Abstract

We present here a facile method to produce macroporous-activated carbon nanofibers (AMP-CNFs) by post-treating electrospun cobalt(II) chloride (CoCl2) containing polyacrylonitrile (PAN/CoCl2) nanofibers with hydrogen sulfide (H2S) followed by carbonization. A range of techniques including scanning and transmission electron microscopy, FTIR and Raman spectroscopy is used to examine and characterize the process. Because of the phase behavior between carbon and cobalt, cobalt particles are formed in the nanofibers, some of which leave the fibers during the heat treatment process leading to macroporous fibrous structures. The number of the macroporous increase significantly with increasing CoCl2 concentration in the precursor H2S-treated PAN/CoCl2 nanofibers. The cobalt phase in the fibers also leads to catalytic graphitization of the carbon nanofibers. The produced AMP-CNFs may be a promising candidates in many applications including anode layer in lithium ion batteries, air and liquid purifiers in filters, as well as in biomedical applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanotechnological developments in the past decades have helped to improve device performances by either enhancing material properties or developing new processing techniques. Synthesis of carbon-based materials at the nanoscale can increase device performance by several orders of magnitude. Nanostructured carbon-based materials have been produced in the form of nanoparticles (fullerenes: C60–100), nanofilms (graphene and graphite layers), and one dimensional (1D) carbon nanotubes (CNTs) via a variety of nanoprocessing techniques [1–3].

Producing carbon-based materials with porous structures in the nanoscale can further enhance the final device performance because the significant increase in total specific surface area leads to better interactions with the targets (can be another material, ion, light, etc.). Porous-activated carbon-based materials have been used for a variety of applications including for anode layers in lithium ion batteries, removing pollutants from air, air filter in gas masks and respirators, distilled alcoholic beverage purification, and controlling overdoses in oral ingestion in biomedical applications, etc. [4–8].

Electrospinning is a powerful processing technique to produce 1D continuous polymer, ceramic, metal, and composite nanofibers [9–12]. With this technique, carbon nanofibers can also be produced by using a variety of polymer precursors including PAN, polybenzimidazole (PBI), polyvinylalcohol (PVA), polyimides (PIs), and their blends [13–17]. Typically, in this process as-spun precursor nanofibers are stabilized in an air atmosphere, followed by carbonization in an inert atmosphere. To produce porous carbon nanofibers via electrospinning, a deviation of this procedure is used. Recently, Liu et al. [18] produced multiple tubular porous structure of carbon nanofibers via electrospinning from a polymer blend solution of PAN and polylactide (PLA). They eliminate PLA from the fibers during the stabilization and carbonization process to obtain porous carbon nanofibrous structure. In another study, porous carbon nanofibrous structure was prepared by Yang et al. [19] via preparation of electrospun porous poly(vinylidene fluoride) fibers from solutions in dimethylformamide, poly(ethylene oxide) (PEO) and water, and converting as-spun fibers into carbon structure by carbonization at high temperatures. Wu et al. [20] produced porous carbon nanofibers through electrospinning of iron acetate and PAN solution and subsequent catalytic carbonization of the fibers.

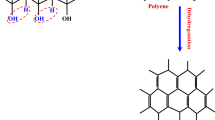

In this study, we produced AMP-CNFs with macroporous morphology and enhanced graphitic structure. The method schematically illustrated in Fig. 1 builds on our previous study in which we synthesized activated carbon nanofibers with random porous structure by using the same precursor (PAN/CoCl2) nanofibers [21]. In this study, we use an additional yet simple step of treating the PAN/CoCl2 precursor nanofibers with H2S before thermal stabilization and carbonization steps. Interestingly, after the carbonization of H2S-treated PAN/CoCl2 nanofibers, regular macroporous carbon nanofibers with enhanced graphitic structures are obtained.

Experimental section

Chemicals

Polyacrylonitrile (PAN, molecular weight of ~150000 g mol−1, Scientific Polymer Product Inc., Ontario, NY, USA), N,N-dimethylformamide (DMF, 99.9 % purity, Fisher Scientific Inc.), and hydrogen sulfide (H2S water solution, 0.4 g H2S per 100 ml solution) were used as received without any purification.

Electrospinning of CoCl2-doped PAN nanofibers, and their treatment with H2S and their further stabilization and carbonization

Electrospinning of CoCl2-doped PAN nanofibers has been explained in detail in our previous article [21]. PAN and CoCl2 dissolved in DMF and the prepared solution was electropun into nanofibrous structure. As-spun PAN/CoCl2 nanofibers were soaked in H2S (liquid) at room temperature for 1 h and then washed several times with distilled water and vacuum dried for 24 h. The dried nanofibers were then stabilized and carbonized in a Lindberg one-zone furnace within a quartz tube with inner diameter of 45 mm (Model 58114). The stabilization process was performed in air atmosphere (heated up to 280 °C with 5 °C min−1 heating rate and maintained for 1 h at that temperature to allow proper chemical reactions in the fibers) following which the carbonization process was conducted in a nitrogen atmosphere (heated up to 800 °C with 5 °C min−1 heating rate and maintained at that temperature for 2 h). Flow rate of the air and nitrogen gases during the heat treatment processes was very low.

Characterization of Nanofibers

Morphological characterizations of as-spun PAN/CoCl2, H2S-treaded PAN/CoCl2, and carbonized macroporous carbon nanofibers were conducted with both transmission electron microscopy with acceleration voltage of 200 kV (TEM, Hitachi HF-2000) and scanning electron microscopy (SEM, FEI/Philips XL30 SEM-FEG, with an acceleration voltage of 5 kV, samples were coated with 100 Å thickness of gold before SEM analyses to reduce charging). Chemical analysis of the nanofibers was carried out with attenuated total reflection-Fourier transform infrared spectroscopy (ATR-FTIR, Thermo Scientific™ FTIR with a Nexus 470 bench, wave number range of 4000–750 cm−1, at least 124 scans were collected to minimize the noise, spectral resolution of 0.125 cm−1) and a X-ray photoelectron spectroscopy (XPS, Kratos Analytical Axis Ultra XPS system), whereas thermal analysis of the nanofibers to screen the weight loss was performed in air and nitrogen atmospheres separately were done using thermo-gravimetric analysis (TA-Instruments TGA-Q500, heating from 25 to 800 °C, heating rate of 10 °C min−1). Microstructures of macroporous carbon nanofibers were also examined using Raman spectra (Horiba Jobin–Yvon LabRAM ARAMIS microscope with the laser line at 632 nm, using He–Ne excitation source).

Results and discussions

Morphological features of the H2S-treated pure PAN and PAN/CoCl2 NFs obtained using SEM are shown in Fig. 2. We find all nanofibers to be relatively uniform, randomly oriented, and forming a 3D interwoven network structure. The differences among the nanofibers in Fig. 2 can be clearly seen in the TEM images and explained at TEM imaging section. The ATR-FTIR of pure PAN, PAN/CoCl2, and H2S-treated PAN/CoCl2 composite nanofibers were recorded in the 750–3550 cm−1 wavelength range and shown in Fig. 3A. The characteristic peaks of PAN observed at ca. 2921 and 2242 cm−1 are assigned to methylene (CH2) and nitrile (C≡N) stretching vibrations, respectively [22]. Bending and stretching vibrations of CH2 groups are seen at ca. 1452 and 2921 cm−1 [21, 23]. Stretching and bending vibration peaks of the hydroxyl (OH) groups that come from the adsorbed water are seen at ca. 3631 and 1664 cm−1, respectively, [24, 25]. The intensities of these peaks increase and get broader with CoCl2 content in as-spun PAN/CoCl2 NFs (Fig. 3A, a), and then decrease again after H2S treatment as a result of drying in vacuum (Fig. 3A, b). The dried H2S-treated PAN/CoCl2 NFs were also analyzed with XPS to examine the elemental composition of the NFs (Fig. 3B). All peaks representative of the formation of cobalt sulfide is observed on the fibers after H2S treatment.

Thermogravimetric measurements in air (Fig. 4A) and nitrogen (Fig. 4B) atmospheres were conducted to screen weight loss and heat of reactions of H2S-treated pure PAN and PAN/CoCl2 NFs during the stabilization and carbonization processes. As seen from Fig. 4, weight loss primarily takes place in two steps, at 300 °C (cyclization and removal of volatiles) and at 500 °C (compositional removal of the byproducts) when we heat the samples in air atmosphere [26, 27]. When we increase the content of CoCl2 in the as-spun PAN/CoCl2 NFs and treat them with H2S under the same conditions, these two temperatures decreases consistently. The presence of CoCl2 initiates the reactions in PAN NFs so the weight loss starts at a lower temperature and this temperature decreases with increasing CoCl2 contents in the fibers. Meanwhile, the residues of the H2S-treated PAN/CoCl2 NFs at 800 °C increase (0.53, 0.71, 2.11, and 2.41 %, respectively, for 0, 1, 5, and 30 wt% H2S-treated PAN/CoCl2 NFs) because of the existence of cobaltous phase and oxidation of some of them.

A TGA plot of H2S-treated PAN/CoCl2 NFs under a nitrogen environment is shown in Fig. 4B. We observe a sharp decrease in weight around 280–300 °C, followed by a slow decay as the temperature is increased. The sharp weight loss can be attributed to removal of volatiles and the complex chemical reactions that occur during the stabilization process (dehydrogenation, cyclization, and crosslinking) [26, 27]. The residuals at 800 °C are also consistently increasing (40.61, 44.51, 53.58, and 53.45 %, respectively, for 0, 1, 5, and 30 wt% H2S-treated PAN/CoCl2 NFs) with increasing CoCl2 content in H2S-treated NFs and corresponds to macroporous carbon nanofibers.

SEM images of the carbonized pure PAN and H2S-treated PAN/CoCl2 NFs are shown in Fig. 5. We find that the carbonized fibers obtained from PAN (CNF) to be uniform and showing no porosity (Fig. 5a). However, macroporous structures are seen after carbonization of the H2S-treated PAN/CoCl2 composite NFs, with the number of the pores increasing with increasing CoCl2 content in the precursor H2S-treated PAN/CoCl2 NFs (Fig. 5b–d). The formation of macroporous structure can be explained by the activation of carbon nanofibers and the migration of cobaltous phase in the fibers during the heat treatment processes. Macroporous structure is obtained (average pore diameter of around 71 nm) because the particles move and escape from the fibers. The motion of cobalt particles in carbon nanofibers can be explained by the phase behavior of cobalt and carbon at high temperatures. In our study, we envisage cobalt particles migrate in the fibers, come together to form big particles, and then dislodge from the fibers. As a result, both the number of the pores and the average diameters of the AMP-CNFs increase with increasing CoCl2 in the precursor H2S-treated PAN/CoCl2 NFs. Random pore formation in the carbonized nanofibers without H2S-treated CoCl2/PAN precursor composites was reported in our previous study shown in Fig. 5e–h for comparison. Interestingly, average fiber diameter decreases dramatically after carbonization comparing H2S-treated and -untreated nanofibers. This can be attributed to removal of vast amount of cobaltous phase from the fibers after carbonization of H2S-treated CNFs. The evidence of this can be found from the TEM imaging.

To further understand the phenomenon, SEM images of stabilized H2S-treated PAN/CoCl2 composite nanofibers at 280 °C in air are taken and shown in Fig. 6a–h. Because of complex chemical reactions (dehydrogenation, cyclization, and crosslinking) during the stabilization process fibers swell, average nanofiber diameter increases tremendously and surface of the fibers becomes much smoother in comparison with as-spun nanofibers.

To understand macroporous formation, TEM images of pure PAN, PAN/CoCl2, H2S-treated PAN/CoCl2, and AMP-CNFs of the H2S-treated CoCl2/PAN precursor nanofibers were obtained and shown in Fig. 7. As-spun PAN NFs are almost translucent (Fig. 7a) and CoCl2 nanoparticles are evident in PAN/CoCl2 NFs corresponding to the dark regions in Fig. 7b. Fuzzy surface represents the formation of cobalt sulfide after soaking as-spun PAN/CoCl2 NFs in H2S (Fig. 7c). During the stabilization and carbonization process, the cobalt phases migrate and escape from the NFs, leaving macroporous structures behind them (Fig. 7e–f). CNF without H2S processing shows dark domains correspond to cobalt particles (Fig. 7d), but these domains cannot be seen at H2S-treated CNFs (Fig. 7e–f).

In order to determine the graphitic structures of the carbonized NFs, Raman spectra of the NFs were conducted and are shown in Fig. 8 and Table 1. We observe two distinct peaks at ca. 1329 cm−1 (D-band) and 1571 cm−1 (G-band) that can be attributed to the carbon structure; these peaks correspond to the disordered carbons in graphene layers and ordered graphite phases in the AMP-CNFs [21, 28]. The intensity ratios R = (I D/I G) of these peaks indicate the nature of the structural order of the graphitic phase in the CNFs. The R value decreases slightly with increasing CoCl2 content in the precursor H2S-treated CoCl2/PAN (Fig. 8a–d) [28]. The decrease of this ratio for macroporous CNFs indicates that more ordered graphitic structures are obtained with the presence of cobalt phase because of the catalytic graphitization of the nanofibers.

Conclusions

AMP-CNFs were synthesized by post treatment of electrospun PAN/CoCl2 composite NFs with H2S followed by stabilization and carbonization. Because of the different phase behavior of cobalt and carbon, AMP-CNFs structures are obtained after the heat treatment processes. The number of the macroporous dramatically increases when we increase the CoCl2 contents in the precursor H2S-treated PAN/CoCl2 nanofibers. The results reveal that graphitic structure of macroporous CNFs is obtained because cobalt in the fibers promotes catalytic graphitization during the carbonization process.

References

Dresselhaus MS, Dresselhaus G, Eklund PC (1996) Science of fullerenes and carbon nanotubes. Academic Press, New York

Vaughan O (2010) Nat Nanotechnol 5:386

Baddour CE, Fadlallah F, Nasuhoglu D, Mitra R, Vandsburger L, Meunier JL (2009) Carbon 47:313

Ji L, Zhang X (2009) Electrochem Commun 11:684

Wang Z, Zhang JS (2011) Build Environ 46(758):768

Romero JV, Smith JWH, Sullivan BM, Mallay MG, Croll LM, Reynolds JA, Andress C, Simon M, Dahn JR (2011) ACS Comb Sci 13:639

Soto ML, Moure A, Dominguez H, Parajo JC (2011) J Food Eng 105:1

Eyer F, Jung N, Neuberger N, Witte A, Poethko T, Henke J, Zilker T (2008) Basic Clin Pharmacol 102:337

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) Compos Sci Technol 63:2223

Li D, Xia Y (2004) Adv Mater 16(14):1151

Wu H, Hu L, Rowell MW, Kong D, Cha JJ, McDonough JR, Zhu J, Yang Y, McGehee MD, Cui Y (2010) Nano Lett 10:4242

Sahay R, Kumar PS, Sridhar R, Sundaramurthy J, Venugopal J, Mhaisalkar SG, Ramakrishna S (2012) J Mater Chem 22:12953

Yan KS, Kim C, Park SH, Kim JH, Lee WJ (2006) J Biomed Nanotechnol 2:103

Fatema UK, Uddin AJ, Uemura K, Gotoh Y (2011) Text Res J 81:659

Chung GS, Jo SM, Kim BC (2005) J Appl Polym Sci 97:165

Kim C, Park SH, Lee WJ, Yang KS (2004) Electrochim Acta 50:877

Kim C, Cho YJ, Yun WY, Ngoc BTN, Yang KS, Chang DR, Lee JW, Kojima M, Kim YA, Endo M (2007) Solid State Commun 142:20

Liu T, Gu SY, Zhang YH, Ren J (2012) J Poly Res 19:9882

Yang Y, Centrone A, Simeon F, Hatton TA, Rutledge GC (2011) Carbon 49:3395

Wu J, Park HW, Yu A, Higgins D, Chen Z (2012) J Phys Chem 116:9427

Aykut Y (2012) Appl Mater Interfaces 4:3405

Ko TH, Chen CY (1999) J Appl Polym Sci 74:1745

Kang YH, Ahn K, Jeong SY, Bae JS, Jin JS, Kim HG, Hong SW, Cho CR (2011) Thin Solid Films 519:7090

Deng S, Bai R, Chen JP (2003) J Colloid Interface Sci 260:265

Rahman MM, Jamal A, Khan SB, Faisal M (2011) J Phys Chem 115:9503

Chen IH, Wang CC, Chen CY (2010) Carbon 48:604

Ji L, Medford AJ, Zhang X (2009) J Mater Chem 19:5593

Kim C, Yang KS, Kojima M, Yoshida K, Kim YJ, Kim YA, Endo M (2006) Adv Funct Mater 16:2393

Acknowledgements

The authors acknowledge funding support from the Nonwovens Cooperative Research Center, NCRC at North Carolina State University and the Ministry of National Education of the Republic of Turkey. YA thanks Dr. Dale Bachelor at the Analytical Instrumentation Facility, NCSU for his assistance in TEM sample characterization.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aykut, Y., Pourdeyhimi, B. & Khan, S.A. Catalytic graphitization and formation of macroporous-activated carbon nanofibers from salt-induced and H2S-treated polyacrylonitrile. J Mater Sci 48, 7783–7790 (2013). https://doi.org/10.1007/s10853-013-7463-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7463-x