Abstract

Oriented flake carbonyl iron/epoxy resin (FCI/EP) composites with enhanced microwave absorption properties were prepared by a magnetic field which was applied to make the plane of FCI parallel to each other. The morphology and the frequency-dependent electromagnetic and microwave absorption properties of the composites were investigated. The measurement results showed that the higher permeability and modest permittivity of the composites were obtained after orientation in the frequency range of 2–18 GHz. The calculated absorption properties indicated that the orientation plays an important role in decreasing the absorber thickness and broadening the absorption bandwidths. The oriented FCI/EP composites containing 75 wt% FCI show a wider absorption frequency range of 12.5 GHz from 5.5 to 18 GHz with reflection loss below −10 dB at thickness of 1.4 mm, while the bandwidth of the un-oriented one is only in a narrow frequency range of 1.4 GHz. This work offers a promising approach for the fabrication of magnetic absorbents for thin–thickness and microwave-absorbing materials with adjustable wider working frequencies range simply by magnetic field.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, electromagnetic waves in the range of gigahertz (GHz) have been widely used in civil and military areas. However, the increasing usage of these electronic devices and communication facilities results in severe electromagnetic wave interference problems. Therefore, microwave-absorbing materials have attracted growing attention because of their excellent properties of thin–thickness, light weight, wide absorbing frequency range, and high absorption ability. It is well known that the absorbent can be classified into three types according to the absorbing mechanisms: the conductive loss, the dielectric loss, and the magnetic loss types [1–6]. Compared with the other two absorbents, the magnetic loss-type absorbents can achieve great microwave absorption properties such as lower thickness and strong microwave absorption due to its high dielectric loss and magnetic loss [7–9].

Among the magnetic loss-type absorbents, carbonyl iron (CI) particles are considered as excellent magnetic absorbents owing to their high Curie temperature, superior thermal stability, large saturation magnetization value, and high permeability [10–12]. However, most of the microwave-absorbing materials based on these CI particles show a RL of only about −10 dB or less with a high weight fraction (i.e., more than 80 wt%) of the absorbents, and microwave-absorbing materials exhibit an effective absorption only in a narrow frequency range [13–15]. This significantly limits their practical applications in microwave absorbing in the fields of civil and military areas. To improve the absorption efficiency and the effective absorbing bands of the absorbers, different methods have been applied, such as adding optimized absorbent [16], using multi-layer structure [17–19], and compounding different types of absorbents [20–22]. However, the enhancement of the absorption properties of the absorber after adding optimized absorbent is proven to be very limited. On the other hand, it is an effective way to improve the absorbing properties of the absorber using the multilayered impedance-graded structure, but its wide application is restricted due to the complex preparation process. Furthermore, much attention have been paid to fabricate highly efficient absorbing materials by employing different loss types of absorbents, such as constructing FCI-based composites by incorporating carbon materials and ferrites. However, the value of the permeability of the multi-component absorber cannot be enhanced obviously due to the low permeability of non-magnetic absorbents. Moreover, these preparation methods generally require complex processes, such as functionalized treatment and complex chemical preparation method and reaction. Additionally, it is difficult for the absorbents to disperse in the matrix completely, which significantly affect the EM properties of the composites. Therefore, it is urgent to find out a more flexible and effective method to improve the EM wave absorption performance of FCI-based composites.

To improve the EM wave absorption properties, higher complex permeability is necessary. It has been proven that the permeability of many kinds of magnetic composites can be enhanced by employing oriented structures [23, 24]. Thus, numerous approaches have been developed for orientation, such as electric field-induced method [25], magnetic field-induced method [26, 27], polymer extrusion technique [28], melt processing method [29], and shear force-induced method [30, 31] in a polymer matrix. Magnetic field-induced approach is an efficient and direct route to prepare materials with oriented structure. The orientation of an object in a magnetic field has been successfully obtained with different structures, including micro-particles [32], carbon fiber [26], carbon nanotubes [33], and flake-shaped particles such as FeCuNbSiB [34] and Pr2Fe17N3–α particles [35]. Therefore, we estimate that the orientation of flake-shaped CI fillers in polymers may result in higher permeability, and further improve the microwave absorption performances of the FCI/EP composite.

In this work, we developed a flexible and an effective method by introducing a magnetic field to prepare oriented FCI to achieve strong absorption, thin–thickness, and broad bandwidths in microwave-absorbing materials. The orientation was obtained due to the mutual interaction between the FCI magnetic flakes in the magnetic field. Random dispersed FCI in the epoxy polymer solution was subjected to a magnetic field in two different directions, followed by the cross-linking of the system. The higher complex permeability and modest permittivity have been obtained by the oriented FCI; the microwave absorption properties of the composite were investigated in detail and compared with the un-oriented ones.

Experimental

Materials

The magnetic carbonyl iron particles were micro-sized, flake-like shaped, and purchased from Xinhua chemical Co. Ltd., Shaanxi province, China. The particles have a variable size with 2–10 μm in diameter and less than 1 μm in thickness. Epoxy resin was used as polymeric matrix. The curing agent used was polyamide, and the solvent was absolute alcohol. All chemicals were used without further treatment.

Preparation of FCI/EP composites

For the preparation of FCI/EP composites, the epoxy resin was dissolved in absolute alcohol and stirred for 30 min for complete dissolution. After adding the FCI and the curing agent, the mixture was stirred for 1 h at 2000 rpm for further distribution, followed by degassing in vacuum for 10 min. The FCI concentration of FCI/EP composites was 75 wt%. As illustrated in Fig. 1, the oriented FCI/EP composites were prepared by introducing a magnetic field, and the control samples were produced without magnetic field. For composites with random FCI magnetic particles, the prepared mixture was poured into a Petri dish and consolidated at room temperature without magnetic field, as shown in Fig. 1b. For magnetic orientation, the mixture was poured into a silicon holder, and was ready for exposing to the magnetic field. The mold containing the mixture was placed in the magnetic field of 1 T, which is generated by a pair of Helmholtz coils. In the process of magnetic orientation, the direction of the silicon holder rotated 90 degrees per 2 min until the mixture lost liquidity; then, the mixture was placed in the magnetic field for at least 24 h at room temperature until the polymer composite completed consolidation. After the FCI/EP composite was formed, it was removed from the mold and dried in an oven for 24 h at 50 °C, and a wafer sample of 10 mm thickness, 100 mm in length, and 60 mm in width was obtained. The oriented FCI/EP composites were obtained in two directions: oriented with its sample surface parallel to magnetic field (marked as direction A) and perpendicular to magnetic field (marked as direction B), as shown in Fig. 1a, c.

Schematic illustration of the Helmholtz coils set-up to generate a uniform magnetic field to obtain samples with different FCI structures. a Oriented FCI with its sample surfaces parallel to magnetic field, b random distribution of FCI, c oriented FCI with its sample surfaces perpendicular to magnetic field, d schematic diagrams of a waveguide method set-up for electromagnetic parameters measurement, e orientation of the testing sample

Characterization and measurement

The microstructure and fracture morphology of the composites were investigated by scanning electron microscope (SEM, Model JSM-6360, JEOL, Tokyo, Japan). The complex electromagnetic parameters of the composite were measured using a vector network analyzer (Agilent technologies E8362B: 10 MHz–20 GHz) in the frequency range of 2–18 GHz using the rectangular waveguide method in collaboration with the coaxial transmission line, which was previously reported by Yang Mu [36]. A schematic illustration of the measurement set-up for electromagnetic parameters is shown in Fig. 1d. A sample holder with its input and output is connected to the network analyzer. The sample was arranged perpendicularly to the incident electromagnetic wave through the thickness direction as shown in Fig. 1e. The electric field vector (E) of the incident electromagnetic wave transmitted along the length orientation of the sample and the magnetic field vector (H) transmitted along the width orientation when the sample is under testing on the network analyzer are shown in Fig. 1a, c. The testing specimens were cut into designated size corresponding to different microwave frequency range for microwave measurement: 72.5 × 33.82, 47.78 × 21.92, 34.48 × 15.42, 22.86 × 10.16, and 15.76 × 7.85 mm at the same thickness of 1 mm for S, C 1, C 2, X, and Ku band, respectively.

To evaluate the microwave absorption performance of the FCI/EP composites, the microwave RL of the composites can be calculated based on the following equations for a single-layer absorbing material [37]:

where Z 0 is the impendency of the free space; Z in is the absorber normalized input impedance; μ r and ε r are the effective permeability and permittivity of the absorber; f is the frequency of the electromagnetic wave; t is the absorber thickness, and c is the velocity of light. Meanwhile, the RL of the oriented FCI/EP composites was compared with the un-oriented ones in detail.

Results and discussion

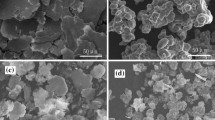

The microstructures of the un-oriented and oriented FCI/EP composites

Figure 2 shows the SEM images of the un-oriented (Fig. 2a) and oriented FCI/EP composites (Fig. 2b, c). It can be seen in the images that FCI have flake shape with diameters ranging from 2 to 10 µm and thickness below 1 µm. In the absence of an applied magnetic field, the FCI are randomly oriented and dispersed in the matrix homogeneously (Fig. 2a). When FCI are exposed to an external magnetic field, the FCI become parallel to the direction of the magnetic field (Fig. 2b, c). Each of the ferromagnetic FCI is equivalent to a magnetic dipole; the FCI in polymer solution turned to the direction of magnetic field quickly to decrease their free energy when the magnetic field was applied. The significant structure change of the flakes comes from the strong mutual interaction between the flakes. The particles attract each other when arranged end to end, and repel each other in side-by-side situation [38]. Owing to the interaction forces, oriented structure develops as shown in Fig. 2.

The EM properties of the un-oriented and oriented FCI/EP composites

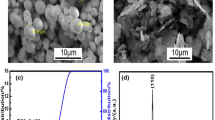

It is believed that the microwave absorption properties of the absorbers filled composites are mainly determined by its complex permittivity (ɛ = ɛ ′ − jɛ ″) and complex permeability (μ = μ ′ − jμ ″), where the real parts of complex permittivity (ɛ ′) and complex permeability (μ ′) represent the storage capability of electromagnetic energy, and imaginary parts (\( \varepsilon ^{{\prime \prime }} \) and μ ″) stand for the loss capability of electromagnetic energy, respectively. In order to evaluate the microwave absorption properties of the FCI/EP composites, the complex permittivity and permeability of the composites were measured in the frequency range of 2–18 GHz. Figure 3 shows the complex permittivity and permeability of the composites with 75 wt% FCI with and without orientation. As shown in Fig. 3a, it is interesting to note that the real part permittivity of oriented FCI/EP composite in direction A is higher than that of the un-oriented one in the whole measurement range, while the permittivity of oriented FCI/EP composites in direction B is lower than that of the un-oriented one. The real part permittivity value of un-oriented FCI/EP composite is between 41 and 26, whereas the oriented composite in direction A increases to 43–28 and the oriented one in direction B decreases to 6–7 rapidly. The enhancement of effective permittivity from un-oriented to oriented in direction A could be explained by cluster model [39]. As interpreted in the cluster model, the effective polarization increases when there are increases the content of metal fillers or the content of metal particles clusters, which corresponds to the ordered structure of composites. It is reasonable that the enhanced permittivity can be obtained by the composites with ordered structure. In order to better explain the reasons for the change of permittivity of the FCI/EP composites after orientation, the interaction direction between the electromagnetic wave and FCI/EP composites measured on the vector network analyzer is shown in Fig. 1. As shown in Fig. 1a and c, the EM wave propagation direction is perpendicular to the planes of FCI which oriented in direction A (Fig. 1a), while it is parallel to the planes of FCI oriented in direction B (Fig. 1c). Meanwhile, the electric field direction of EM wave is parallel to the planes of FCI oriented in direction A and perpendicular in direction B. The conductivity of conductive flake composite in the direction parallel to the orientation is higher than that of perpendicular to the orientation [21]. Therefore, the orientation would affect the permittivity because of the electrical anisotropy. This factor increases the permittivity of the composite oriented in direction A because of higher electrical conductivity and decrease the permittivity of the composite oriented in direction B due to lower electrical conductivity. Furthermore, it is clear to note that the values of the complex permittivity of the composites decreased with increasing frequency; more visible frequency dependence was observed in the composite oriented in direction A, while the weak frequency dependency was observed in the composite oriented in direction B. The interfacial polarization, one of important factors for influencing the permittivity, occurs more easily at lower frequency, and the production of displacement current significantly lags behind the build-up potential as the frequency increased. Moreover, the electrical conductivity can affect the values and frequency dependencies of the complex permittivity of FCI-filled composites [7]. Therefore, the weak frequency dependencies of complex permittivity of composites oriented in direction B are due to their lower electrical conductivity, while the strong frequency dependencies result from the increase of the electrical conductivity of the composites oriented in direction A. The frequency-dependent dielectric response of the oriented composites is profitable for proper impedance matching and high microwave attenuation.

Frequency dependence of a the real part and imaginary part of the complex permittivity, b the real part and imaginary part of the complex permeability, c the corresponding dielectric loss and d magnetic loss tangents of un-oriented FCI/EP composites, oriented FCI/EP composites in direction A and direction B

On the other hand, the imaginary permittivity for the oriented FCI/EP composite in direction A is higher than un-oriented composite, whereas the values in direction B are appreciably lower than that of un-oriented one. According to Debye theory [40], the imaginary permittivity can be defined as follows:

where ω is the angular frequency, τ the polarization relaxation time, ε s the static permittivity, ε ∞ the relative dielectric permittivity at the high-frequency limit, and σ is the electrical conductivity. In the FCI/EP composites system oriented in direction A (Fig. 1a), electrical conductivity is a highly significant factor for influencing the imaginary permittivity. Furthermore, it is reasonable for oriented FCI to have more opportunities to establish conductive paths at the same mass fraction (Fig. 1a), thus achieving enhanced electrical conductivity compared to the un-oriented FCI/EP composites. Therefore, the improved electrical conductivity mainly results in the enhancement of the imaginary permittivity of the FCI/EP composites oriented in direction A. For the FCI/EP composites oriented in direction B, the lower imaginary permittivity may be attributed to the decrease of electrical conductivity caused by the FCI orientation direction, which is perpendicular to the electric field.

Figure 3b shows the complex effective permeability of the un-oriented and oriented FCI/EP composites with 75 wt% FCI. As shown in Fig. 3b, the real part permeability of un-oriented FCI/EP composite at 2.6 GHz is 3.6, whereas the value reaches 4.3 for the oriented one. The effective permeability of oriented FCI/EP composites is higher than that of the un-oriented one in the range of 2.6–6.6 GHz. For the imaginary part of effective permeability, the oriented composites value is higher than that of the un-oriented ones in the whole measurement range; the oriented composites reach a large value of approximate 3.0 at 3.7 GHz, whereas that of the un-oriented one is 2.4. The enhanced permeability of oriented composites is mainly ascribed to the increase in the degree of planar anisotropy [34, 41, 42]. It was proved that the magnetic moments lie preferentially in the easy planes; the parallel arrangement of easy planes of oriented FCI is ascribed to easy magnetization and further results in the enhancement of permeability. Tomotsugu Kato [42] had reported that the permeability of aligned Z-type hexagonal ferrite whose magnetic path lies in the textured plane is higher than the other directions, which indicated that the higher permeability of the aligned sample is ascribed to the easy magnetization of textured planes. The studies have shown that the complex permeability of the oriented sample is 1.2–1.5 times higher than that of the un-oriented samples, which further confirm the validity of the planar anisotropy approach. Moreover, the complex permeability values of the oriented composites in direction A and direction B are almost the same. The magnetic field direction of electromagnetic wave is always parallel to the plane of FCI whether the EM wave propagation direction is perpendicular or parallel to the planes of FCI, in other words, the magnetic field direction of EM wave is always parallel to the easy magnetization planes. Therefore, the permeability of the FCI/EP composites oriented in direction B is the same as the value of composites oriented in direction A and are both higher than the un-oriented ones.

Generally, dielectric loss (tanδ e = ɛ ″/ɛ ′) and magnetic loss (tanδ m = μ ″/μ ′) play important roles in the microwave absorption performance of an absorber. In order to determine the contributions of dielectric loss and magnetic loss on the microwave absorption performance of FCI/EP composites, both the dielectric loss and the magnetic loss of the composite were calculated based on the measured complex permeability and permittivity, and are displayed in Fig. 3c, d. The value of tanδ e increases when the FCI/EP composites oriented in direction A and direction B were compared with the un-oriented composites. The tanδ m of the oriented composites increases sharply in the whole measurement frequency range. It is clear that tanδ m is much larger than tanδ e in the range of 2–18 GHz, which indicates that magnetic loss plays a more important role in the FCI/EP composite in this frequency range. Therefore, the enhanced values of dielectric loss and magnetic loss of the oriented composites act as an important factor, which is profitable for the enhancement of microwave absorption of the oriented FCI/EP composites.

It is well known that higher complex permeability and its suitable combination with the complex permittivity represent one of the most important factors for improving the microwave absorption efficiency of absorbers. As mentioned above, owing to the orientation, the higher permeability as well as modest permittivity was obtained by the oriented FCI/EP composites. It is indicated that orientation plays an important role in tuning the EM parameters of the composites and improving the level of impedance matching, which is important in achieving microwave absorbers with excellent microwave absorption performance.

The microwave absorption of the un-oriented and oriented FCI/EP composites

To investigate the microwave absorbing properties of the composites, we calculated the RLs at different thicknesses using Eqs. (1) and (2). Figure 4a–c shows the calculated RL curves for un-oriented and oriented composites at various thicknesses for the FCI/EP composite containing 75 wt% FCI. For the un-oriented composite, the RLs exceeding −5 dB at different thicknesses can be obtained, and the minimum RL is −13.0 dB at 4.0 GHz with a thickness of 1.5 mm, while the peak frequency is 3.5 GHz at the same thickness for the composite oriented in direction A, as shown in Fig. 4a, b. It is obviously indicated that the peak frequency of the samples oriented in direction A is lower than that of the un-oriented samples at thicknesses from 0.7 to 1.5 mm. The above phenomenon can be explained by quarter-wavelength cancelation model in composite filled with metal magnetic particles. For quarter-wavelength cancelation, the relationship between d and f is given by the following equation [24, 43, 44]:

where c represents velocity of light in free space, d represents thickness of absorber, f represents the frequency of incident electromagnetic wave, µ r represents complex permeability, and ε r represents complex permittivity. According to Eq. (4), the matching frequency decreases as the complex permittivity and permeability increase at the same absorber thickness. Therefore, it is reasonable that the peak frequency of composites oriented in direction A shifts to a lower frequency, compared with un-oriented composites at the same thicknesses. By comparing Fig. 4a, b, it is clear to indicate that smaller absorber thickness is obtained by the FCI/EP composite oriented in direction A when the absorption peak appears at the same frequency. The absorption peaks of the metallic magnetic particle composites are attributed to the λ/4 resonance effect; the absorber thickness is equal to the λ/4 of the composite which is expressed by \( c/4f\sqrt {\left| {\mu_{\text{r}} \varepsilon_{\text{r}} } \right|} \). The λ/4 thickness with peak frequency (f) for the un-oriented and oriented composites is displayed in Fig. 4d. The given absorber thicknesses and corresponding RL peak frequency in Fig. 4d are indicated as squares and circles dots for un-oriented and oriented composites, respectively. It is clear that the absorber thicknesses agree well with the λ/4 thickness of the composites at their corresponding matching frequencies. The above results confirm that the RL peaks for the FCI/EP composites are attributed to the λ/4 resonance effect. Smaller absorber thickness is accomplished owing to the enhancement of µ r and ε r after orientation. These results indicate that the FCI/EP composites oriented in direction A can be used as a thin microwave absorber in the frequency range of 2–18 GHz.

For the FCI/EP composites oriented in direction B, better absorption performance and wider bandwidths with RL below −5 dB are obtained at a thickness ranging from 0.8 to 1.5 mm than that of the un-oriented one. Additionally, the strong absorption with RL below −10 dB is achieved at thicknesses ranging from 1.3 to 1.5 mm, while the bandwidths below −10 dB are only in a narrow frequency range for the un-oriented FCI/EP composites. As shown in Fig. 4d, the effective absorption bandwidth with RL below −10 dB reaches 12.5 GHz from 5.5 to 18 GHz at the thickness 1.4 mm for the composites oriented in direction B, which shows enhanced absorption efficiency and broader bandwidths than the un-oriented one.

Detailed electromagnetic properties and RLs of FCI/EP composites and a comparison of other representative oriented or un-oriented magnetic particle composites are summarized in Table 1 [5, 12, 13, 33, 35, 45–47]. As shown in Table 1, adding optimized absorbent and compounding different types of absorbents have been used to improve the absorption efficiency and the effective absorbing bands of the absorbers, such as adding carbon nanomaterials, ferrites. However, the values of both μ ′ and μ ″ of the composites, such as FeCo@C compounded absorber and graphene/carbonyl iron composite, are much smaller than those of the FCI/EP composites, especially for the oriented FCI/EP composites. It is visible that higher complex permeability and modest permittivity were both obtained by FCI/EP composites after orientation. It is indicated that oriented FCI/EP composites with wider microwave absorption bandwidth and/or thin thickness can be obtained simply by orientation comparing with the other magnetic particle composites and can be optimized by changing the orientation direction. It is well known that the value and frequency dependency of complex permittivity and its combination with permeability are very important for the absorption performance of the absorber. Therefore, the high values of ɛ ’ and μ’ and their proper combination led to a decrease in the absorber optima matching thickness for FCI/EP composites oriented in direction A. The excellent microwave absorption performance of FCI/EP composites oriented in direction B comes from the low value of ɛ ′ and its proper impedance matching with permeability. Therefore, compared with other magnetic particle absorbers with very narrow microwave absorption bandwidth, the enhanced RLs of the oriented FCI/EP absorbers presented here are mainly attributed to the suitable values and frequency dependencies of complex permittivity and permeability, a synergetic consequence of proper impedance matching and high microwave attenuation. Most importantly, the orientation process developed here are simple, without complex functionalized treatment and complex preparation process and reaction, with great potential for industrial-scale applications. Thus, such absorbers could act as effective, thin–thickness and broadband microwave absorbers in the GHz range.

Conclusions

Oriented FCI/EP composites were prepared by a magnetic field, and the microwave absorbing performance of the composites were investigated. Compared with the un-oriented FCI/EP composites, the oriented composites show a larger permeability, as well as modest permittivity due to the increased planar anisotropy induced by FCI orientation. The calculated absorption properties indicated that the orientation plays an important role in decreasing the absorber thickness and broadening the absorption bandwidth. The oriented FCI/EP composites containing 75 wt% FCI show a wider absorption frequency range of 12.5 GHz from 5.5 to 18 GHz with RL below −10 dB at thickness 1.4 mm. This study presents an effective approach to enhance the microwave absorption performance of magnetic composites by magnetic field orientation and indicates that oriented FCI/EP composites are promising candidates as microwave absorption materials.

References

Li G, Xie T, Yang S, Jin J, Jiang J (2012) Microwave absorption enhancement of porous carbon fibers compared with carbon nanofibers. J Phys Chem C 116:9196–9201

Bi S, Su X, Hou G, Liu C, Song W, Cao M (2013) Electrical conductivity and microwave absorption of shortened multi-walled carbon nanotube/alumina ceramic composites. Ceram Int 39:5979–5983

Kong L, Yin X, Yuan X, Zhang Y, Liu X, Cheng L, Zhang L (2014) Electromagnetic wave absorption properties of graphene modified with carbon nanotube/poly(dimethyl siloxane) composites. Carbon 73:185–193

Tong G, Wu W, Guan J, Qian H, Yuan J, Li W (2011) Synthesis and characterization of nanosized urchin-like α-Fe2O3 and Fe3O4: microwave electromagnetic and absorbing properties. J Alloys Compd 509:4320–4326

Wang A, Wang W, Long C, Li W, Guan J, Gu H, Xu G (2014) Facile preparation, formation mechanism and microwave absorption properties of porous carbonyl iron flakes. J Mater Chem C 2:3769–3776

Yu Y, Ma C, Yu K, Teng C, Tien H, Chang K, Kuo Y (2014) Preparation, morphological, and microwave absorbing properties of spongy iron powders/epoxy composites. J Taiwan Inst Chem Eng 45:674–680

Qing Y, Min D, Zhou Y, Luo F, Zhou W (2015) Graphene nanosheet and flake carbonyl iron particle-filled epoxy-silicone composites as thin-thickness and wide-bandwidth microwave absorber. Carbon 86:98–107

Park K, Han J, Lee S, Kim J, Yi J, Lee S (2009) Fabrication and electromagnetic characteristics of microwave absorbers containing carbon nanofibers and NiFe particles. Compos Sci Technol 69:1271–1278

Chen Y, Gao P, Zhu C, Wang R, Wang L, Cao M, Fang X (2009) Synthesis, magnetic and electromagnetic wave absorption properties of porous Fe3O4/Fe/SiO2 core/shell nanorods. J Appl Phys 106:0543031–0543034

He J, Wang W, Guan J (2012) Internal strain dependence of complex permeability of ball milled carbonyl iron powders in 2–18 GHz. J Appl Phys 111:0939241–0939245

Zhou Y, Zhou W, Qing Y, Luo F, Zhu D (2015) Temperature dependence of the electromagnetic properties and microwave absorption of carbonyl iron particles/silicone resin composites. J Magn Magn Mater 374:345–349

Zhu Z, Sun X, Xue H, Guo H, Fan X, Pan X, He J (2014) Graphene-carbonyl iron cross-linked composites with excellent electromagnetic wave absorption properties. J Mater Chem C 2:6582–6591

Xu Y, Zhang D, Cai J, Yuan L, Zhang W (2013) Microwave absorbing property of silicone rubber composites with added carbonyl iron particles and graphite platelet. J Magn Magn Mater 327:82–86

Wang B, Wei J, Yang Y, Wang T, Li F (2011) Investigation on peak frequency of the microwave absorption for carbonyl iron/epoxy resin composite. J Magn Magn Mater 323:1101–1103

Duan Y, Wu G, Gu S, Li S, Ma G (2012) Study on microwave absorbing properties of carbonyl-iron composite coating based on PVC and Al sheet. Appl Surf Sci 258:5746–5752

Liu L, Duan Y, Liu S, Chen L, Guo J (2009) Microwave absorption properties of one thin sheet employing carbonyl-iron powder and chlorinated polyethylene. J Magn Magn Mater 322:1736–1740

Chen L, Duan Y, Liu L, Guo J, Liu S (2011) Influence of SiO2 fillers on microwave absorption properties of carbonyl iron/carbon black double-layer coatings. Mater Des 32:570–574

Liu Y, Liu X, Wang X (2014) Double-layer microwave absorber based on CoFe2O4 ferrite and carbonyl iron composites. J Alloys Compd 584:249–253

Qiao M, Zhang C, Jia H (2012) Synthesis and absorbing mechanism of two-layer microwave absorbers containing flocs-like nano-BaZn1.5Co0.5Fe16O27 and carbonyl iron. Mater Chem Phys 135:604–609

Qing Y, Zhou W, Luo F, Zhu D (2011) Optimization of electromagnetic matching of carbonyl iron/BaTiO3 composites for microwave absorption. J Magn Magn Mater 323:600–606

Qing Y, Wen Q, Luo F, Zhou W, Zhu D (2016) Graphene nanosheets/BaTiO3 ceramics as highly efficient electromagnetic interference shielding materials in the X-band. J Mater Chem C 4:371–375

Qing Y, Wen Q, Luo F, Zhou W (2016) Temperature dependence of the electromagnetic properties of graphene nanosheet reinforced alumina ceramics in the X-band. J Mater Chem C 4:4853–4862

Han R, Yi H, Zuo W, Wang T, Qiao L, Li F (2012) Greatly enhanced permeability for planar anisotropy Ce2Fe17N3-δ compound with rotational orientation in various external magnetic fields. J Magn Magn Mater 324:2488–2491

Zhang Y, Wang P, Wang Y, Qiao L, Wang T, Li F (2015) Synthesis and excellent electromagnetic wave absorption properties of parallel aligned FeCo@C core-shell nanoflake composites. J Mater Chem C 3:10813–10818

Chen G, Wang H, Zhao W (2008) Fabrication of highly ordered polymer/graphite flake composite with eminent anisotropic electrical property. Polym Adv Technol 19:1113–1117

Shi D, He P, Lian J, Chaud X, Bud’ko S, Beaugnon E, Wang L, Ewing R, Tournier R (2005) Magnetic alignment of carbon nanofibers in polymer composites and anisotropy of mechanical properties. J Appl Phys 97:064312–0643125

Kimura T, Ago H, Tobita M, Ohshima S, Kyotani M, Yumura M (2002) Polymer composites of carbon nanotubes aligned by a magnetic field. Adv Mater 14:1380–1383

Cooper C, Ravich D, Lips D, Mayer J, Wagner H (2002) Distribution and alignment of carbon nanotubes and nanofibrils in a polymer matrix. Compos Sci Technol 62:1105–1112

Haggenmueller R, Gommans H, Rinzler A, Fischer J, Winey K (2000) Aligned single-wall carbon nanotubes in composites by melt processing methods. Chem Phys Lett 330:219–225

Lu J, Weng W, Chen X, Wu D, Wu C, Chen G (2005) Piezoresistive materials from directed shear-induced assembly of graphite nanosheets in polyethylene. Adv Funct Mater 15:1358–1363

Sfadi B, Andrews R, Grulke E (2002) Multiwalled carbon nanotube polymer composites: synthesis and characterization of thin films. J Appl Polym Sci 84:2660–2669

Breval E, Klimkiewicz M, Shi Y, Arakaki D, Dougherty J (2003) Magnetic alignment of particles in composite films. J Mater Sci 38:1347–1351. doi:10.1023/A:1022867400786

Kumar M, Jayanisha V, Manjari R, Prabu S, Padmanabhan K (2014) Self-assembly of carbon nanotubes using magnetic positioning and alignment by drop drying. Mater Lett 114:68–71

Yang W, Qiao L, Wei J, Zhang Z, Wang T, Li F (2010) Microwave permeability of flake-shaped FeCuNbSiB particle composite with rotational orientation. J Appl Phys 107:0339131–0339135

Li R, Wang T, Tan G, Zuo W, Wei J, Qiao L, Li F (2014) Microwave absorption properties of oriented Pr2Fe17N3-δ particles/paraffin composite with planar anisotropy. J Alloys Compd 586:239–243

Mu Y, Zhou W, Luo F, Zhu D, Qing Y, Huang Z (2014) Electromagnetic interference shielding effectiveness of SiCf/SiC composites with PIP–SiC interphase after thermal oxidation in air. J Mater Sci 49:1527–1536. doi:10.1007/s10853-013-7834-3

Qing Y, Zhou W, Luo F, Zhu D (2010) Epoxy-silicone filled with multi-walled carbon nanotubes and carbonyl iron particles as a microwave absorber. Carbon 48:4074–4080

Varga Z, Filipcsei G, Zrı´nyi M (2005) Smart composites with controlled anisotropy. Polymer 46:7779–7787

Doyle W, Jacobs I (1990) EfFective cluster model of dielectric enhancement in metal-insulator composites. Phys Rev B 42:9319–9327

Song W, Cao M, Lu M, Liu J, Yuan J, Fan L (2013) Improved dielectric properties and highly efficient and broadened bandwidth electromagnetic attenuation of thickness-decreased carbon nanosheet/wax composites. J Mater Chem C 1:1846–1854

Qiao L, Han R, Wang T, Tang L, Li F (2015) Greatly enhanced microwave absorbing properties of planar anisotropy carbonyl-iron particle composites. J Magn Magn Mater 375:100–105

Kato T, Mikami H, Noguchi S (2010) Performance of Z-type hexagonal ferrite core under demagnetizing and external static fields. J Appl Phys 108:0339031–0339035

Pang H, Fan M, He Z (2012) A method for analyzing the microwave absorption properties of magnetic materials. J Magn Magn Mater 324:2492–2495

Song Z, Xie J, Zhou P, Wang X, Liu T, Deng L (2013) Toughened polymer composites with flake carbonyl iron powders and their electromagnetic/absorption properties. J Alloys Compd 551:677–681

Chen T, Deng F, Zhu J, Chen C, Sun G, Ma S, Yang X (2012) Hexagonal and cubic Ni nanocrystals grown on graphene: phase-controlled synthesis, characterization and their enhanced microwave absorption properties. J Mater Chem 22:15190–15197

Yan L, Wang J, Ye Y, Hao Z, Liu Q, Li F (2009) Broadband and thin microwave absorber of nickel-zinc ferrite/carbonyl iron composite. J Alloys Compd 487:708–711

Zou J, Liu Q, Zi Z, Dai J (2014) Enhanced electromagnetic wave absorption properties of planar anisotropy carbonyl-iron/Fe3O4 composites in gigahertz range. Mater Res Innov 18:304–309

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51402239), Fundamental Research Funds for the Central Universities (No.3102014JCY01002), and the State Key Laboratory of Solidification Processing (NWPU), China (Grant No. KP201422).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Min, D., Zhou, W., Qing, Y. et al. Greatly enhanced microwave absorption properties of highly oriented flake carbonyl iron/epoxy resin composites under applied magnetic field. J Mater Sci 52, 2373–2383 (2017). https://doi.org/10.1007/s10853-016-0532-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0532-1