Abstract

Attachment energy model was adopted to research the influence of external growth environments on ε-HNIW crystal morphology. The morphology of ε-HNIW crystal in acetone–cyclohexane binary systems was simulated with cyclohexane mass fraction of 0.05, 0.10, 0.15 and 0.20, respectively. The influences of 0.80 acetone on ε-HNIW morphology were studied in the acetone–toluene, acetone–benzene and acetone–dichloromethane binary system. Besides, the effects of the temperature and supersaturation on ε-HNIW crystal morphology were also examined in the acetone–cyclohexane system. The simulation results reveal that ε-HNIW crystal morphology almost maintains consistent with the increase in cyclohexane ratio. Contrarily, the variations of the anti-solvent, the temperature and the supersaturation affect ε-HNIW crystal morphology dramatically. Furthermore, the influence of model dimension on the attachment energy was discussed, and a reasonable model size was obtained. The radial distribution function analysis was performed to explore the adsorption and diffusion behaviours of the solvent molecules on the ε-HNIW surfaces. Overall, the simulation results can provide some guidance for the crystallization process of ε-HNIW.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

As the representative of high energy density materials (HEDMs), hexanitrohexaazaisowurtzitane (HNIW) has attracted much attention since it was first synthesized by Nielsen [1]. Compared with octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine (HMX), HNIW possesses higher energy, greater density, stronger detonation pressure, faster detonation velocity as well as higher sensitivity [2, 3]. Sensitivity is a critical property of energetic material that is directly affected by the crystal morphology. Crystals with needle- or plate-like morphology exhibit higher impact and friction sensitivity than that with sphere-shaped crystals of the same size [4]. That is to say, energetic materials can be desensitized by modifying the crystal morphology. Accordingly, it is of important value to investigate the technique of morphology control for the application of HNIW.

The irregular crystal morphology of the energetic materials hinders its application. The morphology is determined by both the internal structure factors and the external conditions [5]. Crystallization is a traditional way to control the morphology by changing solvents, additives and adjusting operation conditions, among which the solvent is considered to be one of the most important factors [6,7,8]. By combining experiment and computation, the influence of solvent on crystal morphology from macroeconomic and microeconomic can be investigated. Computational simulation can achieve the goal in an economical and environment-friendly way, with more microscopic details of the interaction between solvent and crystal. Experiment can examine the accuracy of the simulation. The development of computational technology has generated many simulation methods for the prediction of the crystal morphology, and molecular dynamics (MD) simulation that can provide atomic-scale information has become a powerful one of these methods [5]. Numerous researches have successfully simulated the crystal morphology by MD method [9,10,11,12,13,14,15,16].

In this study, acetone was selected as the solvent for HNIW, while cyclohexane, toluene, benzene and dichloromethane were selected as the anti-solvents [17]. In order to build a crystal/solvent double-layered model with reasonable size for the molecular dynamic simulations, we have discussed the influences of supercell crystal length, width, thickness and the amount of solvent on the attachment energy in the paper. On this basis, Materials Studio (MS) 6.0 software was employed to predict the morphology of HNIW crystals in acetone–cyclohexane binary systems with the cyclohexane mass fraction of 0.05, 0.10, 0.15 and 0.20, as well as that in acetone–toluene, acetone–benzene and acetone–dichloromethane binary system with acetone mass fraction of 0.80. Furthermore, the influence of the temperature ranging from 298 to 328 K together with the supersaturation ranging from 1.00 to 1.35 on the morphology was investigated systematically.

Currently, many researchers adopt attachment energy (AE) model to study the influence of solvent or additive on the crystal morphology [18, 19]. In addition, most articles extend a single-crystal surface to a 3 × 3 × 3 supercell to calculate the solvent-effect attachment energy [10, 14, 18, 20,21,22,23]. But 3 × 3 × 3 supercell is not an universal size, and for many crystal surfaces the accuracy of this size is low. Besides, there is no unified standard for adding how many solvent molecules, which is an important parameter for the morphology simulation. In this study, we systematically investigated the influences of supercell crystal length, width, thickness and the amount of solvent on the attachment energy. Based on the results, we proposed a reasonable size of solvent/crystal surface double-layered model. The size can be applied to other crystal morphology study. Eventually, we predicted the morphology of HNIW in different binary systems, when the model size was confirmed.

Computational and experimental

Theory

The morphology of crystals can be affected by many factors such as temperature, solubility, supersaturation, additive, solvent and adsorption energy of solvent and solute molecules [22]. The classic attachment energy (AE) model assumes that the relative growth rate of a crystal surface is proportional to the absolute value of the attachment energy of the corresponding crystal surface [26]. Most crystals are grown from solvent which can reduce the growth rate of crystal surfaces, because the solvent molecules have to be removed from the surface before the crystal face growth. This costs energy and herewith the attachment energy decreases. Therefore, the classic AE model is failure to simulate crystals morphology grown from solution, which may be attributed to disregarding the external crystallization conditions. Since the effects of the growth environment have been taken into account, the classic attachment energy (AE) model that neglects the external crystallization conditions should be modified accordingly [21].

Based on two-dimensional nucleation mechanism [24], the growth rate of crystal surface is mostly dominated by the nucleation rate of the surface (J). Then, the normal growth rate of crystal face (R hkl ) can be expressed by the following equation:

where h is the height of the step formed by nucleation, generally thought as the interplanar space [25], and S stands for the area of the surface swept by the two-dimensional critical nucleus. The nucleation rate of the crystal surface is expressed as:

where v0 is the collision frequency of atoms or molecules in the growth surface, ΔGC represents the system Gibbs energy change when the formation of a stable critical size of crystal nucleus in the growth surface. The ΔGC can be calculated by the following equation [26, 27]

where γ is the surface free energy in solution, ω stands for the molecular specific volume and kTσ represents the driving force of solution growth.

Hartman [26] has proposed the following equation to show the relation between the attachment energy (Eatt) of the crystal face and its surface free energy

where Z is the number of molecules of formula units in a primitive unit cell of volume, d hkl represents the interplanar spacing of the lattice, and V stands for mesh area.

Saska [28] has concluded that the change of crystal surface free energy in solution resulted from the adsorption interactions between solvents and crystal faces, which can be calculated by the following formula,

where ES represents the solvent adsorption interactions. Therefore, γ in solution can be rewritten as:

Combining Eqs. (3) and (6), the following equation can be derived as:

Then, a deformation of Eq. (1) can be obtained as:

where Z, d hkl and Vp are crystal bulk properties. For a given solution crystallization condition such as the determined T and σ, when the two-dimensional nucleation growth mechanism is obeyed, it is seen from Eq. (8) that R hkl is shown to be approximately proportional to the (Eatt − ES)

The modified attachment energy (E Satt ) is defined to represent the (Eatt − ES). And ES can be calculated by the following equation,

where Aacc is the solvent-accessible area of the crystal face in the unit cell, Abox is the super crystal face area of the (h k l) plane, and Eint is the interaction energy between the solvent and crystal surface that can be calculated by the following equation,

where Etot stands for the total energy of the solvent layer and crystal surface, Esurf represents the energy of the crystal surface without the solvent layer, and Esolv is the energy of the solvent layer without the crystal surface.

Simulation details

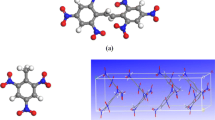

At ambient temperature and 0.1 MPa, HNIW exists in four different polymorphic modifications, i.e. α, β, γ and ε, among which ε-HNIW with lattice parameters of a = 13.696 Å, b = 12.554 Å, c = 8.833 Å, β = 111.18° [29] possesses the highest stability and has higher value in application compared with other polymorphs. Therefore, ε-HNIW was used to conduct the MD simulations in this study. The geometry of the unit lattice is optimized through smart algorithm of Forcite module under COMPASS force field which has been parameterized and validated by the prediction of condensed phase properties [5]. The experimental lattice parameters and the optimized values of ε-HNIW are listed in Table 1. It can be found that the relative deviations between the optimized lattice parameters and the experimental values are within 2%, which demonstrates that the COMPASS force field is suitable for the simulation of ε-HNIW.

The vacuum morphology of ε-HNIW was predicted by the AE model. The dominant faces exposed on ε-HNIW crystal in vacuum were built by cleaving the surface along the corresponding (h k l) directions. Then, the solvent amorphous cells were built, of which the lengths and widths should match the sizes of ε-HNIW faces and the thicknesses depended on the amount of the solvent molecules.

The dynamic simulation of 400 ps for each face was performed in NVT ensemble under COMPASS force field at the given temperature with the Andersen thermostat. The electrostatic interaction was calculated by Ewald method with an accuracy of 0.0001 kcal mol−1, and van der Waals force was computed by the atom-based method with the cut-off distance of 15.5 Å.

Experimental process

The incubator was used to cultivate ε-HNIW crystals in acetone–cyclohexane binary systems with the cyclohexane mass fraction of 0.05, 0.10, 0.15 and 0.20, as well as that in acetone–toluene, acetone–benzene and acetone–dichloromethane binary system with acetone mass fraction of 0.80 under 298 K. Similarly, ε-HNIW crystals were cultivated in the acetone–cyclohexane binary system at 298, 308, 318 and 328 K, respectively. Then, the morphology of the recrystallization samples of ε-HNIW was observed using scanning electron microscopy (SEM) to test the consistency between the computational results and experimental results.

Results and discussion

Vacuum morphology of ε-HNIW

The crystal morphology of ε-HNIW in vacuum with six dominant faces calculated by the AE model is exhibited in Fig. 1a. The predicted crystal habit under vacuum conditions is similar to the spherical shape with an aspect ratio of 1.436. The molecular interactions between ε-HNIW molecules calculated by morphology module and visualized by crystal graph are shown in Fig. 1b. It has been proven that the growth rate of crystal increases as the interaction becomes stronger [30]. In Fig. 1b, the blue lines represent strong interactions, while the red lines represent weak interactions, which means that ε-HNIW grows faster along the direction of blue lines than that of red lines. On the basis of the periodic bond chain (PBC) theory, the strongest bonds usually exist in the direction along which crystals grow fastest. The faces with fast growth rates will disappear and the surfaces with slow growth rates will occupy the final crystal surface, resulting in the crystal habit of ε-HNIW in vacuum dominated by six faces. The relevant parameters of the six dominant faces (1 1 0) (1 1 − 1) (0 0 1) (2 0 0) (0 1 1) and (2 0 − 1) are listed in Table 2. Among them, the (1 1 0) face, with the largest total habit facet area percentage S%, possesses the strongest morphological importance.

In order to understand the interactions between solvent molecules and different ε-HNIW crystal faces, the molecular packing structures of ε-HNIW crystal faces are displayed in Fig. 2, in which the blue grid on the ε-HNIW crystal face stands for the accessible solvent surface. The calculated solvent-accessible area (Aacc), surface area (A hkl ) and corresponding Aacc/A hkl values for different crystal faces of ε-HNIW are presented in Table 3. From the molecular arrangement of ε-HNIW morphologically significant surfaces, it is illustrated that the (2 0 0) (1 1 − 1) (2 0 − 1) and (1 1 0) faces are relatively flat at molecular level, while (0 1 1) and (0 0 1) are uneven with many large voids. Accordingly, a larger value of Aacc/A hkl indicates a more complex surface topography easy for the adsorption of solvent molecules, probably resulting in a larger energy correction term Es and dramatically influencing the final morphology. Besides, the exposed atoms of different ε-HNIW crystal faces are different as well, which may have a great effect on the interaction between ε-HNIW faces and solvent.

The influence of model size on E Satt

Model dimension is a key factor that influences the E Satt and thus significantly affects the final predicted morphology. If the model dimension is too small, the deviation of the calculated E Satt will be large, which results in inaccurate simulated results. On the contrary, if the model size is too large, the simulation will last a long time without a considerable promotion of the accuracy. Therefore, it is a critical step to find out a suitable model size to meet the accuracy requirement and consume less time. In this study, the influence of model size on the E Satt was systematically investigated as follows. Firstly, the size of solvent amorphous cell is fixed, and the thickness of HNIW crystal surface (tc) is changed to search the suitable tc. Secondly, the size of HNIW supercell is fixed, and the thickness of the solvent (ts) is changed to select the suitable ts. Thirdly, the tc and ts are fixed, and the area of HNIW surface is changed to search the suitable area. The detailed steps are displayed in Fig. 3.

The (1 1 0) with the largest S% and (0 1 1) with the largest Aacc/A hkl were taken as examples to illustrate the influence of model size on E Satt . The calculated E Satt affected by the model size is summarized in Table 4 and Fig. 4.

The simulation results demonstrate that with the increase in the model size, the E Satt increases rapidly initially and then almost maintains constant. The studies of the influences of the solvent thickness (ts) and crystal thickness (tc) on the E Satt reveal that when ts and tc are smaller than the cut-off distance (dc) of van der Waals forces, the E Satt increases rapidly, and when ts and tc are larger than dc, the E Satt almost maintains constant. Thus, the ts and tc of the model should be no less than dc, or the accuracy will be low, and it is unnecessary to set the ts and tc too large. The investigation of the influence of crystal area on the E Satt reveals that when both the length and width of the supercell are less than 2dc, the E Satt increases with the increase in the length and width, and when both the length and width are larger than 2dc, the E Satt almost maintains unchanged. Therefore, a ε-HNIW crystal/solvent model with the length and width of the supercell no less than 2dc and the ts and tc larger than dc should be constructed to meet the accuracy and simulation time requirement. Since the intermolecular interactions between ε-HNIW and solvent molecules are mainly hydrogen bonds, van der Waals forces and electrostatic interactions, the effective range of these non-bond energies should be within the dc. When the ts is much larger than dc, the solvent molecules far from the ε-HNIW supercell have little interaction with ε-HNIW, so they have little effect on the simulation results, and so is the tc. Meanwhile, the length and width of the model should be greater than 2dc. Taking a solvent molecule as an example, the interaction range between solvent and crystal is within the red circle, as shown in Fig. 5. Therefore, if the width or length is less than 2dc, the interaction between the solvent and the atoms of ε-HNIW molecules that beyond the range may be neglected. Besides, if the size of the crystal area is too large, the atoms that beyond the red circle have almost no interaction with the solvent, so both the length and width of ε-HNIW supercell should be 2dc.

The influence of anti-solvent ratio on ε-HNIW morphology

Industrially, most crystals grow from solution, which affects the morphology remarkably. Compared with those in vacuum, crystals of ε-HNIW grown from solution need to remove solvent molecules adsorbed on the surfaces, which consumes some energy. The consumed energy is the energy correction term ES, which can be calculated by the interaction energy between ε-HNIW surfaces and solvent molecules. When the ES is obtained, the solvent-effected attachment energy E Satt can be computed, and then, the morphology of ε-HNIW crystal can be predicted. Generally, ε-HNIW is mainly obtained by anti-solvent crystallization method. Acetone and cyclohexane are commonly used as solvent and anti-solvent for ε-HNIW crystallization, respectively. In order to investigate the influence of anti-solvent ratio on ε-HNIW crystal morphology, the morphology of ε-HNIW crystals in acetone–cyclohexane binary systems with cyclohexane mass fraction of 0.05, 0.10, 0.15 and 0.20 was simulated, respectively. The simulated results of interaction energies and crystal habit properties are summarized in Table 5. The negative interaction energies of ε-HNIW crystal/solvent systems indicate that the adsorption of solvent molecules on ε-HNIW faces is exothermic and thermodynamically favourable [5]. The predicted morphologies of ε-HNIW crystals affected by acetone–cyclohexane with different cyclohexane ratios are displayed in Fig. 6. In order to examine the accuracy of the simulation results, ε-HNIW crystals were cultivated in acetone–cyclohexane binary systems with cyclohexane mass fraction of 0.05, 0.10, 0.15 and 0.20 at 298 K using incubator. As the mass fraction of anti-solvent has few influences on HNIW morphology, Fig. 6 only displays the SEM of ε-HNIW in the acetone–cyclohexane binary system with the cyclohexane ratio of 0.2.

From the simulation results, it can be seen that only (1 1 0) and (1 1 − 1) are still exposed on ε-HNIW crystals affected by solvents, probably because these two faces grow slower than others in acetone–cyclohexane binary systems. All the simulated crystal habits of ε-HNIW present fusiform shape, which have a great agreement with the experimental results. Combining the computational and experimental results, it can be concluded that the simulation method and the model size are suitable for the morphology study of ε-HNIW. With the increase in anti-solvent ratio, ε-HNIW crystal morphology almost maintains constant, and the aspect ratio, relative surface/volume ratio and the percentage area (S%) of ε-HNIW-exposed crystal faces change little as well. So, it is impossible to control ε-HNIW crystal morphology by changing cyclohexane ratio. Assuming that the increase in cyclohexane is a continuous process, this simulation can be regarded as the anti-solvent crystallization process. Assuming that ε-HNIW crystal nuclei start to generate when the mass fraction of cyclohexane reaches 0.05 and ε-HNIW crystals continue to grow with the increase in cyclohexane ratio from 0.05 to 0.20, it can be demonstrated that the morphology of crystal is mainly determined by the nucleation step in the crystallization process through the simulation. When the nucleation is occurred, the morphology will stay unchanged without the addition of other additives.

The influence of different anti-solvents on ε-HNIW morphology

The difference in polarity and dipole moment between different anti-solvents may result in different interactions between anti-solvent molecules and crystals, thus having a large influence on crystal morphology. Based on this, the influences of acetone–cyclohexane, acetone–toluene, acetone–benzene and acetone–dichloromethane on ε-HNIW crystal morphology were investigated to figure out whether different anti-solvents can affect ε-HNIW crystal morphology differently. The simulated results of interaction energies and crystal habit properties are summarized in Table 6, and the predicted morphology of ε-HNIW crystals affected by different binary systems is displayed in Fig. 7. The morphologies of ε-HNIW crystal, cultivating from acetone–cyclohexane, acetone–toluene, acetone–benzene and acetone–dichloromethane at 298 K, are depicted in Fig. 7 as well.

The simulation results show that all the ε-HNIW crystals grown from these four systems assume fusiform shape, though there are differences in aspect ratio, relative surface/volume ratio and S% between each other. Besides, there are three dominant faces exposed on ε-HNIW crystals in acetone–toluene system, while there are only two in other cases, because the interaction energy between the (2 0 − 1) face and solvent molecules is much higher in acetone–toluene system than those in other systems, which makes it more difficult to remove the acetone–toluene molecules attached on the surface. Therefore, the growth rate of the (2 0 − 1) face in acetone–toluene is slower than those in other systems, which results in (2 0 − 1) exposed on ε-HNIW crystal surface. The ε-HNIW crystal was cultivated in acetone–cyclohexane, acetone–toluene, acetone–benzene and acetone–dichloromethane at 298 K, respectively. The experimental morphology of ε-HNIW shows a great agreement with the simulation results, which demonstrated that the computation can provide guidances for the experiment. The simulation and experiment results reveal that anti-solvents can significantly affect the growth rate of (2 0 − 1) face that influences the crystal morphology. And the acetone–toluene binary solution contributes to the preparation of spherical crystals of ε-HNIW than acetone–cyclohexane, acetone–benzene and acetone–dichloromethane.

The influence of temperature on ε-HNIW crystal morphology

Temperature greatly affects the growth rate, nucleation rate, solubility, supersaturation and hence the morphology of crystals [6, 31]. Accordingly, the attachment energies at different temperatures were calculated to explore the relationship between ε-HNIW crystal morphology and temperature. The simulated results are summarized in Table 7, and the predicted morphology of ε-HNIW crystals at different temperature is displayed in Fig. 8. The morphologies of ε-HNIW crystal, cultivating from acetone–cyclohexane at 298, 308, 318 and 328 K, are depicted in Fig. 8 as well.

Comparing the morphology of ε-HNIW crystals predicted at different temperatures, it can be concluded that the areas of the (0 0 1) (2 0 − 1) faces increase with the increase in temperature. It is because higher temperature makes the attachment energy between (0 0 1) or (2 0 − 1) and solvent molecules decrease, causing these two faces to grow slower and appear in the final ε-HNIW crystal surface. The simulated results show a great agreement with the experimental outcomes. The experimental results show that with the increase in temperature the particle diameter of ε-HNIW presents the tendency of decrease. The simulation and experiment results reveal that temperature can significantly affect the growth rate of (2 0 − 1) face that influences the crystal morphology. Combining the computational and experimental results, it can be concluded that the increasing temperature makes the aspect ratio decrease and the number of surface increase, which indicates that higher temperature contributes to the preparation of spherical crystals of ε-HNIW.

The influence of supersaturation on ε-HNIW crystal morphology

Supersaturation greatly affects the rate of growth, nucleation rate and hence the morphology of the crystals [22, 31]. Generally, higher supersaturation contributes to nucleation and makes the final crystal volume small. Accordingly, a double-layered model (Fig. 9) was built for the calculation of the attachment energies in acetone–cyclohexane (0.2) with different supersaturations to explore the relationship between ε-HNIW crystal morphology and supersaturation. The simulated results are summarized in Table 8, and the predicted morphology of ε-HNIW crystals affected by acetone–cyclohexane systems with different supersaturations is displayed in Fig. 10.

The increasing supersaturation can hardly change the aspect ratios and relative surface/volume ratios of ε-HNIW crystals. However, the volumes decrease and the areas of (0 0 1) (2 0 − 1) increase evidently with the increase in supersaturation. The nucleation competes with the crystal growth in the crystallization process, based on which higher supersaturation contributes to the nucleation and helps prepare crystals of small particle, while lower supersaturation is conducive to the crystal growth and the preparation of crystals of large particle. Higher supersaturation makes the nucleation possess a higher rate compared with the crystal growth, which is difficult for the growth of most crystal faces. As a result, only the (0 0 1) (2 0 − 1) are exposed on the final ε-HNIW crystal surface.

Radial distribution function (RDF) of the interfacial model

In statistical mechanics, the RDF in a system of particles (atoms, molecules, colloids, etc.) describes how density varies as a function of distance from a reference particle. It is a measure of the probability of finding a particle at a distance of r away from a given reference particle. The RDF analysis is widely used in structural investigations of both solid and liquid packings, studying specific interactions such as hydrogen bonds and van der Waals forces. Ordinarily, the distance ranges of hydrogen bonding interactions and van der Waals interactions are within 3.1 and 3.1–5.0 Å, respectively. In contrast, the electrostatic interactions exhibit a large distance range of above 5.0 Å [10]. Taking the (1 1 0) face and acetone–cyclohexane binary system with cyclohexane mass fraction of 0.20 for example, the RDF diagram of ε-HNIW-O ~ solvent-H, ε-HNIW-N ~ solvent-H and ε-HNIW-H ~ solvent-O is displayed in Fig. 11.

In Fig. 11, there are two strong peaks on the RDF curve of ε-HNIW-H ~ solvent-O, within 3.1 Å and above 5.0 Å, respectively, which illustrates that hydrogen bonding and electrostatic interaction may exist between ε-HNIW-H and solvent-O. Moreover, the intensities of these two peaks are larger than ε-HNIW-O ~ solvent-H and ε-HNIW-N ~ solvent-H peaks, which indicates the interactions between ε-HNIW surface and solvent molecules mainly consist of the interaction between ε-HNIW-H and solvent-O. Similarly, there are two weak peaks on the RDF curve of ε-HNIW-O ~ solvent-H, within 3.1 and 3.1–5.0 Å, respectively, which illustrates that hydrogen bonds and van der Waals forces may exist between ε-HNIW-O and solvent-H. There is no obvious peak on the RDF curve of ε-HNIW-N ~ solvent-H, illustrating that the interaction between ε-HNIW-N and solvent-H is weak. Since the binding energy of hydrogen bonding is higher than Van der Waals forces and Coulomb interaction, for the same surface, the existence of hydrogen bonding will consume more energy for the growth of ε-HNIW, and thus, the surface area of the crystal will be large. On the contrary, if there is not hydrogen bonding, the surface area will be small. Therefore, we can select a solvent which can form hydrogen bonding with the surface of large area and not form hydrogen bonding with the surface of small area to ameliorate crystal morphology.

Conclusions

The morphology and dominant faces of ε-HNIW crystals in vacuum and binary systems were predicted by the AE model. Then, the RDF was employed to analyse the interaction energies between ε-HNIW surface and solvent molecules. The major results obtained can be summarized as follows:

-

1.

The size of ε-HNIW/binary system interfacial model used for molecular dynamic simulations was modified, of which the length, width and thickness of the ε-HNIW supercell should be larger than 2dc, 2dc and dc, respectively, and the thickness of solvent amorphous cell should be larger than dc.

-

2.

Some morphological important faces of ε-HNIW crystals disappear with the effect of solvent molecules. Therefore, external growth environments have great influence on ε-HNIW crystal morphology, which can help prepare products of specific shape to meet the requirements of different applications.

-

3.

The RDF analysis demonstrates that the interaction energies between ε-HNIW and solvents that cause the variation of the attachment energies may consist of hydrogen bonds and electrostatic interactions between ε-HNIW-H and solvent-O. By comparison, the interactions between ε-HNIW-O, ε-HNIW-N and solvent-H are relatively weak.

References

Nielsen AT (1997) Caged polynitramine compound. US Pat 5,693,794

Lobbecke S, Bohn MA, Pfeil A (1998) Thermal behavior and stability of HNIW (CL-20). In: Proceedings of 29th international conference of ICT, Karlsruhe

Vávra P (1999) Procedure for selection of molecular structures of explosives having high performance. In: Proceedings of 30th international conference of ICT, Karlsruhe

Zhou Q, Chen Z, Zheng C, Wang B, Ren X, Wang K, Wang M, Zhou C (2014) Effect of morphology of FOX-7 crystals on its sensitivity. Chin J Explos Propellants 37:67–69

Shi W, Xia M, Lei W, Wang F (2014) Solvent effect on the crystal morphology of 2,6-diamino-3,5-dinitropyridine-1-oxide: a molecular dynamics simulation study. J Mol Graph Model 50:71–77

Singh MK, Banerjee A (2013) Role of solvent and external growth environments to determine growth morphology of molecular crystals. Cryst Growth Des 6:2413–2425

Hod I, Mastai Y, Medina DD (2011) Effect of solvents on the growth morphology of DL-alanine crystals. Cryst Eng Commun 2:502–509

Li C, Choi P (2008) Molecular dynamics study on the effect of solvent adsorption on the morphology of glycothermally produced α-Al2O3 particles. J Phys Chem C 112:10145–10152

Hors JH, Geertman RM, Rosmalen GM (2001) The effect of solvent on crystal morphology. J Cryst Growth 230:277–284

Liu N, Li Y, Zeman S, Shu Y, Wang B, Zhou Y, Zhao Q, Wang W (2016) Crystal morphology of 3,4-bis(3-nitrofurazan-4-yl)furoxan (DNTF) in a solvent system: molecular dynamics simulation and sensitivity study. CrystEngComm 18:2843–2851

Feng L, Cao D, Wang J, Chen L, Chen F, Zhang N, Liu P (2015) Prediction of crystal morphology of MTIN. Chin J Energy Mater 23:443–449

Xiong S, Chen S, Jin S, Li L (2016) Additives effects on crystal morphology of dihydroxylammonium 5,5′-Bistetrazole-1,1′-diolate by molecular dynamics simulations. J Energy Mater 34:384–394

Wang D, Chen S, Li Y, Yang J, Wei T, Li L (2015) Effect of solvent on the crystal morphology of royal demolition explosive. J Beijing Inst Technol 24:260–268

Yan T, Wang J, Liu Y, Zhao J, Yuan J, Guo J (2015) Growth and morphology of 1,3,5,7-tetranitro-1,3,5,7-tetraazacy-clooctane (HMX) crystal. J Cryst Growth 430:7–13

Chen G, Xia M, Lei W, Wang F, Gong X (2013) A study of the solvent effect on the morphology of RDX crystal by molecular modeling method. J Mol Model 19:5397–5406

Berkovitch-Yellin Z (1985) Toward an ab initio derivation of crystal morphology. J Am Chem Soc 107:8239–8253

Jin SH, Lei XD, Ou YX, Liu JQ, Song QC (2005) Influence of anti-solvent property on the modes of crystallization of HNIW. Acta Armamentarii 26:743–745

Xiong SL, Chen SS, Jin SH, Li LJ (2016) Additives effects on crystal morphology of dihydroxylammonium 5,5′-bistetrazole-1,1′-diolate by molecular dynamics simulations. J Energy Mater 4:384–394

Mao XL, Song XF, Lu GM, Xu YX, Sun YZ, Yu JG (2015) Effect of additives on the morphology of calcium sulfate hemihydrate: experimental and molecular dynamics simulation studies. Chem Eng J 278:320–327

Chen F, Liu YY, Wang JL, Su NN, Li LJ, Chen HC (2017) Investigation of the co-solvent effect on the crystal morphology of β-HMX using molecular dynamics simulations. Acta Phys Chim Sin 33:1140–1148

Chen G, Chen CY, Xia MZ, Lei W, Wang FY, Gong XD (2015) Molecular dynamics investigation of the effect of solvent adsorption on crystal habits of hexogen. RSC Adv 5:25581–25589

Wang C, Zhang X, Du W, Huang YH, Guo MX, Li Y, Zhang ZX, Hou BH, Yin QX (2016) Effects of solvent and supersaturation on crystal morphology of cefaclor dihydrate: a combined experimental and computer simulation study. CrystEngComm 18:9085–9094

Chen G, Xia MZ, Lei W, Wang FY, Gong XD (2014) Molecular dynamics investigation of the effect of solvent adsorption on crystal habits of hexogen. Can J Chem 92:849–854

Leamy HJ, Gilmer GH, Jackson KA, Blakely JM (1975) Surface physics of materials. Academic Press, New York

Kim JW, Park DB, Shim HM, Kim HS, Koo KK (2012) Crystallization of RDX by drowning-out combined with fines dissolution and cooling process. Ind Eng Chem Res 51:3758–3765

Hartman P, Bennema P (1980) The attachment energy as a habit controlling factor: I. Theoretical considerations. J Cryst Growth 49:145–156

Zhang Y (2004) Ph.D. thesis, Tianjing university

Saska M, Myerson AS (1983) The theoretical shape of sucrose crystals from energy calculations. J Cryst Growth 61:546–555

Zhao X, Shi N (1996) Crystal and molecular structure of ε-HNIW. Chin Sci Bull 41:574–576

Zhao Q, Liu N, Wang B, Wang W (2016) A study of solvent selectivity on the crystal morphology of FOX-7 via a modified attachment energy model. RSC Adv 6:59784–59793

Singh MK, Tiwari VS (2015) Uncovering the mode of action of solvent and additive controlled crystallization of urea crystal: a molecular-scale study. Cryst Growth Des 15:3220–3234

Acknowledgements

The work was supported by the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lan, G., Jin, S., Li, J. et al. The study of external growth environments on the crystal morphology of ε-HNIW by molecular dynamics simulation. J Mater Sci 53, 12921–12936 (2018). https://doi.org/10.1007/s10853-018-2543-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2543-6