Abstract

TiO2-based thin films and nanomaterials have been fabricated via physical and solution-based techniques by various research groups around the globe. Generally, most applications of TiO2 involve photocatalytic activity for water and air purification, self-cleaning surfaces, antibacterial activity, and superhydrophilicity. As a wide-bandgap semiconductor, modified TiO2 belongs to a class of materials called transparent semiconducting oxides (TSOs), which are simultaneously optically transparent and electrically conductive. TSOs continue to be in high demand for a variety of applications ranging from transparent electronics and sensor devices to light detecting and emitting devices in telecommunications. However, reports on TiO2 applications as an effective TSO for transparent electronics applications have been limited. In general, TiO2 is intrinsically an n-type semiconductor but can be doped to have p-type semiconductivity. This provides a very important opportunity to fabricate all-transparent homojunction devices for light harvesting and energy storage. P-type TSOs have recently attracted tremendous interest in the field of active devices for emerging transparent electronics for potential use in ultra-violet light-based solar cells. Therefore, a detailed overview of the synthesis, band structure modification via doping, properties, and applications of modified TiO2 as n- and p-type TSOs is warranted. This article comprehensively reviews the latest developments. The discussion includes solution-based wet chemical techniques and vacuum-based dry physical techniques fabricating TiO2–TSOs. The synthesis of p-TiO2 in particular is discussed in detail as it may provide interesting breakthroughs in emerging transparent electronics applications. Also, the structural, optical, and electrical properties of TiO2 are discussed in the context of TSO applications, specifically the defect chemistry of TiO2 to obtain n- and p-type semiconductivity, which could provide interesting insights into the band structure engineering of TiO2 for conductivity reversal. Applications of both n- and p-type TiO2 have been reviewed in detail in relation to thin film transparent homo/heterojunction devices, dye-sensitized solar cells, electrochromic displays, and other energy-related applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Transparent semiconducting oxides (TSOs) have high optical transmittance and electrical conductivity at the same time. As a wide-bandgap material, TSOs are expected to have poor electronic conduction because carrier doping for large-gap materials is difficult. Hence, the general notion is that high optical transparency and high electrical conduction cannot go hand in hand in the same material [1–5]. TSOs constitute a unique group of oxide materials with these two mutually incompatible properties together. The conductivity of the TSOs generally varies from 10−8 S-cm−1 to more than 103 S-cm−1 [4–10]. These oxides are divided into two groups based on their electrical conductivity: transparent conducting oxides (TCOs) with conductivity higher than 103 S-cm−1 and transparent oxide semiconductors (TOSs) with conductivity between 10−8 and 103 S-cm−1. Although TCOs have nearly metallic conductivity (hence the nomenclature), their band structures are not metallic type but rather semiconducting type with a large bandgap. We have combined these groups into one category of TSOs. TSOs are well known and have been used industrially for more than 50 years [1, 2]. The first report of a TSO was published in 1907, when Badeker reported that thin films of Cd metal deposited in a glow discharge chamber could be oxidized to make them transparent while maintaining electrical conductivity [3]. TSOs are greatly important for their increasing use in applications such as touch panels and flat-panel displays (FPDs). Other electronic/optoelectronic device applications include Si-based solar cells, light-emitting diodes (LEDs), waveguides, low-emissivity (“low-e”) windows, electrochromic or “smart” windows, oven windows, defrosting windows, invisible security circuits, antistatic coatings, flexible displays, holographic recording media, waveguides for sensors and telecommunication applications, write-once-read-many-times memory chips (WORM), electronic ink, and field-emission displays [4–25].

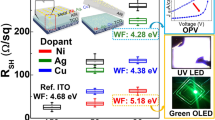

Since the 1960s, the most widely used TSO for optoelectronic device applications has been tin-doped indium oxide (In2−x Sn x O3; ITO) and fluorine-doped tin-oxide (SnO2−x F x ). These materials offered the best performance in terms of conductivity, transmissivity, excellent environmental stability, reproducibility, and surface morphology [12, 13, 21, 22]. Nowadays, TSOs are a major component in organic light-emitting diodes (OLEDs), copper indium gallium diselenide (CIGS) solar cells, dye-sensitized solar cells (DSSC), and blue GaN-based LEDs [4–8, 10, 16, 17], in which other well-known TSOs are also widely used, including SnO2:Sb, ZnO:In/Al/F/B/Ga, In2O3:/F/Sb/Pb, and Cd2SnO4. [26–32]. But due to the scarcity and rapidly expanding consumption in many fields, it is necessary to find alternative TSOs.

Recently, several multicomponent TSOs and their doped versions have been reported, such as Zn2SnO4, ZnSnO3, GaInO3:Ge/Sn, AgInO2:Sn, MgIn2O4, CdSb2O6:Y, Zn2In2O5, ZnGa2O4, In4Sn3O12, and CdIn2O4:Sn. [15, 33–40]. These have interesting electronic/optoelectronic applications but have yet to break into the TSO industry for high volume production because of their costly and complex fabrication processes. Therefore, it is still necessary to explore new TSO materials produced by cost-effective and simple processes for diverse and wide-scale device applications. The fabrication process should also have flexibility in tuning the TSO properties for improved device performance. ZnO, TiO2 (Nb-doped TiO2–TNO), and doped SnO2 are widely used as indium-free TSOs for low-e windows and other applications [17–23, 41–46]. These materials are compared in Table 1. Even though TiO2-based TSOs have optoelectronic performance characteristics close to ITO, they also have significant shortcomings in terms of deposition parameters and chemical stability [44].

The control of oxygen stoichiometry in TNO films is the most important parameter for obtaining high conductivity. The oxygen partial pressure during deposition should be maintained at ~1 × 10−3 Pa to control the oxygen content of the films. The annealing conditions also control the electrical properties of the TNO. Annealing in air at 600 °C yields insulating films [46]. As a result, there is a growing body of research on TSO to look for new indium-free materials outside the group of typical TSOs. The discovery of transparent conducting properties in Nb- and Ta-doped anatase TiO2 thin films has extended the range of materials that can be used for transparent electrodes [44, 45].

TiO2 is a versatile material that has been used in many applications, such as gas sensors, solar cells, photocatalytic layers for self-cleaning glass, photocatalytic degradation of organic wastes, hydrogen production, storage media, optical coatings for filters and waveguides, and various biological- and health-related applications [47–66]. Since the early twentieth century, titanium dioxide (TiO2) has been widely used as a pigment in sunscreens, paints, ointments, toothpaste, etc. [48–50]. A phenomenon of photocatalytic water splitting on a TiO2 electrode under ultra-violet (UV) light was discovered [59–62], which gave new hope in helping ease energy crises through effective utilization of solar energy in photovoltaic and water-splitting devices [63–65]. Transparent thin films based on TiO2 are widely applied in the coating industry for preparation of hydrophobic or hydrophilic films, self-cleaning coatings, optical filters, and protective films [48, 51, 54, 55, 66–68].

TiO2 is a technologically important material with a wide range of applications, easy availability, and cost-effective syntheses processes. In this review article, we focus on recent progress in the synthesis, properties, modifications, and applications of n- and p-type transparent semiconducting TiO2 thin films, their doped versions, and corresponding nanomaterials. The manuscript is arranged as follows. After preliminary introduction of the basic properties of TSO and the importance of TiO2 as a TSO in “Introduction” and “Basic electronic band structure of TSO” section, the synthesis methods for transparent conducting TiO2 nanomaterials is given in “Synthesis of TiO2-based TSO” section, including nanoparticles, nanorods, nanowires, and nanotubes. These methods are primarily categorized into vacuum-based and solution-based techniques. A sub-section introduces the fabrication processes of p-type semiconducting TiO2. p-type TSOs (p-TSO) have recently attracted tremendous interest in the optoelectronics industry for potential applications in transparent electronics and UV-based solar cells [69–73].

It is well known that most of the TSOs mentioned are n-type semiconductors. p-TSOs were developed in the late 1990s, and applications in active devices have been highly limited [74]. Sato et al. [75], and Kawazoe et al. [76] reported p-type conductivity in transparent thin films of binary NiO and ternary CuAlO2 and opened up a new field in transparent electronics. All-transparent p–n junctions of TSO materials could be used as a “functional window” to transmit the visible portion of solar radiation and generate electricity using the UV part, thus potentially extending solar cell applications into the UV region. Undoped TiO2 is a well-known n-type semiconducting material, and it can be made to conduct holes by doping [77]. Therefore, a p–n transparent homojunction fabricated with p- and n-type transparent TiO2 can be used very efficiently if the junction properties can be improved. Hence, a detailed review on the fabrication of p-TiO2 is necessary.

“Properties” section includes a detailed review of the structural, thermal, electronic, and optical properties of TiO2 nanomaterials. The size, shape, and crystal structure of TiO2 nanomaterials influence the surface stability and can make the transitions between different phases of TiO2 under pressure or heat become size dependent. The influence of the size of TiO2 nanomaterials on the X-ray diffraction patterns and Raman vibrational spectra is also summarized. These data could help to determine the size of the materials to some extent, although the correlation between the spectra and size of TiO2 nanomaterials is not straightforward. The review of modifications to TiO2 nanomaterials is mainly limited to research related to the optical properties of TiO2 nanomaterials, which are important in many applications. TiO2 nanomaterials are normally transparent in the visible light region. By doping, sensitization, or size tuning, it is possible to improve the optical sensitivity and activity of TiO2 nanomaterials in the visible light region. Therefore, a detailed review on the tuning of the optical properties of TiO2 nanomaterials is given in terms of bandgap engineering by the quantum size effect for potential TSO applications.

In “Applications” section, transparent electronics (heterojunctions, functional windows), environmental applications (photocatalysis, sensing), and energy applications (photovoltaics, water splitting, photo-/electrochromics, hydrogen storage) are reviewed with emphasis on clean and sustainable energy, since increasing energy demands and environmental pollution are creating a pressing need for clean and sustainable energy solutions. The fundamentals and working principles of TSO-based devices are discussed. TiO2 nanomaterials are used either as a TSO or as a component to facilitate understanding and improvement of current and practical TiO2 nanotechnology. Although TiO2 has been used for many years, there is a complete lack of reports on the application of p-TiO2 as an active channel in electronic and transistor circuit devices. Therefore, the properties and application perspectives of p-TiO2 are discussed in detail in this section.

Finally, “Future developments” section discusses the future prospects of TiO2-based TSO materials and gives concluding remarks. Several previous review articles reported detailed accounts of the synthesis, doping, material properties, and photocatalytic, photoelectrochemical, energy-related, and bio-related applications of TiO2 films and nanostructures [48–50, 59–65, 78–83]. But there is negligible literature reviewing TiO2 as a TSO material. Recently, only Hitosugi et al. [41, 45] presented a brief review of the synthesis and transparent conductive properties of Nb-doped TiO2 (TNO). They discussed the mechanistic differences between TNO and conventional TSOs. But to the best of our knowledge, there has been no other review accounting for the entire TiO2–TSO family, including both n- and p-type TiO2 and energy/TSO-related applications. This review covers a wide spectrum of the recent developments of TiO2 as transparent conductors in terms of syntheses, modification, opto-electrical properties, and TSO-based energy applications (including p-type TiO2 and p–n active junctions for transparent electronics). The content could thus be very useful for the field of TCOs for practical applications.

Basic electronic band structure of TSO

The general band picture of TSO is shown in Fig. 1. Assuming flat band potential, the approximate bandgap of TSO is generally higher than the energy of a 400-nm blue photon (which is roughly 3.1 eV). Therefore, visible photons, which have energy between 2.1 and 3.1 eV, are transmitted through the material without exciting the electrons from the valence band (VB) to the conduction band (CB). The material thus becomes transparent in the visible region of solar radiation. As a wide-bandgap semiconductor, the material can acquire acceptor levels (for p-type) or donor levels (for n-type) under appropriate conditions (doping or induction of non-stoichiometric defects). Visible radiation would have enough energy to excite electrons from the donor level to the CB (for n-type TSOs) or holes from the acceptor level to the VB (for p-type TSOs). Therefore, the optical transmission (%T) should theoretically be 100 % within the visible region (400–800 nm). Slight absorption in the low energy region may occur due to activation of electrons from the donor level to the CB (for n-type TSOs) or holes from the acceptor level to the VB (for p-type TSOs), as shown in Fig. 1.

Bandgap design of TSO. Reproduced from [71] with permission from © 2005 Elsevier Ltd.

According to the band theory of solids, the mobility of carriers (electrons or holes) in TSOs is defined by the position and curvature of the CB minimum (CBM) and VB maximum (VBM), which determine the effective masses of the corresponding carriers and hence the carrier mobility [74]. In general, a majority of TSOs are binary metal oxides where metals have electronic configuration in the form of [n − 1] d 10 ns 2. During oxide formation, the unoccupied ns orbital of the metal cation (Ms) interacts strongly with the occupied 2p orbital of oxygen (O2p) to produce the electronic band structure of the TSOs. Figure 2 schematically depicts the electronic band structure of the TSOs. Figure 2a shows the E–k diagram of a stoichiometric TSO material, where the VB comprises the bonding and non-bonding occupied O2p states and the CB arises from the anti-bonding Ms–Op interaction. Because of this parabolic band formation due to the Ms + Op interaction, a forbidden energy gap (E g) is created between the CBM and VBM to form the wide bandgap in TSOs.

Band structure of a stoichiometric, b non-stoichiometric TSO, and c corresponding density of states. Reproduced from [74] with permission from © 2010, John Wiley and Sons Ltd.

Higher energy states are created by the empty p states of the metal ions (Mp) [70, 74]. For a non-stoichiometric or doped TSO, the creation of degenerate levels pushes the Fermi level (E F) upward, as shown in Fig. 2b, and the corresponding density of states is shown in Fig. 2c. A majority of TSOs show n-type semiconductivity for several reasons. Firstly, the CB of TSO is mostly formed due to the spherically shaped extended metal s orbital, making the carrier transportation within the CB region more favorable than the VB region and leading to better electron conductivity than hole conductivity. Therefore, it is easier to obtain promising n-type TSOs with relatively good conductivity and transparency [70, 74].

Secondly, as the VB comprises occupied O2p levels, the strong electronegativity of oxygen ions makes the VB edge strongly localized, leading to very large hole effective mass and much lower hole mobility than electron mobility. Also, because of the ionicity of metallic oxides, the O2p level becomes far lower than the valence orbit cationic levels (Fig. 3a). Hence, holes (either intrinsically created or externally induced by non-stoichiometry or doping) become strongly localized around the oxygen ions to create deep acceptor levels that are unable to migrate readily within the crystal lattice. These holes require enough energy to overcome a large barrier height to be delocalized and migrate within the crystal lattice, resulting in poor p-type conductivity and hole mobility [70, 71, 76].

a Schematic diagram of the chemical bonding between cation and anion in (a) a typical n-type TSO, b p-type binary metal oxide. Both the atomic orbitals are occupied by electron pairs, which results in the formation of the highest occupied level as the valence band maxima. Inset Density of states of p-TSO. Reproduced from [72] with permission from 2 © 2000, Materials Research Society/© 2011

It is clear that typical TSOs are n-type semiconductors (n-TSO), and the induction of p-type semiconductivity (p-TSO) is difficult unless the holes are delocalized from the highly electronegative oxygen ions. This can be achieved by chemical modulation of the VB (CMVB) [72], where a closed d 10 orbital of metal cations (such as Cu-d 10, Ag-d 10 etc.) with energy level comparable to the O2 p 6 level is combined with an oxygen ion to create degenerate hybridized O2p states (Fig. 3b, inset). This leads to the formation of an extended VB structure, which results in the delocalization of holes, easy migration into the crystal lattice, increased hole mobility, and improved p-type semiconductivity. This is why Cu2O and Ag2O are intrinsically p-type materials, although their bandgaps are less than 3.1 eV, making them unsuitable for p-TSO applications [70]. To obtain intrinsic p-TSO, additional structural requirements need to be satisfied to create superlattice or layered structures to suppress the three-dimensional interactions between d 10 cations, which would increase the bandgap to the transparent regime [70, 71]. The details of the criteria to create intrinsic p-TSOs are not in the scope of this report but are available elsewhere [71].

Electronic structure of TiO2 as TSO

Generally, density functional theory (DFT) calculations for the electronic band structure of semiconductors and insulators are highly underestimated when used with local density approximation (LDA) or generalized gradient approximation (GGA) for the exchange correlation functional [84–89]. One accurate way to predict the band structure is ab initio many-body perturbation theory (MBPT) with dynamically screened interaction or GW approximation (GWA), where the self-energy is considered to be the product of the single-particle Green function G and the screened interaction W [85–92]. Several groups theoretically calculated the bandgaps (\( E_{\text{g}}^{\text{GWA}} \)) of different polymorphs of TiO2 (mainly anatase, rutile, and brookite) by the GWA method combined with some hybrid/correlation/exchange functional. These methods are given in Table 2 [87], and recently reported representative band structure calculations of TiO2 polymorphs are shown in Fig. 4 [91]. The calculated bandgaps are well within the transparent regime, indicating potential for use in TSO applications. The experimentally obtained bandgap values of different TiO2 polymorphs are discussed in “Electro-optical properties” section.

TiO2 band structures for the rutile (left), anatase (middle), and brookite (right) polymorphs. Pictured are the DFT–HSE06 band structure as well as quasiparticle (QP) energies (dots) obtained from PBE–G 0 W 0 calculations. The gray shaded areas correspond to energies below the highest valence band and above the lowest conduction band from DFT–PBE calculations. For PBE and HSE06 eigenvalues, the valence band maximum has been chosen as the zero point of the energy scale. G 0 W 0 QP energies are given with respect to DFT–PBE energy scale. The HSE06 calculations have been carried out with regular 7 × 7 × 11, 9 × 9 × 3 and 3 × 5 × 5 Γ-centered k-point meshes for rutile anatase and brookite. The various high symmetry lines were additionally sampled by 40 k-points to obtain the HSE06 band structure. For rutile, anatase, and brookite, the GW calculations were carried out on top of DFT–PBE calculations with 192, 384, and 768 electronic bands, regular 8 × 8 × 12, 10 × 10 × 4, and 4 × 6 × 6 Γ-centered k-point meshes, and 192 frequency points for sampling the dielectric function, respectively. These numerical parameters provide bandgaps converged within about 0.02 eV accuracy, as tested for the case of rutile. Reproduced from [91] with permission from © 2012 IOP Publishing Ltd., Printed in UK & USA

Hitosugi et al. [93] reported the theoretical band structure of Nb-doped TiO2 by DFT calculations using a standard GGA (Perdew–Wang: PW91) functional. As shown in Fig. 5, the bandgap is much lower (2.24 eV) than the experimental value (3.2 eV) from using the DFT + GGA method and producing an underestimated value. No MBPT calculation with GWA has been reported for Nb-doped TiO2 to predict bandgap values more accurately.

Calculated electron energy band structure of a undoped and b Nb-doped TiO2. Reproduced from [93] with permission from © 2008 The Japan Society of Applied Physics

The band calculations revealed strong hybridization of Nb-4d orbitals with Ti-3d orbitals to form a d-nature CB, without any impurity states within the bandgap. This results in high carrier density and superior visible transparency. Also, it has been observed that the band structure of Nb-doped TiO2 is essentially identical to that of undoped anatase TiO2, although Nb doping changes the band filling without affecting the band dispersions [94]. When the Nb concentration within the TiO2 matrix is increased beyond an optimal level, the carrier concentration is decreased considerably, apparently because of interstitial oxygen atoms, which strongly interact and combine with surrounding Nb atoms to produce in-gap states and compensate for carrier electrons in the heavily doped region [95].

Synthesis of TiO2-based TSO

Transparent conducting TiO2 films have been fabricated by various techniques [41–46]. These include both vacuum-based techniques (like sputtering, pulsed laser deposition—PLD, and chemical vapor deposition—CVD) and solution-based techniques (like sol–gel, dip/spin-coating, and spray pyrolysis). Although the solution-based techniques are simpler and more cost effective than vacuum-based techniques, they are not compatible with modern solid-state device fabrication techniques, especially complementary-metal–oxide–semiconductor integrated-circuit (CMOS-IC) fabrication. Hence, the methods are not commercially viable.

Vacuum-based techniques

Sputtering

Sputtering is suitable for low cost and uniform coating on large-area substrates and has been established as a standard technique for preparing TSO films [96–101]. Niu et al. [102] prepared transparent TiO2 films on PDMS substrate by DC reactive sputtering. The target was titanium, and the distance between the target and substrate was fixed at 100 mm. The chamber was evacuated to a vacuum level lower than 1.2 × 10−3 Pa, and then argon was introduced. The input power and substrate temperature were fixed at 350 W at ambient temperature, and the discharge voltage was maintained at 220 V. When the Ar discharge was stabilized, oxygen was introduced into the sputtering chamber, and the color of the sputtering plasma changed from pink to blue. The gas pressure during the reactive sputtering was increased from 1.0 to 1.6 Pa as the oxygen flow rate was increased from 0 to 3.0 mL/min by adjusting the exhaust through the main gas valve.

Five samples (A 1–A 5) were prepared by changing the ratio of argon and oxygen flow mixtures (1:0.5, 1:1, 1:1.5, 1:2, and 1:4). The sputtering time for sample A 1 was varied from 30 min to 1 h with an average deposition rate of 100 nm/h and constant discharge power of 350 W. All the films were transparent, and their colors changed from slight blue to slight green. The preparation of highly transparent films is very important because it is necessary to have minimal light absorption within the coated films to retain the original transparency of the substrate. Figure 6a shows the optical transmittance spectra of PDMS and five modified samples over a wavelength range of 250–700 nm. After coating TiO2 films, all the five samples have optical absorption over a wavelength range of 250–300 nm, which is typical for the fundamental absorption of TiO2.

a Optical transmittance spectra of PDMS and samples coated with TiO films, b XPS spectra of the TiO2 films with mixed titanium oxidation states. Reproduced from [102] with permission from © 2005 Elsevier B.V.

Sample A 1 showed a transmittance of about 0.57 at a wavelength of 280 nm, indicating relatively low optical loss. A 3–A 5 were prepared at ambient temperature. The samples had large amounts of O2 and showed lower transmittance. The film thickness is a main factor in the film transmittance and it was lowest for sample A 1, which had the highest UV transmittance. The surface morphology is another factor in the film transmittance. A film with larger crystallite size could cause stronger reflection and interference of light, which results in lower transmittance and lower optical absorption. UV spectrum analysis indicates that all the samples have optical absorption over a wavelength range of 250–300 nm. The structure was amorphous, the surface morphology was smooth, and the size of grains was about 30–50 nm. Mixed titanium oxidation states of the film surfaces were found in XPS analysis (Fig. 6b).

Sicha et al. [103] reported low-temperature high-rate sputtering of hydrophilic transparent TiO2 thin films using DC dual magnetron (DM) sputtering in an Ar + O2 mixture on unheated glass substrates. The DM was operated in a bipolar asymmetric mode and equipped with Ti (99.5) targets with 50-mm diameter. A spectrally selective reflector can be fabricated by depositing a TCO on a reflective substrate. The films were deposited on unheated microscope glass slides (26 × 26 × 1 mm3) and unheated polycarbonate (PC) substrates (26 × 26 × 3 mm3). TiO2 films with a constant thickness t ≈ 1000 nm were prepared to avoid a strong influence of the film thickness on the properties [104, 105]. Figure 7 presents the time evolution of the pulse waveforms of the current (I d) and voltage (U d) in the dual magnetron discharge generated in the oxide mode of sputtering (\( {\text{P}}_{{{\text{O}}_{2} }} \) = 0.15 Pa) at different values of the repetition frequency f r, an average discharge current I da 1, 2 of 3 A, and P T of 0.9 Pa. It is clear from Fig. 7 that the utilization of the period T = 10 µs (f r = 100 kHz) can be improved if f r of the pulses is increased. Due to shortening of the pulses and cutting of the stationary regime, only the first time interval with strong sputtering is present, and plasma build-up regime starts to dominate.

The time evolution of discharge voltage U d and current I d in the DC pulsed discharge generated by the dual magnetron equipped with Ti targets at I da1,2 = 3 A, \( {\text{P}}_{{{\text{O}}_{2} }} \) = 0.15 Pa (oxide mode), P T = 0.9 Pa and three values of repetition frequency (f r) = 100, 200, and 300 kHz; I da1,2 is the discharge current averaged over the pulse lengths. Reproduced from [103] with permission from © 2007 Springer-Verlag

The conclusion is that transparent hydrophilic TiO2 film composed of a mixture of the anatase and rutile phases can be obtained with transition-mode sputtering at high deposition rate (a D = 80 nm/min) on glass substrate with substrate-to-target distance d s–t = 100 mm and T surf ≈ 180 °C. TiO2 film with excellent hydrophilic properties was successfully sputtered in oxide mode at T surf ≈ 120 °C, a D = 5.2 nm/min, and f r = 350 kHz on a PC substrate without thermal destruction. The evolution of the film structure with increasing f r is shown in Fig. 8. Nb-doped anatase TiO2 (Ti1−x Nb x O2; TNO) has a high refractive index (~2.4), which plays an important role in increasing the plasma wavelength and suppressing electron scattering by impurities [106]. Excellent electrical conductivity (σ ~ 2173.9 Ω cm) and visible transparency of 60–80 % were achieved, even with polycrystalline TNO films on glass prepared by crystallizing amorphous films at high temperature (>500 °C) [107]. This demonstrates the potential of TNO as a next-generation TSO.

a Development of the structure in the ~1000-nm-thick transparent TiO2 films reactively sputtered on unheated glass substrates at I da1,2 = 3 A, d s–t = 100 mm and T surf ≈ 160–180 °C, P T = 0.9 Pa and \( {\text{P}}_{{{\text{O}}_{2} }} \) = 0.15 Pa with increasing f r. b The X-ray structure of the 1000-nm-thick transparent TiO2 films sputtered on glass and polycarbonate substrates at f r = 350 kHz, I da1,2 = 2 A, P T = 0.9 Pa, \( {\text{P}}_{{{\text{O}}_{2} }} \) = 0.2 Pa, d s–t = 100 mm, T surf ≈ 120 °C, and a D = 5.2 nm/min and their hydrophilicity as a function of time of UV irradiation. Reproduced from [103] with permission from © 2007 Springer-Verlag

Maghanga et al. [108] deposited TiO2:Nb thin films on glass substrate by DC magnetron sputtering followed by optical characterization to extract the related optical parameters. They used these parameters to model optimized solar effective reflectors (SSRs) for solar cell applications. SSRs may offer advantages in photovoltaic systems by concentrating sunlight. When the reflector in a photovoltaic concentrator is replaced with an SSR, such as in a compound parabolic reflector (CPC), the reflectance for the SSR should depend on the wavelength λ. Ideally, the reflectance should also be unity for wavelengths below that corresponding to the bandgap of the absorber (λ c) and zero for λ > λ c. Then, the SSR can direct the solar radiation that is effective for photoelectric conversion towards the solar cell and simultaneously suppress radiation that would only heat up the cell and thereby reduce its efficiency.

The significant design parameters are the integrated reflectance values (R cell and R therm):

where G(λ) is the AM 1.5 solar spectrum. A structure with a TSO on top of an aluminum substrate coated with an aluminum oxide layer was considered, and literature data for the optical constants of Al [109] and Al2O3 [110] were used. Corresponding films were then successfully produced. The best wavelength-integrated reflectance values were 79 and 31 % in the ranges of 300 < λ < 1100 nm and 1100 < λ < 2500 nm, respectively. An SSR based on TiO2:Nb film was modeled and then successfully produced experimentally [108]. An intermediate buffer layer of Al2O3 deposited between a reflective substrate and the TSO is necessary to suppress the deep fringes arising from the high refractive index of the TiO2:Nb film. This intermediate film also plays a role in reducing the reflectance around the absorption edge.

An increase in the doping concentration reduces R therm drastically due to increased free carrier absorption. The modeled reflectance data in Fig. 9a show that the reflectance around λmin is systematically reduced as the Nb concentration is increased, while λmin seems to shift to lower wavelengths as the Nb content is increased. This is due to free carrier absorption. The variation of R cell and R therm is a function of the Nb concentration in the film based on the modeled reflectance data (Fig. 9b). R therm drops sharply with increasing Nb concentration, whereas R cell is not affected. Experimental and theoretical reflectance data agree well, as shown in Fig. 9c for TiO2:Nb film on Al substrate without an intermediate layer and for a three-layer construction with a 90-nm Al2O3 intermediate layer. The minor deviations can be attributed to the non-ideal thickness of the Al2O3 layer. The inconsistency in thickness could also be due to oxidation of the Al substrate. There is an additional layer besides the sputtered layer before the sputter deposition. The effect may vary depending on how successful the initial etching of the substrate is. Moreover, the optical constants of Al obtained from the literature may differ slightly from those of the actual Al substrate used. Comparison of the two figures shows that besides minimizing the fringe depth, the Al2O3 layer reduces the reflectance around the absorption edge and shifts it toward longer wavelengths.

a Modeled reflectance of TiO2:Nb/Al2O3/Al three-layer film. Nb doping level is represented. b Variation of R cell and R therm for TiO2:Nb/Al2O3/Al three-layer films with Nb doping, as calculated from the modeled reflectance. c Comparison between calculated and measured spectral reflectance for a TiO2:Nb/Al two-layer structure, d TiO2:Nb/Al2O3/Al three-layer structure. The layer thicknesses are shown. Reproduced from [108] with permission from © 2009 SPIE, CCC code: 0277-786X/09/$18

Kasai et al. [111] reported anatase Nb-doped TiO2 TCO formation on GaN(0001) surfaces using a sputtering method. Thin films of Nb-doped TiO2 were deposited on an insulating GaN(0001) template using RF sputtering at substrate temperatures (T s) ranging from RT to 400 °C. A two-inch Ti0.94Nb0.06O2 disk was used as a target [101], with the base pressure of the sputter chamber below 5 × 10−5 Pa prior to each deposition. Film deposition was carried out in a mixture of Ar and O2 with various O2/(Ar + O2) flow ratios with f (O2) in the range of 0–0.2 % and a total pressure of 0.8 Pa. The RF power applied to the target was kept constant at 100 W during sputtering, and the target-sample distance was set to 75 mm.

The films had a resistivity of 8.1 × 10−4 Ω cm with absorption less than 5 % at a wavelength of 460 nm (film thickness ~170 nm). The refractive index values of the Nb-doped TiO2 and GaN match very well with each other, and the results appear to indicate that the light extraction efficiency of GaN-based LEDs can be further enhanced using TiO2-based films as transparent electrodes. Figure 10(1) shows the transport properties of annealed films as functions of oxygen partial pressure [f(O2)]. The resistivity value (ρ) tends to decrease with increasing f(O2) from 0 to 0.1 % (Fig. 101a). This may be due to the volume fraction of rutile phase (which has a higher ρ than anatase) decreasing with f(O2). At f(O2) = 0.125 %, ρ shows a minimum value of 8.1 × 10−4 Ω cm. However, further increases in f(O2) result in increased ρ. The carrier concentration n e shows a weak dependence on f(O2) and reaches a maximum of n e = 1.5 × 1021 cm−3 at f(O2) = 0.125 % (Fig. 101b). The activation efficiency of Nb donors exceeds 90 %, which is a characteristic feature of TNO. The Hall mobility µ H attained a maximum value of 4.5 cm2/V s, which is approximately half that of TNO on glass substrate.

1 Transport properties of polycrystalline anatase Ti0.96Nb0.06O2 thin films on insulating GaN template measured at room temperature. 1(a) resistivity, (b) carrier density, and (c) Hall mobility shown as functions of oxygen flow ratio (f(O2). 2 Color line (a) Optical transmittance T and reflectance R spectra of GaN template (black or thin curves) and polycrystalline anatase Ti0.96Nb0.06O2 films on GaN template (red or thick curves). The Ti0.96Nb0.06O2 film was prepared at f(O2) = 0.125 %. (b) Absorbance A evaluated from the relation A = 100 − T − R. The dashed vertical line indicates the wavelength of 460 nm. The A value of the Ti0.96Nb0.06O2 film is less than 5 % at 460 nm film thickness (170 nm). Reproduced from [111] with permission from © 2010 American Institute of Physics (Color figure online)

Figure 10(2) shows the optical transmittance (T), reflectance (R), and absorbance spectra of a polycrystalline TNO thin film (f(O2) = 0.125 %) and a GaN template. Interference patterns were found to originate from the GaN template on the Al2O3 substrate. The optical properties at the wavelength of 460 nm determine the performance of blue or white LEDs. At this wavelength, the reflectance values with and without TNO are almost identical, suggesting that TNO and GaN have nearly equivalent refractive indices. The TNO film on the GaN template has a transmittance of approximately 70 %, and an absorptance as low as 5 % estimated from A = 100 − (T + R). The absorption of the insulating GaN template is less than 1 % at 460 nm. The A value can be further reduced to 3.2 % by increasing f(O2) to 0.15 %, although a slight increase in ρ to 1.2 × 10−3 Ω cm occurs (n e = 1.3 × 1021 cm−3, µ H = 3.9 cm2/V s).

Pulsed laser deposition

PLD is an efficient technique for producing robust nanostructured films capable of assisting laser desorption/ionization for low-molecular-weight analyses for cationization by metals. Tantalum-doped TiO2 films were synthesized on glass substrate at 300 °C by PLD technique [112–115]. The target used in the experiments was prepared by the traditional ceramic process. TiO2 and Ta2O5 powders with 99.99 % purity were mixed in molar ratio of 0.96:0.04 and then ground by ball milling for 12 h. The homogenous mixture was pelletized, pressed into a disk, calcined at 1100 °C for 5 h in air, and then cooled to room temperature before introduction to a PLD chamber for film deposition.

After film deposition and post-annealing in vacuum (~10−4 Pa) at temperatures ranging from 450 to 650 °C, the films crystallize into anatase TiO2 structure and have very good conductive features. With increasing post-annealing temperature up to 550 °C, the measured resistivity of the films was around 8.7 × 10−4 Ω cm. The films had high transparency over 80 % in the visible light region. These results indicate that tantalum-doped anatase TiO2 films have great potential as TCOs [114].

The XRD profiles of the deposited films do not show any obvious diffraction peaks, implying an amorphous structure. Diffraction peaks at around 25.1° in Fig. 11a corresponding to the anatase structure were observed for the samples followed by vacuum annealing at temperatures higher than 450 °C. The diffraction profiles change with the annealing temperatures. Figure 11b shows the resistivity of the samples annealed at different temperatures. The sample annealed at 550 °C had the lowest resistivity of 8.7 × 10−4 Ω cm, and the films had the largest crystallite size compared with samples annealed at other temperatures. The resistivity of the films was very large due to the amorphous structure. After post-annealing in vacuum, all the films became conductive. The annealing conditions were very effective for increasing conductivity.

a XRD patterns of the Ti0.96Ta0.04O2 at different temperatures, b resistivities of Ti0.96Ta0.04 O2 films on the glass before and after annealing at different temperatures. Reproduced from [114] with permission from © 2011 Chinese Physical Society and IOP Publishing Ltd

Hsu et al. [115] investigated the morphological, structural, and optical properties of anatase TiO2 thin films synthesized by PLD technique. High-quality photocatalytic polycrystalline TiO2 anatase films can be grown by PLD at moderate substrate temperature under oxygen pressures between 1.0 and 20.0 mTorr, followed by annealing with an O2 pressure of 1 atm at 600–650 °C for 1 h. A large amount of amorphous phase was found in the as-deposited films. Raman data showed that nano-crystallization occurred in films deposited on SiO2 and MgO substrates, for which the XRD patterns displayed a lack of crystallinity. The structural data correlate well with the optical and contact-angle results. Films deposited at low pressures are oxygen-deficient and become stoichiometric after subsequent annealing in oxygen. Surface roughness is an additional factor for increased film hydrophilicity.

Tonooka et al. [116] deposited conducting Nb-doped TiO2 thin films on glass substrates by PLD method and examined the dependence of their electrical and crystalline properties on the deposition and annealing conditions. The development of anatase phase in the Nb-doped TiO2 film was suggested to be the dominant factor influencing the conductivity of the film. The O2 pressure during deposition and the annealing temperature were optimized to fabricate the most conductive Nb-doped TiO2 thin films. The lowest resistivity of 6.7 × 10−4 Ω cm was obtained for the film deposited at RT in 0.92-Pa O2 partial pressure followed by annealing at 350 °C for 10 min in vacuum (<10−5 Pa). The Nb-doped TiO2 thin films showed high reflectance between 10.0 and 24.0 µm and low absorbance of less than 10 % in the visible region.

Chemical vapor deposition

Among the different TiO2 deposition techniques, CVD offers several advantages, including purity of the coating, moderately low cost compared to other vacuum-based techniques, versatility to produce different morphologies, and good adhesion to the substrate [117–120]. Mills et al. [121] fabricated a series of novel CVD films of titanium (IV) oxide of different thicknesses in the range of 10–91 nm on quartz substrate by reacting titanium (IV) chloride and ethyl acetate. The films were clear, mechanically robust, and comprised a thin layer of nanocrystalline anatase titania of different thicknesses that absorbs UV light. The photocatalytic activity depended directly on the fraction of light absorbed, and the quantum yield for the overall process was 3.5 × 10−4, which is lower than that for sol–gel TiO2 films.

Pazoki et al. [122] developed a simple atmospheric pressure CVD setup to grow different TiO2 morphologies on glass substrates simultaneously (Fig. 12). Rapid film growth at relatively low temperature (250 °C) was obtained using TiCl4, O2, and H2O as reactants. Depending on the zone in the hot-wall reactor, spherical particles, nanowires, and mesoporous structures were found due to local differences in temperatures, reactant concentrations, and boundary layer conditions. Two types of light-scattering paste were tested: the CVD paste and commercial paste PST-400C (JGC Catalysts and Chemicals Ltd.) containing 400-nm-sized anatase TiO2 microcrystals. Figure 13 shows the total transmission spectra of the different TiO2 films on the FTO substrates. The transparent film shows a high transmittance of about 82 %.

Schematic representation of the CVD setup, illustrating 3 sample zones A, B, and C, separated by 3 cm from each other. Zone C is in the center of the reactor. The corresponding SEM images of the deposited films at each sample zone are shown on top. Reproduced from [122] with permission from © 2012 The Royal Society of Chemistry

Total (specular + diffuse) transmission of T, T + CVD, and T + JGC films on TEC15 substrates [70]. T, T + CVD, and T + JGC are representative of DSCs with 1 layer of transparent Dyesol paste, 1 layer of Dyesol paste plus 1 layer of CVD paste, and 1 layer of Dyesol paste plus 1 layer of JGC_PST-400C scattering paste, respectively. Reproduced from [122] with permission from © 2012 The Royal Society of Chemistry

Adding the CVD scattering layer decreased the transmittance to 33 % in the wavelength range of 600–700 nm, while adding the JGC layer reduced the transmittance to about 22 %. Since TiO2 does not absorb light at these wavelengths, the decrease in transmittance is directly attributed to the light-scattering properties of the CVD and JGC films. This was confirmed by the pure white appearance of the films. The total reflectances at these wavelengths were thus 67 and 78 % for the CVD and JGC film, respectively. Table 3 presents the optical and electrical properties of TiO2 thin films obtained with different dopant concentrations and various vacuum-based synthesis processes.

Solution-based techniques

Sol–gel

The sol–gel process has distinct advantages over other techniques, including excellent compositional control, homogeneity at the molecular level due to the mixing of liquid precursors, and lower crystallization temperature [123–126]. Moreover, the microstructure (i.e., the pore size, pore volume, and surface area) of films can be tailored by controlling the processing parameters such as the ratio of the components and temperature [127]. TiO2 thin films prepared by sol–gel processing have been reported as new materials for humidity sensors [128]. TiO2–SnO2 sol–gel thin films were also investigated for this application. The film with 20 wt% TiO2 had the highest sensitivity with a change of over three orders of magnitude in resistance when varying the relative humidity (RH) between 20 and 90 % [129].

Figure 14(1) shows SEM images of TiO2 and TiO2–SnO2 thin films. The images reveal that the TiO2–SnO2 films have rougher surfaces than TiO2 films, which may be due to slight agglomeration by mixtures of both SnO2 and TiO2 colloids. The TiO2–SnO2 films have nanometer grain size and nanoporous structure. This structure is likely to facilitate the adsorption process of water molecules because of the capillary pores and large surface area. Figure 14(2) shows the resistance as a function of RH for the TiO2 and TiO2–SnO2 thin films. All the films were annealed at 500 °C for 30 min. The resistance of the films decreases linearly with increasing RH with about three orders change at RH of 20–90 % with a good exponential relationship. In particular, the resistance of the TiO2-20 wt% film decreases considerably in this range, showing very high sensitivity. The electrical properties of the films responded quickly to exposure to water in the atmosphere. The response times at 70 % RH for the TiO2–SnO2 films with 0, 5, 20, and 40 wt% SnO2 content were 5, 6, 15, and 20 s, respectively. The shorter response time in the films with increased TiO2 content seems to be due to the hydrophilic property of TiO2.

1 The SEM micrographs for TiO2–SnO2 films: (a) TiO2–5 wt% SnO2; (c) TiO2–20 wt% SnO2; (d) TiO2–40 wt% SnO2. 2 Humidity sensing properties for TiO2–SnO2 films with different SnO2 contents. Reproduced from [129] with permission from © 2002 Published by Elsevier Science B.V.

Humidity sensors consisting of ceramic particles are quite stable for about 3 h at 60 % RH. Thin films of mixed oxides of CeO2–TiO2 with a Ce/Ti molar ratio of 0.5 have been obtained by a sonocatalytic sol–gel method [130]. The precursor sols consist of a mixture of Ce(NH4)2(NO3)6, titanium alkoxide (Ti(OiPr)4), and isopropanol. The films were deposited by dip coating technique and calcined at 450 °C in an oxygen atmosphere. The films prepared from the precursor sols were subjected to electrochemical measurements (cyclic voltammetry and chronoamperometry), SEM, and AFM. CeO2-TiO2 films approximately 100 nm thick presented good electrochemical response under Li ion insertion. The cathodic and anodic charges at a scan rage of 50 mV/s were about 16 mC/cm2, and the process was fully reversible. The values were constant for up to 4500 cycles, indicating good electrochemical stability of the films. The stability test and optical measurements confirm that the films can be used for ion storage (as counter electrodes) in electrochromic devices [130]. TiO2 is considered a promising candidate for TSO applications, and the ion-storage and humidity sensing properties of this technologically important material could lead to very important TSO-related electronic/optoelectronic applications in electrochromic or smart windows, defrosting windows, and transparent functional window sensors, among others.

Spray pyrolysis

Spray pyrolysis is particularly attractive because it is scalable and a potential low-cost process suitable for highly uniform deposition of dense TiO2 layers onto large-area substrates [107, 131–133]. Abou-Helala et al. [134] successfully prepared transparent TiO2 thin films on glass substrates using spray pyrolysis technique. The films were amorphous at deposition temperatures up to 450 °C. Starting at about 550 °C, the films partially crystallized (anatase phase; Fig. 15).

XRD of TiO2 films at different deposition temperatures and 10 min spray time. Reproduced from [134] with permission from © 2002 Published by Elsevier Science B.V.

The prepared films have good homogeneity with some porosity, which is suitable for photocatalytic applications. TiO2 films can be prepared by spray pyrolysis at different substrate temperatures. The film thickness can be controlled by the number of spray pulses. Deposition or annealing at 500 °C results in anatase phase without contaminants. Annealing at 700 °C in air leads to crystalline anatase formation for films deposited below 400 °C. Films prepared at 435 °C are a mixture of anatase and rutile, and those obtained at 500 °C are rutile. Transparent TiO2 anatase films grown at 375 °C and annealed at 700 °C show refractive indices of 2.2–2.4 and RMS roughness of 2.6 nm.

Cost-effective spray pyrolysis methods could be used to prepare TiO2 films with an effective dielectric constant of 75 at 10 kHz [135]. TiO2 thin film deposited by spray pyrolysis at a substrate temperature of 100 °C is amorphous, but when annealed at 400 °C, it changes phase to anatase with sharp XRD peaks showing crystallization as temperature increases. XRD studies showed that after annealing, the films were predominantly anatase with characteristic (101), (112), and (204) planes [135]. Table 4 compares the properties of TiO2 thin films prepared by sol–gel and spray pyrolysis methods.

Fabrication of p-type TiO2

One of the efficient ways to modify the physical and chemical properties of TiO2 is doping with other elements. However, the low electrical n-type semiconductivity of TiO2 inhibits its practical implementation as a conductometric sensor. The addition of foreign atoms into a TiO2 host such as Sn, Cr, Nb, W, and Mo has been widely studied to improve gas sensing behaviors [136–145]. p-type conductivity in TiO2 can be achieved by doping with a suitable acceptor (Cr3+, Fe3+, Ni2+, or Co+2) at various concentrations [146–153]. Cation doping provides additional bands within the bandgap of TiO2 for easy charge transportation. This can also be used to optimize charge injection and transport for efficient organic light-emitting devices [154] and to reduce the turn-on voltage in optoelectronic devices [155].

Bally et al. [156] prepared Fe-doped TiO2 thin films by reactive RF sputtering (power-700 W) with deposition rates between 0.2 and 0.4 Å/s under a pressure of 10−1 Pa in a mixed Ar and O2 atmosphere (33 % of oxygen). Silicon, glass, and indium tin-oxide (ITO)-coated glass substrates were heated to 260 °C during the deposition. The target was a metallic titanium disk (99.5 % purity, 60-mm diameter). Holes drilled into the titanium target (3-mm diameter) were filled with iron oxide powder to obtain Fe-doped TiO2 thin films. The iron doping induces transformation from anatase to rutile without amorphization for doping lower than 1.3 at.%. The transition from n-type to p-type electrical conduction occurs with iron concentration around 0.13 at.%.

The highest p-type conductivity reached at room temperature is 10−6 S/m. The dispersion of the permittivity with frequency indicates that the electrical conduction of the thin films is inhomogeneous. The influence of the iron atoms depends on the crystal structure of the oxide. The introduction of iron generates more oxygen vacancies in anatase than in rutile. A large fraction of the acceptors created by the iron atoms is compensated by the oxygen vacancies created by the same iron atoms. The results show that pure rutile TiO2 doped with iron has higher p-type conductivity than mixed anatase/rutile TiO2 iron-doped thin films.

Cr-doped TiO2 could exhibit p-type properties under high Cr doping (higher than 8 %) or high preparation temperature (up to 900 °C) [157, 158]. The high preparation temperature melts down TSO substrates, and the high Cr doping results in strong electron–hole recombination, which greatly hinders the fabrication and application of p-type Cr-TiO2 photo-electrodes. As a photo-electrode material, TiO2 has the advantages of large carrier diffusion length (~1 mm), high chemical stability, and non-toxicity [159]. Based on the excellent PEC properties of TiO2-related materials, p-type photo-electrodes are predicted to have high potential for use as a cathode for photo-reduction. Cao et al. [77] prepared p-type Cr-doped TiO2 photo-electrodes on an ITO substrate using the PLD method. Figure 16 presents the STEM/SEM images with I-V characteristics of the films. A uniformly Cr-doped TiO2 photo-electrode, an inner Cr-doped TiO2 photo-electrode, and an inner Cr-doped TiO2 photo-electrode with Pt loading were fabricated, and their PEC properties were discussed in detail (Fig. 17).

a STEM cross-section image of the inner Cr-doped TiO2 thin film; b atom ratio of Cr/Ti at different thicknesses of the TiO2 layer; c SEM image of the Pt-loaded inner Cr-doped TiO2 thin film d the I–V curves of the as-prepared thin films. The inset shows the I–V curves of the uniformly Cr-doped TiO2 thin film. Reproduced from [77] with permission from © 2013 The Royal Society of Chemistry

1(a) XPS spectrum of Cr 2p in the uniformly Cr-doped TiO2 thin film; inset shows the XPS spectrum of O 1s; (b) Raman spectra of the uniformly Cr-doped TiO2 thin film and TiO2 thin film. 2(a) XPS spectrum of the TiO2 thin film at the valence band region; (b) XPS spectrum of the uniformly Cr-doped TiO2 thin film at the valence band region. Furthermore, by utilizing the local doping strategy and Pt loading, the PEC activity of the as-prepared p-type Cr-doped TiO2 photo-electrodes was improved significantly. Reproduced from [77] with permission from © 2013 The Royal Society of Chemistry

TiO2-based mixed oxides have also been reported to show p-type semiconductivity and good visible transparency for interesting TSO applications. For example, Li et al. [160] prepared Ti–Al-V–O oxide nanofilms with anatase structures by anodization and annealing. Anatase TiO2 nanofilms doped with Al and V were fabricated through anodic oxidation of Ti6Al4 V alloy and annealing treatment. The anodic substrate was Ti6Al4V alloy plate. Cast plate samples with dimensions of 10 × 10 × 1 mm were ground and polished with emery paper and ultrasonically cleaned with absolute alcohol. Finally, they were rinsed with deionized water and dried in a N2 stream. All of the samples were anodized using a DC voltage stabilizer at 15 V for 1.5 h in electrolytes of 1 M NaH2PO4 containing 0.5 wt% HF. The as-anodized samples were annealed at either 450 °C or 550 °C for 1 h in air to obtain crystallized nanofilms.

Nanofilm sensors were fabricated using circular Pt electrodes and conductive wires for printed circuit board (PCB) assembly. During hydrogen sensing experiments, a Keithley 2700 multimeter (Cleveland, OH, USA) was used to test the resistance of the nanofilm sensor. The nanofilm sensors were tested in alternating atmospheres of air and 1000-ppm H2 at temperatures ranging from 25 to 300 °C. Annealing at different temperatures resulted in different hydrogen sensing performance. Al and V doping reduced the bandgap of TiO2 oxide. The Al- and V-doped anatase nanofilms demonstrated p-type hydrogen sensing characteristics, which was quite different from the undoped TiO2 nanotubes (Fig. 18). Hydrogen sensing properties of the oxide nanofilms were tested with operating temperature ranging from 25 to 300 °C. The resistance of the Ti–Al–V–O nanofilm sensors tested in the hydrogen atmosphere was recorded. The response (ΔR/R 0) of the nanofilm sensor is defined as follows:

where R 0 is the original resistance of the sensor before exposure to the hydrogen-containing atmosphere, and R is the sensor resistance after exposure to or removal of the hydrogen-containing atmosphere. The Ti–Al–V–O nanofilms annealed at 450 °C demonstrated sensitivity to 1000-ppm H2 at elevated operating temperatures, while Ti–Al–V–O nanofilms annealed at 550 °C had good sensing response at both room temperature and elevated temperatures.

XPS analyses of the Ti–Al–V–O oxide nanofilms annealed at different temperatures. a Deconvolution of survey spectrum and b Ti 2p3, c Al 2p, d V 2p3, e O 1s scan curves. Reproduced from [160] with permission from © 2013 licensee Springer

Similarly, Sieradzka et al. [161, 162] reported a p-type transparent Ti–V oxides semiconductor thin film obtained by reactive magnetron sputtering technique. The sputter target was Ti pellets combined with V metallic foils, and the sputtering was performed in an oxygen-diluted Ar atmosphere with special conditions of the magnetron power to enhance the nucleation energy. A nearly 334-nm-thick film of Ti–V mixed oxide was deposited on glass, Si, and SiO2 substrates. The optical transmittance spectra depict more than 60 % visible transparency for the Ti–V mixed oxide thin film, and electrical measurements reveal thermally activated conduction. This is often found in semiconductor thin films with considerably higher room temperature conductivity over undoped film, indicating potential applications in transparent electronics (Fig. 19). The p-type conductivity of the mixed oxide film was confirmed by thermopower measurements, and the room temperature Seebeck coefficient was +685 μV/K. The p-type semiconductivity of this Ti–V mixed oxide film is considered to come from the reduced oxidation state of V (+3 valance state of V2O3), which manifests vanadium vacancies that act as acceptor levels and introduce holes in the VB.

a Transmission spectra of TiO2 and Ti–V oxides thin films, b Temperature-dependent resistivity measurements of Ti–V oxides thin film deposited on glass, c p-TSO/n-Si heterojunction based on Ti–V oxides thin films. Reproduced from [161] with permission from © 2011 Elsevier B.V.

The same group further verified the p-type semiconductivity of their Ti–V mixed oxide film by fabricating an n-Si/p-Ti–V oxide heterojunction to show rectifying characteristics (Fig. 19). Although the use of Si as the n-layer is restricted in transparent diodes, some well-known n-TSOs (like ITO, ZnO, SnO2, and TiO2) can potentially be used in transparent electronics. Sieradzka et al. also reported multi-element doping into rutile TiO2 to observe inversion in the semiconductivity of the magnetron sputtered thin film [163]. Simultaneous doping of Tb and Pd into TiO2 (TiO2:Tb + Pd) produces p-type semiconductivity, whereas Eu and Pd doping (TiO2: Eu + Pd) produces an n-type thin film. Both films showed considerably high visible transparency and carrier concentrations for potential use in TSO applications.

Properties

Structures

There are four commonly known polymorphs of TiO2 found in nature: anatase (tetragonal), brookite (orthorhombic), rutile (tetragonal), and TiO2 (B) (monoclinic) [164–168]. Among the many poly types of TiO2, the technologically important crystal structures are rutile and anatase (Fig. 20). Although TSOs have been investigated for many years, the mechanisms accounting for their electrical and optical properties are still somewhat poorly understood. Over the last few years, TiO2 has gained increasing attention as a TSO material after by Furubayashi et al. produced an Nb-doped anatase TiO2 film with excellent conductivity and transmittance comparable to ITO. [44]. The advantages of anatase TiO2 as a TSO include relatively low effective mass, low cost, and stability in a hydrogen plasma atmosphere, which is used to produce solar cells. Undoped anatase is an anisotropic tetragonal insulator (a¼ 0.378 nm and c¼ 0.952 nm) with a bandgap of 3.2 eV [44].

Crystal structures of a anatase and b rutile, and a schematic representation of the TiO6 networks in c anatase and d rutile. Red and blue spheres denote Ti and O atoms, respectively. Reproduced from [41] with permission from © 2010 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim (Color figure online)

Rutile

Rutile TiO2 has a tetragonal structure and contains 6 atoms per unit cell (Fig. 20b). The TiO6 octahedron is slightly distorted [81, 169–171]. The rutile phase is stable at most temperatures and pressures up to 60 kbar, where TiO2(II) becomes the thermodynamically favorable phase [172]. Anatase and brookite structures transform to the rutile phase after reaching a certain nanoparticle size, with the rutile phase becoming more stable than anatase for particle sizes greater than 14 nm [173]. Once the rutile phase forms, it grows much faster than the anatase. The activity of the rutile phase as a photocatalyst is generally very poor. However, it was suggested that the rutile phase can be active or inactive, depending on its preparation conditions [81].

Anatase

Anatase TiO2 also has a tetragonal structure, but the distortion of the TiO6 octahedron is slightly larger [167, 174]. The anatase phase is more stable than the rutile at 0 K, but the energy difference between these two phases is small (2–10 kJ/mol) [175]. The photoreactivity is increased by the slightly higher Fermi level, lower capacity to adsorb oxygen, and higher degree of hydroxylation in the anatase phase [176]. The reactivity of (001) facets is greater than that of (101) facets in an anatase crystal [177]. Uniform anatase crystals containing 47 % (001) facets were synthesized using hydrofluoric acid as a morphology-controlling agent [178].

Brookite

Brookite TiO2 belongs to the orthorhombic crystal system. Its unit cell is composed of 8 formula units of TiO2 and is formed by edge-sharing TiO6 octahedra. It is more complicated, has a larger cell volume, it is the least dense of the 3 forms, and it is not often used for experimental investigations. TiO2 is a large-band semiconductor with bandgaps of 3.2, 3.02, and 2.96 eV for the anatase, rutile, and brookite phases, respectively [179]. The VB of TiO2 is composed of the 2p orbitals of oxygen hybridized with the 3d orbitals of titanium, while the CB is only the 3d orbitals of titanium [180].

Raman spectroscopy

Raman spectroscopy is a powerful tool in studying microstructure or nanostructure of materials. Depending on various vibrational modes, different phases can be obtained in a mixed crystal. Hence, this technique is promising for microstructural characterization and phase identification of TiO2 [181–183]. Additionally, Raman spectroscopy can also be used to identify and quantify the amorphous and crystalline TiO2 phases [183]. Figure 21 presents typical Raman spectra of amorphous, brookite, anatase, and rutile TiO2. As expected, amorphous TiO2 has the lowest Raman activity and does not show any significant Raman peak except for some broad bands.

Room temperature Raman spectra of the various phases of Titania. Reproduced from [188] with permission from Gonzalez RJ, Ph.D. Thesis, Virginia Polytechnic Institute and State University (1996) Raman, Infrared, X-ray, and EELS Studies of Nanophase Titania

Temperature treatments convert the amorphous TiO2 into crystalline phases by the evolution of sharp Raman peaks, as shown in the figure. The Raman spectrum of rutile TiO2 shows some sharp and broad peaks assigned with different Raman-active lattice vibrations: B 1g (144 cm−1), B 1g (236–242 cm−1), E g (300–400 cm−1), E g + A 1g (unresolved doublet around 440–446 cm−1), B 2g (589 cm−1), A 1g (610 cm−1), and B 2g (827 cm−1) [169, 184, 185]. Although phonon vibrations corresponding to E g @ 300–440 cm−1, B 2g @ 589 cm−1, and B 2g @ 827 cm−1 are masked either by neighboring stronger peaks or high background noise, several groups reported significant intensities of these peaks, which are hence assigned here for completeness [183].

For anatase TiO2, the factor group analysis reveals six Raman-active modes (one A 1g, two B 1g, and three E g) [184], which were also experimentally observed by various groups and assigned as follows [181, 182, 185–187]: E g (144/147 cm−1), E g (197 cm−1), B 1g (397/399 cm−1), A 1g + B 1g (unresolved doublet around 513–519 cm−1), E g (639/640 cm−1). According to space group theory, 36 Raman-active modes are predicted for Brookite TiO2 (nine A 1g, nine B 1g, nine B 2g and nine B 3g) [188–190], out of which 17 bands were experimentally observed by several groups and assigned as follows: A 1g (127/128, 155/156, 194, 245/246, 412, 637/638 cm−1), B 1g (133, 213/214, 322/323, 501/502 cm−1), B 2g (365/366, 395/396, 460/461, 583 cm−1), and B 3g (172, 287/288, 545 cm−1) [191–195]. Other Raman modes are masked by a high level of coincidence and weak band intensities.

Apart from phase identification, Raman characterization is also used for the determination of size and non-stoichiometry of TiO2 nanocrystals [182, 186, 196–201], both of which are very important in TSO-related applications. Broadening and shifting of Raman bands are observed when particle dimensions change or oxygen deficiency is induced in the TiO2 crystal lattice (also, to some extent, strain, non-homogeneity of the size distribution, and anharmonic effects due to temperature increase can contribute to changes in the peak position and shape [182]). Regarding the size effect, Raman bands broaden and blue-shift with decreasing nanocrystal dimension d [187]. In a low-dimensional nanocrystal of size d, the phonon wave vector (k) is subjected to a k-space uncertainty that is inversely proportional to the nanocrystal dimension (1/d). Thus, the “infinite-crystal” k-space selection rule is replaced by a relaxed version with order 1/d, and instead of only the k = 0 mode of a phonon branch being Raman-active (for a Raman-allowed mode symmetry), all modes of the phonon branch within a range of k values (approximately k = 0–1/d) become Raman-active, leading to broadening of the Raman bands with decreases in the nanocrystal dimension. The blue-shift of the bands is due to the effect of smaller particle size on the force constants, where a volume contraction occurs within the nanoparticles, resulting in decreased interatomic distances and an increase in the force constant. This leads to shifting of the Raman bands toward a higher frequency region [201].

Knowing the phonon dispersion relation, it is possible to estimate the crystallite sizes from the Raman shift and broadening. In particular, this phonon confinement effect is more dominant at low frequency, so it is possible to determine the size of nanoparticles from a measurement of the maximum of the low frequency Raman band [201–203]. Additionally, because of the increase in the surface-to-volume ratio at the nanoscale, the surface modes become dominant as particle size decreases. This technique provides valuable information about the effects of the finite size of the nanoparticles on the surface modes, which means that new bands can be observed [200]. Several groups experimentally observed this size effect in nanocrystalline TiO2 [182, 186, 200].

Electro-optical properties

TSO materials are electrically conductive due to either intrinsic defects (oxygen vacancies or metal interstitials) or extrinsic dopants (typically a higher-valency metal). The extrinsic dopant concentration of the well-developed TSOs typically varies from 1020 to 1021 cm−3. Usually, the resistivity, ρ = 1/σ, rather than the conductivity, σ, is used as the figure of merit, which is on the order of 10−4 Ω cm for many TSO materials of practical viability. While the carrier concentration in TSO is limited by the solubility of dopants, the mobility µ is limited by scattering of the charge carriers in the lattice. Several electron scattering mechanisms could be operative in TSO, such as scattering by ionized impurities, neutral centers (point defects and their complexes), thermal vibrations of the lattice (acoustical and optical phonons), structural defects (vacancies, dislocations, stacking faults), and grain boundaries, depending on the carrier concentration and crystal quality of the material [204–214].

The transmission window of TSOs is defined by two imposed boundaries. One is in the near-UV region and determined by the effective bandgap E g, which is blue shifted due to the Burstein–Moss effect [215, 216]. Owing to high electron concentrations, the absorption edge is shifted to higher photon energies. The sharp absorption edge near the band edge typically corresponds to the direct transition of electrons from the VB to the CB. The other is in the near-infrared (NIR) region due to the increase in reflectance caused by the plasma resonance of electron gas in the CB.

The absorption coefficient α is very small within the defined window, and transparency is consequently very high [13, 217–220]. The positions of the two boundaries defining the transmission window are closely related to the carrier concentration. For TSOs, both boundaries defining the transmission window shift to shorter wavelength with the increase of carrier concentration. The plasma frequency at which the free carriers are absorbed has a negative correlation with the free carrier concentration. The shift in the near-IR region is more pronounced than in the near-UV region. Therefore, the transmission window becomes narrower as the carrier concentration increases. This means that both the conductivity and the transmittance window are interconnected since the conductivity is also related to the carrier concentration, as discussed above. Thus, a compromise between material conductivity and transmittance window is needed, and the specifics are application dependent. For LED applications, the transparency is needed in only a narrow range around the emission wavelengths, while solar cells require high transparency in the whole visible solar spectral range. Therefore, for photovoltaics, the carrier concentration should be as low as possible for reducing the unwanted free carrier absorption in the IR spectral range, while the carrier mobility should be as high as possible to retain a sufficiently high conductivity.

Among the many polytypes of TiO2, the most technologically important crystal structures are rutile and anatase (Fig. 20). Both have tetragonal symmetry and can be described as networks of TiO6 octahedra, but the two structures differ in the distortion and linkage of these octahedra. In the anatase structure, each octahedron is in contact with eight neighbors (four shared edges and four shared corners), as shown in Fig. 20, while the coordination number of rutile is 10 (two shared edges and eight shared corners) (Fig. 20d). Anatase TiO2 tends to incorporate oxygen vacancies, which can be expressed as TiO2-d. The amount of oxygen vacancies in d can be controlled by adjusting film growth or annealing conditions. The oxygen vacancies generate n-type carriers in the Ti-3d CB, so the resistivity (ρ) of TiO2 can be decreased by introducing oxygen vacancies. However, oxygen-deficient TiO2-d films lose their transparency and thus cannot be used as a TSO.

In addition to the introduction of oxygen vacancies, the substitution of Nb for Ti could introduce charge carriers. Indeed, Nb doping in rutile TiO2 decreases ρ by a factor of more than 5500 [221], although the minimum ρ value (~10−2 Ω cm at room temperature) [222, 223] is insufficient for TSO applications due to the low electron mass (≪1 m 0) in rutile [224]. Anatase has a higher mobility than rutile and is more suited to TSO applications. However, the transport properties of anatase have not been thoroughly studied since anatase is a thermodynamically metastable structure and it is difficult to grow single crystals in bulk form. Lévy et al. [225] first reported single-crystal growth of anatase using chemical vapor transport. They measured the optical and transport properties and obtained ρ on the order of 10−1 Ω cm with an electron mobility exceeding 600 cm2/Vs at 50 K [226]. Single crystals of Nb-doped anatase TiO2 were investigated by Mulmi et al. [226], who reported ρ values of 5 × 10−2 Ω cm. Their ρ versus temperature (ρ–T) curve exhibited semiconducting behavior, possibly due to the low Nb concentration. Anatase TiO2 films have been fabricated by various techniques [227, 228], as discussed in “Basic electronic band structure of TSO” section.

Maghanga et al. [228] prepared transparent and conducting thin films of TiO2:Nb on glass by reactive DC magnetron sputtering in Ar + O2 atmosphere at 8.5 mTorr pressure. Post-deposition annealing in vacuum at 450 °C led to good electrical conductivity and optical transparency. Sputtering was conducted with 220 W of power applied to the Ti target. The power applied to the Nb target was between zero and 45 W to make films with different Nb contents. Sputtering was performed on glass microscope slides, and Si plates were positioned ~13 cm below the targets on a rotatable holder. A small amount of H2 was added to avoid target poisoning. The substrates were maintained at 330 °C during sputtering, as measured by a thermocouple. After the deposition, the films were first allowed to cool within the sputter unit and then vacuum-annealed at 450 °C for 30 min in the deposition chamber.

Figure 22a, b show a comparison between experimental spectra on R(λ) and T(λ) for two Nb concentrations with the best fit obtained with the Drude–Brendel model [229]. The agreement between the experiment and the fitted data is generally good with standard deviation between 0.0001 and 0.0004 according to the fitting software. Some inconsistency occurred in the bandgap region and the long wavelength region for samples with more than 2 at.% Nb. This is due to the approximate nature of Drude–Brendel Equations for the case of complex conducting oxides.

Spectral normal transmittance (upper set of curves) and near-normal reflectance (lower set of curves) for sputter-deposited and annealed TiO2:Nb films with a 1.3 at.% Nb and b 2.1 at.% Nb. Spectral refractive index, n(λ), c and extinction coefficient, k(λ) d for sputter-deposited and annealed TiO2:Nb films with the shown Nb contents. Reproduced from [228] with permission from © 2009 Elsevier B.V.

Figures 22c, d show n(λ) and k(λ) for TiO2 and for TiO2:Nb with two different doping levels. The undoped film has dielectric behavior with n ≈ 2.2, irrespective of wavelength for λ > 500 nm. For the Nb-doped films, the optical constants are qualitatively different. In this case, k(λ) increases with λ, as expected for a metallic material, while n(λ) drops gently with larger λ. These effects increase the magnitude with increasing doping level of Nb. This study summarized the combined effect of doping and post-deposition heat treatment, which inhibited the formation of the rutile phase of TiO2. The optical properties were well illustrated by Drude free electron theory for frequencies below the bandgap in the case of doped films. Analysis of the individual contributions to the optical constants demonstrated that the Drude contribution increases with increasing Nb content. Good harmony was found between measured DC resistivity and the resistivity obtained from optical data.

A majority of researchers have reported that rutile TiO2 has both direct and indirect bandgap values around ~3.6 and ~3.10 eV, respectively [230, 231]. However, there is controversy over the exact bandgap transition (direct or indirect) within anatase TiO2. Although many groups predicted indirect transition [232], few have reported direct bandgap transition within nanostructured anatase TiO2 [233, 234]. In either case, the reported values of the bandgap of anatase TiO2 fall within the range of 2.86–3.34 eV [232]. For Brookite TiO2, theoretical and experimental works reported bandgap values both smaller and larger than that of anatase. For natural brookite mineral, the bandgap is reported to be indirect, but there is disagreement on whether the optical response of synthetic Brookite is attributable to direct or indirect transitions. In any case, the experimentally reported bandgap values lie within the range of 3.1–3.4 eV [192, 194], but in nanostructured brookite TiO2, direct band transition with considerably high bandgap values (>3.4 eV) is reported, which is very useful for TSO applications [235]. Generally, a lower bandgap of TiO2 (less than the energy of a blue photon (~3.1 eV)) is suitable for visible light-induced photocatalysis, whereas higher bandgap (>3.1 eV) is preferred for TSO applications.

Apart from the Burstein–Moss effect of the blue-shift of the fundamental absorption edge discussed earlier, the quantum size effect is also used to enhance the bandgap of TiO2 nanostructures for suitable TSO applications [48]. It is well known that in semiconductor nanocrystals, when the nanoparticle dimension becomes comparable to the bulk excitonic Bohr radius, the bandgap of the nanomaterial tends to increase due to the quantum confinement effect [236–238]. By proper tuning of the particle size, one can effectively enhance the bandgap, and especially for TSO nanomaterials, this bandgap enhancement is very useful for photovoltaics and other TSO electronics [239–245].

Several groups theoretically predicted a strong confinement effect in rutile TiO2 nanocrystals and proposed that around a crystallite size of 2.5 nm, the bandgap enhancement would be considerable [245, 246]. Similarly, several groups experimentally observed the size effect of bandgap enhancement in TiO2 nanocrystals and reported a considerable increase in the bandgap to beyond 3.1 eV, which is suitable for TSO-related applications [246–249]. Several groups observed this quantum size effect in multilayer/heterojunction/nanocomposite TiO2/Ge and TiO2/ZnO films with interesting photovoltaic/photoconductive applications [250–252].

Defect chemistry in TiO2

In general, stoichiometric metal oxides are considered to act insulators, and the corresponding bandgap values are effectively governed by the electropositivity and the outer-shell configuration of the metal ions (cations) within the lattice. For example, electropositive atoms without d-electron effects form wide-bandgap oxides that are essentially insulating. In contrast, metal atoms with d-electron effects form semiconducting oxide, and the defect mechanism plays an important role in the type of charge conduction within these types of metal oxides [70]. Metal excess (or oxygen deficiency) generally induces n-type semiconductivity, whereas metal deficiency (or oxygen excess) produces p-type semiconductivity in TSOs [253]. The general defect equilibrium for n- and p-type TSOs is respectively given by [253, 254]