Abstract

In this study, high-energy electron beam irradiation was used for the first time for graft polymerization of acrylic acid onto the surface of carbon black (CB) to prepare water-dispersible CB. The grafted CB was characterized by Fourier transform infrared spectroscopy, thermo-gravimetric analysis and X-ray photoelectron spectroscopy. The results indicate that polyacrylic acid (PAA) has been successfully grafted onto the surface of CB. The particle size and dispersion stability of unmodified and modified CBs in aqueous solution were determined by dynamic light scattering, transmission electron microscopy and ultraviolet–visible spectrophotometer. The results show that the grafted CB has smaller average aggregate size and better dispersion than unmodified CB. In addition, there is no significant difference in the grafting degree among grafted CBs prepared in nitrogen and air at different irradiation doses, indicating that oxygen and irradiation dose have a negligible effect on the grafting degree of PAA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carbon black (CB) has been widely used as reinforcing filler, conductive agent and pigment due to its excellent physical and chemical properties [1,2,3], and it can improve the mechanical and electrical properties of polymers in many industrial applications [4, 5]. CB consists of many irregular aggregates with a particle size ranging from tens of nanometers to hundreds of nanometers [6]. However, it is susceptible to agglomeration and exhibits a poor dispersion in aqueous solution due to its strong hydrophobicity [7, 8]. Therefore, the surface of CB needs to be modified in order to improve its dispersion. Many methods have been proposed for this purpose, such as oxide modification, graft modification and addition of dispersants [9,10,11]. Chen et al. [12] prepared oxidized CB by ozone treatment, and they found that surface oxidation could decrease surfactant adsorption of CB. Li et al. [13] decomposed polyvinyl alcohol (PVA) into long-chain groups, which were then grafted onto the CB surface by the ultrasonic method, and the modified CB showed excellent dispersion in aqueous solution. Itoh et al. [14] showed that the lattices of poly(meth)acrylates functioned efficiently as dispersants and binders for aqueous CB paint, which resulted in good painting on the paper surface. Thus, grafting polymers onto the surface of CB are capable of improving its dispersion in the polymer matrix [15].

Anionic, cationic and radical graft polymerizations onto the CB surface have been studied extensively [16]. CB is an excellent radical scavenger that can easily capture free radicals. In recent years, radiation (e.g., ultrasonic radiation, high-energy electron beam (EB) radiation and γ-ray radiation) has been widely used as an efficient and environmentally friendly radical polymerization method for preparing new or modified polymers [17, 18]. However, EB irradiation appears to be more efficient and convenient in commercial production than other radiation methods, thus making it widely used in polymer processing and material modification [19,20,21]. Wu et al. modified CB by EB irradiation in air and investigated the effect of irradiation dose on the morphology and particle size of modified CB. They found that EB irradiation resulted in a dramatic increase in oxygen content on the CB surface and its average particle size decreased with the increase in EB irradiation dose [22]. EB has also the ability to produce crosslinked networks, under initiator-free or ambient temperature conditions [23]. Ahmad et al. [24] reported that EB irradiation induced chain scission and crosslinking in CB filled with linear low density polyethylene.

CB is widely used as a colorant in water-based ink, a sustainable printing ink because of its environmentally friendly advantages [25], and considerable interests have been devoted to the preparation of CB dispersible in aqueous solution. High-energy EB irradiation-induced graft polymerization of hydrophilic monomers is a suitable method for preparing water-dispersible CB.

In a previous study, Bo et al. [26] prepared methyl methacrylate (MMA) monomer and maleic anhydride/diallylphthalate (MAH/DAP) co-monomer grafted CBs by γ-ray irradiation at normal pressure and room temperature. However, the irradiation process lasted a long time and the modified CBs were oil-soluble. In this study, EB irradiation was applied to initiate the graft polymerization of acrylic acid (AA) onto the surface of CB in order to prepare water-dispersible CB for use in water-based ink and pigment. The results show that EB irradiation is much more efficient than γ-ray radiation, and more importantly, it can be applied to prepare water-dispersible CB in a large scale. To our knowledge, this is for the first time to use EB to prepare PAA-grafted CB.

Experimental

Materials

Conductive CB VXC-72 with an average primary particle size of 30 nm was donated by Cabot Corp (Boston, MA). Its specific surface area was 254 m2 g−1, which was calculated using the Brunauer–Emmett–Teller (BET) method. The as-received CB was fully dried under vacuum at 120 °C for 24 h in order to eliminate the water absorbed on the surface of CB particles before use.

AA was purchased from Shanghai Lingfeng Chemical Reagent Co., Ltd. (Shanghai, China). It was purified by reduced pressure distillation and stored in a refrigerator at 2 °C. Ethyl alcohol (EA) (AR, Shanghai Titan Scientific Co., Ltd., China) was used without any further purification.

Sample preparation

The modified CB was prepared as follows: 2 g of CB, 4 mL of AA and 40 mL of EA were put into a 100-mL beaker and then treated by ultrasound at 40 Hz and 350 W for 30 min. After that, the mixture was irradiated by a high-energy EB at 40, 60 or 80 kGy in N2 or air atmosphere, respectively, and the products were filtrated and washed three times with EA and dried at 120 °C for 24 h under vacuum. Before characterization, all modified CBs were extracted by Soxhlet for 48 h in order to remove PAA homopolymer and residual AA monomer. Figure 1 shows the flowchart for preparation of PAA-grafted CB.

Characterization

Fourier transform infrared spectra (FT-IR)

The FT-IR spectra of CB samples in KBr pellets were recorded using a Nicolet 5700 spectrophotometer from 500 to 4000 cm−1 at a scan number of 32 and a resolution of 4 cm−1 under ambient conditions.

Thermo-gravimetric analysis (TGA)

The thermo-gravimetric properties of CB samples were characterized on a NETZSCH STA 449F3 analyzer. About 10 mg of dried sample was placed in an aluminum pan under nitrogen atmosphere and heated from room temperature to 700 °C at 10 °C min−1.

Dynamic light scattering (DLS)

The aggregate particle size of CB samples dispersed in deionized water was determined by DLS on a Marvern ZEN 3600 Zetasizer (measurement range 0.04–2000 μm) at 25 °C. The multiple scattering effect could be avoided using a very low concentration of CB dispersed in deionized water (10 mg L−1).

Measurement of grafting degree

The degree of grafted CB with PAA was determined by the difference in weight loss between modified CB and unmodified CB. The grafting degree (G) was calculated by the following equation:

where WA and WB are the weight loss of modified CB and unmodified CB during the heating process from 190 to 540 °C and WC is the weight of grafted CB at 500 °C. The results of grafting degree are the average values of three measurements.

X-ray photoelectron spectroscopy (XPS)

XPS was performed on an ESCALAB 250Xi spectrometer, using a standard Al Kα X-ray source at the analyzer pass energy of 20 eV. Samples were mounted using a double-sided adhesive tape, and binding energies were referenced to the C1s binding energy of adventitious carbon at 284.6 eV.

Transmission electron microscopy (TEM)

TEM observation was performed on a JEM-1400 electron microscope at an accelerating voltage of 120 kV. CB samples dispersed in deionized water (0.5 g L−1) were dropped onto a 200-mesh copper mesh with a carbon supporting film, and excess liquid was removed by filter paper and dried under an infrared lamp.

Ultraviolet–visible spectrophotometer (UV–Vis)

The dispersion stability of CB in deionized water was measured by a UV-2550 spectrophotometer at a wavelength of 364 nm. Before testing, CB was added into the deionized water at a concentration of 0.1 mg mL−1 and dispersed for 30 min by supersonic wave. The light transmittance of the diluted suspension was determined using a spectrophotometer, and the dispersion stability was characterized by the following dispersion stability index (D) [27]:

where T0 is the light transmittance of pure water and Ts is the light transmittance of CB or modified CB dispersion.

Results and discussion

Effects of oxygen and irradiation dose

Oxygen can inhibit the graft polymerization of polymer monomers onto CB surface because it is a scavenger of radicals and graft polymerization is mostly carried out under nitrogen atmosphere. In order to investigate the effects of oxygen and irradiation dose on the grafting degree of CB, CB samples irradiated in air or N2 at different irradiation doses were prepared.

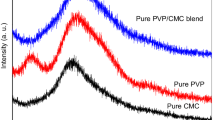

The chemical groups on CB surface were determined by FT-IR. Figure 2 shows the FT-IR spectrum of PAA. The characteristic peak of PAA is observed at 1718 cm−1, which can be assigned to the stretching vibration of C=O and can be used to confirm the grafting of PAA onto CB surface [28]. The broad absorption peak at ~ 3400 cm−1 corresponds to the –OH stretching of PAA [29].

The FT-IR spectra of unmodified and modified CB samples irradiated in air and N2 at different irradiation doses are shown in Fig. 3. The absorption peaks at 3434 and 1629 cm−1 are attributed to the stretching vibration of O–H and C=C on the surface of unmodified CB, respectively. The absorption peaks at around 1710 and 2900 cm−1 are observed in the FT-IR spectra of all modified CBs, which are attributed to the stretching vibration of C=O and C–H on CB surface, respectively. The peak at about 3400 cm−1 can be attributed to the –OH stretching vibration [30]. Compared with unmodified CB, a new peak appears at 1710 cm−1 which is close to the characteristic peak of PAA at 1718 cm−1, indicating that PAA has been successfully grafted onto the surface of CBs. The shift of carbonyl stretching vibration may be influenced by the interaction between PAA and CB [31]. However, it is interesting to note that there is no obvious difference in the FT-IR spectra among modified CBs under different irradiation conditions.

The TGA and corresponding derivative thermo-gravimetric (DTG) curves of unmodified CB and pure PAA are shown in Figs. 4 and 5. Figure 4 shows that almost no decomposition of unmodified CB occurs below 500 °C. Figure 5 shows three weight loss stages for PAA. The first stage occurring at < 150 °C can be attributed to the evaporation of moisture [32]; the second one occurring at 190–276 °C can be attributed to the decomposition of carboxylic acid groups in PAA [33]; and the last one occurring at 380–540 °C can be attributed to the rupture of PAA backbone. Figure 6 shows the TGA curves of modified CBs under different conditions. All modified CBs experience obvious thermal weight loss below 500 °C and a decrease tendency which is similar to that of unmodified CB above 540 °C. The thermal weight loss of modified CBs at 190–540 °C is similar to that of PAA, indicating that PAA has been successfully grafted onto the surface of CB.

Figure 7 shows the grafting degree and its error bar of modified CBs under different irradiation conditions obtained from Eq. (1). It shows that as the irradiation dose increases from 40 to 80 kGy, the grafting degree of CBs irradiated in air increases from 5.16 to 6.14 wt%, while that irradiated in N2 increases from 5.61 to 6.54 wt%. The difference in the grafting degree is within 1 wt%, indicating that irradiation dose has low impact on the grafting degree in the experimental dose range. This may be because irradiation dose can only slightly affect the number of active sites on the CB surface. The grafting degree of modified CB prepared in nitrogen atmosphere without oxygen is slightly higher than that prepared in air atmosphere with oxygen. Oxygen is a scavenger of radicals, and thus, it can affect the radical polymerization. However, the difference in the grafting degree is within 0.4 wt% at the same irradiation dose, indicating that oxygen may have a negligible effect on the grafting degree of modified CB during the irradiation reaction process.

The distribution of aggregate particle sizes of unmodified CB and modified CBs dispersed in water is shown in Fig. 8, and their average aggregate particle sizes are shown in Table 1. The average aggregate size of modified CBs decreases with the decrease in irradiation dose. Moreover, the average aggregate size of CBs modified in air is smaller than that modified in N2 at the same irradiation dose, both of which are smaller than that of unmodified CB (376.2 nm). It is noteworthy that the particle size of CB irradiated at 80 kGy in N2 is 387.1 nm, with an increase of 2.9% compared with that of unmodified CB. The difference in aggregate particle sizes between modified CBs prepared in air and N2 can be attributed to the fact that oxygen can inhibit the radical polymerization and thus can reduce the molecular chain length of grafted PAA.

The high surface area of CB makes it easy to form aggregates due to the van der Waals interaction [34]. PAA grafting can not only decrease the surface energy of CB, but also increase its hydrophilic characteristics. The comparison between the grafting degree and the DLS results shows that the average aggregate size of modified CB can be affected by both surface coating and improved dispersion in the solution.

The average aggregate size of CB prepared in air at 40 kGy is much smaller than that prepared under other conditions, with a decrease of up to 32% compared with that of unmodified CB. Taking into account the production cost, production efficiency and water dispersibility, EB irradiation in air at 40 kGy is preferable, and thus, the modified CB prepared under this condition is discussed later.

XPS analysis of unmodified CB and modified CBs

The XPS analysis shows that the main elements of CB are carbon and oxygen. The grafting of PAA results in a decrease in carbon content, but an increase in oxygen content. Table 2 shows that the carbon content is decreased from 97.72 to 92.23%, while the oxygen content is increased from 2.28 to 7.77%.

The C1s peaks of XPS spectra of unmodified and modified CBs are curve fitted, as shown in Fig. 9 and Table 3. C–OH and C–O–C (binding energy (BE): 285.4 eV), C–O (BE: 286.9 eV), and COOH and COO– (BE: 288.7 eV) groups are observed in the XPS spectra of both unmodified and modified CBs [35]. There is an obvious change in the functional groups on the CB surface after modification. The dominant functional groups are C–O and COO– groups in both unmodified and modified CBs. EB irradiation results in a significant increase in the C=O (4.5%) and COO– groups (25.7%) compared with that of unmodified CB (1.6 and 21.0%, respectively), indicating that the oxygenous groups are introduced onto the surface of modified CB by grafting with PAA.

Dispersion of unmodified and modified CBs

Figure 10 shows the TEM micrographs of unmodified and modified CBs at different magnifications. It is clear that unmodified CB has some large aggregates of several micrometers in size, which, however, are not observed in modified CB, and the average aggregate size of modified CB is smaller than that of unmodified CB. CB particles tend to aggregate due to the strong van der Waals force. CB is hydrophobic, and thus, the interaction between CB particles and water molecules is very weak, which makes it difficult for CB particles to disperse in water. However, PAA-grafted CB particles become hydrophilic because of the strong interaction between PAA molecular chains with water molecules, and thus, they are easily dispersible in water. Besides, the PAA chains on the surface of modified CB can produce steric hindrance and electrostatic repulsion, which can prevent the aggregation of CB particles [36, 37]. The breakage of CB aggregates by high energy of EB can also contribute to the smaller average aggregate size of modified CB.

Figure 11 shows the dispersion stability of unmodified and modified CBs in aqueous solution under the condition of free settlement according to Eq. (2). The dispersion stability index of unmodified and modified CBs after 150 h changes by 66.2 and 3.2%, respectively. Thus, PAA grafting can improve the dispersion and stability of CB in aqueous solution.

Conclusions

PAA-grafted CB was successfully prepared by high-energy EB irradiation in this study, and the results show that the grafting degree of modified CBs obtained under different conditions ranges from 5.16 to 6.54%. There is no significant difference in the grafting degree among PAA-grafted CBs prepared in air or nitrogen atmosphere at the same irradiation dose, indicating that oxygen has a negligible effect on the grafting degree of modified CB during the irradiation. Besides, the effect of irradiation dose on the grafting degree of modified CB can also be ignored. The high-energy EB irradiation enables PAA-grafted CB to have excellent dispersion and stability in aqueous solution. EB is a promising approach for preparing water-dispersible CB in a large scale.

References

Donnet JB, Bansal RC, Wang MJ (1993) Carbon black: science and technology, 2nd edn. Marcel Dekker, New York. ISBN 082478975X

West DHD, Mcbrierty VJ, Delaney CFG (1979) A positron annihilation study of carbon black and carbon-black-filled polybutadiene. Appl Phys 18:85–92. https://doi.org/10.1007/s10853-017-1680-7

Iijima M, Yamazaki M, Nomura Y, Kamiya H (2013) Effect of structure of cationic dispersants on stability of carbon black nanoparticles and further processability through layer-by-layer surface modification. Chem Eng Sci 85:30–37. https://doi.org/10.1016/j.ces.2012.02.020

Zhang W, Blackburn RS, DehghaniSanij AA (2009) Carbon black reinforced epoxy resin nanocomposites as bending sensors. J Compos Mater 43:367–376. https://doi.org/10.1177/0021998308099308

Francis LF, Grunlan JC, Sun J, Gerberich WW (2007) Conductive coatings and composites from latex-based dispersions. Colloids Surf A 311:48–54. https://doi.org/10.1016/j.colsurfa.2007.08.026

Zhu L, Lu Y, Wang Y, Zhang L, Wang W (2012) Preparation and characterization of dopamine-decorated hydrophilic carbon black. Appl Surf Sci 258:5387–5393. https://doi.org/10.1016/j.apsusc.2012.02.016

Zhou X, Li Q, Wu C (2008) Grafting of maleic anhydride onto carbon black surface via ultrasonic irradiation. Appl Organomet Chem 22:78–81. https://doi.org/10.1002/aoc.1352

Hauptman N, Gunde MK, Kunaver M, Bešter-Rogac M (2011) Influence of dispersing additives on the conductivity of carbon black pigment dispersion. J Coat Technol Res 8:553–561. https://doi.org/10.1007/s11998-011-9330-5

Shi PW, Li QY, Li YC, Wu CF (2014) Preparation and characterization of poly(sodium 4-styrenesulfonate)-decorated hydrophilic carbon blackby one-step in situ ball milling. Colloids Surf A 443:135–140. https://doi.org/10.1016/j.colsurfa.2013.10.060

Buttrya DA, Pengb JCM, Donnetb JB, Rebouillatc S (1999) Immobilization of amines at carbon fiber surfaces. Carbon 37:1929–1940. https://doi.org/10.1016/s0008-6223(99)00064-0

Donnet JB, Rebouillat S, Wang TK, Peng J (1998) Carbon fibers, 3rd edn. Marcel Dekker Inc, New York. ISBN 0824701720

Chen X, Farber M, Gao Y, Kulaots I et al (2003) Mechanisms of surfactant adsorption on non-polar, air-oxidized and ozone-treated carbon surfaces. Carbon 41:1489–1500. https://doi.org/10.1016/s0008-6223(03)00053-8

Li Q, Wu G, Ma Y, Wu C (2007) Grafting modification of carbon black by trapping macroradicals formed by sonochemical degradation. Carbon 45:2411–2416. https://doi.org/10.1016/j.carbon.2007.06.052

Itoh Y, Ozaki K, Maezawa R (2013) Hydrolyzable-emulsifier-containing polymer latices as dispersants and binders for waterborne carbon black paint. J Appl Polym Sci 130:3869–3873. https://doi.org/10.1002/app.39479

Tsubokawa N, Satoh T, Murota M, Sato S, Shimizu H (2001) Grafting of hyperbranched poly(amidoamine) onto carbon black surfaces using dendrimer synthesis methodology. Polym Adv Technol 12:596–602. https://doi.org/10.1002/pat.148

Liu T, Jia S, Tomasz Kowalewski A, Matyjaszewski K et al (2003) Grafting poly(n-butyl acrylate) from a functionalized carbon black surface by atom transfer radical polymerization. Langmuir 19:6342–6345. https://doi.org/10.1021/la034219d

Reichmanis E, Nalamasu O, Houlihan FM, Novembre AE (2015) Radiation chemistry of polymeric materials: novel chemistry and applications for microlithography. Polym Int 48:1053–1059. https://doi.org/10.1002/(SICI)1097-0126(199910)48:10<1053::AID-PI268>3.0.CO;2-T

Iwata H, Nakanoya T, Morohashi H, Chen J et al (2006) Novel gas and contamination sensor materials from polyamide-block-poly(ethylene oxide)-grafted carbon black. Sens Actuat B Chem 113:875–882. https://doi.org/10.1109/icsens.2003.1279080

Singh D, Singh NL, Qureshi A, Gavade C, Avasthi DK et al (2010) Electrical and thermal studies on the polyvinylchloride/carbon black composites induced by high energy ion beam. Integr Ferroelectr 117:85–96. https://doi.org/10.1080/10584587.2010.489429

Trenikhin MV, Ivashchenko OV, Eliseev VS (2015) Electron microscopy investigation of structural transformation of carbon black under influence of high-energy electron beam. Fuller Nanotub Carbon Nanostruct 23:801–806. https://doi.org/10.1080/1536383x.2014.1003639

Sapinski M, Dehning B, Guerrero A, Meyer M, Kroyer T, Switzerland G, Carbon fiber damage in particle beam. In: Proceedings of HB2010, Morschach, Switzerland

Wu Y, Wen S, Shen J, Jiang J, Hu S, Zha L, Liu L (2015) Improved dynamic properties of natural rubber filled with irradiation-modified carbon black. Radiat Phys Chem 111:91–97. https://doi.org/10.1016/j.radphyschem.2015.02.020

Sahoo BP, Naskar K, Dubey KA, Choudhary RNP, Tripathy DK (2013) Study of dielectric relaxation behavior of electron beam-cured conductive carbon black-filled ethylene acrylic elastomer. J Mater Sci 48:702–713. https://doi.org/10.1007/s10853-012-6782-7

Ahmad A, Mohd DH, Abdullah I (2004) Electron beam irradiation of carbon black filled linear low-density polyethylene. J Mater Sci 39:1459–1461. https://doi.org/10.1023/b:jmsc.0000013917.04266.79

Zhou X, Li Y, Fang C, Li S, Cheng Y, Lei W, Meng X (2015) Recent advances in synthesis of waterborne polyurethane and their application in water-based ink: a review. J Mater Sci Technol 31:708–722. https://doi.org/10.1016/j.jmst.2015.03.002

Bo Y, Cui J, Cai Y, Xu S (2016) Preparation and characterization of poly(methylmethacrylate) and poly(maleicanhydride-co-diallylphthalate) grafted carbon black through γ-ray irradiation. Radiat Phys Chem 119:236–246. https://doi.org/10.1016/j.radphyschem.2015.11.005

Xu H, Cao Y, He X, Wu Y, Zhang Y, Wu C (2009) Influence of in situ grafting on the dispersion of carbon black in solvents and natural rubber. J Macromol Sci B 48:1190–1200. https://doi.org/10.1080/00222340903275768

Socrates G (1994) Infrared characteristic group frequencies: tables and charts, 2nd edn. Wiley, New York. ISBN 0471852988

Lee S, Lee H, Sim JH, Sohn D (2014) Graphene oxide/poly(acrylic acid) hydrogel by γ-ray pre-irradiation on graphene oxide surface. Macromol Res 22:165–172. https://doi.org/10.1007/s13233-014-2025-x

Ding W, Wang L (2014) Synthesis of poly(acrylic acid) grafted carbon black and its application for sensing ethanol. J Polym Res 21:1–7. https://doi.org/10.1007/s10965-014-0425-4

Li Q, Wu G, Zhang X, Wu C (2006) Preparation of poly(n-butyl acrylates) en-capsulated carbon black via ultrasonic irradiation initiating emulsion poly-merization. Polym J 38:1245–1250. https://doi.org/10.1295/polymj.pj2006053

Lu S, Duan M, Lin S (2003) Synthesis of superabsorbent starch-graft-poly(potassiumacrylate-co-acrylamide) and its properties. J Appl Polym Sci 88:1536–1542. https://doi.org/10.1002/app.12025

Zhu L, Zhang L, Tang Y, Yang J (2013) Synthesis and adsorption of organo-montmorillonite/poly(acrylic acid) superabsorbent composite. Polym Polym Compos 21:21–26. https://doi.org/10.1016/j.polymertesting.2013.01.001

Ding W, Wang L, Yang Q et al (2013) Recent research progress on polymer grafted carbon black and its novel applications. Int Polym Proc 28:132–142. https://doi.org/10.3139/217.2678

Strzemiecka B, Voelkel A, Donate-Robles J, Martín-Martínez JM (2014) Assessment of the surface chemistry of carbon blacks by TGA-MS, XPS and inverse gas chromatography using statistical chemometric analysis. Appl Surf Sci 316:315–323. https://doi.org/10.1016/j.apsusc.2014.07.174

Liu H, Wang S, Xiao Y, Li X (2016) Studies on the dispersity of polymethacrylate-grafted carbon black in a non-aqueous medium: the influence of monomer structure. J Mater Sci-Mater Electron 27:2022–2030. https://doi.org/10.1007/s10854-015-3986-z

Bao Y, Huang J, Xue P, Wang J, Li Q, Wu C, Guo W (2011) Effect of pH-responsive on the dispersion of PVM/MA grafted carbon black in water and waterborne polyurethane. J Dispers Sci Technol 32:1459–1464. https://doi.org/10.1080/01932691.2010.513312

Acknowledgements

This research is financially supported by the Thousand Talents Program of Qinghai Province and Kunlun Scholar Award Program of Qinghai Province.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Q., Wang, S. & Xu, S. Preparation and characterization of water-dispersible carbon black grafted with polyacrylic acid by high-energy electron beam irradiation. J Mater Sci 53, 6106–6115 (2018). https://doi.org/10.1007/s10853-017-1966-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1966-9