Abstract

High purity \(\hbox {In}_2\hbox {O}_3\) nanopowders were subjected to different thermal treatments to investigate the role of defects on the lattice thermal conductivity. The powders were first treated by spark plasma sintering (SPS) at \(700\,^{\circ}\hbox {C}\) and annealed in air between 700 and \(1300\,^{\circ}\hbox {C}\). X-ray diffraction measurements show that the samples are single phase, and the diffraction peaks become sharper with increasing of annealing temperature, indicating improvement in crystallinity and increase in grain size. The \(\hbox {In}_2\hbox {O}_3\) nanopowders were also treated by SPS sintering at different temperatures without subsequent annealing. On the contrary, the average grain size of \(\hbox {In}_2\hbox {O}_3\) treated by SPS has no obvious change with the increase in sintering temperatures. Positron annihilation measurements reveal large amounts of monovacancies and vacancy clusters in the \(\hbox {In}_2\hbox {O}_3\) nanocrystals. The monovacancies gradually recover and the vacancy clusters transform into smaller vacancies with increasing annealing or sintering temperatures. The lattice thermal conductivity increases with the increase in annealing or sintering temperature, which shows close correlation with the recovery of vacancy defects after heat treatment. This gives us strong evidence that vacancy defects play an important role on the suppression of lattice thermal conductivity in nanostructured thermoelectric materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Based on the principles of Seebeck effect, Peltier effect and Thomson effect, thermoelectric (TE) materials can convert temperature difference into electric voltage and vice versa. They have found potential application in waste heat recovery and solid-state cooling [1,2,3]. The utilization of waste heat energy by this technique has potential contribution to the relief of the dependence on fossil fuels and the improvement in environmental pollution. The performance of TE materials is evaluated by the dimensionless figure of merit \(\hbox {ZT}=\sigma S^2T/\kappa \), where S, T, \(\sigma \) and \(\kappa \) are Seebeck coefficient, absolute temperature, electric conductivity and thermal conductivity, respectively.

It is clear that high ZT thermoelectric materials should possess simultaneously large Seebeck coefficient, high electric conductivity and low thermal conductivity. However, these three parameters are not independently controllable, and they are determined by the detailed characteristics of a system, such as carrier concentration, crystalline structure and energy band. [4, 5]. So far, the effective way to increase the dimensionless figure of merit is the reduction in thermal conductivity rather than the improvement in power factor (\(\sigma {S}^2\)). The total thermal conductivity \(\kappa \) is the sum of lattice thermal conductivity \(\kappa _{\mathrm{L}}\) and electronic thermal conductivity \(\kappa _{\mathrm{E}}\) as: \(\kappa = \kappa _{\mathrm{L}} +\kappa _{\mathrm{E}}\), within which the electronic thermal conductivity is related to the electric conductivity by the Wiedemann–Franz law (\(\kappa _{\mathrm{E}}=L\sigma T\), where L is the Lorentz constant).

One effective way to decrease the thermal conductivity is to minimize the lattice thermal conductivity \(\kappa _{\mathrm{L}}\), which is the only independently controllable parameter. This can be accomplished by several approaches, such as the alloy scattering by substituting host atoms with guest dopants, or the “rattle” scattering in skutterudites and clathrates [6]. In case of alloy scattering, it can efficiently increase ZT by enhancing the phonon scattering. The scattering factor A of the guest atom is related to the mass difference of the host and guest atoms as follows [7,8,9]:

where \(\Omega _0\) is the volume of the unit cell, v is the lattice sound velocity, x is the fraction of the guest atom, \(\Delta M\) is the atomic mass difference between the guest and host atoms, and M is the average mass of the cell. It can be seen that the mass difference \(\Delta M\) plays a key role on the reduction in the lattice thermal conductivity, and the larger the mass difference, the larger will be the reduction in \(\kappa _{\mathrm{L}}\). The maximal mass difference can be achieved by introducing vacancies on one or more lattice sites; therefore, the maximal phonon scattering by mass fluctuation can be achieved. Up to now there are several reports which suggest possible effects of vacancy defects on the thermoelectric properties in various materials [10,11,12,13,14,15,16].

It was found that nanostructured thermoelectric materials can also efficiently reduce the lattice thermal conductivity [17,18,19,20]. This is supposed to be due to the phonon scattering at nanoscaled interfaces, which is especially effective for the mid- to long-wavelength phonons, since the grain size is smaller than the phonon mean free path. On the other hand, due to the high fraction of interface region in the nanostructured materials, there are large amounts of defects in these regions, which may also act as phonon scattering centers. However, up to now it is still difficult to confirm the contribution of these interfacial defects to the reduction in lattice thermal conductivity in nanostructured materials, since there is a lack of appropriate probe which is particularly sensitive to the defects in the interface region.

Oxide-based semiconductors are regarded as promising thermoelectric materials because of their superb structural and chemical stability [21]. They can operate at high temperatures in oxygen-containing atmosphere. Among the oxides, indium oxide (\(\hbox {In}_2\hbox {O}_3\)) is a wide band gap semiconductor, which is one candidate for the thermoelectric materials [22]. By co-doping with Zn and Ce, a ZT value of 0.4 at 1050 K has been achieved in \(\hbox {In}_2\hbox {O}_3\) with grain size of 50 nm [23]. A higher ZT value of 0.7 can be obtained when the grain size is further decreased to 20 nm [23]. This suggests that either grain boundary or defect scattering are responsible for the increase in ZT value in naostructured \(\hbox {In}_2\hbox {O}_3\). The role of defects may play a more important role on the reduction in lattice thermal conductivity, since the phonon mean free path will decrease significantly when the oxides work at temperatures higher than 1000 K, and the contribution of grain boundary scattering decreases drastically.

In order to verify the role of vacancies on the lattice thermal conductivity, a proper method to characterize the atomic-scaled defect is necessary. Positron annihilation spectroscopy (PAS) has been proved to be a very sensitive probe to investigate vacancy defects in materials [24, 25]. Positrons are trapped preferentially by vacancy defects where electron density is lower than the perfect bulk crystal. Positron annihilation parameters at vacancy defects are different from those in the bulk state. Therefore, identification of vacancies is very straightforward. A longer positron lifetime or narrower Doppler broadening of the annihilation radiation than the defect-free bulk state thus indicates existence of vacancy defects. Positrons are particularly sensitive to the interfacial defects in nanocrystals. This is because that the grain size is usually smaller than the positron diffusion length (typically about 100 nm). The defect-rich grain boundaries are effective positron trapping centers, so almost all the positrons will diffuse to these regions and annihilate there. In this sense, positron is a self-seeking probe for the interfacial defects, which greatly enhances the sensitivity of positron to interfacial defects. Several works have been published about PAS studies in various nanomaterials [26,27,28,29,30,31,32,33].

In this paper, we studied the effect of thermal treatment on the interfacial defects in \(\hbox {In}_2\hbox {O}_3\) nanocrystals. Positron lifetime, X-ray diffraction (XRD) and scanning electron microscope (SEM) were measured for a comprehensive understanding of the structure and defect characteristics of \(\hbox {In}_2\hbox {O}_3\) nanocrystals after thermal treatment. The electrical properties and thermal conductivity were also studied. An intimate correlation between the phonon thermal conductivity and vacancy defects has been observed.

Experiment

Pure \(\hbox {In}_2\hbox {O}_3\) nanopowders were purchased from Beijing DK nanotechnology Co. LTD with purity \(\ge \,99.9\%\) and grain size of about 20 nm. The powders were hand milled in an agate mortar with pestle for about 2 h, then part of the powders were treated by a spark plasma sintering (SPS) process at \(700\,^{\circ}\hbox {C}\) for 5 min under pressure of 80 Mpa. After sintering, the samples were further annealed in vacuum in a furnace at 700, 900, 1000, 1100, 1200 and \(1300\,^{\circ}\hbox {C}\) for 2 h, respectively. The other part of powders were treated by a SPS process at six temperatures of 500, 600, 700, 800, 900 and \(1000\,^{\circ}\hbox {C}\) for 5 min under pressure of 80 Mpa.

Positron lifetime measurements were performed using a conventional fast–fast coincidence system with a time resolution of 220 ps in full width at half maximum. \(\hbox {A}^{22}\hbox {Na}\) positron source with activity of about 20 μCi was deposited on a Kapton foil with thickness of about 7.5 μm and was then covered by another identical Kapton foil. The source was sandwiched between two identical samples pellets for measurements. Two lifetime spectra with total counts of \(10^6\) for each were measured for every sample after different treatment to ensure the reliability of the measurements. X-ray diffraction (PANalytical Xpert Pro) measurements were conducted using Cu \(\hbox {K}\alpha \) radiation (\(\lambda =0.15418\,\hbox {nm}\)). Scanning electron microscopy (FEI SIRION) was used to investigate the morphology of the specimens after sintering and annealing at different temperatures. Electrical resistivity \(\rho \) and Seebeck coefficient S were measured by a standard four-probe method (ZEM-3, Ulvac Riko, Inc.) under a low-pressure inert gas (He) atmosphere. The thermal conductivity \(\kappa \) was calculated from the measured thermal diffusivity (D), specific heat (\(C_p\)), and density (d) by the formula \(\kappa = D C_p d\). The thermal diffusivity D was measured by the laser flash diffusivity method using a Netzsch LFA-457 system. The relative bulk density d was measured by the Archimedes method, and the specific heat \(C_p\) was measured by a power compensation differential scanning calorimeter (DSC Q20, TA Instruments, USA) in an Ar atmosphere.

Results and discussion

Effect of thermal annealing treatment

Figure 1 shows the XRD patterns measured for the \(\hbox {In}_2\hbox {O}_3\) nanocrystals after SPS treatment at \(700\,^{\circ}\hbox {C}\) and annealed at different temperatures. The samples all show cubic bixbyite-type structure of \(\hbox {In}_2\hbox {O}_3\) (JCPDS Card No. 06-0416) without impurity phase within the detection limit of XRD. The peaks grow higher and become narrower with increasing annealing temperature. This implies that the crystallinity of the sample becomes better after annealing. The average grain size of the annealed \(\hbox {In}_2\hbox {O}_3\) samples is estimated by Scherrer’s formula [34]:

where \(D_\mathrm{hkl}\) is the grain size perpendicular to the (hkl) plane, K is the shape factor (usually taken as 0.9), \(\lambda \) is the X-ray wavelength, \(\beta \) is the linewidth at half maximum intensity of the XRD peak (every observed peak in the spectra was fitted with a Gaussian function), and \(\theta \) is taken as the Bragg angle [34]. The contribution of instrumental broadening in \(\beta \) has been taken into consideration using the standard method. The average grain size of \(\hbox {In}_2\hbox {O}_3\) as a function of annealing temperature is shown in Fig. 2. There is no obvious grain growth after annealing the SPS-treated sample up to \(1000\,^{\circ}\hbox {C}\) with an average grain size of about 35 nm. With increasing annealing temperatures above \(1000\,^{\circ}\hbox {C}\), the grain size shows continuous increase and reaches about 72 nm after annealing at \(1300\,^{\circ}\hbox {C}\).

The morphology of fractured cross section of the samples annealed at some selected temperatures (700, 900, 1100 and \(1300\,^{\circ}\hbox {C}\)) was examined by the scanning electron microscope. The corresponding SEM images are shown in Fig. 3a–d. The average particle size of the \(\hbox {In}_2\hbox {O}_3\) samples annealed at 700 and \(900\,^{\circ}\hbox {C}\) is about 80 nm, which is about two times of the grain size calculated from XRD patterns. This indicates that most particles are small clusters of \(\hbox {In}_2\hbox {O}_3\) crystalline grains. After annealing at \(1100\,^{\circ}\hbox {C}\), the particle morphologies become inhomogeneous. The smallest particle has a diameter of about 50 nm which is consistent with the grain size estimated from the XRD pattern, while the largest one has a diameter of about 500 nm. The larger particles seem to be clusters composed of dozens of small grains. After annealing at \(1300\,^{\circ}\hbox {C}\), significant reorganization of crystallites can be observed, as shown in Fig. 3d. The particle size ranges from 1 to 3 μm which is much larger than the estimated grain size, indicating further agglomeration of grains after annealing at \(1300\,^{\circ}\hbox {C}\).

A detailed study of the microstructural defects in the \(\hbox {In}_2\hbox {O}_3\) nanocrystals was performed by positron lifetime measurements. All the measured positron lifetime spectra were resolved into two components by the computer program PATFIT [35], and the contribution of the background and source component (positron annihilation lifetime and intensity in Kapton foils) was subtracted. Figure 4 shows positron lifetime \(\tau _1\), \(\tau _2\), intensity \({I}_2\) and the average lifetime \(\tau _\mathrm{av}\) of \(\tau _1\) and \(\tau _2\) as a function of annealing temperature. The average positron lifetime \(\tau _\mathrm{av}\) is calculated by the following formula:

The shorter positron lifetime \(\tau _1\) is generally attributed to the free annihilation of positrons without trapping by defects [36, 37]. However, in some disordered systems, annihilation of positrons in smaller vacancies such as monovacancies may also contribute to \(\tau _1\). The reported positron lifetime in perfect \(\hbox {In}_2\hbox {O}_3\) lattice (bulk lifetime \(\tau _\mathrm{b}\)) is about 183 ps [38]. In our result, \(\tau _1\) is obviously longer than the bulk lifetime \(\tau _\mathrm{b}\). This suggests that \(\tau _1\) is a weighted average lifetime of free and trapped positrons. As shown in Fig. 4, the longer lifetime component \(\tau _2\) also decreases monotonically from about 435 to 277 ps with increasing annealing temperature. The ratio of \(\tau _2/\tau _\mathrm{b}\) has the highest value of 2.37 for the sample annealed at \(700\,^{\circ}\hbox {C}\). This suggests that \(\tau _2\) is due to positron trapping at some larger vacancies, such as vacancy clusters, since it is much longer than the bulk lifetime of 183 ps.

According to the two-state positron trapping model [39], the measured lifetime \(\tau _1\) should be related to the trapping rate \(\kappa \) by the following equation:

where \(\lambda _\mathrm{b}\) is the inverse of positron bulk lifetime \(\tau _\mathrm{b}\), and the positron trapping rate \(\kappa \) is proportional to the defect concentration \(C_\mathrm{d}\) (\(\kappa =\mu C_\mathrm{d}\), where \(\mu \) is the trapping coefficient). It can be seen from Fig. 4 that the lifetime \(\tau _2\) shows continuous decrease with increasing annealing temperature, and the average lifetime also shows similar decrease. This suggests that the positron trapping rate most probably decreases after annealing. According to Eq. (3), if we suppose that positrons are trapped by only one type of defects (two-state trapping model), i.e., the lifetime \(\tau _1\) is purely the free annihilation lifetime of positrons, then it should be shorter than \(\tau _\mathrm{b}\), and it will increase with annealing temperature due to the decrease in positron trapping rate \(\kappa \). However, in the present paper, \(\tau _1\) is longer than \(\tau _\mathrm{b}\), and it shows decrease from about 234 ps to about 196 ps with increasing annealing temperature from 700 to \(1300\,^{\circ}\hbox {C}\) as shown in Fig. 4. The opposite trend of \(\tau _1\) confirms that it is a mixture of free annihilation lifetime and trapped lifetime at small vacancies. The decrease in \(\tau _1\) is just due to the recovery of these small vacancies such as In monovacancies.

In order to estimate the size of vacancy defects corresponding to \(\tau _2\), we calculated positron lifetime of vacancy clusters with various size in \(\hbox {In}_2\hbox {O}_3\) using the atomic superposition method [40]. The vacancy clusters contain different number of In–O vacancy pairs, since they contain less dangling bonds and then are more stable in \(\hbox {In}_2\hbox {O}_3\) structures. The calculated positron lifetimes for different vacancy clusters are shown in Fig. 5. The results of In monovacancy are also presented. The positron bulk lifetime in \(\hbox {In}_2\hbox {O}_3\) is about 161 ps, which is shorter than the experimental value. With increasing size of vacancy clusters, positron lifetime shows continuous increase. The ratio of defect lifetime to the bulk lifetime (\(\tau _2/\tau _\mathrm{b}\)) is a relatively reliable parameter to evaluate the size of vacancy defects. For the sample annealed at \(700\,^{\circ}\hbox {C}\), the experimental value of \(\tau _2/\tau _\mathrm{b}\) is 2.37, which corresponds to a vacancy cluster with about ten pairs of atoms of In and O. After annealing at \(1300\,^{\circ}\hbox {C}\), \(\tau _2\) decreases to about 277 ps, and according to the theoretical calculation, the corresponding size of defect reduces to small vacancy cluster which contains only one or two pairs of In and O, indicating that larger vacancy clusters gradually transform into smaller vacancy clusters with increasing annealing temperature. The transformation of clusters suggests that the larger vacancy clusters becomes unstable at higher temperature. As shown in Fig. 4, the average positron lifetime \(\tau _\mathrm{av}\) decreases monotonically from about 270 to 205 ps by almost 65 ps after annealing at \(1300\,^{\circ}\hbox {C}\). This is a more reliable parameter to evaluate any change of the defect properties, because it is insensitive to the decomposition of positron lifetime spectrum by the computer program PATFIT. Thus, it further confirms the recovery of larger vacancy clusters after annealing.

The decrease in positron lifetime shown in Fig. 4 might be also due to the increase in grain size after annealing, since increase in grain size will cause decrease in the fraction of interface region, therefore, the fraction of positron trapping and annihilating at interfacial defects will also decrease. For our samples annealed at different temperatures, the grain size did show some increase from about 35 nm to about 72 nm. But even for grain size of 72 nm, the radius of the grain (36 nm) is still shorter than the positron diffusion length (typically \(\sim 100\,\hbox {nm}\)). Then almost all the positrons will still diffuse to the interface region and annihilate there. So if the defects themselves do not show any recovery, the increase in grain size to only 72 nm will not cause sufficient decrease in positron lifetime. So we believe that the decrease in positron lifetime is due to recovery of interfacial defects, and is less likely due to the increase in grain size.

Figure 6 shows the temperature dependence of electrical resistivity \(\rho \), Seebeck coefficient S, total lattice thermal conductivity \(\kappa \) and lattice thermal conductivity \(\kappa _{\mathrm{L}}\) of \(\hbox {In}_2\hbox {O}_3\) nanocrystals after annealing at different temperatures. For all annealed samples, the Seebeck coefficients are negative, and they decrease almost linearly with increasing measurement temperatures, but they are not very sensitive to the annealing temperatures. The negative Seebeck coefficient indicates that the dominant charge carrier of \(\hbox {In}_2\hbox {O}_3\) samples is electron. This is in agreement with the n-type conductivity of undoped \(\hbox {In}_2\hbox {O}_3\), though the origin of the native donor is still unclear [41]. All the samples show an increasing trend in electrical resistivity with increasing measuring temperature, indicating a metallic conducting behavior. On the other hand, the electrical resistivity decreases monotonically with increasing annealing temperature, which indicates that the electrical resistivity is quite sensitive to the annealing temperature. This is a common phenomenon in oxides, in which the electrical conductivity will increase abruptly after high-temperature annealing due to the production of donor-type defects such as In interstitials or oxygen vacancies. The increase in the carrier mobility might be another reason for the decrease in the resistivity after annealing, since the crystallinity shows improvement as indicated by XRD measurements.

For all the annealed samples, the thermal conductivity shows an overall decrease with increasing measurement temperature. Furthermore, in the whole measurement temperature range of \(25{-}600\,^{\circ}\hbox {C}\), \(\kappa \) shows an increasing trend with increasing annealing temperature. At about \(25\,^{\circ}\hbox {C}\), the value of \(\kappa \) increases from 2.6 to \(5.6\,\hbox {Wm}^{-1}\hbox {K}^{-1}\) after annealing at \(1300\,^{\circ}\hbox {C}\), and at \(600\,^{\circ}\hbox {C}\) it increases from 1.3 to \(2.1\,\hbox {Wm}^{-1}\hbox {K}^{-1}\). The total thermal conductivity \(\kappa \) contains contribution from the lattice thermal conductivity \(\kappa _{\mathrm{L}}\) and electronic thermal conductivity \(\kappa _{\mathrm{E}}\) by the formula \(\kappa =\kappa _{\mathrm{L}}+\kappa _{\mathrm{E}}\). The electronic thermal conductivity can be calculated from the measured electric conductivity by using the Wiedemann–Franz law (\(\kappa _{\mathrm{E}}=L\sigma T\)), where the Lorenz number \(L = 2.45 \times 10^{-8}\,\hbox {W}\Omega \hbox {K}^{-2}\). The lattice thermal conductivity is then estimated after subtracting the calculated electronic thermal conductivity from the total thermal conductivity and is also plotted in Fig. 6. It is clear that the change of lattice thermal conductivity with annealing temperature is nearly the same as the total thermal conductivity, indicating that the contribution of electronic thermal conductivity is very small. Comparing with the positron annihilation measurements, we can find that the increase in lattice thermal conductivity is closely correlated with the recovery process of vacancy defects after annealing. This implies that the phonon scattering by the vacancy-type defects is an effective approach to reduce the lattice thermal conductivity of \(\hbox {In}_2\hbox {O}_3\) nanocrystals.

Figure 7 shows ZT value of the \(\hbox {In}_2\hbox {O}_3\) nanocrystals as a function of measurement temperature after annealing at different temperatures. It is clear that the ZT value shows overall increase with increasing annealing temperature in the whole measurement temperature range of \(25{-}600\,^{\circ}\hbox {C}\). At \(600\,^{\circ}\hbox {C}\), it increases from about 0.07 to about 0.12 after annealing at \(1300\,^{\circ}\hbox {C}\). This is primarily due to the increase in the electrical conductivity after annealing. Though the thermal conductivity shows substantial increase due to the recovery of vacancies after annealing, the electrical conductivity shows a larger increase, thus leads to an increase in ZT value after annealing the sample.

Effect of SPS sintering treatment

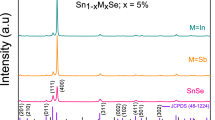

Figure 8 shows the XRD patterns of \(\hbox {In}_2\hbox {O}_3\) nanocrystals after SPS treatment at different temperatures. All the samples show single phase which can be indexed by the cubic bixbyite-type structure of \(\hbox {In}_2\hbox {O}_3\) (JCPDS Card No. 06-0416), and the peaks have no obvious change after sintering. The average grain size is calculated by Eq. (1) and its variation with SPS temperature is shown in Fig. 9. Sintering at different temperatures has no apparent effect on the growth of grain size. After sintering at \(500\,^{\circ}\hbox {C}\), the average grain size is estimated to be around 33 nm, and it has only a slight increase by about 12 nm when the sintering temperature increases to \(900\,^{\circ}\hbox {C}\).

SEM images of fractured cross section of the \(\hbox {In}_2\hbox {O}_3\) compounds sintered at temperatures of 500, 700, and \(1000\,^{\circ}\hbox {C}\) are shown in Fig. 10. The average particle size of the sample sintered at \(700\,^{\circ}\hbox {C}\) is about 60 nm, and it increases with increasing sintering temperature. When the sintering temperature reaches \(1000\,^{\circ}\hbox {C}\), the average particle size is about 400 nm, which indicates significant agglomeration of small crystalline grains, while the grain size keeps almost unchanged as revealed by XRD measurements.

Figure 11 shows the positron lifetime \(\tau _1\), \(\tau _2\), the intensity \({I}_2\) as well as the average lifetime \(\tau _\mathrm{av}\) as a function of the sintering temperature. It is seen that \(\tau _1\) keeps almost constant at about 200 ps before the sintering temperature reaches \(800\,^{\circ}\hbox {C}\), then it begins to decrease, which indicates recovery of some small defects such as monovacancies. The lifetime \(\tau _2\) also keeps unchanged with sintering temperature below \(700\,^{\circ}\hbox {C}\). In this temperature range, the value of \(\tau _2/\tau _\mathrm{b}\) is about 2.09. By comparing with the result of theoretical calculation, the corresponding defect is estimated to be vacancy clusters containing 7 pairs of In and O. When the sintering temperature is above \(700\,^{\circ}\hbox {C}\), \(\tau _2\) shows continuous decrease, and the ratio \(\tau _2/\tau _\mathrm{b}\) decreases to about 1.43 when sintering temperature reaches \(1000\,^{\circ}\hbox {C}\). This ratio corresponds to divacancy which contains one pair of In and O. During the whole sintering temperature range, the intensity \({I}_2\) has no obvious change. The average positron lifetime shows only slight decrease when the sintering temperature is below \(700\,^{\circ}\hbox {C}\), then it shows fast decrease with increasing sintering temperature. This is in agreement with the change of \(\tau _1\) and \(\tau _2\), indicating recovery of monovacancies and vacancy clusters.

The temperature dependence of Seebeck coefficient S, electrical resistivity \(\rho \), total lattice thermal conductivity \(\kappa \) and lattice thermal conductivity \(\kappa _{\mathrm{L}}\) for all the \(\hbox {In}_2\hbox {O}_3\) nanocrystals sintered at different temperatures are shown in Fig. 12. The Seebeck coefficients are all negative in the whole measurement temperature range of \(100{-}600\,^{\circ}\hbox {C}\), which indicates that the carriers are electrons. For the samples sintered at 500, 700 and \(1000\,^{\circ}\hbox {C}\), the electrical resistivity increases monotonically with increasing measurement temperature, which shows the characteristic of metals. It is also clear to see that the electrical resistivity decreases with increasing sintering temperature. This suggests that either more donors are produced, or the mobility of electron increases after high-temperature treatment.

As shown in Fig. 12, the total thermal conductivity \(\kappa \) increases monotonously with increasing sintering temperatures. At measurement temperature of \(600\,^{\circ}\hbox {C}\), the thermal conductivity increases from 0.6 to \(3.5\,\hbox {Wm}^{-1}\,\hbox {K}^{-1}\) after sintering at \(1000\,^{\circ}\hbox {C}\). A similar procedure was performed to subtract the contribution of the electronic thermal conductivity \(\kappa _{\mathrm{E}}\), and the obtained lattice thermal conductivity \(\kappa _{\mathrm{L}}\) of the samples sintered at 500, 700 and \(1000\,^{\circ}\hbox {C}\) is also plotted in Fig. 12. It is found that \(\kappa _{\mathrm{L}}\) increases with the increasing sintering temperature, which shows very similar trend as that of the total thermal conductivity \(\kappa \). Considering the defect properties revealed by positron annihilation measurements, good correlation between the increase in the lattice thermal conductivity and the recovery of vacancy defects after sintering \(\hbox {In}_2\hbox {O}_3\) nanocrystals at elevated temperatures can be observed once again. However, after sintering at high temperatures, the electrical conductivity shows much larger increase, which compensate for the increase in the thermal conductivity, therefore, the ZT factor plotted in Fig. 13 shows increase at higher sintering temperatures. This is similar to the change of ZT for the samples annealed at different temperatures.

There are several reports of the reduced lattice thermal conductivity in nanocrystalline thermoelectric materials [43,44,45,46]. It is generally believed that the grain boundaries are the key factor to reduce lattice thermal conductivity [42]. A large number of experiments have confirmed the decrease in lattice thermal conductivity with decreasing grain size in the nanocrystalline thermoelectric materials [23, 42, 47, 48]. However, in the nanocrystals there are also large amounts of defects in the grain boundary region. With decreasing grain size, the defect concentration also increases due to increase in the fraction of the grain boundary region. The defects are obviously phonon scattering centers in the nanocrystalline thermoelectric materials [49]. Therefore, it is difficult to clarify whether the effect on lattice thermal conductivity comes mainly from defect or grain boundary scattering. In the present study, we also could not distinguish these two factors for the samples annealed at different temperatures, since the grain size shows considerable increase with increasing annealing temperature. However, for the samples sintered at different temperatures, the grain size has no obvious change, which indicates that the fraction of grain boundary region is almost the same. Interestingly, the lattice thermal conductivity still shows increase with elevated sintering temperature. This indicates that the change of lattice thermal conductivity is due to other factors instead of grain size effects. Our positron lifetime results clearly indicate that the In monovacancies gradually recover and vacancy clusters also transform into smaller vacancy clusters at higher sintering temperature. Therefore, we can conclude that the increase in lattice thermal conductivity after sintering is mostly due to the recovery of vacancies in the interface region. In other words, the vacancies in the grain boundary region are effective phonon scattering centers in nanocrystalline thermoelectric materials.

Conclusion

\(\hbox {In}_2\hbox {O}_3\) nanopowders were treated with the spark plasma sintering (SPS) at \(700\,^{\circ}\hbox {C}\) followed by annealing at temperatures between 700 and \(1300\,^{\circ}\hbox {C}\). The average grain size of the annealed samples was obtained by XRD measurements, which increases with increasing annealing temperature. A comparative study is also performed in which the \(\hbox {In}_2\hbox {O}_3\) nanopowders were sintered at temperature between \(500{-}1000\,^{\circ}\hbox {C}\). On the contrary, the average grain size of the samples sintered at different temperatures has no obvious change. Positron lifetime measurements reveal monovacancies and vacancy clusters in the nanocrystalline samples, and they gradually recover with increasing thermal treatment temperature. It can be concluded that vacancy-type defects in the grain boundary region play an important role in the lattice thermal conductivity of nanocrystalline \(\hbox {In}_2\hbox {O}_3\).

References

Nolas GH, Sharp GJ, Goldsmid HJ (2001) Thermoelectrics. Springer, Berlin

Venkatasubramanian R, Siivola E, Colpitts T, O’Quinn B (2001) Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 413:597–602

Bell LE (2008) Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 321:1457–1461

Wang Y, Sui Y, Wang XJ, Su WH, Liu XY (2010) Enhanced high temperature thermoelectric characteristics of transition metals doped \({\text{Ca}}_3{\text{Co}}_4{\text{O}}9+\delta \) by cold high-pressure fabrication. J Appl Phys 107:033708

Mahan GD (1997) Good thermoelectrics. Solid State Phys 51:81–157

Beekman M, Morelli DT, Nolas GS (2015) Better thermoelectrics through glass-like crystals. Nat Mater 14:1182–1185

Callaway J, von Baeyer HC (1960) Effect of point imperfections on lattice thermal conductivity. Phys Rev 120:1149–1154

Klemens PG (1955) The scattering of low-frequency lattice waves by static imperfections. Proc Phys Soc Sect A 68:1113–1128

Abeles B (1963) Lattice thermal conductivity of disordered semiconductor alloys at high temperatures. Phys Rev 131:1906–1911

Pei YZ, Morelli DT (2009) Vacancy phonon scattering in thermoelectric \({\text{In}}_2{\text{Te}}_3\) CInSb solid solutions. Appl Phys Lett 94:122112

Dasgupta T, Stiewe C, Hassdorf R, Zou AJ, Boettcher L, Mueller E (2011) Effect of vacancies on the thermoelectric properties of \({\text{Mg}}_2{\text{Si}}_{1-x}{\text{Sb}}_x\) (0\(\le \) x \(\le \) 0.1). Phys Rev B 83:235207

Zhu GH, Lan YC, Wang H, Joshi G, Hao Q, Chen G, Ren ZF (2011) Effect of selenium deficiency on the thermoelectric properties of \(n\)-type \({\text{In}}_{4}{\text{Se}}_{3- x}\) compounds. Phys Rev B 83:115201

Ji HS, Kim H, Lee C, Rhyee JS, Kim MH, Kaviany M, Shim JH (2013) Effect of selenium deficiency on the thermoelectric properties of n-type \({\text{In}}_4{\text{Se}}_{3-x}\) compounds. Phys Rev B 87:125111

Popuri SR, Scott AJM, Downie RA, Hall MA, Suard E, Decourt R, Pollet M, Bos JWG (2014) Glass-like thermal conductivity in \({\text{SrTiO}}_{3}\) thermoelectrics induced by A-site vacancies. RSC Adv 4:33720–33723

Bennett NS, Wight NM, Popuri SR, Bosb JWG (2015) Efficient thermoelectric performance in silicon nano-films by vacancy-engineering. Nano Energy 16:350–356

Li W, Lin SQ, Zhang XY, Chen ZW, Xu XF, Pei YZ (2016) Thermoelectric properties of \({\text{Cu}}_2{\text{SnSe}}_4\) with intrinsic vacancy. Chem Mater 28:6227–6232

Pichanusakorn P, Bandaru P (2010) Nanostructured thermoelectrics. Mater Sci Eng R 67:19–63

Wu Y, Finefrock SW, Yang HR (2012) Nanostructured thermoelectric: opportunities and challenges. Nano Energy 1:651–653

Alam H, Ramakrishna S (2013) A review on the enhancement of figure of merit from bulk to nano-thermoelectric materials. Nano Energy 2:190–212

Fitriani OR, Long BD, Barma MC, Riaz M, Sabri MFM, Said SM, Saidur R (2016) A review on nanostructures of high-temperature thermoelectric materials for waste heat recovery. Renew Sustain Energy Rev 64:635–659

Ren GK, Lan JL, Zeng CC, Liu YC, Zhan B, Butt S, Lin YH, Nan CW (2015) High performance oxides-based thermoelectric materials. JOM 67:211–221

Guilmeau E, Berardan D, Simon C, Maignan A, Raveau B, Ovono D, Delorme F (2009) Tuning the transport and thermoelectric properties of \({\text{In}}_{2}{\text{O}}_{3}\) bulk ceramics through doping at In-site. J Appl Phys 106:053715

Lan JL, Lin YH, Liu Y, Xu SL, Nan CW (2012) High thermoelectric performance of nanostructured \({\text{In}}_{2}{\text{O}}_{3}\)-based ceramics. J Am Ceram Soc 95:2465–2469

Dupasquier A, Mills AP Jr (1995) Positron spectroscopy of solids. IOS Press, Amsterdam

Krause-Rehberg R, Leipner HS (1999) Positron annihilation in semiconductors, defect studies, springer series in solid-state sciences, vol 127. Springer, Berlin

Nambissan PMG, Upadhyay C, Verma HC (2003) Positron lifetime spectroscopic studies of nanocrystalline \({\text{ZnFe}}_2{\text{O}}_4\). J Appl Phys 93:6320–6326

Chakrabarti S, Chaudhuri S, Nambissan PMG (2005) Positron annihilation lifetime changes across the structural phase transition in nanocrystalline \({\text{Fe}}_2{\text{O}}_3\). Phys Rev B 71:064105

Biswas S, Kar S, Chaudhuri S, Nambissan PMG (2006) Positron annihilation studies of defects and interfaces in ZnS nanostructures of different crystalline and morphological features. J Chem Phys 125:164719

Dutta S, Chattopadhyay S, Jana D, Banerjee A, Manik S, Pradhan SK, Sutradhar M, Sarkar A (2006) Annealing effect on nano-ZnO powder studied from positron lifetime and optical absorption spectroscopy. J Appl Phys 100:114328

Mishra AK, Chaudhuri SK, Mukherjee S, Priyam A, Saha A, Das D (2007) Characterization of defects in ZnO nanocrystals: photoluminescence and positron annihilation spectroscopic studies. J Appl Phys 102:103514

Ghoshal T, Biswas S, Kar S, Chaudhuri S, Nambissan PMG (2008) Positron annihilation spectroscopic studies of solvothermally synthesized ZnO nanobipyramids and nanoparticles. J Chem Phys 128:074702

Wang D, Chen ZQ, Wang DD, Qi N, Gong J, Cao CY, Tang Z (2010) Positron annihilation study of the interfacial defects in ZnO nanocrystals: correlation with ferromagnetism. J Appl Phys 107:023524

Chaudhuri SK, Ghosh M, Das D, Raychaudhuri AK (2010) Probing defects in chemically synthesized ZnO nanostrucures by positron annihilation and photoluminescence spectroscopy. J Appl Phys 108:064319

Cullity BD (1978) Elements of X-ray diffraction, vol 9. Addison-Wesley, Philippines, p 284

Kirkegaard P, Pederson NJ, Eldrup M (1989) \({\text{Ris}}\phi \) Report M2740; \({\text{Ris}}\phi \) National Laboratory: DK-4000 Roskilde, Denmark

Sanyal D, Banerjee D, De U (1998) Probing (\({\text{Bi}}_{0.92}{\text{Pb}}_{0.17})_2{\text{Sr}}_{1.91}{\text{Ca}}_{2.03}{\text{Cu}}_{3.06}{\text{O}}_{10+\delta}\) superconductors from 30 to 300 K by positron-lifetime measurements. Phys Rev B 58:15226–15230

de la Cruz RM, Pareja R, Gonzalez R, Boatner LA, Chen Y (1992) Effect of thermochemical reduction on the electrical, optical-absorption, and positron-annihilation characteristics of ZnO crystals. Phys Rev B 45:6581–6586

Korhonen E, Tuomisto F, Bierwagen O, Speck JS, Galazka Z (2014) Compensating vacancy defects in Sn- and Mg-doped \({\text{In}}_2{\text{O}}_3\). Phys Rev B 90:245307

Puska MJ, Nieminen RM (1994) Theory of positrons in solids and on solid surfaces. Rev Mod Phys 66:841–897

Puska MJ, Nieminen RM (1983) Defect spectroscopy with positrons: a general calculational method. J Phys F Met Phys 13:333–346

Tomita T, Yamashita K, Hayafuji Y, Adachi H (2005) The origin of n-type conductivity in undoped \({\text{In}}_2{\text{O}}_3\). Appl Phys Lett 87:051911

Takashiri M, Miyazaki K, Tanaka S, Kurosaki J, Nagai D, Tsukamoto H (2008) Effect of grain size on thermoelectric properties of n-type nanocrystalline bismuth-telluride based thin films. J Appl Phys 104:084302

Takashiri M, Borca-Tasciuc T, Jacquot A, Miyazaki K, Chen G (2006) Structure and thermoelectric properties of boron doped nanocrystalline \({\text{Si}}_{0.8}{\text{Ge}}_{0.2}\) thin film. J Appl Phys 100:54315

Wang XW, Lee H, Lan YC, Zhu GH, Joshi G, Wang DZ, Yang J, Muto AJ, Tang MY, Klatsky J, Song S, Dresselhaus MS, Chen G, Ren ZF (2008) Enhanced thermoelectric figure of merit in nanostructured n-type silicon germanium bulk alloy. Appl Phys Lett 93:193121

Poudel B, Hao Q, Ma Y, Lan YC, Minnich A, Yu B, Yan X, Wang DZ, Muto A, Vashaee D, Chen XY, Liu JM, Dresselhaus MS, Chen G, Ren ZF (2008) High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320:634–638

Bux SK, Blair RG, Gogna PK, Lee H, Chen G, Dresselhaus MS, Kaner RB, Fleurial JP (2009) Nanostructured bulk silicon as an effectivethermoelectric material, fleurial. Adv Funct Mater 19:2445–2452

Chiritescu C, Mortensen C, Cahill DG, Johnson D, Zschack P (2009) Lower limit to the lattice thermal conductivity of nanostructured \({\text{Bi}}_{2}{\text{Te}}_{3}\)-based materials. J Appl Phys 106:073503

Foley BM, Brown-Shaklee HJ, Duda JC, Cheaito R, Gibbons BJ, Medlin D, Ihlefeld JF, Hopkins PE (2012) Thermal conductivity of nano-grained \({\text{SrTiO}}_3\) thin films. Appl Phys Lett 101:231908

Lan YC, Minnich AJ, Chen G, Ren ZF (2010) Enhancement of thermoelectric figure-of-merit by a bulk nanostructuring approach. Adv Funct Mater 20:357–376

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant Nos. 11475130, 11575131 and 11775163.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, H.F., Zhao, B., Qi, N. et al. Role of vacancy defects on the lattice thermal conductivity in In2O3 thermoelectric nanocrystals: a positron annihilation study. J Mater Sci 53, 12961–12973 (2018). https://doi.org/10.1007/s10853-018-2544-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2544-5