Abstract

In situ measurements of the strain-induced martensitic transformation (SMTs) of SUS304 stainless steel that takes place during tensile loading at room temperature were performed around the notch of a dumbbell-shaped specimen where high stress concentration occurs. Even in the low plastic strain regime, with loading to 0.2 % proof stress (σ 0.2), some SMTs occurred. However, the area fraction of the Fe-α′-martensite phase did not increase significantly even when the sample was loaded to the ultimate tensile strength (σ UTS). After the σ UTS point, the total fraction of the Fe-α′ phase increased dramatically to the fracture point (σ f). The phase textures of Fe-α′ and Fe-γ were almost equal at (σ UTS − σ f)/2, and the Fe-α′ phase was observed over almost the entire measurement area around the notch at the σ f point. However, the area fraction of the Fe-α′ phase at the σ f point decreased far away from the fracture surface, to an extent that the total fraction of the Fe-α′ phase was almost the same as that of the Fe-γ phase in an area about 1.7 mm from the fracture face. Different martensite characteristics were detected in the stainless steel, depending on the applied load level. This was attributed to the severity of deformation. In particular, deformation twinning, created around σ UTS, and severe plastic deformation before fracture make a strong Fe-α′ phase. Details of this phenomenon are interpreted using various approaches, including electron backscatter diffraction analysis and finite element analysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Austenitic stainless steels have received special attention because of their use for various engineering components, such as in power plants and the automobile industries, owing to their excellent machinability, high corrosion resistance, high strength and high ductility. However, although austenitic stainless steels have high material ductility, this is significantly affected by strain-induced martensitic transformations (SMTs). A variety of stainless steel components are produced by mechanical processes including stretching, drawing and bending, all of which cause severe plastic deformation [1]. Experimental and numerical approaches have been used to attempt to understand the stress–strain characteristics in stainless steel components [2, 3]. It is believed that austenite phases in some stainless steels are metastable owing to the presence and amount of Cr and Ni, both of which lead to a SMT when the stainless steel is subjected to plastic deformation. The life of stainless steel components in service is generally a function of the severity of this plastic deformation. Consequently, an examination of plastic strain characteristics in these stainless steels is of considerable importance, and several techniques have been proposed to observe the localised plastic deformation zone [4]. It is believed that austenitic stainless steels exhibit significant work hardening, resulting in the transformation from metastable austenite to martensite [5]. It is also considered that a marked increase in elongation occurs when martensites are formed during the deformation, which is called transformation-induced plasticity [6]. The volume fraction of austenite to martensite transformation depends on the strain level, temperature and strain rate [3].

Zong-yu et al. [7] investigated the influence of pre-transformed martensite on the work hardening behaviour of metastable SUS304 austenitic stainless steel. One of their results was that the work hardening exponent of the stainless steel decreases with an increase of pre-transformed martensite. SUS304 stainless steel is a typical austenitic stainless steel and is known to exhibit considerable work hardening; hence a pre-strained-type stainless steel would be expected to show a martensitic transformation [1]. In the study by Dan et al. [5], a constitutive model for the transformation-induced plasticity accompanying the SMT was developed. The increase in the number of nucleation sites in austenite owing to plastic deformation is formulated as an increase of the shear band intersection. The nucleation site probability is dependent not only on the stress state, plasticity strain and temperature of the environment but also on the strain rate. During their analysis of the tensile process at a strain rate of 0.001 s−1, an increase in temperature led to a slow martensite transformation. The shear band, driving force and parameter-α′ transformation also decrease when the deformation temperature is higher [5]. This is because the shear band intersection is reduced at higher temperature, resulting in weak plasticity-induced transformation. Beese and Mohr examined the effect of the stress state on the transformation kinetics of stainless steel sheets (301LN) at room temperature using newly developed experimental techniques for simple shear and large strain in-plane compression. Their experimental results indicated that the martensite transformation kinetics cannot be described solely by a monotonically increasing function of stress triaxiality. For instance, less martensite is developed under equibiaxial tension compared with uniaxial tension for the same increase in equivalent plastic strain [8].

To date, several studies have systematically investigated the SMT characteristics of austenitic stainless steels, along with relevant information used to explain their material characteristics. Although some significant information has been reported, it is believed that further study is required to obtain more effective SMT characteristics for these stainless steels. This is especially true, as the SMT characteristics have been examined mainly using X-ray diffraction, TEM and magnetic permeability measurements, [9–11] which may not show clear phase textures, e.g. with two-dimensional images. In the present study, in situ measurements of SMT behaviour were made during tensile loading, and the effects of deformation and crystal orientation characteristics on the SMT behaviour were investigated using electron backscatter diffraction (EBSD) analysis.

Experimental procedures

Materials and experiments

The study reported used a commercial SUS304 stainless steel plate, produced by a hot-rolling process, with chemical composition Fe–Ni8.6–Cr18.4–Si0.45–Mn1.8–Mo0.3–S0.03–C0.08 (wt%). The SUS304 was annealed at 1150 °C for 2 h and air-cooled to remove any residual stresses. The stainless steel consisted of an austenite phase with a mean grain size of 92 μm in diameter. Figure 1 shows a test specimen. The specimens were machined into the form of rectangular dumbbell shapes with two notches. The reason for the notches was to measure the SMT characteristics in the same area and similar stress level. Specimens were machined by a wire electric discharge machine. The stress concentration rate in the specimens around the notches was about K t = 2.4 [12]. In this case, the specimen surfaces were finished with a smooth level of R a = 1.6 to reduce the stress concentration arising from tool marks. It should be pointed out that the material properties of the notched specimens are different from those of standard smooth tensile specimens. In this case, the ductility of the sample would be reduced by the notch effect [13].

Tensile tests were conducted using an electro-servo-hydraulic system with 50 kN capacity. The applied load and strain were measured with a commercial load cell and a strain gauge, respectively. After a specimen was loaded to several specific loading points, the SMT characteristics of the specimen were examined adjacent to the notch tip (A′, see Fig. 1), where relatively high stress concentration occurs. Note first that the area A′ does not have the highest stress concentration, owing to the area being about 1 mm away from the notch tip. The reason for this measurement was to obtain clear SMT characteristics during the tensile tests. In fact a clear SMT cannot be obtained in the area of the sample adjacent to the notch tip (the highest stress concentration area) because of severe material damage. This examination was carried out only at room temperature (about 293 K) as a first approach even though the SMT is sensitive to sample temperature [14]. The crystal orientation characteristics were investigated by EBSD analysis, using a high-resolution electron microscope (JSM-7000F, JEOL Ltd). Based upon an analysis of the EBSD patterns, the phase textures (Fe-α′ and Fe-γ phases) of the matrix were determined using HKL Channel 5 software. The main measurement conditions for this analysis were as follows: the sample was tilted to an angle of 70°, and an accelerating voltage of 15 kV, beam current of 5 nA and measurement step size of 4 μm were used. The sample surfaces for this examination were polished for about 2 h to mirror level in a vibro-polisher using colloidal silica. The polishing process was executed carefully with a low applied load so as to reduce sample damage.

Finite element analysis

To investigate the stress–strain distribution in the test specimen of SUS304 stainless steel after tensile loading, finite element analysis was conducted using ANSYS software. In this analysis, a two-dimensional finite element simulation with 8-node quad elements was employed. The finite element analysis model was designed to simulate the actual specimen, as shown in Fig. 1. The mesh size of the model was set to 0.05 mm, giving a total of 3251 quadrilateral solid elements. To identify the plastic strain levels in this analysis, the option of bilinear kinematic hardening was selected, in which the initial slope of the stress–strain relationship is taken as the Young’s modulus of the material. After the yield point, the curve continues along a second slope defined by the tangent to the curve. Based on our experimental results, the following material properties were determined: Young’s modulus E = 210 GPa, tangent modulus T = 1105 MPa, Poisson’s ratio ν = 0.3 and yield strength σ 0.2 = 290 MPa. Note that, in this case, the yield strength was defined as the stress value at which 0.2 % permanent deformation occurs.

Results and discussion

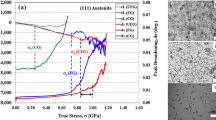

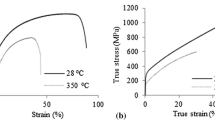

Figure 2 displays representative tensile stress (σ)–strain (ε) curves for our SUS304 stainless steel. Because the specimen has notches, its tensile properties are different from those of a standard smooth specimen, i.e. there is a notch effect. We have examined the tensile properties of the smooth specimen in addition to those of the notched one, and it appears that both ultimate tensile strength and Young’s modulus are almost the same, but the strain to failure for the notched specimen is slightly lower compared to the smooth specimen. This is because the presence of triaxial stress field and steep stress (such as arise at a notch) gradients with the notch effect results in a change of ductility.

In the present study, several specimens were loaded to the specific loading (or strain) points labelled A, B, C, D, E and F in Fig. 2. Point A is the specimen without any applied load, i.e. 0 N. Points B, D and F are the yield point σ 0.2, ultimate tensile strength σ UTS and fracture point σ f, respectively. Finally, points C and E are at load levels of (σ UTS − σ 0.2)/2 and (σ UTS − σ f)/2, respectively. It should be noted that, in the tensile test, the applied load was applied at a low strain rate of about 0.0005 s−1, which is much lower than that used in previous studies [15, 16]. The reasons behind the low strain rate are (i) to create a clear SMT [3, 17] and (ii) to easily control the load level at the specific points (points A–F). The effect of strain rate on SMT characteristics has been investigated by Das et al. [17]. One of their conclusions is that the total volume fraction of martensite decreases when the strain rate is increased because of the enhancement of sample temperature. Talonen et al. [18] have also similarly reported that more strain-induced α′-martensite is formed in steel at a lower strain rate and higher M d30 temperature. The M d30 temperature of our stainless steel approximated using Gladman’s formula is 11.7 °C, i.e. 497–462(C + N)–9.2(Si)–8.1(Mn)–13.7(Cr)–20(Ni)–18.5(Mo), which is similar to that for a related stainless steel [19]. However, an opposite trend for SMT is obtained in the stainless steel after impact loading tests, in which the volume fraction of martensite increases with increasing strain rate, i.e. 8 × 102 to 4.8 × 103 s−1 [20]. The increase in martensite volume fraction caused by the increase of strain rate can lead to high strength, where a high dislocation density would be introduced into the austenite to accommodate the martensite volume expansion [21]. Figure 3 shows photographs of the specimens after loading to the specific points mentioned above. The different degrees of permanent deformation around the notches can clearly be seen, especially after the material yields (samples C–F), while no clear deformation can be observed in sample B. In sample D, severe deformation occurs because it undergoes necking [12], and more severe deformation occurs in samples E and F. In previous reports, similar load–strain relationships were obtained for the appropriate stainless steel, where high strain increases the severity of the martensitic transformation [22].

Photographs of the test specimens after loading to the specific points shown in Fig. 2

Figure 4 depicts the crystal orientation maps obtained at points A–F. The colour level of each pixel in the crystal orientation map is defined according to the deviation of the orientation measured from the direction parallel to ND (see the colour key of the stereographic projection). Moreover, the dark areas in this analysis are associated with regions in which data cannot be collected. This is because of the severe material damage, e.g. collapse of microstructure and micro-cracks. Austenite grains can be clearly seen in the SUS304 stainless steel when it is loaded to an extent less than the ultimate tensile strength. On the other hand, some twinning-like deformation zones are observed in sample D, as indicated by the circles. The grain formations in samples E and F are seen to have collapsed to tiny regions and randomly distributed crystal orientation caused by more severe slip deformation. Basically, the crystal orientation in samples A–D is different depending on the grain, whereas this cannot be seen clearly in samples E and F.

Crystal orientation maps of the SUS304 stainless steels after loading to the specific points shown in Fig. 2 (Color figure online)

Figure 5 shows orientation imaging microscopy maps for samples A–F, and Fig. 6 shows the variations of the area fraction of Fe-α′-martensite and Fe-γ phases as a function of tensile strain. Note that the measurement areas displayed in Fig. 5 are the same as those shown in Fig. 4. It is clear that a strong texture of Fe-γ is apparent until the samples are strained to about 40 %, at which point the total area fraction of Fe-γ is about 85 % (samples A–D). It is interesting to mention first that even if a relatively high strain (ε = 40 %) is present in sample D, the SMT is weak. In addition, the characteristics of Fe-α′-martensite formation for sample D (Fig. 5) are different from those for samples A, B and C. For example, several Fe-α′ phase colonies are obtained for sample D, and the Fe-α′ phase can be detected, with many tiny regions (dot-like formations), for samples B and C, as indicated by the dashed circles. This contrasting martensitic characteristic will be discussed later. In the present study, the total area fraction of the Fe-α′ phase apparently increases with increasing strain level beyond ε = 40 % (or σ UTS), during which the phase textures of Fe-α′ and Fe-γ are similar (Fe-α′ = 55 % and Fe-γ = 45 %) at ε = 45 % (sample E). In sample F, almost the whole measurement area is characterised by the presence of the Fe-α′-martensite phase (Fe-α′ ≈ 80 %). Interestingly, corresponding results were reported by Ogata et al. [14], where there is no clear SMT in SUS316L until a strain level of 40 %. In another report, the volume fraction of martensite increased sharply when the sample was strained to about 25–50 %, which was dependent on the strain rate: the higher the strain rate, the lower the volume fraction of martensite [17]. Although the strain levels used in previous studies to alter the texture are close to our result, further study will be required, because notched specimens were employed in our approach. A different result was also reported by Spencer et al. [23], where the stainless steel was virtually saturated with α′-martensite before necking (i.e. σ < ultimate tensile strength), which may be affected by the experiments being conducted at the lower temperature of 77 K [12, 23]. An interesting approach was used by Hecker et al. [24]. They investigated the SMT characteristics for 304 stainless steel using the von Mises effective strain criterion, which gives a reasonable correlation of transformation kinetics under general strain states: the principal effect of increased strain rate was obtained at strains greater than 0.25 [24].

Variation of the area fraction of Fe-α′-martensite and Fe-γ phase as a function of the tensile strain, obtained on the basis of Fig. 5

Consideration should be given as to whether micro-cracks affect SMT or not in the present study. In general, the micro-cracks would be created by the following process: micro-voids are created during the earlier failure process, and their coalescence occurs as the load becomes greater than the ultimate tensile strength [25]. Because of stress relaxation, caused by micro-crack generation, this could be a significant factor in the SMT characteristics. It is considered that micro-cracks are created during the tensile tests especially in samples E and F. Since the data collection rate in the EBSD analysis was decreased for the samples loaded to points E and F as mentioned for Figs. 4 and 5, this occurrence may be attributed to the micro-cracks. However, further study will be required in the future.

It is also considered that the nucleation of α′-martensite is always confined to microscopic shear bands, including strain, faults and twin intersections [11]. Details of those microstructural effects on the martensite transformation are discussed below.

Figure 7 depicts the lattice strain distribution in samples A–F. In this case, the lattice strain was defined by the crystal orientation angle. It is seen that there are different strain distribution characteristics. Compared to the orientation imaging microscopy maps in Fig. 5, the severe strain is randomly distributed in the area of Fe-α′ phase, which may be associated with severe plastic deformation [6]. In addition, lattice strain, which is related to SMT, is enhanced in twins, although that strain is at a low level as indicated by the dashed circles. From this result, SMT can be attributed to two different strain patterns: plastic deformation and twin formation. Note that although there are deformation twins in samples B and C as indicated by the circles, those are not attributed to SMT [26]. This is because those twins are not created during the tensile loading.

Several researchers have investigated the associated SMT characteristics of SUS304 stainless steels. In the study by Shen et al. [15] it is made clear that a high fraction of martensite phase is obtained in related stainless steels when loaded at a lower strain rate of 3 × 10−3. Furthermore, they found, using careful TEM observations, that stacking faults and twins preferentially occur before martensitic nucleation and both ε-martensite and α′-martensite are observed in the deformed microstructures. The presence of α′-martensite is attributed to the twinning deformation and the presence of ε-martensite to the plastic deformation [15]. It is generally considered that the twinning deformation occurs most readily in steels subjected to high strain rate and/or low temperature conditions [12]. The observation of SMT, obtained with the low strain rate of 3 × 10−3 in the study by Shen et al. [15], might be related to the texture of the ε-martensite. From the above information, it may be considered that strong SMT, obtained in previous study after tensile tests at a lower temperature [22], is influenced by the twinning deformation, thus resulting in α′-martensite formation [15, 22].

Interesting results were further reported by Shen et al. [15], who showed that different kinds of martensite can be formed. Alpha prime martensite is mainly formed when high loads are applied to the sample, e.g. loads greater than the ultimate tensile strength, as for our samples D, E and F. In contrast, ε-martensite is observed when the loading is less than about (σ UTS − σ 0.2)/2, which is the case for our samples B and C. As mentioned in the discussion of Fig. 5, the texture of Fe-α′-martensite formation is different in our SUS304 when it is loaded with more than or less than the ultimate tensile strength (samples B and C vs. sample D). This difference in texture may be attributed to the different degree of martensite formation. In addition, for sample D, the Fe-α′-martensite phases seem to be distributed mainly in the twinning deformation zones, as evident from Figs. 4 and 5. It has been reported that mechanical twinning could give α′-martensite resulting from uniaxial tensile tests at room temperature [27], where the formation of the mechanical twin structure was detected at a strain level of ε = 0.4 [27]. This result is similar to that for sample D (at σ UTS). Note that a Lüders band front may have given significant SMT because of the high initial dislocation density especially in samples D and E [23], but this cannot be clarified in the present study, and will be studied in the future.

The Fe-α′ and Fe-γ phases were further investigated after the tensile tests. Figure 8 shows the orientation imaging microscopy map recorded for sample F around the notch and fracture surface (crack), and Fig. 9 shows the variation of the area fraction of the Fe-α′ and Fe-γ phases as a function of the distance from the fracture surface. A high concentration of the Fe-α′-martensite phase is detected near the crack, which could be a result of the high plastic strain. The area fraction of the Fe-α′ phase decreases in the area far away from the crack face. The total area fraction of the Fe-α′ phase is almost the same as that of the Fe-γ phase in the area about 1.7 mm from the crack face. In the study by Huang et al. [21] variation of the area fraction of martensite was similarly examined, and the area fraction of Fe-α′ and Fe-γ phases was almost the same in the area about 5 mm away from the fracture surface, which is slightly different from our findings. This may be attributed to the different specimen geometry, namely with or without notches. An associated experiment was also carried out by Nakajima et al. They investigated the occurrence of SMT in SUS304 stainless steels after fatigue tests (cyclic loading), but no clear SMT was detected in their sample adjacent to fatigue cracks [28]. The reason behind this may be the weaker plastic deformation, arising from the high cyclic loading speed of 53 Hz.

Variation of the area fraction of Fe-α′ and Fe-γ phase as a function of the distance from the crack surface, obtained on the basis of Fig. 8

Figure 10 displays the plastic strain distribution obtained by finite element analysis. In this analysis, the specimen was loaded to its ultimate tensile strength of 695.9 MPa, i.e. σ UTS. This analysis reveals high plastic strain in the sample adjacent to the notch owing to the high stress concentration, and the plastic strain level decreases in the area far away from the notch (Fig. 10). The value of the plastic strain in area A′ (Fig. 10) is found to be about 48 %, and this value is relatively close to the experimentally obtained strain level after loading with more than the ultimate tensile strength, e.g. points E and F (Fig. 2). Note that area A′ is the same area as that used for the EBSD measurements (Fig. 1). This numerical approach suggests that SMT in associated SUS304 stainless steels can occur to a great degree when the sample is strained by more than 40 %.

Conclusions

A SMTs in SUS304 stainless steel near a notch was examined using an electron backscattering diffraction approach. The results obtained were as follows:

-

(1)

Even if low strain at the σ 0.2 point occurs, a slight increase of the Fe-α′-martensite fraction is obtained. The total area fraction of the Fe-α′-martensite phase at the σ UTS point is almost the same as that at the σ 0.2 point. After loading at greater than σ UTS (or ε > 40 %), the area fraction of the Fe-α′ phase increases dramatically, although the phase textures of Fe-α′ and Fe-γ are almost the same as at (σ UTS − σ f)/2. In addition, the Fe-α′-martensite phase is formed over almost the entire region at σ f.

-

(2)

The characteristics of the Fe-α′-martensite phase are apparently different, depending on the sample. For example, many tiny fractions of the Fe-α′ phase are distributed in the un-twinning deformation zones when the sample is subjected to a load of less than (σ UTS − σ 0.2)/2, whereas several Fe-α′-martensite colonies are formed in the twinning deformation zones when the load is greater than σ UTS. In this case, two main factors are observed to affect the Fe-α′-martensite phase: (i) twinning deformation and (ii) severe plastic deformation. In particular, deformation twinning is created around σ UTS and severe plastic deformation is detected before fracture.

-

(3)

A high area fraction of the Fe-α′-martensite phase is detected near the notch, but the area fraction of the Fe-α′ phase decreases in the area far away from the crack surface. The total fraction of the Fe-α′ phase is almost the same as that of the Fe-γ phase in an area about 1.7 mm from the crack surface.

References

Nakajima M, Akita M, Uematsu Y, Tokaji K (2010) Proc Eng 2:323

Jia N, Peng RL, Chai GC, Johansson S, Wang YD (2008) Mater Sci Eng A 491:425

Chen X, Wang Y, Gong M, Xia Y (2004) J Mater Sci 39:4869. doi:10.1023/B:JMSC.0000035327.55210.99

Okayasu M, Sato K, Takasu S (2010) J Mater Sci 45:1220. doi:10.1007/s10853-009-4068-5

Dan WJ, Zhang WG, Li SH, Lin ZQ (2007) Comput Mater Sci 40:101

Tamura I (1982) Met Sci 16:245

Zong-yu X, Sheng Z, Xi-Cheng W (2010) J Iron Steel Res Int 17:51

Beese AM, Mohr D (2011) Acta Mater 59:2589

Zhang HW, Hei ZK, Liu G, Lu J, Lu K (2003) Acta Mater 51:1871

Varma SK, Kalyanam J, Murr LE, Srinivas V (1994) J Mater Sci Lett 13:107

Murr LE, Staudhammer KP, Hecker SS (1982) Metall Trans A 13A:627

Hertzberg RW (1996) Deformation and fracture mechanics of engineering materials, 4th edn. Wiley, New York, p 18

Dieter GE (1986) Mechanical metallurgy, 3rd edn. McGraw-Hill, Inc, New York, p 314

Ogata T, Yuri T, Ono Y, Cryo J (2007) Soc Jpn 42:10 in Japanese

Shen YF, Li XX, Sun X, Wang YD, Zuo L (2012) Mater Sci Eng A 552:514

Mirzadeh H, Najafizadeh A (2010) Mater Sci Eng A 527:1856

Das A, Sivaprasad S, Ghosh M, Chakraborti PC, Tarafder S (2008) Mater Sci Eng A 486:283

Talonen J, Nenonen P, Pape G, Hänninen H (2005) Metall Mater Trans A 36A:421

Nebel Th, Elfler D (2003) Sādhanā 28:187

Lee W-S, Lin C-F (2000) Scr Mater 43:777

Huang GL, Matlock DK, Krauss G (1989) Metall Trans A 20A:1239

Muller-Bollenhagen C, Zimmermann M, Christ H-J (2010) Int J Fatigue 32:936

Spencer K, Embury JD, Conlon KT, Véron M, Bréchet Y (2004) Mater Sci Eng A 387–389:873

Hecker SS, Stout MG, Staudhammer KP, Smith JL (1982) Metall Trans A 13A:619

Benzerga AA, Leblond J-B (2010) Adv Appl Mech 44:169

Kinoshita Y, Yardley VA, Tsurekawa S (2011) J Mater Sci 46:4261. doi:10.1007/s10853-010-5241-6

Choi J-Y, Jin W (1997) Scr Mater 36:99

Nakajima M, Uematsu Y, Kakiuchi T, Akita M, Tokaji K (2011) Proc Eng 10:299

Acknowledgement

This study was technically supported by Mr. Yuki Sato at Akita Prefectural University in Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Okayasu, M., Fukui, H., Ohfuji, H. et al. Strain-induced martensite formation in austenitic stainless steel. J Mater Sci 48, 6157–6166 (2013). https://doi.org/10.1007/s10853-013-7412-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7412-8