the current density of 0.5 A g−1, respectively. This study could provide an efficient and potential applications of the cerium-based perovskites into the supercapacitor electrode materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the fast increase in population, the energy crisis and air pollution become more and more serious. Owing to this, it is extremely urgent to develop sustainable, inexpensive, and eco-friendly energy generation, storage, and delivery devices [1, 2]. Supercapacitor attracts worldwide attention due to its ultrahigh power density, fast charging and discharging rate, short charging time, and excellent cyclic stability [2,3,4]. In accordance with the charge storage mechanisms, supercapacitor can be divided into electrical double layer capacitor, which is depended on the accumulation of ions at the interface of electrode/electrolyte, and pseudocapacitor, which is counted on the Faradic redox reactions occurred between electrode and electrolyte [4]. Transition metal oxides are the most promising candidates for pseudocapacitors because of their favorable electrochemical behaviors, low cost, stable chemical and thermal properties, and abundance [4,5,6,7]. However, there is a critical issue that the low electrical conductivity confines the electrochemical performance of the transition metal oxides [4, 5]. Therefore, perovskite oxides, with typical ABO3 structure and versatility in chemical composition, have attracted increasing attentions for the application into supercapacitors due to their unique electronic, catalytic, and optical properties [1, 4, 8, 9]. LaMnO3 perovskites as high-performance supercapacitor electrodes were investigated by modulating Mn4+ ions and oxygen vacancies [10]. LaNiO3 perovskites with hollow spherical structure presented excellent electrochemical behaviors with brilliant specific capacitance and favorable cycling life [11]. Solvothermal synthesized porous LaCoO3 nanospheres exhibited a high specific capacitance and stable cyclic properties [12]. The electrochemical properties of LaMO3 perovskites were demonstrated that the specific capacitances of LaNiO3, LaFeO3, LaCrO3, and LaMnO3 were 106.58, 16.43, 24.4, and 56.78 F g−1, respectively [13]. As a common rare earth oxide, cerium oxide has the merits of natural abundance, high dielectric constant, high bandgap, low cost, as well as variable valence states between Ce3+ and Ce4+ [14,15,16]. Until now, the researches of cerium-based perovskites are few and most of those are focused on the catalytic behaviors rather than the electrochemical performances [17,18,19]. The catalytic property of CeCoO3 perovskite for carbon monoxide oxidation was investigated [17]. It was reported that CeNiO3 perovskite exhibited favorable photothermocatalytic performance for the degradation of gaseous styrene under visible sunlight because of the narrow bandgap and high visible light absorption [18]. The catalytic activities of CeCuOx for the oxidation reaction of organics, such as methanol, acetone, and toluene, were investigated [19]. However, the studies of cerium-based perovskites as supercapacitor electrodes are few. Therefore, in this study, the cerium-based CeMO3 (M = Co, Ni, Cu) perovskites were efficiently synthesized, and the structure, morphology, valence state, and electrochemical properties were investigated in detail. The tolerance factors were accurately calculated to predict the stability of CeMO3 perovskite structure. The electrochemical properties of CeMO3 perovskites were demonstrated. The specific capacitances of CeCoO3, CeNiO3, and CeCuO3 perovskites are calculated by the electrochemical measurements. This study could provide a competent and practical way to apply these cerium-based perovskites into the supercapacitor electrode materials.

Experimental

Analytical grade reagents, cerium nitrate hexahydrate (Ce(NO3)3·6H2O), cobalt acetate tetrahydrate (CoAc·4H2O), nickel nitrate hexahydrate (Ni(NO3)2·6H2O), cupper nitrate trihydrate (Cu(NO3)2·3H2O), N, N-dimethylformamide (DMF), polyvinylpyrrolidone (PVP, Mw ≈ 1300000), polytetrafluoroethylene (PTFE), and N-methyl-2-pyrrolidone (NMP), without further purification were directly employed in this study.

The CeMO3 (M = Co, Ni, Cu) perovskite nanomaterials were synthesized via electrospinning and calcination process. The homogeneous precursor solution was prepared by adding Ce(NO3)3·6H2O (1.25 mmol), transition metal salt (1.25 mmol), and PVP (1.125 g) into DMF (8.25 ml), and vigorously stirring for 14 h. Then, this uniform solution was poured into a 10 ml plastic syringe. In the electrospinning process, the flow rate was 0.8 ml h−1, the power source was 18 kV, and the working distance was 15 cm. The calcination process was performed at 500 °C for 2 h with a heating rate of 1 °C min−1 in a muffle furnace.

X-ray diffraction analysis (XRD, Bruker D8 Focus), Raman spectroscopic analysis (inVia, 633 nm excitation laser), and UV–vis diffuse reflectance spectroscopy (DRS, Agilent Cary 300) were carried out to investigate the crystalline structures, vibrational modes, and optical properties, respectively. Scanning electron microscope (SEM, Hitachi S-4800, 20 kV), transmission electron microscope (TEM, JEOL JEM 2100, 200 kV), and energy-dispersive X-ray spectroscopy (EDS) were implemented to observe the morphology, microstructure, and elemental composition of CeMO3 perovskites. Moreover, X-ray photoelectron spectroscopy (XPS, Al Kα) was performed to analyze the valence states of CeMO3 perovskite nanomaterials.

The CeMO3 perovskites act as active materials for the supercapacitor electrodes. The electrochemical properties were detected in a standard three electrode system in 6 M KOH solution. A homogeneous slurry with CeMO3 perovskites (80 wt%), acetylene black (10 wt%), and PTFE (10 wt%) was coated on pretreated nickel foams. A saturated calomel electrode (SCE) was used as reference electrode. Cyclic voltammetry (CV) and galvanostatic charge–discharge (GCD) tests were performed on an electrochemical workstation (Biologic VMP-3) at the scan rate changing from 1 to 100 mV s−1, and the current densities altering from 0.5 to 5 A g−1, respectively. In addition, electrochemical impedance spectroscopy (EIS) tests were measured with the frequency ranging from 0.01 to 105 Hz with an alternating current signal amplitude of 5 mV.

Results and discussion

The stability of the ABO3 perovskite structure is mainly related to the Goldschmidt tolerance factor (t) which is described as [20,21,22,23]

where RA, RB, and RO are the ionic radii of A-site cation, B-site cation, and oxygen ion, respectively. Stable perovskite structure can be obtained when the tolerance factor is in the range from 0.75 to 1.0. In CeMO3 perovskites, A-site cation is Ce, while B-site cation is the transition metal of Co, Ni, and Cu, respectively. The ionic radii of O, Ce, Co, Ni, and Cu are listed in Table 1. There are two valence states of Ce, namely Ce3+ and Ce4+. If A-site cation is Ce3+ and B-site cation is M3+, according to Table 1 [24, 25], the calculated tolerance factors of Ce3+M3+O3 are presented in Table 2. If A-site cation is Ce4+ and B-site cation is M2+, the calculated tolerance factors of Ce4+M2+O3 are presented in Table 2. Because of the t values lowered than 0.75, the perovskite of Ce4+Co2+O3 is not stable. The perovskite structure of CeMO3 was depicted as shown in Fig. 1.

The morphologies and microstructures of the precursors and calcinated perovskite nanomaterials are detected by SEM and displayed in Fig. 2. The Ce(NO3)3–CoAc/PVP precursor shows nanofiber-like structure with uniform diameter of 750 nm (Fig. 2a, b). The precursors of Ce(NO3)3–Ni(NO3)2/PVP and Ce(NO3)3–Cu(NO3)2/PVP exhibit beige and smooth nanobelt-like structures (Fig. 2e, f, i, j). The calcinated precursors were fractured into sections due to the combustion of PVP into gaseous molecules, the decomposition of metal salts, and the crystallization of CeMO3 [26, 27]. As shown in Fig. 2g, h, k, l, the CeNiO3 and CeCuO3 nanomaterials exhibited nanoplate-like structures, while the CeCoO3 shows nanofiber-like structure (Fig. 2c, d). The shrink and fracture of the three kinds of nanomaterials are derived from the burning of PVP and the decomposition of nitrates and acetate.

a and b SEM images of as-spun Ce(NO3)3–CoAc/PVP nanofibers; c and d SEM images of CeCoO3 nanofibers; e and f SEM images of as-spun Ce(NO3)3–Ni(NO3)2/PVP nanobelts; g and h SEM images of CeNiO3 nanoplates; i and j SEM images of as-spun Ce(NO3)3–Cu(NO3)2/PVP nanobelts; k and l SEM images of CeCuO3 nanoplates

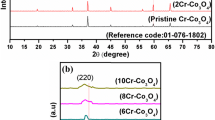

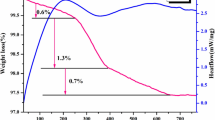

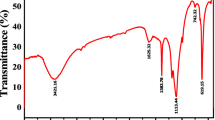

The crystal structures of CeMO3 nanomaterials were detected by XRD patterns, which are shown in Fig. 3a. All the peaks are intense in the scanning range (20°–80°), indicating high crystallization of prepared samples. The peaks at 28.55° originate from CeO2 [15]. The diffraction peaks of CeCoO3 and CeNiO3 are in good agreement with the previous references [18, 28]. The diffraction patterns of CeCuO3 at 33.1°, 47.5°, and 69.4° are indexed to (110), (200), and (220) planes, respectively [29]. According to Ref. [28, 30], the XRD pattern of CeCoO3 indicates the cubic structure with space group Pm3m and the lattice constants of a = 5.41 Å, b = 5.41 Å, and c = 5.41 Å. CeNiO3 has orthorhombic structure with space group Pnma and the lattice constants of a = 5.32 Å, b = 5.72 Å, and c = 7.67 Å [31, 32]. It is reported that CeCuO3 has a cubic structure with space group Pm3m and the lattice constants of a = 3.83 Å, b = 3.83 Å, and c = 3.83 Å [29]. The optical properties and the estimated band gap energies of the as-synthesized perovskite nanomaterials are illustrated by UV–vis DRS, and the results are shown in Fig. 3b. The DRS were conducted between 200 and 800 nm, including ultraviolet (200–420 nm), visible (420–700 nm), and partial near-infrared (700–800 nm) regions. The three perovskite samples exhibit high absorbance characteristics in UV region and low absorbance behaviors in visible region. In CeCoO3, CeNiO3, and CeCuO3 perovskites, a considerable increase in absorbance starts from 787, 600, and 751 nm, respectively. The band gap energies of CeCoO3, CeNiO3, and CeCuO3 perovskites were calculated to be 2.95, 2.70, and 2.57 eV, respectively, according to the extrapolated value, which is the straight line to the x-axis. Raman spectroscopy is an important method to analyze the chemical bonds and molecule symmetry. The vibrational modes of perovskite nanomaterials were illustrated by Raman spectra, as shown in Fig. 3c. It was reported that CeO2 has a main Raman band at 460 cm−1, which is ascribed to first-order F2g (vF2g, Fm3m group) symmetric stretching of oxygen atoms around cerium ions in CeO2 with fluorite structure [33, 34]. Three major Raman bands at 186, 474, and 656 cm−1 are observed in CeCoO3 [31]. Co3O4 shows the dominant peaks at 194, 481, and 686 cm−1 which probably arise from F2g, Eg, and A1g modes, respectively [35]. The A1g mode corresponds to the octahedral sites, while F2g and Eg modes associate with the combination of tetrahedral site and octahedral oxygen motion [36, 37]. The obvious downshifts from 686 to 656 cm−1, from 481 to 474 cm−1, and from 194 to 186 cm−1, respectively, might be resulted from the incorporation of Co species into ceria lattice [38]. In addition, the downshifts indicate the formation of oxygen vacancies [38]. Raman spectrum of CeNiO3 shows a strong peak at 458 cm−1 and a broad weak peak ranging from 497 to 718 cm−1. The former peak is assigned to first-order F2g symmetric stretching of oxygen atoms around cerium ions. The latter peak could be related to the combination of Ni–O modes of one phonon LO mode at 560 cm−1 and two phonon 2TO modes at 740 cm−1 [39]. One well-defined Raman band at 454 cm−1 is shown in CeCuO3 sample. In addition, three relatively weak bands occurring at 288, 347, and 590 cm−1 can be observed. It was reported that CuO has three main Raman bands at 290, 340, and 628 cm−1, which are assigned to Ag, Bg, and Bg modes, respectively [37, 40]. The Raman bands downshift from 628 to 590 cm−1 and from 460 to 454 cm−1, and upshift from 340 to 347 cm−1. The shifts imply the copper incorporation and possible formation of Ce3+ [19]. The Raman band shifts cannot be caused by the quantum confinement effects due to the considerable large size (> 500 nm) of CeCuO3 sample [41]. Therefore, the band shifts might be derived from the incorporation of transition metal species into ceria lattice.

The morphologies and elemental compositions of the synthesized CeCoO3, CeNiO3, and CeCuO3 perovskites were further investigated using TEM and EDS. Figure 4a shows the CeCoO3 nanofiber with several micrometers in length and with 240 nm in diameter. The nanofibers with porous surface are derived from the random decomposition of PVP during the calcination process. The porous structure facilitates the electrolyte ions dispersion into active material during the Faradic redox reaction. The elemental distributions of oxygen, cerium, and cobalt elements can be clearly observed in the same area, confirming the uniform growth of CeCoO3 nanofiber (Fig. 4b). The morphology of CeNiO3 is exhibited in Fig. 4c, showing nanoplate-like structure. The elemental mapping images, including oxygen, cerium, and nickel elements, are separately listed in Fig. 4d, manifesting the consistent distributions of all the elements and the uniform formation of CeNiO3. Figure 4e, f shows the morphology and elemental distributions of CeCuO3 nanoplate. The elemental mapping displays that oxygen, cerium, and cupper elements are homogeneously distributed across a single CeCuO3 nanoplate, indicating the uniform formation of CeCuO3.

The chemical bonding states of the elements in CeMO3 perovskites have been identified by XPS analyses as shown in Fig. 5. For the CeCoO3 nanofibers, in the survey spectrum, the peaks of O 1s, Co 2d, and Ce 3d can be obviously seen (Fig. 5a). The fitted O 1s peaks at 529.69 and 531.62 eV indicate the crystal lattice oxygen species and the oxygen vacancies of the oxygen deficient region in CeCoO3 nanofibers, respectively [42]. In the Co 2p spectrum (Fig. 5c), two discernible peaks at 780.41 and 795.55 eV correspond to Co 2p3/2 and Co 2p1/2, respectively, indicating the existence of Co2+ and Co3+ [43]. As shown in Fig. 5d, six major peaks located at 882.52, 888.65, 898.45, 900.95, 907.75, and 916.65 eV, respectively, assign to the components of Ce 3d5/2 and Ce 3d3/2 [44, 45]. Therefore, the synthesized CeCoO3 presents the mixed valences of Co2+/Co3+ and Ce3+/Ce4+, respectively. In the survey spectrum of CeNiO3 perovskite, the peaks of O 1s, Ni 2p, and Ce 3d are presented in Fig. 5e. The O 1s peaks in Fig. 5f manifest the existence of crystal lattice oxygen species and oxygen vacancies in CeNiO3 [42]. Two prominent peaks at 855.12 and 872.35 eV, and two satellite peaks at 861.21 and 882.75 eV are visualized in Ni 2p XPS spectrum (Fig. 5g), suggesting the energy levels of Ni 2p3/2 and Ni 2p1/2, thus the oxidation states of Ni2+ and Ni3+ [46, 47]. Six clear peaks are displayed in Ce 3d spectrum (Fig. 5h), signaling the presence of the oxidation states of Ce3+ and Ce4+ [44, 45]. Therefore, the synthesized CeNiO3 exhibits the mixed oxidation states of Ni2+/Ni3+ and Ce3+/Ce4+, respectively. In the survey spectrum of CeCuO3 in Fig. 5i, the observed peaks are assigned to O 1s, Cu 2p, and Ce 3d. Similar to CeCoO3 and CeNiO3, the O 1s peaks in Fig. 5j indicate the appearance of crystal lattice oxygen species and oxygen vacancies in CeCuO3 [42]. As shown in Fig. 5k, three main peaks at 933.83, 941.23, and 953.7 eV, with two satellites at 943.73 and 962.29 eV, correspond to Cu 2p3/2 and Cu 2p1/2 indicating the oxidation states of Cu2+ [42, 48, 49]. Six different peaks are exhibited in Ce 3d spectrum (Fig. 5l), demonstrating the energy levels of Ce 3d5/2 and Ce 3d3/2 and the oxidation states of Ce3+ and Ce4+ [44, 45]. Therefore, it is revealed that the synthesized CeCuO3 with the oxidation state of Cu2+ and the mixed oxidation states of Ce3+/Ce4+. The information of Ce 3d in each material is summarized in Table 3 [44, 45]. With the analyses of XPS, the tolerance factor of CeCoO3 should be located between 0.745 and 0.8479, and that of CeNiO3 should be ranged between 0.768 and 0.8522. In addition, with the appearance of Cu2+, the tolerance factor should be 0.754.

The electrochemical properties of CeCoO3, CeNiO3, and CeCuO3 perovskites were investigated in detail, respectively. Figure 6a shows the CV curves of CeCoO3 between − 0.1 and + 0.7 V in 6 M KOH solution at various scan rates ranging from 1 to 100 mV s−1 with obvious redox peaks indicating the pseudocapacitive behavior. The capacitance of CeCoO3 is ascribed to the redox reactions of Ce4+/Ce3+ and Co2+/Co3+. No obvious shape deformation of CV curves occurs as the scan rate increases, implying the good reversibility and stability of CeCoO3 perovskite [50]. The specific capacitances were calculated at the scan rate ranging from 1 to 100 mV s−1, respectively, as shown in Fig. 6b. The decrease in specific capacitance with the increase in scan rate is derived from the insufficient time for electrolyte ions diffusion into active material [51]. Low scan rate manifests that the electrolyte ions have sufficient time to diffuse into CeCoO3 surface and participate in the electrochemical reactions proceeded at the electrode surface, resulting in a high specific capacitance [45, 52]. Additionally, the anodic and cathodic peaks slightly shift to high and low potential directions, respectively, which could be attributed to the slow diffusion of OH− ions [53]. The relationship of anodic and cathodic peak currents on scan rate is depicted in Fig. 6c. The linear dependence indicates that the anodic and cathodic reactions are attributed to the diffusion controlled electron transfer [45]. GCD analyses are performed to investigate the charge storage behavior of CeCoO3 perovskite. During GCD measurements, the potential window was located between − 0.1 and + 0.6 V at various current densities from 0.5 to 5 A g−1 as shown in Fig. 6d. The specific capacitances are calculated to be 128, 112, 99, 86, 78, and 70 F g−1 at the current density of 0.5, 1, 2, 3, 4, and 5 A g−1, respectively (Fig. 6e). To clarify the electrical properties of the fabricated CeCoO3 electrode, the EIS analysis was carried out in the frequency range between 10 mHz to 100 kHz. An inclined line at the low frequency and no obvious semicircle at the high frequency are seen in Fig. 6f. The absence of a semicircle manifests the low charge transfer resistance at the interface of working electrode/electrolyte, which is originated from the ample and disperse mesopores [54, 55]. The equivalent series resistance evaluated from the intercept at x-axis is 0.39 Ω, demonstrating the fast charge diffusion between KOH and CeCoO3 [56].

a CV curves of CeCoO3 nanofibers electrode at different scan rates. b Specific capacitance of CeCoO3 nanofibers electrode at different scan rates. c Corresponding anodic and cathodic peak currents of CeCoO3 nanofibers versus square root of scan rate. d GCD curves of CeCoO3 nanofibers electrode at different current densities. e Specific capacitance of CeCoO3 nanofibers electrode at different current densities. f Electrochemical impedance spectra of CeCoO3 nanofibers

The electrochemical properties of CeNiO3 perovskite are displayed in Fig. 7a. The CV curves exhibit the typical pseudocapacitive behavior of CeNiO3. At the potential window from − 0.1 to + 0.7 V, the clear anodic and cathodic peaks are observed, implying the redox reactions of Ce3+/Ce4+ and Ni3+/Ni2+. The specific capacitances were estimated at the scan rate ranging from 1 to 100 mV s−1, respectively, as shown in Fig. 7b. As the scan rate increases, the anodic and cathodic peaks slightly move to high and low potential directions, respectively. According to the dependence of anodic and cathodic peak currents on scan rate (Fig. 7c), the anodic and cathodic reactions are ascribed to the diffusion controlled electron transfer. In order to investigate the charge storage behavior of CeNiO3 perovskite, GCD analyses were implemented at the potential ranging from − 0.1 to + 0.65 V at several current density as shown in Fig. 7d. In addition, the specific capacitances are 189, 181, 141, 123, 112, and 108 F g−1 at the current density ranging from 0.5 to 5 A g−1, respectively (Fig. 7e). As depicted in Fig. 7f, the EIS analysis was carried out in the frequency range between 10 mHz and 100 kHz to elucidate the electrical properties of the fabricated CeNiO3 electrode. Like CeCoO3, there is an inclined line at the low frequency and no obvious semicircle at the high frequency as shown in Fig. 7f. Therefore, the low charge transfer resistance occurs at the interface of working electrode/electrolyte.

a CV curves of CeNiO3 perovskite electrode at different scan rates. b Specific capacitance of CeNiO3 perovskite electrode at different scan rates. c Corresponding anodic and cathodic peak currents of CeNiO3 perovskite versus square root of scan rate. d GCD curves of CeNiO3 perovskite electrode at different current densities. e Specific capacitance of CeNiO3 perovskite electrode at different current densities. f Electrochemical impedance spectra of CeNiO3 perovskite

The electrochemical properties of CeCuO3 perovskite are exhibited in Fig. 8a. The CV curves of CeCuO3 perovskite present the common pseudocapacitive characteristics. At the potential window from − 0.1 to + 0.7 V, the clear appearances of anodic and cathodic peaks manifest the redox reactions of Ce3+/Ce4+. The specific capacitances were calculated at the scan rate ranging from 1 to 100 mV s−1, respectively, as shown in Fig. 8b. As the scan rate increases, the anodic and cathodic peaks slightly transfer to high and low potential directions, respectively. In accordance with the linear dependence of anodic and cathodic peak currents on scan rate, the anodic and cathodic reactions are assigned to the diffusion controlled electron transfer (Fig. 8c). To understand the charge storage behavior of CeCuO3 perovskite, GCD measurements were performed at the potential ranging from − 0.1 to + 0.7 V at different current densities as shown in Fig. 8d. The specific capacitances are 117, 89, 77, 59, 48, and 38 F g−1 at the current density of 0.5, 1, 2, 3, 4, and 5 A g−1, respectively, as shown in Fig. 8e. The EIS analysis was carried out in the frequency range between 10 mHz and 100 kHz to illustrate the electrical properties of the fabricated CeCuO3 electrode. Similar to CeCoO3 and CeNiO3, an inclined line at the low frequency and no obvious semicircle at the high frequency are observed in Fig. 8f. Therefore, the low charge transfer resistance occurs at the interface of working electrode/electrolyte.

a CV curves of CeCuO3 perovskite electrode at different scan rates. b Specific capacitance of CeCuO3 perovskite electrode at different scan rates. c Corresponding anodic and cathodic peak currents of CeCuO3 perovskite versus square root of scan rate. d GCD curves of CeCuO3 perovskite electrode at different current densities. e Specific capacitance of CeCuO3 perovskite electrode at different current densities. f Electrochemical impedance spectra of CeCuO3 perovskite

Cyclic stability is significant to illustrate the stability of the electrode material. Figure 9 exhibits the capacitance retentions of CeCoO3, CeNiO3, and CeCuO3 perovskites at a current density of 5 A g−1 for 1000 cycles. According to these, the capacitance retentions of 79%, 72%, and 81% are obtained, respectively, illustrating the favorable stability of CeCoO3, CeNiO3, and CeCuO3 perovskites as supercapacitor electrode materials. Therefore, it confirms an efficient and potential application of cerium-based perovskites into the supercapacitors.

Conclusions

Cerium-based CeMO3 (M = Co, Ni, Cu) perovskites were effectively synthesized. The tolerance factor confirms the structure stability of those perovskites. The diffraction peaks in XRD are in good agreement with the typical CeCoO3, CeNiO3, and CeCuO3 perovskite structures. The band gap energies of CeCoO3, CeNiO3, and CeCuO3 perovskites are estimated to be 2.95, 2.70, and 2.57 eV, respectively, by UV–vis DRS. The vibrational modes of perovskite nanomaterials were confirmed by Raman spectra. The synthesized CeCoO3, CeNiO3, and CeCuO3 perovskites exhibit the mixed oxidation states of Ce3+/Ce4+, and the mix oxidation states of Co2+/Co3+, Ni2+/Ni3+, and Cu2+, respectively. The specific capacitances of CeCoO3, CeNiO3, and CeCuO3 perovskites are calculated to be 128, 189, and 117 F g−1 at the current density of 0.5 A g−1, respectively. This study could provide an efficient and potential applications of the cerium-based perovskites into the supercapacitor electrode materials.

References

Liu Yu, Dinh JD, Tade MO, Shao Z (2016) Design of perovskite oxides as anion-intercalation type electrodes for supercapacitors: cation leaching effect. ACS Appl Mater Interfaces 836:23774–23783

Chodankar NR, Dubal DP, Kwon Y, Kim D-H (2017) Direct growth of FeCo2O4 nanowire arrays on flexible stainless steel mesh for high-performance asymmetric supercapacitor. NPG Asia Mater 9:e419

Ling T, Da P, Zheng X, Ge B, Zhenpeng H, Mengying W, Xi-Wen D, Wen-Bin H, Jaroniec M, Qiao S-Z (2018) Atomic-level structure engineering of metal oxides for high-rate oxygen intercalation pseudocapacitance. Sci Adv 4:eaau6261

Muhammed Shafi P, Joseph N, Thirumurugan A, Chandra Bose A (2018) Enhanced electrochemical performances of agglomeration-free LaMnO3 perovskite nanoparticles and achieving high energy and power densities with symmetric supercapacitor design. Chem Eng J 338:147–156

Abouali S, Garakani MA, Zhang B, Zheng-Long X, Heidari EK, Huang J-Q, Huang J, Kim J-K (2015) Electrospun carbon nanofibers with in situ encapsulated Co3O4 nanoparticles as electrodes for high performance supercapacitors. ACS Appl Mater Interfaces 7(24):13503–13511

Vidhyadharan B, Zain NKM, Misnon II, Aziz RA, Ismail J, Yusoff MM, Jose R (2014) High performance supercapacitor electrodes from electrospun nickel oxide nanowires. J Alloys Compd 610:143–150

Moosavifard SE, El-Kady MF, Rahmanifar MS, Kaner RB, Mousavi MF (2015) Designing 3D highly ordered nanoporous CuO electrodes for high performance asymmetric supercapacitors. ACS Appl Mater Interfaces 7(8):4851–4860

Tyler Mefford J, Hardin WG, Dai S, Johnston KP, Stevenson KJ (2014) Anion charge storage through oxygen intercalation in LaMnO3 perovskite pseudocapacitor electrodes. Nat Mater 13:726–732

Galal A, Hassan HK, Jacob T, Atta NF (2018) Enhancing the specific capacitance of SrRuO3 and reduced graphene oxide in NaNO3, H3PO4 and KOH electrolytes. Electrochim Acta 260:738–747

Elsiddig ZA, Hui X, Wang D, Zhang W, Guo X, Zhang Y, Sun Z, Chen J (2017) Modulating Mn4+ ions and oxygen vacancies in nonstoichiometric LaMnO3 perovskite by a facile sol-gel method as high-performance supercapacitor electrodes. Electrochimica Acta 253:422–429

Shao T, You H, Zhai Z, Liu T, Li M, Zhang L (2017) Hollow spherical LaNiO3 supercapacitor electrode synthesized by a facile template-free method. Mater Lett 201:122–124

Guo Y, Shao T, You H, Li S, Li C, Zhang L (2017) Polyvinylpyrrolidone-assisted solvothermal synthesis of porous LaCoO3 nanospheres as supercapacitor electrode. Int J Electrochem Sci 12:7121–7127

Arjun N, Pan GT, Yang TCK (2017) The exploration of Lanthanum based perovskites and their complementary electrolytes for the supercapacitor applications. Results Phys 7:920–926

Dou C, Kakushima K, Ahmet P, Tsutsui K, Nishiyama A, Sugii N, Natori K, Hattori T, Iwai H (2012) Resistive switching behavior of a CeO2 based ReRAM cell incorporated with Si buffer layer. Microelectron Reliab 52:688–691

Wang Y, Guo CX, Liu J, Chen T, Yang H, Li CM (2011) CeO2 nanoparticles/graphene nanocomposite-based high performance supercapacitor. Dalton Trans 40:6388–9391

Maheswari N, Muralidharan G (2015) Supercapacitor behavior of cerium oxide nanoparticles in neutral aqueous electrolytes. Energy Fuels 29:8246–8253

Ghiasi M, Malekzadeh A (2014) Structural features of (Ce, La or Sr) (Mn or Co)O3 nano-perovskites as a catalyst for carbon monoxide oxidation. Acta Metallurgica Sinica (English Lett) 27(4):635–641

Chen J, He Z, Li G, An T, Shi H, Li Y (2017) Visible-light-enhanced photothermocatalytic activity of ABO3-type perovskites for the decontamination of gaseous styrene. Appl Catal B 209:146–154

Wang Q, Li Z, Bañares MA, Weng L-T, Qinfen G, Price J, Han W, Yeung KL (2019) A novel approach to high-performance aliovalent-substituted catalysts—2D bimetallic MOF-derived CeCuOx microsheets. Small 15:1903525

Fabbri E, Pergolesi D, Traversa E (2010) Materials challenges toward proton-conducting oxide fuel cells: a critical review. Chem Soc Rev 39:4355–4369

Kieslich G, Sun S, Cheetham AK (2015) An extended Tolerance Factor approach for organic–inorganic perovskites. Chem Sci 6:3430–3433

Qiao HW, Yang S, Wang Y, Chen X, Wen Tian Yu, Tang LJ, Qilin Cheng Yu, Hou HZ, Yang HG (2018) A gradient heterostructure based on tolerance factor in high-performance perovskite solar cells with 0.84 fill factor. Adv Mater 31(5):1804217

Li Z, Yang M, Park J-S, Wei S-H, Berry JJ, Zhu K (2016) Stabilizing perovskite structures by tuning tolerance factor: formation of formamidinium and cesium lead iodide solid-state alloys. Chem Mater 28:284–292

Shannon RD (1976) Revised effective ionic radii and systematic study of inter atomic distances in halides and chalcogenides. Acta Crystallogr A A32:751–767

Van Horn JD (2001) Electronic table of Shannon ionic Radii, 2001, downloaded from http://v.web.umkc.edu/vanhornj/shannonradii.htm. Accessed 13 Aug 2010

Yuan C, Wang H-G, Liu J, Wu Q, Duan Q, Li Y (2017) Facile synthesis of Co3O4–CeO2 composite oxide nanotubes and their multifunctional applications for lithium ion batteries and CO oxidation. J Colloid Interface Sci 494:274–281

Cui Q, Dong X, Wang J, Li M (2008) Direct fabrication of cerium oxide hollow nanofibers by electrospinning. J Rare Earths 26(5):664–669

Hammouda SB, Zhao F, Safaei Z, Srivastava V, LakshmiRamasamy D, Iftekhar S, Kalliola S, Sillanpää M (2017) Degradation and mineralization of phenol in aqueous medium by heterogeneous monopersulfate activation on nanostructured cobalt based-perovskite catalysts ACoO3 (A = La, Ba, Sr and Ce): characterization, kinetics and mechanism study. Appl Catalysis B: Environ 215:60–73

Persson K (2016) Materials data on CeCuO3 (SG:221) by Materials Project, 2016. https://doi.org/10.17188/1315648

Wang W-R, Da-Peng X, Wen-Hui S, Ding Z-H, Xue Y-F, Song G-X (2005) Raman active phonons in RCoO3 (R = La, Ce, Pr, Nd, Sm, Eu, Gd, and Dy) perovskites. Chin Phys Lett 22(9):2400–2402

Barad H-N, Keller DA, Rietwyk KJ, Ginsburg A, Tirosh S, Meir S, Anderson AY, Zaban A (2018) How transparent oxides gain some color: discovery of a CeNiO3 reduced bandgap phase as an absorber for photovoltaics. ACS Comb Sci 20:366–376

Persson K (2014) Materials data on CeNiO3 (SG:62) by Materials Project, 2014. https://doi.org/10.17188/1304611

Schilling C, Hofmann A, Hess C, Ganduglia-Pirovano MV (2017) Raman spectra of polycrystalline CeO2: a density functional theory study. J Phys Chem C 121:20834–20849

Liu G, Yue R, Jia Y, Nia Y, Yang J, Liu H, Wang Z, Xiaofeng W, Chen Y (2013) Catalytic oxidation of benzene over Ce–Mn oxides synthesized by flame spraypyrolysis. Particuology 11(4):454–459

Yang J, Liu H, Martens WN, Frost RL (2010) Synthesis and characterization of cobalt hydroxide, cobalt oxyhydroxide, and cobalt Oxide nanodiscs. J Phys Chem C 114:111–119

Na CW, Woo H-S, Kim H-J, Jeong U, Chung J-H, Lee J-H (2012) Controlled transformation of ZnO nanobelts into CoO/Co3O4 nanowires. CrystEngComm 14:3737–3741

Rashad M, Rüsing M, Berth G, Lischka K, Pawlis A (2013) CuO and Co3O4 nanoparticles: synthesis, characterizations, and Raman spectroscopy. J Nanomater 2013:1–6

Parwaiz S, Bhunia K, Das AK, Khan MM, Pradhan D (2017) Cobalt-doped ceria/reduced graphene oxide nanocomposite as an efficient oxygen reduction reaction catalyst and supercapacitor material. J Phys Chem C 121:20165–20176

Mironova-Ulmane N, Kuzmin A, Sildos I, Pärs M (2011) Polarisation dependent Raman study of single-crystal nickel oxide. Cent Eur J Phys 9:1096–1099

Luo M-F, Fang P, He M, Xie Y-L (2005) In situ XRD, Raman, and TPR studies of CuO/Al2O3 catalysts for CO oxidation. J Mol Catal A: Chem 239:243–248

Wang W, Liu Z, Liu Y, Xu C, Zheng C, Wang G (2003) A simple wet-chemical synthesis and characterization of CuO nanorods. Appl Phys A 76:417–420

Li H, Chen Y, Ma Q, Wang J, Che Q, Wang G, Tan Y, Yang P (2018) The effect of ZIF-8 on the phase structure and morphology of bead-like CuMn2O4/ZnO photocatalystic electrospun nanofibers. Mater Lett 216:199–202

Pettong T, Iamprasertkun P, Krittayavathananon A, Suktha P, Sirisinudomkit P, Seubsai A, Chareonpanich M, Kongkachuichay P, Limtrakul J, Sawangphruk M (2016) High-performance asymmetric supercapacitors of MnCo2O4 nanofibers and N-doped reduced graphene oxide aerogel. ACS Appl Mater Interfaces 8(49):34045–34053

Shah LR, Ali B, Zhu H, Wang WG, Song YQ, Zhang HW, Shah SI, Xiao JQ (2009) Detailed study on the role of oxygen vacancies in structural, magnetic and transport behavior of magnetic insulator: Co–CeO2. J Phys: Condens Matter 21:486004

Kumar M, Yun J-H, Bhatt V, Singh B, Kim J, Kim J-S, Kim BS, Lee CY (2018) Role of Ce3+ valence state and surface oxygen vacancies on enhanced electrochemical performance of single step solvothermally synthesized CeO2 nanoparticles. Electrochimica Acta 284:709–720

Peck MA, Langell MA (2012) Comparison of nanoscaled and bulk NiO structural and environmental characteristics by XRD, XAFS, and XPS. Chem Mater 24:4483–4490

Gawali SR, Dubal DP, Deonikar VG, Patil SS, Patil SD, Gomez-Romero P, Patil DR, Pant J (2016) Asymmetric supercapacitor based on nanostructured Ce-doped NiO (Ce:NiO) as positive and reduced graphene oxide (rGO) as negative electrode. ChemistrySelect 1:3471–3478

Xia H, Li J, Ma L, Liu Q, Wang J (2018) Electrospun porous CuFe2O4 nanotubes on nickel foam for nonenzymatic voltammetric determination of glucose and hydrogen peroxide. J Alloy Compd 739:764–770

Jang J, Chung S, Kang H, Subramanian V (2016) p-type CuO and Cu2O transistors derived from a sol-gel copper (II) acetate monohydrate precursor. Thin Solid Films 600:157–161

Zhu Y, Murali S, Stoller MD, Ganesh KJ, Cai W, Ferreira PJ, Pirkle A, Wallace RM, Cychosz KA, Thommes M, Su D, Stach EA, Ruoff RS (2011) Carbon-based supercapacitors produced by activation of graphene. Science 332:1537–1541

Li J, Le D-B, Ferguson PP, Dahn JR (2010) Lithium polyacrylate as a binder for tin-cobalt-carbon negative electrodes in lithium-ion batteries. Electrochimica Acta 55:2991–2995

Dezfuli AS, Ganjali MR, Naderi HR, Norouzi P (2015) A high performance supercapacitor based on a ceria/graphene nanocomposite synthesized by a facile sonochemical method. RSC Adv 5:46050–46058

Zhang K, Mao L, Zhang LL, Chan HSO, Zhao XS, Wu JS (2011) Surfactant-intercalated, chemically reduced graphene oxide for high performance supercapacitor electrodes. J Mater Chem 21:7302–7307

Saravanan T, Shanmugam M, Anandan P, Azhagurajan M, Pazhanivel K, Arivanandhan M, Hayakawad Y, Jayavel R (2015) Facile synthesis of graphene-CeO2 nanocomposites with enhanced electrochemical properties for Supercapacitors. Dalton Trans 44:9901–9908

Zhang H, Jiangna G, Tong J, Yongfeng H, Guan B, Bin H, Zhao J, Wang C (2016) Hierarchical porous MnO2/CeO2 with high performance for supercapacitor electrodes. Chem Eng J 286:139–149

Maiti S, Pramanik A, Mahanty S (2014) Extraordinarily high pseudocapacitance of metal organic framework derived nanostructured cerium oxide. Chem Commun 50:11717–11720

Acknowledgments

This work was financially supported by the Doctoral Scientific Research Foundation of Inner Mongolia University for Nationalities (Project No: BS456), and the Scientific Research Program of Inner Mongolia University for Nationalities (Project No: NMDYB19040, NMDYB19044, NMDYB19045). This work was financially supported by the National Natural Science Foundation of China (21961024, 21961025), Inner Mongolia Natural Science Foundation (2018JQ05). This work was financially supported by Incentive Funding from Nano Innovation Institute (NII) of Inner Mongolia University for Nationalities (IMUN), Inner Mongolia Autonomous Region Funding Project for Science & Technology Achievement Transformation (CGZH2018156), Inner Mongolia Autonomous Region Incentive Funding Guided Project for Science & Technology Innovation (2016), and Tongliao Funding Project for Application Technology Research & Development (2017).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, Q., Yue, B., Shao, H. et al. Facile syntheses of cerium-based CeMO3 (M = Co, Ni, Cu) perovskite nanomaterials for high-performance supercapacitor electrodes. J Mater Sci 55, 8421–8434 (2020). https://doi.org/10.1007/s10853-020-04362-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04362-7