Abstract

The structure evolution and thermal behaviors of polyacrylonitrile homopolymer (PAN) and terpolymer [P(AN–MMA–IA)] containing about 4.19 wt% methyl methacrylate (MMA), 0.98 wt% itaconic acid (IA) and 94.83 wt% acrylonitrile (AN) during heat treatments were studied by Fourier transform infrared (FTIR), differential scanning calorimetry and thermogravimetry. It was found that the presence of IA comonomer in PAN promoted the cyclization reactions significantly though initiating the cyclization reactions at lower temperature and proceeding at a faster rate than these of PAN homopolymer. Moreover, it was found that the dehydrogenation was based on the formation of cyclized structures. From the results of FTIR analysis, we found the MMA comonomer blocked the cyclization reactions to some extent. Extent of cyclization reactions at different temperatures was calculated through the data of FTIR. The sequence of reactions happened during the stabilization was oxidation > cyclization > dehydrogenation. The higher rate constant k implied that the ionic mechanism actually showed a kinetic advantage at low temperature over the free radical mechanism, even though the MMA comonomer inhibited cyclization reactions to some extent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Carbon fibers, due to excellent mechanical properties, good chemical and high temperature inertness and low weight-to-volume ratio, have been widely used in the high-tech aerospace and defense areas in the recent years [1–4]. Although carbon fibers can be from pitch, rayon and polyacrylonitrile (PAN) [5–7], due to low cast, good processibility, and greater carbon yield [8, 9], PAN commonly containing a small amount of comonomers has been found to be the most suitable precursors for producing high-performance carbon fibers compared to pitch and rayon [10, 11]. When convert PAN fibers into carbon fibers, two heat treatment stages are needed. The first stage is mostly conducted in the oxidative atmosphere at the temperature range of 200–300 °C with a ladder-like formed, namely ‘pre-oxidation’ or thermal-oxidative ‘stabilization.’ This second stage is usually carried out at temperature above 1000 °C in an inert atmosphere, with the formation of a graphite-like structure [10–12].

The stabilization stage is one of the most complicated stages, since a lot of chemical reactions take place, primarily dehydrogenation, oxidative and cyclization [10, 11]. These three types of reactions would lead to the formation of a ladder-like structure, making the oxidized PAN fibers heat-resistant and infusible; and most properties of the resulting carbon fibers depend greatly on this stage. Moreover, the oxidized fibers would maintain the dimensions during the subsequent higher temperature carbonization, in which the non-carbon atoms, such as nitrogen, oxygen and hydrogen, would be kept out, leaving of a graphite structure [13–15].

Due to comonomers play an important role in PAN precursor fibers [16–18], the effects of comonomers on the physicochemical properties of PAN copolymers during thermal-stabilization are always highly attractive to researchers. In the past decades, studies have been carried out to investigate the chemical changes in PAN and related copolymers during the heat treatments and different mechanisms have been postulated according to the experiment results. Coleman and Sivy [19] studied the degradation of the polyacrylonitrile copolymers containing vinyl acetate (VAc), acryamide (AM) and methacrylic acid (MAA), under a reduced pressure condition by Fourier transform IR (FTIR), indicating that the rate of degradation was markedly dependent on the chemical structure of the commoner. Grsssie and McGuchan [20] studied the pyrolysis of PAN copolymers containing the comonomers acrylic acid (AA), MAA, IA and AM, respectively, using DTA, TGA and TVA. The results showed that the corporation of certain comonomers reduced the intensity of the exotherm during heat treatments. Watt and Johnson [21] studied homopolymer PAN and copolymer PAN with carboxylic acid comonomer in oxidative atmosphere. They found that the oxygen uptake at 230 °C was greater for the acid-containing copolymer. By now, it is widely accepted that cyclization of homopolymer PAN is a radical mechanism, while cyclization of acidic PAN copolymers, such as itaconic acid, methacrylic acid and acrylic acid, is thought to occur by a ionic mechanism which is initiated at acid groups in the polymer backbone and lowers the initiation temperature of cyclization reactions, in the meanwhile moderates exothermic reactions during heat treatments [10–25]. FTIR spectroscopy has been proved to be an excellent technique to study the structure evolution of PAN and related copolymers during stabilization. For example, Collins et al. [26] have studied the kinetic relationships between heat degradation and nitrile consumption in the reaction of PAN homopolymer and PAN copolymer in air at 265 °C by FTIR. Furthermore, some attentions [26–30] have been given to the solubility, hydrophilicity, drawability and spinnability, which can be improved by some neutral comonomers such as methyl acrylate (MA) and methyl methacrylate (MMA) efficiently, to get better carbon fiber precursors. But the influences of the neutral comonomers on the cyclization have rarely been investigated, in the meanwhile, the sequence of the dehydrogenation, cyclization and oxidation is always the focus of debate. So, to optimize the process of the stabilization, the chemical reactions in PAN polymers need to be investigated particularly the chemical kinetic and mechanism.

In the present work, the composition of P(AN–MMA–IA) was investigated by 13C NMR. FTIR, DSC and TG were used to study the structure evolution and thermal behaviors of PAN during the heat treatments, as compared to a PAN homopolymer. Moreover, a quantitative calculation of the extent of stabilization was made based on FTIR spectroscopy, and kinetic parameters of cyclization of homopolymer PAN and terpolymer PAN were determined based on DSC data to better understand the role of the IA comonomer in the stabilization and the influence of MMA comonomer on the cyclization. And the isothermal TG mode was used to investigate the thermal behavior of PAN polymers. Additionally, an attempt was made to give the sequence of the dehydrogenation, cyclization and oxidation during the stabilization.

Experimental

Materials

Polyacrylonitrile homopolymer and polyacrylonitrile copolymer [P(AN–MMA)] containing about 2 wt% MMA were prepared by precipitation polymerization in water with ammonium persulphate as initiator at 50 °C under nitrogen. Polyacrylonitrile terpolymer [P(AN–MMA–IA)], fed about 3 wt% MMA and 1 wt% IA, was kindly provided by JILIN CHEMICAL FIBRE CO. LTD. Both of the polyacrylonitrile homopolymer and polyacrylonitrile copolymer have a viscosity-average molecular weight of about 17.5 × 105, and that of terpolymer is about 2.2 × 105.

Treatment and characterization

Thin films of the samples were prepared for heat treatments and the following FTIR analysis. The process used was as follows: First, a solution containing about 2 wt% polymers in dimethylformamide (DMF) was prepared, and then, the dilute solution was cast onto a horizontal glass slice, leaving a transparent thin polymer film. Second, the film was extracted in methanol at 50 °C for 24 h to remove the residual DMF. Finally, the film was dried at 75 °C for 24 h under vacuum with the thickness about 7 μm. All films were prepared by casting the same volume of the dilute solution onto the same horizontal glass slice. The films for heat treatment were prepared by cutting the dried films into approximately 2 cm by 2 cm. Particular care was taken to remove the non-uniform edges from the cast film, forming a usable portion from which heat treatment samples could be cut. Stabilization was carried out in an air oven at a constant temperature with a temperature accuracy of 1 °C.

13C NMR sample was dissolved in deuterated dimethyl sulfoxide (DMSO-d6) (20 %, w/w polymer solution) and analysis was performed at room temperature in a 5 mm o.d. NMR tube using Bruker AVANCE III 400 Spectrometer operating at 100 MHz, with a recycle time of 10 s.

The Nicolet AVATR-360 FTIR spectrometer was used to detect the structural changes during the heat treatment in 4000–400 cm−1 range at a resolution of 4 cm−1. Powdered samples of PAN homopolymer, copolymer and terpolymer were used for TG analysis using a PerkinElmer TGA PYRIS-1 thermal analyzer at the temperature range between 50 and 600 °C. Isothermal TG was carried out at 200, 220 and 250 °C, respectively. The same samples were used for DSC analysis using a PerkinElmer DSC-7 thermal analyzer at the temperature range between 30 and 330 °C.

Results and discussion

Composition of polyacrylonitrile terpolymer

A typical 13C NMR spectrum of a polyacrylonitrile terpolymer is shown in Fig. 1. The ratio of integrations of the nitrile carbons, methyl carbons and carboxyl carbons (shown as a, b and c) was used to calculate the compositions by Eqs. (1–3):

where A (a), A (b) and A (c) are the areas of peaks a, b and c shown as in Fig. 1. And f (IA), f (MMA) and f (AN) are the mole fractions of IA, MMA and AN in P(AN–MMA–IA) terpolymer, respectively.

The result is that the polyacrylonitrile terpolymer contains 0.98 wt% (IA) and 4.19 wt% MMA and 94.83 wt% AN, respectively. However, the content of MMA comonomer in P(AN–MMA–IA) is higher than that in the feed. That is because that the reactivity of acrylonitrile comonomers is lower than that of ester comonomers.

Structure evolution of PAN terpolymer during heat treatments

The structure evolution of P(AN–MMA–IA) polymer was measured by means of FTIR technology during the heat treatments in air. Fig. 2 shows the spectra of P(AN–MMA–IA) terpolymer heated at 250 °C for different times. The vibrations characteristic of PAN structure is those of CN nitrile group at 2242 cm−1, and the bands in the regions 2939–2870, 1460–1450, 1380–1350 and 1270–1220 cm−1 assigned to the aliphatic CH group vibrations of different modes in CH3, CH2 and CH [9, 31]. The strong band at 1735 cm−1 is attributed to the C=O stretching due to the presence of ester or acid [9, 31]. It can be seen clearly that the most prominent structure changes are the decrease in the intensity of 2939, 2871, 2243, 1735 and 1454 cm−1 band as a function of heat treatment time. In the meanwhile, the bands of 1620–1600 and 810 cm−1 occur and increase with the increasing of treatment time, which are assigned to a mix of C=N, C=C, N–H and the out-plane bending of C=C–H, respectively [9, 31]. All of these indicate that the cyclization and dehydrogenation reactions have occurred during the heat treatments and progressed with the time increasing. By careful observation of the spectra, one can see that the bands of 1735 and 1600 cm−1 shift to 1715 and 1592 cm−1 gradually combined a shoulder-like peak at 1660 cm−1 generates as the treatment time increasing, respectively, indicating that some conjugation structures have generated and became perfect gradually. In addition, a shoulder-like appearance at 2197 cm−1 near the characteristic absorption for CN may be attributed to the formation of amino-substituted unsaturated nitriles and aminonitriles as a result of partial cyclization or thermal degradation [8, 31, 32]. But, to our surprise, even after treated at 250 °C for 12 h, there still is a small peak around 2230 cm−1 due to residual isolated CN groups in the molecular chains, which are difficult to convert into a ladder-like polymer structure and will be lost at higher temperature during carbonization [22, 23].

Also, some significant changes are in the region of 3200–3650 cm−1. In the initial stage of heat treatment, the peaks around 3630 cm−1 (due to OH) [33], 3340 and 3250 cm−1 (due to NH) [19] appear and increase the intensity with time increasing, but the peak of 3630 cm−1 seems to appear sooner than 3340 and 3250 cm−1. More clear evidence can be shown in Figs. 3 and 4 that FTIR spectra of P(AN–MMA–IA) terpolymer heated at 220 and 200 °C for different times, respectively. This implies that oxygen uptake reaction may be easier to happen than the reaction between two nitriles. It is believed that the oxygen uptake reaction happens through the formation of hydroperoxide, and in the following step, the hydroperoxide decomposes into ketone with the removal of water [33]. As shown in Figs. 2, 3 and 4, the oxygen uptake reaction in P(AN–MMA–IA) is difficult to be identified through the generation of C=O, because the new generated C=O bands are overlapped by the ones of the comonomers. But two shoulder-likes at 1715 and 1660 cm−1, which may be due to oxygen uptake reaction, can be probably explained to be C=O stretching vibration of a free ketone and a conjugated ketone. It is an interesting phenomenon to be noticed that the band of 810 cm−1 emerges only when the band of 1620–1600 cm−1 increases to a certain extent. So we believe that the dehydrogenation is based on the premise of the formed cyclized structures, because the cyclized structures generate very active site of allylic hydrogen, which can be dehydrogenated in the form of H2 (Scheme 1).

Structure evolution of PAN homopolymer during heat treatments

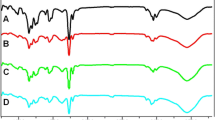

Figures 5, 6 and 7 show the spectra of PAN homopolymer heated at different temperatures as a function of time. By comparing the spectra of PAN terpolymer and homopolymer, we find that the overall trends are similar during the heat treatments. The intensity of bands at 2939, 2871, 2243 and 1454 cm−1 decreases as a function of heat treatment time. The increasing of intensity of the bands at 3630, 3340, 3250, 1620–1600 cm−1 can be seen clearly and the appearance of 810 cm−1 can be observed as a function of treatment time. And the shift of 1620–1600 to 1592 cm−1 and the shoulder-like peaks of 1715 and 1660 cm−1 can also be found. All of these indicate that the reactions of cyclization, dehydrogenation and oxidative have occurred during the heat treatments. But some differences should be noticed that the spectra changes in PAN homopolymer seem to be slower than that of PAN terpolymer. For example, the changes in spectrum of PAN terpolymer are more significant than that of PAN homopolymer at 250 °C for 10 min, especially the bands of 1620 and 810 cm−1. This shows that the corporation of IA comonomer into PAN chains has promoted the cyclization reactions as well as dehydrogenation reactions to some extent. This can be explained by the different mechanisms of cyclization. Cyclization of PAN homopolymer is thought to occur by a free radical mechanism (Scheme 2) which a higher temperature is needed to make homolysis of CN, and difficult to be controlled once it is triggered [18, 22–24]. In the contrast to the PAN homopolymer, cyclization of PAN terpolymer can be initiated by an ionic mechanism (Scheme 3), in which the hydroxyl group attacks the adjacent nitrile carbon, accompanied by subsequent proton transfer [16–24]. The ionic mechanism can be initiated by acid comonomers at a faster rate, which is the reason why the spectra of PAN terpolymer change faster. In order to investigate the role of MMA comonomer in P(AN–MMA–IA) during the stabilization, the P(AN–MMA) copolymer was used to be heated at 220 °C in air for 60 min. The results are shown in Fig. 8. We find that the changes in PAN are clear, but the changes in P(AN–MMA) are still small, indicating that the MMA comonomer in PAN chains not only do not promote but also inhibit the cyclization reactions. So it is necessary to find a monomer with the ability to improve the spinnability and promote the cyclization reactions in the same time to replace the MMA commoner.

The extent of cyclization was calculated from the infrared spectrum of each film sample by the following formula which has been previously derived in the literature [26]:

where ABS(2240) = absorbance of nitrile groups, ABS(1590) = absorbance of –C=N– groups, f = ration of CN and –C=N– group absorptivity constants = 0.29.

The extent of cyclization of PAN terpolymer and homopolymer at different temperatures as a function of time are shown in Figs. 9 and 10, respectively. With the increasing of the treatment time, CN fraction decreases and reaches a constant level at last for 250, 220 and 200 °C, respectively. From the cyclization data, we can see that as the increasing of temperature, the rate of cyclization becomes faster and the extent of cyclization is higher, showing that the reaction of nitriles depends significantly on temperature. The induction period is less distinct or not present in the cyclization data for PAN terpolymer, but for PAN homopolymer, there is a distinct induction period, especially the data for 200 °C. There is no clear decrease in CN fraction of PAN homopolymer even when the film was heated at 200 °C for 240 min. While for PAN terpolymer at 200 °C for 240 min, CN fraction reaches a decay period of a value near 0.65. So we believe that at low temperature, such as 200 °C, there is no occurrence of cyclization of PAN homopolymer through free radical mechanism, but by ionic mechanism, cyclization reactions are easily initiated because of the stronger nucleophilicity of the hydroxyl group. In addition, even at high temperature of 250 °C, it can be seen clearly that the rate of cyclization of PAN terpolymer is greater than that of PAN homopolymer during the initial period.

DSC and TG analyses of PAN homopolymer and terpolymer

The DCS curves of PAN and P(AN–MMA–IA) heated at 7 °C/min under N2 are shown in Fig. 11 Under the condition of N2 and no oxidative reactions occurred during this process, the DSC exotherms of PAN homopolymer and P(AN–MMA–IA) terpolymer can be attributed to the cyclization reactions. As shown in Fig. 11, there is only one sharp exothermic peak in PAN homopolymer. It is well known that the cyclization reactions are initiated by a free radical mechanism, causing a large amount of heat to be released at the same time, which results in the breakage of molecular chains giving off some kinds of volatile components and poor performance of resultant carbon fiber [16–18, 23, 24]. The DSC curve of P(AN–MMA–IA) also exhibits one peak, but the peak is broader than that of PAN homopolymer, showing that the cyclization reactions were initiated by ionic mechanism at lower temperature and the sharply exothermic reactions were diluted to an extent in the presence of IA comonomer, which is beneficial to making high-performance carbon fibers. Furthermore, the results of DSC curves are consistent with that of FTIR spectra.

Typical TG curves of PAN homopolymer and terpolymer recorded under air atmosphere at a programmed heating rate of 5 °C/min are shown in Fig. 12. These curves can be roughly divided into three steps according to the extent of weight loss. The first weight step is up to 250 °C, where it is nominal and occurs at a very slow rate. In combination of the DSC results, we roughly believe that there is only cyclization occurring in the step. The second step is up to about 400 °C. During this step, the rate of weight loss becomes rapid, which is mainly attributed to the dehydrogenation, the evolution of hydrogencyanide (HCN), aliphatic species and the moieties containing –CN or CN structures, which lead to weight loss greatly [17, 34]. As shown in Fig. 12, it is apparent that the weight loss of P(AN–MMA–IA) is larger than in this step that of PAN around 280 °C, which shows that IA comonomer has promoted the dehydrogenation to some extent. In the last step, 400–600 °C, the rate of weight loss is quiet steady; in this step, the weight loss of P(AN–MMA–IA) is smaller than that of PAN at the same temperature, suggesting that the structure changes from linear to ladder formed by cyclization reactions have been promoted by IA comonomer, which gives P(AN–MMA–IA) terpolymer better stability than PAN homopolymer at higher temperature. During the TG experiment, on the one hand, the fragmentation of chains occurs leading to weight loss, and on the other hand, the oxygen uptake reaction takes place, which causes amount of weight gain through the generation of oxygen-bearing groups, as discussed above. So, the net weight loss is the total of weight gain and weight loss.

In order to better understand the thermal behaviors of PAN and P(AN–MMA–IA) during the heat treatment at different temperatures, the isothermal TG mode was adapted to track the behavior of weight loss of PAN polymers. The specific steps are as follows: At first, the rate of 25 °C/min was adapted to rise temperature from 40 °C to a certain temperature (200, 220 and 250 °C). And then, the temperature was kept for 300 min. The results of P(AN–MMA–IA) and PAN are shown in Figs. 13 and 14, respectively. Figures 13 and 14 only show the results of isothermal step by subtracting the dynamic step from the original curves. One can see that at the beginning of isothermal step, there is about 1 wt% weight loss, which may be attributed to the loss of water at temperature raising step. As the increasing of treatment time, the weight losses increase gradually both for PAN and P(AN–MMA–IA). By comparing Figs. 13 and 14, we can find that all the weight losses of P(AN–MMA–IA) are greater than that of PAN, and the net weight losses are within 4 wt% at 220 and 200 °C as shown in Table 1. Although some side reactions of carboxyl may be happened, such as the formation of cyclicanhydrides, we believe that most carboxyls were used to initiate the cyclization reactions. So the weight loss of PAN and P(AN–MMA–IA) is attributed to dehydrogenation in general at the temperature of 220 and 200 °C. From Figs. 13 and 14, we find that the presence of IA has promoted the dehydrogenation to some extent and this is consistent with the results of FTIR spectra. To our surprise, the weight losses of PAN and P(AN–MMA–IA) at 250 °C are around 10 wt%, which cannot be solely attributed to dehydrogenation. Some side reactions may happened during the heat treatments giving off ammonia (NH3), HCN, and the moieties containing –CN or CN structures and so on [17, 34]. It seems to be contradictory between the data of dynamic and isothermal TG. But it is reasonable when notice that the weight loss is still small even at 250 °C for 300 min. That is to say that the rate of weight loss is very slow even at 250 °C. Additionally, the residence time around 250 °C is very short in dynamic TG measurement even at a rate of 5 °C/min. So the weight loss in the dynamic mode can be neglected. From the TG data, we can be sure that there is no occurrence of vast chain scissions occurred, and only the removal of some side groups and chain scissions at weak bonds of chains happened at around 250 °C.

Evaluation of kinetic parameters of cyclization reactions

Figures 15 and 16 give the DSC curves of PAN and P(AN–MMA–IA) heated at different rates (3, 5, 7, and 9 °C/min) from ambient temperature to 330 °C under N2. As the increasing of the heating rate, all exotherms shift to higher temperature and the peaks become more and more strong. The apparent activation energy (E a) of cyclization was determined by using Kissinger method and Ozawa method [35, 36]. These two methods are mostly adapted to calculate E a in the literatures, because no prior knowledge of reaction mechanism is required to quantify E a, but just requiring a series of DSC curves heated at different rates. Table 2 gives the parameters obtained from DSC curves.

The equation of Kissinger’s method is as follows:

where T m is the temperature corresponding to the maximum peak of DSC curve at a heating rate ϕ. E a is calculated from the slope of the linear plot of ln(ϕ/T 2m ) versus 1000/T m as shown in Fig. 17.

Ozawa method makes use of the following equation:

E a is calculated from the slope of the linear plot of ln(ϕ/T 2m ) versus 1000/T m as shown in Fig. 18.

The pre-exponential factor A was calculated in both cases from the following relation [37]:

The calculated results of E a and A values are listed in Table 3. It is found that the values of E a and A calculated from Kissinger and Ozawa method are almost the same. But, the value of apparent activation energy of P(AN–MMA–IA) is greater than that of PAN. It is contrary to the results reported in the literatures [18, 23]. We believe that it is attributed to the presence of MMA comonomer in PAN chains, which blocked the cyclization to an extent. And it is consistent with the results of FTIR.

The rate constant k at different temperatures was calculated from E a and A by Arrhenius equation,\( k = A{\text{e}}^{{{\raise0.7ex\hbox{${ - E_{\text{a}} }$} \!\mathord{\left/ {\vphantom {{ - E_{\text{a}} } {RT}}}\right.\kern-0pt} \!\lower0.7ex\hbox{${RT}$}}}} \), and shown in Fig. 19. It shows that the rate of cyclization of P(AN–MMA–IA) is faster than that of PAN, although the value E a of P(AN–MMA–IA) is greater than that of PAN. This indicates that the presence of IA comonomer in PAN chains has promoted cyclization significantly.

Conclusions

In the present work, the structure evolution and thermal behaviors of polyacrylonitrile and related copolymers during the stabilization were studied by FTIR, DSC and TG technologies. The following conclusion can be drawn based on the results above:

-

1.

The presence of IA comonomer in PAN promoted cyclization reactions by means of initiating at lower temperature and proceeding at faster rate than these of PAN homopolymer. In the meanwhile, the IA comonomer broadened the DSC curves and eased the sudden heat release.

-

2.

The sequence of reactions happened during the heat treatments was oxidative > cyclization > dehydrogenation.

-

3.

The presence of MMA comonomer in PAN chains blocked the cyclization reactions to some extent and increased the apparent activation energy of cyclization reactions. However, the higher rate constant k showed that the ionic mechanism actually had a kinetic advantage at lowing cyclization reactions temperature and accelerating cyclization reactions over the free radical mechanism.

References

Chand S (2000) Review carbon fibers for composites. J Mater Sci 35:1303

Kim HS, Shioya M, Takaku A (1999) Kinetic studies on hot-stretching of polyacrylonitrile-based carbon fibers by using internal resistance heating Part I. Changes in resistivity and strain. J Mater Sci 34:3299

Kim HS, Shioya M, Takaku A (1999) Kinetic studies on hot-stretching of polyacrylonitrile-based carbon fibres by using internal resistance heating Part II. Changes in structure and mechanical properties. J Mater Sci 34:3307

Li W, Long D, Miyawaki J, Qiao W, Ling L, Mochida I, Yoon SH (2012) Structural features of polyacrylonitrile-based carbon fibers. J Mater Sci 47:919

Cato AD, Edie DD (2003) Flow behavior of mesophase pitch. Carbon 41:1411

Edie DD (1998) The effect of processing on the structure and properties of carbon fibers. Carbon 36:345

Takaku A, Shioya M (1990) X-ray measurements and the structure of polyacrylonitrile-and pitch-based carbon fibres. J Mater Sci 25:4873

Bahl OP, Mathur RB (1979) Effect of load on the mechanical properties of carbon fibres from PAN precursor. Fibre Sci Tech 12:31

Wangxi Z, Jie L, Gang W (2003) Evolution of structure and properties of PAN precursors during their conversion to carbon fibers. Carbon 41:2805

Ko TH, Day TC, Lin MF (1993) The effect of precarbonization on mechanical properties of final polyacrylonitrile-based carbon fibres. J Mater Sci Lett 12:343

Rahaman MSA, Ismail AF, Mustafa A (2007) A review of heat treatment on polyacrylonitrile fiber. Polym Degrad Stab 92:1421

Jain MK, Abhiraman AS (1987) Conversion of acrylonitrile-based precursor fibers to carbon fibers. J Mater Sci 22:278

Ko TH (1991) The influence of pyrolysis on physical properties and micro-structure of modified PAN fibers during carbonization. J Appl Polym Sci 43:589

Zhu D, Xu C, Nakura N, Matsuo M (2002) Study of carbon films from PAN/VGCF composites by gelation/crystallization from solution. Carbon 40:363

Mittal J, Konno H, Inagaki M, Bahl OP (1998) Denitrogenation behavior and tensile strength increase during carbonization of stabilized PAN fibers. Carbon 36:1327

Gupta AK, Paliwal DK, Bajaj P (1996) Effect of the nature and mole fraction of acidic comonomer on the stabilization of polyacrylonitrile. J Appl Polym Sci 59:1819

Gupta AK, Paliwal DK, Bajaj P (1995) Effect of an acidic comonomer on thermooxidative stabilization of polyacrylonitrile. J Appl Polym Sci 58:1161

Anqi J, Shanyi G, Hongyao X (2013) Effect of comonomer structure on the stabilization and spinnability of polyacrylonitrile copolymers. Carbon 54:323

Coleman MM, Sivy GT (1981) Fourier transform IR studies of the degradation of polyacrylonitrile copolymers—I: introduction and comparative rates of the degradation of three copolymers below 200 °C and under reduced pressure. Carbon 19:123

Grassie N, McGuchan R (1970) Pyrolysis of polyacrylonitrile and related polymers—I. Eur Polym J 6:1277

Watt W, Johnson W (1975) Mechanism of oxidisation of polyacrylonitrile fibers. Nature 257:210

Beltz LA, Gustafson RR (1996) Cyclization kinetics of poly (acrylonitrile). Carbon 34:561

Qin Ouyang LuC, Haojing W, Kaixi L (2008) Mechanism and kinetics of the stabilization reactions of itaconic acid-modified polyacrylonitrile. Polym Degrad Stab 93:1415

Bajaj P, Screekumar TV, Sen K (2001) Thermal behaviour of acrylonitrile copolymers having methacrylic and itaconic acid comonomers. Polymer 42:1707

Park OK, Lee S, Joh HI, Kim JK, Kang PH, Lee JH et al (2012) Effect of functional groups of carbon nanotubes on the cyclization mechanism of polyacrylonitrile (PAN). Polymer 53:2168

Collins GL, Thomas NW, Williams GE (1988) Kinetic relationships between heat generation and nitrile consumption in the reaction of poly (acrylonitrile) in air at 265 °C. Carbon 26:671

Bhanu VA, Rangarajan P, Wiles K, Bortner M, Sankarpandian M, Godshall D et al (2002) Synthesis and characterization of acrylonitrile methyl acrylate statistical copolymers as melt processable carbon fiber precursors. Polymer 43:4841

Rangarajan P, Bhanu VA, Godshall D, Wilkes GL, McGrath JE, Baird DG (2002) Dynamic oscillatory shear properties of potentially melt processable high acrylonitrile terpolymers. Polymer 43:2699

Rangarajan P, Yang J, Bhanu V, Godshall D, McGrath J, Wilkes G et al (2002) Effect of comonomers on melt processability of polyacrylonitrile. J Appl Polym Sci 85:69

Shuiping L, Huiyu J, Weiping D, Ding P (2012) Spinnability in pre-gelled gel spinning of polyacrylonitrile precursor fibers. Fiber Polym 13:846

Hideto K, Kohji T (1997) Mechanism and kinetics of stabilization reactions of polyacrylonitrile and related copolymers III. Polym J 29:557

Boccara AC, Fournier D, Kumar A, Pandey GC (1997) Nondestructive evaluation of carbon fiber by mirage-FTIR spectroscopy. J Appl Polym Sci 63:1785

Memetea LT, Billingham NC, Then ETH (1995) Hydroperoxides in polyacrylonitrile and their role in carbon-fibre formation. Polym Degrad Stab 47:189

Fitzer E, Frohs W, Heine M (1986) Optimization of stabilization and carbonization treatment of PAN fibres and structural characterization of the resulting carbon fibres. Carbon 24:387

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702

Ozawa T (1965) A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn 38:1881

Preta IFC, Sakata SK, Garcia G, Zimmermann JP, Galembeck F, Giovedi C et al (2007) Thermal behavior of polyacrylonitrile polymers synthesized under different conditions and comonomer compositions. J Therm Anal Calorim 87:657

Acknowledgements

Financial support of this work from National Natural Science Foundation of China (Grant Nos. 51073027 and 51273026) was gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, Z., Gui, Y., Cao, C. et al. Structure evolution and mechanism of polyacrylonitrile and related copolymers during the stabilization. J Mater Sci 49, 2864–2874 (2014). https://doi.org/10.1007/s10853-013-7992-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7992-3