Abstract

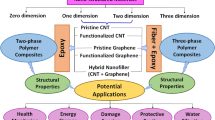

Graphene and its derivatives (G) are promising nanofillers with the ability to boost versatile properties of composites despite the low addition due to their combined excellent performances. Moreover, aligning G into various matrices can achieve stronger improvement in properties compared to composites with randomly distributed G. Aligning G is an effective strategy to take full advantage of its properties. In the present work, the state-of-the-art progress in preparations and resulted properties of aligned-graphene (and aligned-graphene derivatives) composites (AGCs) is comprehensively reviewed. The mechanisms of various preparation methods are presented, such as liquid crystal method, vacuum filtration method, and combinations of vacuum filtration and spark plasma sintering method, for both polymer-based and metal-based AGCs. Furthermore, the relevant influencing factors in procedures are analyzed. In addition, influences of aligned-graphene (and aligned-graphene derivatives) on the resulting electric, thermal, and mechanical properties have been discussed and the reasons why AGCs possessed better properties have been summarized. Current challenges associated with AGCs and the pathways toward future progress in AGCs are discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

G) are allotropes of carbon materials with a 2D structure, which have a unique combination of properties such as excellent tribological property, large α (2600 m2/g), high electronic conductive property, extraordinary thermal conductivity, and superior mechanical property [1,2,3,4,5]. These properties suggest the outstanding versatility of G in fillers such as GO, rGO, and FLG for various applications of composites ranging from TIM, structure materials, anti-wear materials, electric conductive materials, and anti-corrosion materials [6,7,8,9,10]. The integration of G is an effective way to boost the performance of composites; however, in many cases, the actual performances of the resulting composites are noticeably lower than the theoretical predictions [11, 12].

The properties intensely respond to the architectures of composites. Therefore, the structural design of composites is a key factor for the improvement of various properties. Research on aligning anisotropic nanofillers (such as the arrangement of nanoscale zinc oxide [11], CNTs [12] and nanofibers [13]) in diverse matrices, thus enabling approximation of the properties of the composites toward the theoretical value, has drawn significant attention and has achieved notable progress in recent years. For example, G is used as an anisotropic 2D material whose properties at IPD are predominantly higher than those of TTD, and it has recently been verified that the orientation control of the distribution of G in matrices can facilitate the resultant properties, thus closing the gap to the theoretical value [14].

In this review, efforts have been devoted to summarizing the fabrications and properties as well as the applications of AGCs. A number of synthetic methods for AGCs have been reviewed, such as the liquid crystal method, the exerting electronic field method, and the exerting magnetic field method. The electrical, thermal, mechanical, anti-corrosion, tribological, and EMI shielding properties of AGCs are mainly discussed, and the reasons for the better performances of AGCs compared to RGCs are analyzed. This review provides guidance and stimulates the development for high-performance AGCs.

Preparations of AGCs

In recent years, a number of methods have been developed for the preparations of various matrices AGCs. The methods reported herein for the preparations of polymer-based AGCs can be divided into six categories: (1) LC, (2) exerting eternal field method (both magnetic field and electronic field), (3) VF, (4) LBL, (5) SEI, and (6) UFC. For metal-based AGCs, there are mainly two ways: (1) RPS and (2) VFSPS. The following provides a detailed discussion of those methods and their influencing factors.

Preparations of polymer-based AGCs

LC

Several of the materials after melting or dissolving, despite the loss of rigidity of solid materials, have obtained liquid flowability, retained the anisotropic orderly crystalline material, and formed an intermediate state with both crystal and liquid properties. The ordered fluid in the process of solid–liquid transformation is called liquid crystal. LC is widely applied to prepare AGCs due to its simplicity. In theory, the G crystalline liquid mainly originates from the ultra-high α and moderate viscosity of the mixtures [15]. Specifically, steric hindrance forms in LMPG and GAD with low viscosity when the flaky G overlaps, and the effect induces a transition from isotropy to a long-range-order liquid crystal structure. In general, researchers use the concentration of G to control the viscosity of mixtures due to the linear relationship between viscosity and concentration. The G critical concentration, which is the lowest concentration for the formation of a liquid crystal, is a central parameter to control the formation of liquid crystal [16]. Aboutalebi et al. quantitatively calculated the G critical concentration by assuming circular G sheets [17]. The G critical concentration can be calculated by Eq. (1):

where D, ρ, C, d, and t represent G diameter, quantity of G of per unit area, concentration of G (in g/m3), mass density of G (in g/cm), and thickness of G, respectively. Theoretical analysis shows that the liquid crystal phenomenon emerges when the ρD3 exceeds the critical value of 4.12. As we can see from Eq. (1), the higher α, the easier the liquid crystal can be formed. Figure 1 shows the optical images of the crystal liquid phase with different GO concentrations in water. With increasing GO concentrations, the GO liquid crystal increases. However, exorbitant concentration is not encouraged because high viscosity hampers G spontaneous stacking. Furthermore, the shape of G, the presence of functional groups attached on G, and the viscosity of solvents also influence the formation of the liquid crystal, because these factors can affect the steric hindrance behavior.

(see Ref. [17])

Optical images of liquid crystals with a 0.15 wt%, b 0.2 wt%, c 0.5 wt%, and d 1.0 wt% GO in water.

Following the liquid crystal formation in diverse systems, LMPG curing is conducted by adding curing agents [18], casting [19], and other methods. For instance, a GO liquid crystal formed in chitosan solution at an incorporation of GO above 0.25 wt%; then, the mixtures were casted in molds to obtain AG/chitosan composites [19]. In general, despite the simple procedures of LC, several limitations still exist. (1) Although the macroscopic arrangement of G is perfect (Fig. 2b), the microcosmic distribution of G in matrices is inhomogeneous (Fig. 2d); (2) several parameters, especially the G concentration, are limited at a related narrow range, due to the requirements of critical concentration and viscosity of LMPG.

We summarize the critical concentrations of multifold G forming liquid crystal in diverse systems (in Table 1). In the available reports, the lowest critical concentration (0.1 wt%) of GO was obtained in water [17], due to the small viscosity of the water medium and the large size of GO.

EMF and EEF

G is featured as having diamagnetism, a ubiquitous property of materials due to the magnetic response of orbital electrons [27]. This property enables researchers to align G via the theory of Landau diamagnetism [28]; however, relevant studies are still rare because of the requirement of exerting an enormous magnetic field to rotate G. It is an imperfect technique that cannot be applied and engineered at a large scale. To date, anchoring paramagnetic nanoparticles, especially Fe3O4, onto the surface of G is a prevalent practical way to align G under a relatively small external magnetic field.

The EMF (here, the magnetic field is defined as static magnetic field) normally consists of two steps for the preparation of AGCs. The first procedure mainly anchors paramagnetic nanoparticles onto G, then dispersing the magnetic G in liquid polymer solutions to obtain LMPG. Next, the LMPG undergoes curing under the external magnetic field. A schematic of EMF is shown in Fig. 3. The initial G-Fe3O4 would rotate parallel to the orientation of the magnetic induction line. One advantage of the strategy is that is imposes few limitations of G concentration and LMPG viscosity, for which it can be potentially applied for preparations of AGCs with ultra-low and ultra-high G contents. A further method allows very convenient control of the alignment direction of G by regulating the orientation of the magnetic induction line. Moreover, it is preferable for G to load nanoparticles than other anisotropic materials, such as CNTs [30] and Al2O3 [31], due to their ultrahigh α. EMF can not only be used for the preparation of 2D film materials but is also suitable for the synthesis of 3D bulk materials. Typically, G-Fe3O4 hybrid nanoparticles were in situ grown onto G by a coprecipitation method, and the AG/bismaleimides composite was prepared by casting under a 2.0 T external magnetic field [32]. The resultant composites showed excellent tribological properties (friction coefficient as low as 0.07 when the addition of G-Fe3O4 content was 0.6 wt%). In another case, Yan et al. deposited Fe3O4 (about 8 nm) onto G by a modified coprecipitation method, and the liquid mixture of G-Fe3O4 and EP monomer was placed to a 300 mT magnetic field [33]. Finally, AG/EP was obtained by adding a curing agent. The AG/EP composites exhibited obvious anisotropy in thermal conductivity. The increase in thermal conductivity along with IPD was far higher than that in vertical direction. Renteria et al. applied EMF to prepare AG/EP TIM, which led to a decreasing temperature rise by as much as 10 °C in response to the addition of 1 wt% AG in AG direction [34]. In addition to the mentioned applications, the AGCs prepared by EMF were applied in magnetic-controlled switches [35], transparent and flexible electrodes [36], and thermal conductive materials [37].

(see Ref. [29])

Mechanism of aligning G-Fe3O4 by the statics magnetic field.

In recent years, nonlinear alignment dynamics have been demonstrated as a strategy for arraying magnetic nanosheets in suspensions at a biaxial orientation under a rotating magnetic field (Fig. 4b) [38, 39]. The composites possess higher anisotropic properties than those prepared by EMF. The rigorous demands for the strategy shown in Fig. 4a, such as the frequency of the magnetic field and the rheological properties of the LMPG, require research into the alignment of G by rotating magnetic field; however, no such studies have been published to date.

(in Ref. [38])

a Universal curve shows the dependence of the critical frequency on magnetic field strength, magnetic susceptibility, and fluid viscosity. b The cross-section morphology of biaxial alumina platelet composites.

Nanoparticles with high electron mobility are easily polarized and generate orientation torsion under the induction of an electric field, followed by alignment along the direction of parallel to electric field [40]. The essential metrics of G and rGO, high electron mobility, and large α, are available for preparing AGCs by EEF. Both DC or AC can achieve the alignment of G in liquid; however, G is inclined to electrophoretic alignment in DC electric field resulting in their aggregation near electrodes [41]. Therefore, AC is often used to induce G orientation. Wang presented an analytical model to predict the electric field-induced alignment of cantilevered G nanoribbons and showed that G can be easily arrayed than CNTs under electric fields [42]. Experimentally, AG/EP composites were prepared by exerting an AC electric field (25 V/mm, 10 kHz), and the as-prepared composites exhibited 7–8 orders of magnitude improvement in the electrical conductivity and achieve an increase in the mode I fracture toughness of nearly 900% [41]. Pang et al. prepared AG/polystyrene composites by EEF in the process of annealing and verified that G formed the conductive network easier than CNTs [43]. Compared to EMF, EEF is a relatively rare technique for preparing AGCs, because the high experimental equipment and energy consumption requirements restrict its large-scale development and application.

VF

G and CNTs inherit the major feature of 2D and 1D structures, respectively, which equip them with facile fabrication of anisotropic stacked structure by the flowing of solvents [44, 45]. For G, the VF is not only suitable for the preparation of 2D AG membrane composites, but is also available for preparing 3D bulk AGCs. VF consists of two approaches shown in Fig. 5. Approach (i) obtains G paper by filtrating GAD and then penetrating aimed polymers monomers into G layers of G paper by soaking the G paper in the polymer monomer liquid. Finally, ACGs are obtained by polymer monomer polymerization. Typically, G was dispersed in a mixture of water and ethanol (at a volume ratio of 1:4), and then, the mixture was vacuum-filtrated with a PTFE membrane to obtain the G paper. Next, the G paper was immersed in a mixture of EP monomer and curing agent to obtain AG/EP composites [44]. With the same procedures, Xia et al. prepared aligned G-diamine composites with excellent performance for the removal of natural organic matter [47]. For the steps of approach (ii), the LMPG is prepared, and following the mixture is filtrated through a porous filter membrane to obtain AGCs. In comparison with approach (i), approach (ii) is widely applied due to its simple preparation steps. For example, Liu et al. prepared AG/PVA by filtrating the mixture of G dispersion and PVA solution [48]. Song et al. applied approach (ii) to obtain flexible film of AG/cellulose composite with excellent anisotropic thermal conductivity [49]. A notable difference between approaches (i) and (ii) is that AGCs with wider content range of G prepared by approach (i), while approach (ii) only can prepare AGCs with ultra-high G content.

Theoretical studies revealed the influencing factors of aligning G by VF. The higher α, the better the alignment through the “excluded volume” interaction will be. In other words, a high α value is a main factor for the alignment of G [49]. Moreover, the π–π stacking and the van der Waals forces between adjacent G lead to their stacking [50]. The functional degree of G also affects the preparation of AGCs by filtration due to the interaction between adjacent amphiphilic groups on the basal plane [18]. Table 2 lists the recent studies on AGCs prepared by VF. It is worth noting that AGCs with high G contents can be prepared by VF, which is a complementary method of LC.

LBL

LBL is a simple and environment-friendly preparation technique and has been widely applied for the preparation of 1D, 2D, and 3D nanomaterials [53,54,55]. It offers a powerful tool for the preparation of tailored nanostructures with controlled thickness and functionality. Due to the inherent advantages of LBL, the as-obtained AGCs by LBL have been used for sensors, heterojunction, inkjet printing, hybrid lubricating films, and as anode material for lithium ion batteries [53, 55,56,57,58].

There are mainly two mechanisms for conducting LBL: non-covalent interactions and covalent interactions. Figure 6 shows both mechanisms. (1) A non-covalent interaction forms via intermolecular force between adsorbate and adsorbents, such as π–π stacking and formation of hydrogen bonding. Interestingly, π–π interaction between π-conjugated organic materials and the 2D sp2 carbon network G is a non-modified method in theory, while the poor dispersity and inevitable gathering of unmodified G in solvents would impel G to modify. (2) Covalent interaction is the transfer, exchange, or coexistence of electrons. In contrast to approach (i), a covalent bond is formed between atoms by sharing electron pairs. Due to the good dispersity of graphene derivative in various solvents, LBL, GO, rGO, and FLG are widely applied in LBL to fabricate AGCs. However, depending on the applications of the AGCs, diverse types of G are chosen for LBL. Given the moderate combined electrics of thermotics and mechanic properties, rGO is preferably used in preparation of AGCs for high electric, thermal conductive, and mechanical applications, such as anode materials for lithium ion batteries, sensors, and TIM [55, 58]. For the improvement in mechanical properties of matrices alone, GO, which possesses similar mechanics to rGO and inexpensive cost, is in the leading material in use. The procedures of approach (i) and (2) are identical. Substrate is circularly dipped into GAD and matrix solvents and the cycle times correspond to the assembled layers of G. Therefore, the thickness and performances of the AGCs are controllable by adjusting the assembled times. For instance, the AG/PVA membranes were fabricated by circularly dipping hydroxyl group modified quartz substrates into PVA solution and GO solution [59]. The resulting 300-bilayer AGCs achieved improvements of 98.7% and 240.4% in elastic modulus and hardness, respectively.

Approaches (i) and (ii) can be used simultaneously in many cases. PDDA and PSS, two types of polyelectrolytes, are prevalently used in terms of LBL [60]. In light of the charge distribution (positive or negative) of the G surface, PDDA (PSS) was selected to adsorb on the surface via electrostatic interaction. In the meantime, the functional groups on G would interact with the macromolecule long chain via non-covalent interactions (dispersion force, induction force, hydrogen bond, and π–π bond). Kirschner et al. demonstrated that the strongest driving forces in LBL are covalent interactions [61].

Table 3 summarizes the various ACGs prepared by LBL in recent years. It shows that preparing 2D films by covalent interactions is the mainstream technique due to the facile control of the thickness by times of replication. The complex 1D and 3D structures of AGCs limit the development of preparing AGCs by LBL. LBL mainly offers a facile way to prepare controllable properties of AG film composites that can be applied in diverse fields.

SEI

Inspired by the preparation of G paper with layer-by-layer stacked structure [72,73,74], SEI, a method of aligning G by induction of solvents evaporation, has been developed for the synthesis of AGCs. From this point, under the effect of solvent evaporation, G would be subjected to a uniform upward orientation force, which leads to stacks at a near horizontal or vertical manner in the air–liquid interface. The most remarkable advantage of SEI is that the properties, such as thermal conductivity and electric conductivity, can be regulated by precisely controlling the AGCs thickness. Furthermore, the thickness of AGCs can be regulated via the added quantity of G. The facile maneuverability is a further merit of SEI. Based on both advantages, these types of AGCs were widely applied in electrode [75], sensors [76], and FETs [77]. The AGCs prepared by SEI consists of two categories: (1) AGLCs and (2) MGACs.

For the preparation of AGLCs, the procedures start with uniformly coating the substrates with DAG. Then, an AG film forms via evaporation of the solvents. The compression of the AG film follows this stage. Several parameters influence the formation and properties of the AG film. In general, the order and degree of the stacked G layer structure and the integrity of the film increase with increase in addition of G. Additionally, the usages of surfactants are a central element for the formation of AG film on substrates. Research verified that no G films can be obtained when CTAB and SDS are employed as surfactants of G, and small-size AG films formed when SLS is used as surfactant [78]. For instance, Malekpour et al. deposited AG film on the PET substrate by using nonionic polymer-type surfactant dispersed G ink and then compressing the AG film with a compression roller. The resulting composites showed potential application as a photoelectricity technique due to the significant improvements in thermal conductivity along the IPD [77]. However, in many cases, due to the good dispersity of GO, rGO, and FLG in solvents, no surfactants are added. Using similar procedures, Kim et al. synthesized flexibly aligned rGO FETs. The FETs were operated at low voltages of < 2 V with a hole and electron mobility of 214 and 106 cm2/V s, respectively [79]. With regard to the properties of G film, the compression procedure will improve the thermal and electric conductivity because this step can enhance the contact of G. (The detailed mechanisms are discussed in "Properties of AGCs" section.) Compared to the preparation of AGLCs by CVD, the SEI offers large-scale production capability and allows for designing G film directly onto substrates without transfer steps; however, the drawback is the relative low quality of G film due to surface modification, which decreases the intrinsic properties of G.

Similar to the VF, the preparation steps of the MGAs by SEI also include two steps. Preparing the LMPG and evaporating the solvents are both required to obtain the MGAs. Current reports showed that the G content is an important parameter for the control of the formation of AG [78]. G and GD tend to be arranged in disorder when the added amount is low. When the G content is high, the steric hindrance and excluded volume are more obvious, making G tend to stack orderly at the air-liquid interface. In addition to that, the evaporation rate of solvents is vital for the array of G. Low evaporation speed corresponds to a low induction force, which can align G parallel to substrates, whereas a high evaporation rate aligns G vertical to substrates [80]. Experiments showed that AG (parallel to substrate) formed in the G/SBR system at a curing temperature of 30 °C and concentrations of G above 1 wt%; AG (vertical to substrate) formed at a curing temperature above 60 °C [80]. Fan et al. prepared AG/PVDF (AG parallel to substrate) composites by evaporating the LMPG solvent (N,N-dimethylacetamide) under 60 °C. The prepared composites showed a high dielectric constant (7940) when the cooperation of rGO was 0.0177 vol% [81].

UFC

The freeze-casting technique with traits of versatility, facile accessibility, and capability of producing materials with complex shapes and structures, is extensively used to fabricate 3D GA and GA composites [82, 83]. In addition to the afore-mentioned advantages of the freeze-casting technique, the resulting materials with porous structure, ultra-low density, and promising interface connection between G attract tremendous attention [84]. By regulating experimental parameters such as freeze temperature and the degree of super-cooling, a peculiar morphology and structure can be engineered [85]. In particular, the porosity, ultra-low density, and robust AG network and AGCs were designed by a modified freeze-drying process named UFC. A critical step of the UFC is the control of orientated growth of dispersing medium crystallization via high temperature gradient. The formation mechanism of the AG 3D network by UFC is shown in Fig. 7. An ultra-high degree of super-cooling can promote crystal growth along the orientation of the maximum temperature gradient, and can restrain the possible growth of secondary dendrites [86]. Furthermore, the rapid growth of dispersing medium crystallization can remove G and polymer solutions from crystals, and the removal reaction forces G to array parallel to the growth direction of the crystal. In recent years, liquid nitrogen has been employed to generate nearly 200 °C degree of super-cooling. Typically, the bottom of LMPG (DAG) is placed onto liquid nitrogen, while the roof is in contact with room-temperature air. The degree of super-cooling of the dispersing mediums is the difference between the theoretical crystallization temperature and the temperature of liquid nitrogen (~196 °C). Moreover, the concentrations of G also affect the construction of 3D AG structure [87]. Only if the concentration overtops the percolation threshold, G forms an architecture of continuous, well-interconnected, and aligned pores [88]. It has been reported that an AG network would form when the GO concentration of DAG is above 1 mg/mL [89]. The UFC also comprises two approaches to synthesize AGCs. Approach (i): frozen GAD are freeze-dried to obtain an AG aerogel into which the aimed matrices are then filled. Li et al. followed approach (i) prepared AG/EP composites with excellent EMI shielding efficiency [90]. Approach (ii): freezing the LMPG directly followed by freeze-drying to obtain AGCs. In contrast to bulk AGCs from approach (i), AGCs with porous morphology can be prepared by approach (ii). With approach (ii), Vickery et al. prepared porous and ultra-low-density AG/PVA composites with excellent mechanical properties [91], while Wang et al. prepared AG/PVA composites with analogous structures with benign dielectric properties [92].

(see Ref. [87])

Mechanism of the UFC method for constructing 3D AG.

Recently, the distinctive 3D AG structure has attracted extensive attention in the preparation of high-performance electrodes because the porous AG structure can provide rapid ion diffusion and high electric conductivity and can buffer the expansion of electrode materials (such as silicon and SnO2) during the transversion of alloying [93]. To date, vertical AG (vertical to the collector) electrodes were synthesized by high-cost PECVD [94]. The AGCs prepared by approach (ii) possess high conductivity, orientation degree of G, and mechanical stability. Therefore, UFC is a promising alternative to PECVD for the preparation of vertical 3D AGCs. Despite the afore-mentioned advantages of UFC, the obvious drawback of the requirement of ultra-high super-cooling in the progress hinders its large-scale application.

Preparations of metal-based AGCs

The above-mentioned methods are for the preparation of AG/polymer composites. In recent years, researchers have developed effective methods to synthesize metal-based AGCs due to their high thermal and dimensional stability and the superior strength of metals compared to polymers. Inspired by nature, biomimetics implement the insights into researchers to array G in metals. The “brick and mortar” structure of natural nacre with nearly 95% hard mineral aragonite as “mortar” and about 5% soft protein as ‘brick’ was simulated to construct metal-based AGCs. Until now, both RPS and VFSPS have been developed mainly to synthesize metal-based AGCs with a “brick and mortar” structure [95, 96]. The procedures of RPS are shown in Fig. 8a. Metals are used to replicate layered porous structure materials, adsorb the G inside of porousm and press the embodied G porous metal structure to obtain AGCs. Xiong et al. employed copper to chemically replicate fir wood with a layered porous structure and the prepared AG/copper composites significantly enhanced the obtained mechanical properties [95]. For the steps of VFSPS, G was adsorbed on the surface of metal micron particles by filtrating a mixture of metal powder and GAD, and then consolidating the bulk powder mixture by SPS (see Fig. 8b). Following the VFSPS, AG/copper composites were obtained with excellent mechanical, electronic, and tribological performance [96,97,98]. In addition to PRS and VFSPS methods, complicated CVDS which consist of two steps was developed to prepared AG/metal composites. For example, Kim et al. and Gao et al. prepared AG/copper composites with excellent mechanics and electronic conductivity [99, 100]. However, CVDS is a rarely used method for the preparation of metal-based AGCs. Most metals (excluding Cu, Ni, and their alloys) are incapable of directly growing G, suggesting that CVDS can prepare Cu-based, Ni-based, and Cu/Ni alloy-based AGCs without transferal of G to the surface of other metals. Moreover, it is difficult to prepare metal-based AGCs with uniformly distributed nano-level AG because the large-size G film forms by CVD.

In summary, for the preparation of metal-based AGCs reported so far, copper is only used for the matrix due to the following two reasons: Copper powder possesses high chemical stability in the air environment, and it is favorable that copper powder does not form a copper oxide film on the surface of copper particles in the procedures. Furthermore, when using copper oxide powder as precursor, it reduces easily. Due to the disadvantages of the copper matrix, such as high density and poor corrosion resistance in the alkaline environment, more metal matrices should be developed to meet the requirements of applications and industries. Furthermore, the discussion of influencing factors and the establishment of a theoretical model should also be achieved to enable the precise control of preparation procedures.

Properties of AGCs

Electrical conductivity

Based on the electric conductive percolation theory, the conductive network formation of fillers is an important condition for enhancing the electric conductivity of composites. In general, the value of increasing volume fraction of conductive fillers to a critical value and an insulator-to-conductor transition occurs (Pc) and σ are two parameters used for the evaluation of the electric performances of polymer composites. A desirable lower Pc and higher σ at lower addition of G mean that lower consumption of the expensive G can achieve higher electric conductivity performances. For metal-based composites, the percent increase of σ is used as evaluation criterion.

As a conductive nanofiller with ultra-high σ and α, G has been considered as an ideal conductive filler. In particular, the arrangement of G in matrices affects the construction of the conductive network and the conductivity of composites. Because the electric conductivity of G at IPD is higher than that at TTD, the array can fully utilize their electric conductivity [23]. Furthermore, a large body of work indicated that the AG would facilitate the formation of a conductive network. Various matrices, such as PU [22], EP [18], PVDF-HFP [25], cellulose [68], SBR [80], PVDF [81], and copper [99] have boosted electric conductive properties via the alignment of G, and the resulting AGCs demonstrated lower Pc and higher σ in the orientation of the aligned G. For example, the Pc (0.22 vol%) of AG/EP composites was twofold higher than that of RG/EP composites, and the σ of AG/EP composites increased by nearly two orders of magnitude compared to that of RG/EP composites [41]. In addition, experiments showed that the electric properties of RG/EP composites and AG/EP composites at TTD are almost identical [41]. An effective-medium theory of σ for AG/polymer composites has been developed [14], demonstrating that aligning G is a better way to improve the resulting electric properties, as well as achieving the conductive applications of AP/EP composites. The comprehensive electric property of AGCs outperforms that of RGCs.

Several intrinsic properties of G significantly affect the electric properties of AGCs: (1) the presence of functional groups on G. The more functional groups there are, the lower σ will be. Basically, the introduction of groups onto G can damage the inherent sp2 structure, which then rapidly decreases the σ of G. For example, Yousefi et al. showed that aligned GO composites functioned as an insulator even if the addition of GO was as high as 3 wt% [18]. (2) The dispersity of G in matrices. Good dispersity implies that the formation of a conductive network is possible even at low G addition. However, it is well known that G inevitably gathers in matrices without modification. By adsorbing surfactants and anchoring functional groups onto G, G obtains good dispersity, while it decreases their σ. To address this contradiction, rGO, with the have combined performances of moderate dispersity and σ, is widely used in conductive AGCs as a compromising strategy [25, 78, 80]. (3) Size of G. The σ of large-area G is higher than that of small-area G because large-area G possess smaller inter-sheet contact resistance in matrices [101]. Kumar et al. exhibited large-area reduced-AG/PVDF-HFP composites, the σ of the composites was obviously higher than that of small-area reduced-AG/PVDF-HFP composites [25].

Here, we summarize and compare the electric properties of RGCs and AGCs for different directions. As shown in Table 4, the results mostly correspond to the presented viewpoints, although the Pc and σ are strongly influenced by a number of factors. Aligning G into matrices is a more effective way to enhance the electric performance of composites.

Mechanical properties

G is considered to be one class of the emerging enhanced phases for various matrices due to their incomparable mechanics and ultra-high α, that can effectively boost the mechanical performance of matrices when the additional content is low. Figure 9 shows the AG enhancement mechanisms for both polymer-based and metal-based composites. It is reasonable to assume that the introduction of AG is a more effective way to improve the mechanical performances for matrices than RG because flake-like G can bear loads only at the IPD. Furthermore, the arranged G can effectively inhibit the slip of the polymer chains in AG/polymer composites [107] and the plane slip in AG/metal composites [99].

Therefore, theoretically, the orientation distribution of G in matrices has a pivotal effect on the improvement of mechanics [110]. A large number of studies investigated the array of G in various matrices, such as PI [22], chitosan [19], PU [20, 22], EP [18], Tween [51], and copper [99], to enhance mechanics. To date, because most of the presented studies focused on the increase in tensile strength and elastic modulus, we, therefore, discuss the reinforcement mechanisms of AGCs for tensile strength and elastic modulus.

Based on the Halpin–Tsai model [108], the moduli of AGCs are theoretically calculated by Eqs. (2–3):

Here, E, Em, and Ef represent elastic moduli of AGCs, matrices, and fillers respectively, and Vf represent the volume fraction of G in Eqs. (2–3). Since Ef and α are directly proportional to E, the ultra-high elastic modulus and α of G have intrinsic superiority as oriented enhanced phases. In addition to the afore-mentioned influencing factors, the interfacial interaction between G and matrices also plays a key role in the improvement of mechanics. The stronger interfacial interaction leads to better reliable transfer of the loads between matrices and G. The formations of covalent bonds, hydrogen bonds, and π–π bonds have been applied between matrices and G to enhance the interfacial interaction. Establishing chemical bonds between functional groups of G and polymer monomers during the procedures of polymerization of polymer normally reduces GO. Yousefi et al. expounded the detailed reaction mechanism of GO and EP monomers in procedures of in situ polymerization, and using a modulus as high as 800 MPa resulted in AG/EP with 2 wt% GO, which demonstrated a strong interfacial interaction between GO and EP [18]. The contained oxygen, nitrogen, and fluorine functional groups on G and polymer matrices probably form strong hydrogen bonds. The prime formation mechanism of hydrogen bonds mainly includes highly polar polyalcohols and G in a G/polymer system. Huang et al. explained the formation of hydrogen bonds between hydroxyl of PVA and oxygenated groups of GO by a shift of vibration peak position [109]. G and many polymers with abundant aromatic rings are an important prerequisite for the improvement of the interfacial bonding by π–π stacking, as has been reported by PEDOT and GO [110]. As an unavoidable problem, the dispersity of G in matrices also significant affects the improvement of the resulting mechanics. With increasing G content, the moduli and strength of AGCs showed a first increasing and then decreasing trend in most relevant studies, as a result of the unavoidable gathering at high contents, while leads to a decrease of load transfer.

Table 5 summarizes and compares the elastic modulus and tensile strength of AGCs and RGCs with different G contents by various preparation methods. Although the mechanic improvement in composites is strongly influenced by the matrices, G types, and preparation methods, AGCs possess higher mechanics than RGCs.

Thermal properties

In addition to the high phonon λ of honeycomb-like G as a result of the strong covalent bonds, the super-high α and thermal stability, which can minimize the thermal interface resistance, indicate G as an ideal thermal conductive enhanced filler. Similar to the improvement in σ, the G network plays the role of thermal conductive channels in composites. AG can facilitate the formation of the thermal conductive network and noticeably decrease the thermal interfacial resistance between G and matrices. The thermal conductive mechanism is shown in Fig. 10. Renteria et al. reported that the thermal properties of AG/EP composites far exceeded those of RG/EP composites [37]. Moreover, aligning G with anisotropic λ, ultra-high 2000–5000 W/mK along the IPD or 10–20 W/mK along TTD [119], can make the best use of G as a 2D material as well as can provide the possibility for designing AGCs with extraordinary λ at the aligned G orientation. The anisotropic thermal conductive AGCs are hopefully applied in TIM, dissipating materials [37, 52, 120,121,122,123], which have a strong requirement for oriented heat conduction. The thermal properties of AGCs and RGCs are listed in Table 6. The summarized reasons indicate that AGCs have better thermal properties.

(Ref. [118])

Thermal conductive mechanism of pure matrix, RGCs, and AGCs.

Anti-corrosion properties

In the natural environment, H2O, O2, and Cl- are the nemesis of corrosion in most materials. Therefore, isolating the metal interface from the electrolyte is a rational way to protect materials from corrosion by introducing organic coating at the surface of materials [132]. However, the anti-permeability properties of pure organic coatings are poor. The combination with fillers for polymer coatings is an effective method to enhance their anti-corrosion properties. G with high α, chemical inertness, and excellent anti-permeability (only protons can pass through) have inspired considerable work to utilize G/polymer composites as anti-corrosion coatings [133,134,135]. A proven theory indicates that the cooperation of G strongly increases the diffusion pathway of the electrolyte from the surface of coatings to the metal interface [136, 137]. Moreover, experiments have shown that the alignment of G would strongly affect the anti-corrosion properties of coatings because AG (vertical to the direction of electrolyte diffusion) can effectively increase the diffusion pathway. The anti-corrosion mechanisms of AGCs and RGCs are shown in Fig. 11. Luo et al. reported that the AG/EP anti-corrosion property far exceeded that of RG/EP coating [138]. Li et al. synthesized an AG/PU anti-corrosion coating via the LC method, and verified that the anti-corrosion performance of AGCs was higher than that of RGCs vis EIS analysis [21]. Because the anti-permeabilities of G and GO are nearly identical, GO with high processability and dispersibility in aqueous media was widely applied in anti-corrosion coatings [132, 139, 140]. However, reported studies on anti-corrosion of AGCs are limited, due to the undeniable difficulty for the preparation of AGCs on the surface of materials by the afore-mentioned methods.

(Ref. [21])

Anti-corrosion mechanisms of a RGCs and b AGCs.

Trinological property

Graphite carbon including G has been found to have outstanding tribological properties [141]. Furthermore, many studies indicated that AG can fully utilize the self-lubricating property of 2D material [32, 142]. Several mechanisms have been developed to explain the excellent tribological properties of AGCs: (1) AGCs can boost the contact area between AG and friction counterparts. (2) AG facilitate the formation of G transform film on friction counterparts under a moderate content of G addition. The schematic is shown in Fig. 12. Both phenomena transfer the wear from between the friction counterparts and matrices to between counterparts and AG. For instance, Liu et al. prepared AG/bismaleimides composites via EMF, and the obtained composites have a friction coefficient of as low as 0.07 for an addition of G-Fe3O4 of 0.06 wt% [32].

(Ref. [142])

Tribological schematic of AGCs.

Friction coefficient and volume wear rate are used to evaluate the friction properties. We summarized and compared the friction coefficient and volume wear rate of AGCs and RGCs. As shown in Table 7, the tribological performances of AGCs far exceed those of the RGCs although there are limited reports on the tribological properties of AGCs. Interestingly, additions of rGO and FGS into SSBR-BR have a side effect on the tribological properties of composites [143]. It is plausible that the existence of a disordered alignment of rGO (FSG) in rubber matrices can greatly induce tear, curling, and peeling off on worn surfaces of the composites, emphasizing the importance of AG to enhance the wear performance.

EMI shielding property

Traditional metallic coatings and cases of EMI shields with heavy weight are undesirable for their applications. G (including partial graphene derivatives) with low density, ultra-high electronic and thermal conductivity, and mechanics are indicated as ideal fillers for EMI shielding composites. The EMI shielding behavior of G primary stems from the strong electrical loss of microwaves [146, 147]. Normally, the EMI shielding performance is proportional to the σ value of G composites. In "Electrical conductivity" section, the advantages of AGCs have been discussed in electrics. However, the design of G composites with high dielectric permittivity is a further way to boost the EMI shielding property [148]. In microstructures of polymer-based AGCs, any pair of adjacent conductive G separated by an insulating polymer thin film can serve as a nanoscale capacitor. The enormous AG network, containing millions of capacitors, can hold an extremely large capacity for the storage of electric charges, thus equipping the AGCs with superior dielectric permittivity [149]. A schematic of nanoscale capacitors is shown in Fig. 13a. AGCs combine both merits of excellent electronic conductivity and the formation of numerous nanoscale capacitors, leading to the following two enhancements for EMI shielding performance: (1) capability of absorbing the incidental electromagnetism waves via polarization in numerous nanoscale capacitors; (2) the G aligned in IPD contributes positively to shielding the electromagnetic waves that emanate through the thickness direction by increasing the reflective area (Fig. 13b) [150]. Yousefi et al. prepared an AG/EP composite with 3 wt% of rGO via LC, and the composites exhibited a dielectric constant exceeding 14000 at 1 kHz and an EMI shielding efficiency of about 40 dB in 500–4000 MHz [149], which was far higher than similar RGCs [9, 151, 152]. Song et al. prepared an AG/wax composite via the hot-press method and the obtained AGCs presented above 30% increment in shielding effectiveness based on unaligned G/wax composite [150]. The afore-mentioned studies indicate that the cooperation of AG in polymers is a more effective means to boost the EMI shielding property of G composites.

Conclusions and prospects

In summary, the methods for preparation and the resulting properties of AGCs have been summarized. With regard to the preparation methods, each has its own merits, such as the simple procedures of LC, VF, and SEI, which limit the G content of EMF, EEF, and VFSPS little, as well as the porous structure of UFC, energy conservation of LC, VF, LBL, and SEI. Researchers can choose the most suitable method for their experiments. With regard to the properties of AGCs, the enhanced mechanisms of AGCs and influencing factors have been discussed in detail. Aligning G in matrices is an ideal method to fully utilize its excellent properties. Based on these outstanding multifunctional properties, AGCs are promising as structural and functional materials (sensors, heterojunction, inkjet printing, hybrid lubricating films, and anode material for lithium ion batteries).

However, several existing issues still need to be addressed. (1) The studies on the influencing factors of the G orientation and alignment are not thorough, especially lacking systematic mathematical models for methods such as VF, SEI, UFC, and VFSPS. (2) The macroscopical order degree of AGCs is imperfect. (3) It remains difficult to prepare more metal-based and ceramic-based AGCs. (4) The current methods for preparing AGCs need to be studied in depth, existing methods need to be constantly improved, and new technologies for the large-scale industrial production need to be developed.

Abbreviations

- G:

-

Graphene and its derivatives

- GO:

-

Graphene oxide

- FLG:

-

Functional graphene

- CNTs:

-

Carbon nanotubes

- TTD:

-

Through-thickness direction of graphene (graphene derivatives)

- EMI:

-

Electromagnetic interference

- LC:

-

Liquid crystal method

- LBL:

-

Layer-by-layer self-assemble method

- UFC:

-

Unidirectional freeze-casting method

- VFSPS:

-

Vacuum filtration and spark plasma sintering method

- GAD:

-

Graphene (graphene derivative) aqueous dispersions

- AG:

-

Aligned-graphene (aligned-graphene derivatives)

- TEM:

-

Transmission electron microscope

- EP:

-

Epoxy

- PAA:

-

Poly(amic acid)

- EMF:

-

Exerting magnetic field method

- G-Fe3O4 :

-

Fe3O4 anchored graphene (graphene derivatives)

- DC:

-

Direct current

- 1D:

-

One dimensional

- G-diamine:

-

Diamine-modified graphene

- PDDA:

-

Poly(diallyldiamine chloride)

- AGLCs:

-

Aligned-graphene (aligned-graphene derivative) laminated composites

- CTAB:

-

Hexadecyl trimethyl ammonium bromide

- SLS:

-

Sodium lignosulfonate

- GA:

-

Graphene (graphene derivative) aerogel

- FETs:

-

Field effect transistors

- SPS:

-

Spark plasma sintering

- CVDS:

-

Growing graphene by chemical vapor deposition onto surface of metals and sintering the graphene/metals sheets

- α :

-

Specific area

- RG:

-

Random-graphene (random-graphene derivatives)

- PAMPs:

-

Poly(2-acrylamido-2-methyl-1-propanesulfonic acid)

- KH550-G:

-

KH550-modified graphene

- PI:

-

Polyimide

- PEM/PSS/PAH:

-

Polyelectrolyte/poly(sodium 4-styrenesulfonate)/poly(allylamine hydrochloride)

- PS-GO:

-

Polystyrene-grafted graphene oxide

- SSBR-BR:

-

Solution styrene butadiene/butadiene rubber

- λ :

-

Thermal conductivity

- EIS:

-

Electrochemical impedance spectroscopy

- CA:

-

Cellulose acetate

- 2D:

-

Two dimensional

- rGO:

-

Reduced graphene oxide

- TIM:

-

Thermal interface materials

- IPD:

-

In-plane direction of graphene (graphene derivatives)

- AGCs:

-

Aligned-graphene (aligned-graphene derivative) composites

- RGCs:

-

Random-graphene (random-graphene derivative) composites

- VF:

-

Vacuum filtration method

- SEI:

-

Solvent evaporation induction method

- RPS:

-

Replication of the ordered porous structure method

- LMPG:

-

Liquid mixtures of polymers and graphene (graphene derivatives)

- PTFE:

-

Polytetrafluoroethylene

- SEM:

-

Scanning electron microscope

- GCA:

-

Graphene carboxylic acid

- PU:

-

Polyurethane

- PVDF-HFP:

-

Poly(vinylidene fluoride-co-hexafluoropropylene)

- EEF:

-

Exerting electric field method

- 3D:

-

Three dimensional

- AC:

-

Alternating current

- PVA:

-

Poly vinyl alcohol

- MG:

-

Multilayer G

- PSS:

-

Poly(styrene sulfonate)

- MGACs:

-

Monolithic aligned-graphene (aligned-graphene derivative) composites

- SDS:

-

Sodium dodecyl sulfate

- PET:

-

Polybutylene terephthalate

- SBR:

-

Styrene butadiene rubber

- PECVD:

-

Plasma-enhanced chemical vapor deposition

- CVD:

-

Chemical vapor deposition

- Pc:

-

Percolation threshold value

- rGO-Fe3O4 :

-

Fe3O4 anchored reduced graphene oxide

- UHMWPE:

-

Ultra-high molecular weight polyethylene

- PEEK:

-

Poly(ether ether ketone)

- PEDOT:

-

Poly(3,4-ethylene dioxythipphene)

- PSI-GO:

-

Poly(styrene-co-isoprene)-grafted graphene oxide

- BTESPT:

-

Bis(triethoxysilylpropyl)tetrasulfide

- VTMS-GO:

-

Vinyl tri-methoxysilane grated graphene oxide

- FGS:

-

Fluorinated graphene

- σ :

-

Electronic conductivity

References

Novoselov KS, Fal′Ko VI, Colombo L, Gellert PR, Schwab MG, Kim K (2012) A roadmap for graphene. Nature 490:192–200

Kaur K, Jeet K (2017) Electrical conductivity of water-based nanofluids prepared with graphene-carbon nanotube hybrid. Fuller Nanotub Carbon Nanostruct 25:726–734

Lee Y, Bae S, Jang H et al (2010) Wafer-scale synthesis and transfer of graphene films. Nano Lett 10:490–493

Nika DL, Balandin AA (2012) Two-dimensional phonon transport in graphene. J Phys Condens Matter 24:233203

Nika DL, Balandin AA (2017) Phonons and thermal transport in graphene and graphene-based materials. Rep Prog Phys 80:036502

Kuilla T, Bhadra S, Yao D, Kim NH, Bose S, Lee JH (2010) Recent advances in graphene based polymer composites. Prog Polym Sci 35:1350–1375

Zhan Y, Wu J, Xia H, Yan N, Fei G, Yuan G (2011) Dispersion and exfoliation of graphene in rubber by an ultrasonically-assisted latex mixing and in situ reduction process. Macromol Mater Eng 296:590–602

Mao Y, Wen S, Chen Y et al (2013) High performance graphene oxide based rubber composites. Sci Rep 3:2508

Liang J, Wang Y, Huang Y et al (2009) Electromagnetic interference shielding of graphene/epoxy composites. Carbon 47:922–925

Jafari Y, Ghoreishi SM, Shabani-Nooshabadi M (2016) Polyaniline/graphene nanocomposite coatings on copper: electropolymerization, characterization, and evaluation of corrosion protection performance. Synth Met 217:220–230

Fan D, Zhang R, Wang X, Huang S, Peng H (2012) Influence of silver dopant on the morphology and ultraviolet emission in aligned zno nanostructures. Phy Status Solidi A 209:335–339

Huard M, Roussel F, Rouzière S, Patel S, Pinault M, Mayne LM, Launois P (2014) Vertically aligned carbon nanotube-based composite: elaboration and monitoring of the nanotubes alignment. J Appl Polym Sci 131:1–15

Nain AS, Wang J (2013) Polymeric nanofibers: isodiametric design space and methodology for depositing aligned nanofiber arrays in single and multiple layers. Polym J 45:695–700

Xia X, Hao J, Wang Y, Zhong Z, Weng GJ (2017) Theory of electrical conductivity and dielectric permittivity of highly aligned graphene-based nanocomposites. J Phys Condens Matter 29:205702

Shivanandareddy AB, Krishnamurthy S, Lakshminarayanan V, Kumar S (2013) Mutually ordered self-assembly of discotic liquid crystal-graphene nanocomposites. Chem Commun 50:710–712

Eppenga R, Frenkel D (1984) Monte carlo study of the isotropic and nematic phases of infinitely thin hard platelets. Mol Phys 52:1303–1334

Aboutalebi SH, Gudarzi MM, Zheng QB, Kim JK (2011) Spontaneous formation of liquid crystals in ultralarge graphene oxide dispersions. Adv Funct Mater 21:2978–2988

Yousefi N, Lin X, Zheng Q et al (2013) Simultaneous in situ reduction, self-alignment and covalent bonding in graphene oxide/epoxy composites. Carbon 59:406–417

Pan Y, Wu T, Bao H, Li L (2011) Green fabrication of chitosan films reinforced with parallel aligned graphene oxide. Carbohyd Polym 83:1908–1915

Yousefi N, Gudarzi MM, Zheng Q et al (2013) Highly aligned, ultralarge-size reduced graphene oxide/polyurethane nanocomposites: mechanical properties and moisture permeability. Compos Part A Appl S 49:42–50

Li Y, Yang Z, Qiu H, Dai Y, Zheng Q, Li J, Yang JH (2014) Self-aligned graphene as anticorrosive barrier in waterborne polyurethane composite coatings. J Mat Chem A 2:14139–14145

Gudarzi MM, Aboutalebi SH, Yousefi N, et al (2011) Self-aligned graphene sheets-polyurethane nanocomposites. In: Mrs online proceedings library archive, p 1344

Yousefi N, Gudarzi MM, Zheng Q, Aboutalebi SH, Sharif F, Kim JK (2012) Self-alignment and high electrical conductivity of ultralarge graphene oxide–polyurethane nanocomposites. J Mater Chem 22:12709–12717

Kim GY, Choi MC, Lee D, Ha CS (2012) 2D-aligned graphene sheets in transparent polyimide/graphene nanocomposite films based on noncovalent interactions between poly(amic acid) and graphene carboxylic acid. Macromol Mater Eng 297:303–311

Kumar P, Yu S, Shahzad F, Hong SM, Kim YH, Chong MK (2016) Ultrahigh electrically and thermally conductive self-aligned graphene/polymer composites using large-area reduced graphene oxides. Carbon 101:120–128

Behabtu N, Lomeda JR, Green MJ et al (2010) Spontaneous high-concentration dispersions and liquid crystals of graphene. Nat Nanotechnol 5:406–411

Ominato Y, Koshino M (2013) Orbital magnetism of graphene flakes. Phys Rev B 87:269–275

Tian B, Lin W, Zhuang P, Li J, Shih TM, Cai W (2018) Magnetically-induced alignment of graphene via landau diamagnetism. Carbon 131:66–71

Li D, Liu Y, Ma H, Wang Y, Wang L, Xie Z (2015) Preparation and properties of aligned graphene composites. RSC Adv 5:31670–31676

Babaei H, Keblinski P, Khodadadi JM (2013) Thermal conductivity enhancement of paraffins by increasing the alignment of molecules through adding CNT/graphene. Int J Heat Mass Transf 58:209–216

Babonneau D, Camelio S, Simonot L, Pailloux F, Guérin P, Lamongie B, Lyon O (2011) Tunable plasmonic dichroism of au nanoparticles self-aligned on rippled Al2O3 thin films. EPL 93:26005

Liu C, Yan H, Chen Z, Yuan L, Liu T (2015) Enhanced tribological properties of bismaleimides filled with aligned graphene nanosheets coated with Fe3O4 nanorods. J Mater Chem A 3:10559–10565

Yan H, Tang Y, Long W, Li Y (2014) Enhanced thermal conductivity in polymer composites with aligned graphene nanosheets. J Mater Sci 49:5256–5264. https://doi.org/10.1007/s10853-014-8198-z

Renteria J, Legedza S, Salgado R et al (2015) Magnetically-functionalized self-aligning graphene fillers for high-efficiency thermal management applications. Mater Des 88:214–221

Liang J, Xu Y, Sui D et al (2010) Flexible, magnetic, and electrically conductive graphene/fe3o4 paper and its application for magnetic-controlled switches. J Phys Chem C 114:17465–17471

Ferrand HL, Bolisetty S, Demirörs AF, Libanori R, Studart AR, Mezzenga R (2016) Magnetic assembly of transparent and conducting graphene-based functional composites. Nat Commun 7:12078

Yan H, Wang R, Li Y, Long W (2015) Thermal conductivity of magnetically aligned graphene–polymer composites with fe3o4 -decorated graphene nanosheets. J Electron Mater 44:658–666

Erb RM, Segmehl J, Charilaou M, Löffler JF, Studart AR (2012) Non-linear alignment dynamics in suspensions of platelets under rotating magnetic fields. Soft Matter 8(29):7604–7609

Billaud J, Bouville F, Magrini T, Villevieille C, Studart AR (2016) Magnetically aligned graphite electrodes for high-rate performance Li-ion batteries. Nat Energy 1:16097

Castellano RJ, Akin C, Giraldo G, Kim S, Fornasiero F, Shan JW (2015) Electrokinetics of scalable, electric-field-assisted fabrication of vertically aligned carbon-nanotube/polymer composites. J Appl Phys 117:1942–1945

Wu S, Ladani RB, Zhang J et al (2015) Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites. Carbon 94:607–618

Wang Z (2009) Alignment of graphene nanoribbons by an electric field. Carbon 47:3050–3053

Pang H, Chen C, Zhang YC, Ren PG, Yan DX, Li ZM (2011) The effect of electric field, annealing temperature and filler loading on the percolation threshold of polystyrene containing carbon nanotubes and graphene nanosheets. Carbon 49:1980–1988

Li Q, Guo Y, Li W et al (2012) Ultrahigh thermal conductivity of assembled aligned multilayer graphene/epoxy composite. Chem Mate 26:4459–4465

Koo B, Goli P, Sumant AV, Claro PCDS, Rajh T, Johnson CS, Balandin AA, Shevchenko EV (2014) Toward lithium ion batteries with enhanced thermal conductivity. ACS Nano 8:7202–7207

Liang Q, Yao X, Wang W, Liu Y, Wong CP (2011) A three-dimensional vertically aligned functionalized multilayer graphene architecture: an approach for graphene-based thermal interfacial materials. ACS Nano 5:2392–2401

Xia S, Ni M, Zhu T, Zhao Y, Li N (2015) Ultrathin graphene oxide nanosheet membranes with various d-spacing assembled using the pressure-assisted filtration method for removing natural organic matter. Desalination 371:78–87

Liu W, Song N, Wu Y, Gai Y, Zhao Y (2017) Preparation of layer-aligned graphene composite film with enhanced thermal conductivity. Vacuum 138:39–47

Song N, Jiao D, Ding P, Cui S, Tang S, Shi LY (2015) Anisotropic thermally conductive flexible films based on nanofibrillated cellulose and aligned graphene nanosheets. J Mater Chem C 4:305–314

Lin X, Shen X, Zheng Q, Yousefi N, Ye L, Mai YW, Kim JK (2012) Fabrication of highly-aligned, conductive, and strong graphene papers using ultralarge graphene oxide sheets. ACS Nano 6:10708–10719

Park S, Mohanty N, Suk JW et al (2010) Biocompatible, robust free-standing paper composed of a tween/graphene composite. Adv Mater 22:1736–1740

Zhang YF, Ren YJ, Bai SL (2018) Vertically aligned graphene film/epoxy composites as heat dissipating materials. Int J Heat Mass Tran 118(18):510–517

Zhang J, Xu X, Yao C, Li L (2016) Facile fabrication of an organic semiconductor/graphene microribbon heterojunction by self-assembly. RSC Adv 6:52878–52883

Zhao L, Zhang H, Kim NH et al (2016) Preparation of graphene oxide/polyethyleneimine layer-by-layer assembled film for enhanced hydrogen barrier property. Compos Part B Eng 92:252–258

Zhang B, Cui T (2011) An ultrasensitive and low-cost graphene sensor based on layer-by-layer nano self-assembly. Appl Phys Lett 98:073116

Hong JY, Shin KY, Kwon OS, Kang H, Jang J (2011) A strategy for fabricating single layer graphene sheets based on a layer-by-layer self-assembly. Chem Commun 47:7182–7184

Pu J, Mo Y, Wan S, Wang L (2013) Fabrication of novel graphene-fullerene hybrid lubricating films based on self-assembly for mems applications. Chem Commun 50:469–471

Tang J, Yang J, Zhou L, Xie J, Chen G, Zhou X (2014) Layer-by-layer self-assembly of a sandwich-like graphene wrapped snox@graphene composite as an anode material for lithium ion batteries. J Mater Chem A 2:6292–6295

Zhao X, Zhang Q, Hao Y, Li Y, Fang Y, Chen D (2010) Alternate multilayer films of poly(vinyl alcohol) and exfoliated graphene oxide fabricated via a facial layer-by-layer assembly. Macromolecules 43:9411–9416

Zhang D, Tong J, Xia B (2014) Humidity-sensing properties of chemically reduced graphene oxide/polymer nanocomposite film sensor based on layer-by-layer nano self-assembly. Sens Actuator B Chem 197:66–72

Kirschner J, Wang Z, Eigler S, Steinrück HP, Jäger CM, Clark T, Hirsch A, Halik M (2014) Driving forces for the self-assembly of graphene oxide on organic monolayers. Nanoscale 6:11344–11350

Li Y, Yang J, Zhou Y, Zhao N, Zeng W, Wang W (2016) Fabrication of gold nanoparticles/graphene oxide films with surface-enhanced raman scattering activity by a simple electrostatic self-assembly method. Colloid Surf A 512:93–100

Zhang D, Liu J, Xia B (2016) Layer-by-layer self-assembly of zinc oxide/graphene oxide hybrid toward ultrasensitive humidity sensing. IEEE Electron Device Lett 37:916–919

Chettri P, Vendamani VS, Tripathi A, Pathak AP, Tiwari A (2016) Self-assembly of functionalised graphene nanostructures by one step reduction of graphene oxide using aqueous extract of artemisia vulgaris. Appl Surf Sci 362:221–229

Yu S, Li N, Higgins D et al (2014) Self-assembled reduced graphene oxide/polyacrylamide conductive composite films. ACS Appl Mater Interfaces 6:19783

Yao Y, Ma W (2014) Self-assembly of polyelectrolytic/graphene oxide multilayer thin films on quartz crystal microbalance for humidity detection. IEEE Sens J 14:4078–4084

Lee KH, Hong JH, Kwak SJ, Min P, Son JG (2015) Spin self-assembly of highly ordered multilayers of graphene-oxide sheets for improving oxygen barrier performance of polyolefin films. Carbon 83:40–47

Tang L, Li X, Du D, He C (2012) Fabrication of multilayer films from regenerated cellulose and graphene oxide through layer-by-layer assembly. Prog Nat Sci 22:341–346

Zhang D, Tong J, Xia B, Xue Q (2014) Ultrahigh performance humidity sensor based on layer-by-layer self-assembly of graphene oxide/polyelectrolyte nanocomposite film. Sens Actuator B Chem 203:263–270

Qi W, Xue Z, Yuan W, Wang H (2013) Layer-by-layer assembled graphene oxide composite films for enhanced mechanical properties and fibroblast cell affinity. Mater Chem B 2:325–331

Yang L, Niu T, Zhang H, Xu W, Zou M, Xu L et al (2017) Self-assembly of suspended graphene wrinkles with high pre-tension and elastic property. 2D Mater 4:041001

Peng L, Xu Z, Liu Z, Guo Y, Li P, Gao C (2017) Ultrahigh thermal conductive yet superflexible graphene films. Adv Mater 29:1700589

Zhang M, Wang Y, Huang L, Xu Z, Li C, Shi G (2015) Multifunctional pristine chemically modified graphene films as strong as stainless steel. Adv Mater 27:6708

Ye X, Zhu Y, Tang Z, Wan Z, Jia C (2017) In-situ chemical reduction produced graphene paper for flexible supercapacitors with impressive capacitive performance. J Power Sources 360:48–58

Bae S, Kim H, Lee Y et al (2010) Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat Nanotechnol 5:574–578

Schwierz F (2010) Graphene for electronic applications: transistors and more. In: Bipolar/bicmos circuits and technology meeting. IEEE. https://doi.org/10.1109/bipol.2010.5668069

Malekpour H, Chang KH, Chen JC, Lu CY, Nika DL, Novoselov KS, Balandin AA (2014) Thermal conductivity of graphene laminate. Nano Lett 14:5155–5161

Lv W, Xia Z, Wu S et al (2011) Conductive graphene-based macroscopic membrane self-assembled at a liquid–air interface. J Mater Chem 21:3359–3364

Kim T, Kim H, Kwon SW et al (2012) Large-scale graphene micropatterns via self-assembly-mediated process for flexible device application. Nano Lett 12:743–748

Wang F, Mao J (2018) The self-aligning behaviour of graphene nanosheets in the styrene butadiene rubber by controlling curing temperature. Fuller Nanotub Carbon Nanostruct 26:61–68

Fan P, Wang L, Yang J, Chen F, Zhong M (2012) Graphene/poly(vinylidene fluoride) composites with high dielectric constant and low percolation threshold. Nanotechnology 23:365702

Sun H, Xu Z, Gao C (2013) Multifunctional, ultra-flyweight, synergistically assembled carbon aerogels. Adv Mater 25:2554–2560

Bai H, Li C, Wang X, Shi G (2011) On the gelation of graphene oxide. J Phys Chem C 115:5545–5551

Estevez L, Kelarakis A, Gong Q, Da’as EH, Giannelis EP (2011) Multifunctional graphene/platinum/nafion hybrids via ice templating. J Am Chem Soc 133:6122–6125

Deville S (2010) Freeze-casting of porous ceramics: a review of current achievements and issues. Adv Eng Mater 10:155–169

Li WL, Lu K, Walz JY (2012) Freeze casting of porous materials: review of critical factors in microstructure evolution. Int Mater Rev 57:37–60

Qiu L, Liu JZ, Chang SL, Wu Y, Li D (2012) Biomimetic superelastic graphene-based cellular monoliths. Nat Commun 3:1241

Xu Z, Zhang Y, Li P, Gao C (2012) Strong, conductive, lightweight, neat graphene aerogel fibers with aligned pores. ACS Nano 6:7103–7113

Wang Z, Shen X, Han NM, Liu X, Wu Y, Ye W, Kim JK (2016) Ultralow electrical percolation in graphene aerogel/epoxy composites. Chem Mater 28:6731–6741

Li XH, Li X, Liao KN, Min P, Liu T, Dasari A, Yu ZZ (2016) Thermally annealed anisotropic graphene aerogels and their electrically conductive epoxy composites with excellent electromagnetic interference shielding efficiencies. ACS Appl Mater Interfaces 8:33230–33239

Vickery JL, Patil AJ, Mann S (2010) Fabrication of graphene–polymer nanocomposites with higher-order three-dimensional architectures. Adv Mater 21:2180–2184

Wang Z, Han NM, Wu Y, Liu X, Shen X, Zheng Q, Kim JK (2017) Ultrahigh dielectric constant and low loss of highly-aligned graphene aerogel/poly(vinyl alcohol) composites with insulating barriers. Carbon 123:385–394

Zhou X, Yin YX, Cao AM, Wan LJ, Guo YG (2012) Efficient 3d conducting networks built by graphene sheets and carbon nanoparticles for high-performance silicon anode. ACS Appl Mater Inter 4:2824–2828

Zhang Z, Lee CS, Zhang W (2017) Vertically aligned graphene nanosheet arrays: synthesis, properties and applications in electrochemical energy conversion and storage. Adv Energy Mater 7:1700678

Xiong DB, Cao M, Guo Q, Tan Z, Fan G, Li Z, Zhang D (2015) Graphene-and-copper artificial nacre fabricated by a preform impregnation process: bioinspired strategy for strengthening-toughening of metal matrix composite. ACS Nano 9:6934–6943

Chu C, Wang XH, Wang F et al (2018) Largely enhanced thermal conductivity of graphene/copper composites with highly aligned graphene network. Carbon 127:102–112

Chu K, Wang F, Wang XH, Huang DJ (2018) Anisotropic mechanical properties of graphene/copper composites with aligned graphene. Mater Sci Eng A 713:269–277

Chu K, Wang XH, Li YB et al (2018) Thermal properties of graphene/metal composites with aligned graphene. Mater Des 140:85–94

Cao M, Xiong DB, Tan Z et al (2017) Aligning graphene in bulk copper: nacre-inspired nanolaminated architecture coupled with in-situ processing for enhanced mechanical properties and high electrical conductivity. Carbon 117:65–74

Kim Y, Lee J, Yeom MS et al (2013) Strengthening effect of single-atomic-layer graphene in metal-graphene nanolayered composites. Nat Commun 4:2114

Kumar P, Shahzad F, Yu S, Hong SM, Kim YH, Chong MK (2015) Large-area reduced graphene oxide thin film with excellent thermal conductivity and electromagnetic interference shielding effectiveness. Carbon 94:494–500

Alsaleh MH (2016) Electrical and electromagnetic interference shielding characteristics of gnp/uhmwpe composites. J Phys D Appl Phys 49:195302

Kim H, Miura Y, Macosko CW (2010) Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem Mater 22:3441–3450

Yang L, Zhang S, Zheng C, Guo Y, Luan J, Zhi G, Wang G (2014) Design and preparation of graphene/poly(ether ether ketone) composites with excellent electrical conductivity. J Mater Sci 49:2372–2382. https://doi.org/10.1007/s10853-013-7940-2

Ding JN, Fan Y, Zhao CX, Liu YB, Yu CT, Yuan NY (2012) Electrical conductivity of waterborne polyurethane/graphene composites prepared by solution mixing. J Compos Mater 46:747–752

Shah R, Kausar A, Muhammad B, Shah S (2015) Progression from graphene and graphene oxide to high performance polymer-based nanocomposite: a review. Polym Plast Technol Eng 54:173–183

Huang T, Lu R, Su C et al (2012) Chemically modified graphene/polyimide composite films based on utilization of covalent bonding and oriented distribution. ACS Appl Mater Interfaces 4:2699–2708

Gao J, Itkis ME, Yu A, Bekyarova E, Zhao B, Haddon RC (2005) Continuous spinning of a single-walled carbon nanotube-nylon composite fiber. J Am Chem Soc 127:3847–3854

Huang HD, Ren PG, Chen J, Zhang WQ, Ji X, Li ZM (2012) High barrier graphene oxide nanosheet/poly(vinyl alcohol) nanocomposite films. J Membr Sci 409–410:156–163

Tung VC, Kim J, Cote LJ, Huang JX (2011) Sticky interconnect for solution-processed tandem solar cells. J Am Chem Soc 133(24):9262–9265

Chen F, Ying J, Wang Y, Du S, Liu Z, Huang Q (2016) Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon 96:836–842

Liu P, Zhang X, Jia H, Yin Q, Wang J, Yin B, Xu D (2017) High mechanical properties, thermal conductivity and solvent resistance in graphene oxide/styrene-butadiene rubber nanocomposites by engineering carboxylated acrylonitrile-butadiene rubber. Compos Part B Eng 130:257–266

Höltker G (2013) Enhanced mechanical and gas barrier properties of rubber nanocomposites with surface functionalized graphene oxide at low content. Polymer 54:1930–1937

Xing W, Wu J, Huang G, Li H, Tang M, Fu X (2014) Enhanced mechanical properties of graphene/natural rubber nanocomposites at low content. Polym Int 63(9):1674–1681

Uddin ME, Layek RK, Kim HY, Kim NH, Hui D, Lee JH (2016) Preparation and enhanced mechanical properties of non-covalently-functionalized graphene oxide/cellulose acetate nanocomposites. Compos Part B Eng 90:223–231

Wu Y, Chen L, Li J, Zhou H, Zhao H, Chen J (2017) Understanding the mechanical and tribological properties of solution styrene butadiene rubber composites based on partially graphene oxide. Eur Polym J 89:150–161

Gao X, Yue H, Guo E, Zhang H, Lin X, Yao L, Wang B (2016) Mechanical properties and thermal conductivity of graphene reinforced copper matrix composites. Powder Technol 301:601–607

Li A, Zhang C, Zhang YF, Li A, Zhang C, Zhang YF (2017) Thermal conductivity of graphene-polymer composites: mechanisms, properties, and applications. Polymers 9:437

Balandin AA (2011) Thermal properties of graphene and nanostructured carbon materials. Nat Mater 10:569

Shahil KMF, Balandin AA (2012) Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett 12:861–867

Goyal V, Balandin AA (2012) Thermal properties of the hybrid graphene-metal nano-micro-composites: applications in thermal interface materials. Appl Phys Lett 100:073113

Saadah M, Hernandez E, Balandin AA (2017) Thermal management of concentrated multi-junction solar cells with graphene-enhanced thermal interface materials. Appl Sci 7:589

Renteria JD, Ramirez S, Malekpour H, Alonso B, Centeno A, Zurutuza A, Cocemasov AI, Nika DL, Balandin AA (2015) Strongly anisotropic thermal conductivity of free-standing reduced graphene oxide films annealed at high temperature. Adv Funct Mater 25:4664–4672

Ma WS, Li J, Zhao XS (2013) Improving the thermal and mechanical properties of silicone polymer by incorporating functionalized graphene oxide. J Mater Sci 48:5287–5294. https://doi.org/10.1007/s10853-013-7320-y

Chatterjee S, Wang JW, Kuo WS et al (2012) Mechanical reinforcement and thermal conductivity in expanded graphene nanoplatelets reinforced epoxy composites. Chem Phys Lett 531:6–10

Aradhana R, Mohanty S, Nayak SK (2018) Comparison of mechanical, electrical and thermal properties in graphene oxide and reduced graphene oxide filled epoxy nanocomposite adhesives. Polymer 141:109–123

Yang B, Shi Y, Miao JB, Xia R, Su LF, Qian JS, Chen P, Zhang QL, Liu JW (2018) Evaluation of rheological and thermal properties of polyvinylidene fluoride (PVDF)/graphene nanoplatelets (GNP) composites. Polym Test 67:122–135

Zhang W, Zuo H, Zhang X, Wang J, Guo L, Peng X (2018) Preparation of graphene-perfluoroalkoxy composite and thermal and mechanical properties. Polymers 10:700

Huang X, Lin Y, Fang G (2018) Thermal properties of polyvinyl butyral/graphene composites as encapsulation materials for solar cells. Sol Energy 161:187–193

Guo Y, Xu G, Yang X, Ruan K, Ma T, Zhang Q, Gu J, Wu Y, Liu H, Guo Z (2018) Significantly enhanced and precisely modeled thermal conductivity in polyimide nanocomposites with chemically modified graphene via in situ polymerization and electrospinning-hot press technology. J Mater Chem C 6:3004

Saboori A, Pavese M, Badini C, Fino P (2017) A novel approach to enhance the mechanical strength and electrical and thermal conductivity of Cu-GNP nanocomposites. Metall Mater Trans A 49:1–13

Li J, Cui J, Yang J, Li Y, Qiu H, Yang J (2016) Reinforcement of graphene and its derivatives on the anticorrosive properties of waterborne polyurethane coatings. Compos Sci Tech 129:30–37

Okafor PA, Singh-Beemat J, Iroh JO (2015) Thermomechanical and corrosion inhibition properties of graphene/epoxy ester-siloxane-urea hybrid polymer nanocomposites. Prog Org Coat 88:237–244

Hikku GS, Jeyasubramanian K, Venugopal A, Ghosh R (2017) Corrosion resistance behaviour of graphene/polyvinyl alcohol nanocomposite coating for aluminium-2219 alloy. J Alloy Compd 716:259–269

Liu J, Lei H, Li S, Yu M (2015) Graphene dip coatings: an effective anticorrosion barrier on aluminum. Appl Surf Sci 327:241–245

Chang CH, Huang TC, Peng CW, Yeh TC, Lu HI, Hung WI, Weng CJ, Yang TI, Yeh JM (2012) Novel anticorrosion coatings prepared from polyaniline/graphene composites. Carbon 50:5044–5051

Mahato N, Cho MH (2016) Graphene integrated polyaniline nanostructured composite coating for protecting steels from corrosion: synthesis, characterization, and protection mechanism of the coating material in acidic environment. Constr Build Mater 115:618–633

Luo X, Zhong J, Zhou Q, Du S, Yuan S, Liu Y (2018) Cationic reduced graphene oxide as self-aligned nanofiller in the epoxy nanocomposite coating with excellent anticorrosive performance and its high antibacterial activity. ACS Appl Mater Interfaces 10:18400–18415

Liu J, Yu Q, Yu M, Li S, Zhao K, Xue B, Zu H (2018) Silane modification of titanium dioxide-decorated graphene oxidenanocomposite for enhancing anticorrosion performance of epoxy coatings on AA-2024. J Alloy Compd 744:728–739

Pourhashem S, Vaezi MR, Rashidi A, Bagherzadeh MR (2016) Exploring corrosion protection properties of solvent based epoxy-graphene oxide nanocomposite coatings on mild steel. Corros Sci 115:78–92

Li Y, Wang Q, Wang T, Pan G (2012) Preparation and tribological properties of graphene oxide/nitrile rubber nanocomposites. J Mater Sci 47:730–738. https://doi.org/10.1007/s10853-011-5846-4

Wang F, Mao J (2018) Double layer aligned-graphene nanosheets/styrene-butadiene rubber composites: tribological and mechanical properties. J Appl Polym Sci. https://doi.org/10.1002/app.46939

Wu Y, Chen L, Qin S, Li J, Zhou H, Chen J (2017) Functionalized graphene reinforced rubber composite: mechanical and tribological behavior study. J Appl Polym Sci 134:44970

Chen C, Qiu S, Cui M, Qin S, Yan G, Zhao H, Wang L, Xue Q (2017) Achieving high performance corrosion and wear resistant epoxy coatings via incorporation of noncovalent functionalized graphene. Carbon 114:356–366

Pang W, Ni Z, Wu JL, Zhao Y (2018) Investigation of tribological properties of graphene oxide reinforced ultrahigh molecular weight polyethylene under artificial seawater lubricating condition. Appl Surf Sci 434:273–282

Wang W, Huang C, Guo Y, Song Y, Zhang Y, Liu Y, Du W (2015) Application research progress of graphene composites in electromagnetic fields. Eng Plast Appl 43:143–146

Kang J, Kim D, Kim Y, Choi JB, Hong BH, Kim SW (2017) High-performance near-field electromagnetic wave attenuation in ultra-thin and transparent graphene films. 2D Mater 4:025003

Drakakis E, Kymakis E, Tzagkarakis G, Louloudakis D, Katharakis M, Kenanakis G, Suchea M, Tudose V, Koudoumas E (2016) A study of the electromagnetic shielding mechanisms in the GHz frequency range of graphene based composite layers. Appl Surf Sci 398:15–18

Yousefi N, Sun X, Lin X, Shen X, Jia J, Zhang B, Tang B, Chan M, Kim JK (2014) Highly aligned graphene/polymer nanocomposites with excellent dielectric properties for high-performance electromagnetic interference shielding. Adv Mater 26:5480–5487

Song WL, Cao MS, Lu MM, Yang J, Ju HF, Hou ZL, Liu J, Yuan J, Fan L (2013) Alignment of graphene sheets in wax composites for electromagnetic interference shielding improvement. Nanotechnology 24:115708

Zhang HB, Yan Q, Zheng WG, He Z, Yu ZZ (2011) Tough graphene-polymer microcellular foams for electromagnetic interference shielding. ACS Appl Mater Interfaces 3:918–924

Kim JM, Lee Y, Jang MG, Han C, Kim WN (2016) Electrical conductivity and emi shielding effectiveness of polyurethane foam-conductive filler composites. J Appl Polym Sci 134:44373

Acknowledgement

This work was supported by Supported by Sichuan Science and Technology Program (2018GZ0459).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, F., Wang, H. & Mao, J. Aligned-graphene composites: a review. J Mater Sci 54, 36–61 (2019). https://doi.org/10.1007/s10853-018-2849-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2849-4