Abstract

The recent increasing interest of T-phase in Al alloy has been switched to its twins. In this study, we employed high resolution transmission electron microscopy to study and compare the morphology and orientation relationships (OR) of T-phase and its twins in an Al–Cu–Mg–Mn alloy. It is found that T-phase tends to form on the {403}Al habit planes and exhibit a rod-like shape, with it longitudinal axis, [010]T, being parallel to the matrix [010]Al direction. Three different OR types are determined between T-phase and Al matrix, namely, {200}T〈010〉T//{200}Al〈010〉Al (OR-I), {200}T〈010〉T//\( \{ 40\bar{3}\}_{\text{Al}} \)〈010〉Al (OR-II), and {200}T〈010〉T//{301}Al〈010〉Al (OR-III). OR-II is the most widely observed OR, while OR-I and III can form from the OR-II by twinning. During the twinning, the cross-section of T-phase transforms from a parallelogram-like shape into a shell-like shape. Further analyses on the shell-like T-twins strongly suggest that tenfold twins could form directly from the successive twinning of an individual T crystal.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Al–Cu–Mg alloys have attracted increasing research interest in recent years, due to their excellent fracture toughness and fatigue resistance for the application as lightweight, high damage-tolerance engineering materials [1–3]. Particularly for aerospace applications, the resistance of these alloys to crack growth is of critical importance [4]. It is recognized that the extent of crack growth resistance can be greatly affected by the precipitation of T-phase (Al20Cu2Mn3) during heat treatments, where a uniform spatial distribution of fine T precipitates is always desirable [5–7].

T-phase is the most common precipitate phase in Al–Cu–Mg alloys, and can be also observed in many other Al alloys, such as Al–Zn–Mg–Cu [8, 9] and Al–Li–Cu [10]. T-phase has a B-centered orthorhombic lattice [11] (space group: Bbmm) with a = 2.42 nm, b = 1.25 nm, and c = 0.775 nm [12, 13], and is found to be extremely stable in these alloys. It can precipitate from the matrices as early as during homogenization treatment, and once there, does not dissolve and re-precipitate during subsequent heat treatments [14]. Fine and uniformly distributed T-phase particles can act as effective barriers to dislocation slip [15], but promote cross-slip and homogeneous deformation in the matrices [16]. On account of its pinning effect at grain boundaries [17], T-phase can also stabilize grain size at elevated temperatures, thus retarding recovery [18], recrystallization [19, 20], and even texture evolution in the matrices during thermo-mechanical processes [21]. Furthermore, the interfaces between T-phase particles and the Al matrices may provide heterogeneous nucleation sites for other second phase particles [22–24], which can suppress the normal intragranular precipitation of these second phases and thus degrade the effectiveness of age-hardening in the alloys.

Extensive twinning was also observed for T-phase in Al by Wang et al. [11], with a glide vector of (1/4) (a ± c) along the {101}T plane (here and hereafter the subscript of T denotes T-phase). Since then, research focus has been largely switched to the twinning of T-phase. Chen et al. [25] further identified two different symmetries between neighboring components of T-twins in Al as glide reflection and reflection, as we schematically shown in Fig. 1. The twinning of T-phase can relieve stress concentration due to dislocation entanglement, and hence the suppressed formation of T-twins (by Ce-doping) could be strongly related to the degradation of strength and elongation of an Al–Cu–Mn alloy [25]. The twinning of T-phase also contributes to the improvement of fatigue properties by suppressing the formation of large-size T-phase particles, particularly those with irregular shapes, which are often regarded as potential initiation sites of cracks [19, 26].

Schematics of two twinning symmetries of T-phases in an Al matrix [25]: a glide reflection and b reflection

It has been recognized that the interfacial microstructures and geometric morphologies associated with T-phase and its twins have profound effects on the overall mechanical properties of Al alloys [27, 28]. However, it is somewhat surprising that very little such information has been obtained and reported in the literature. In this study, a thorough high resolution transmission electron microscopy (HRTEM) study was carried out, to characterize the microstructures and morphologies of T-phase precipitates in an Al–Cu–Mg alloy. Three ORs between T-phase and the Al matrix were identified, and the twinning within T-phase particles were discussed.

Experiments

The material used in this study was a commercial 2524 alloy with a nominal composition of Al–1.9Cu–1.7Mg–0.2Mn (at.%). The 10 mm square coupons were taken from the ingot (with a size of φ120 × L200 mm) at the mid-radius section. The samples were then annealed at 485 °C for 48 h for homogenization, followed by water quenching. HRTEM observations were carried out by using a Tecnai G2 F 20 transmission electron microscopy with an accelerating voltage of 200 kV. Thin foils for HRTEM were prepared by mechanical polishing and final twin-jet electro-polishing conducted at −25 °C and 20 V in a solution of 25 % nitric acid and 75 % methanol. A total of about 100 precipitates were analyzed and results were collected for discussions.

Results and discussions

Figure 2 shows the bright-field electron micrograph of a typical quenched sample obtained from the 〈010〉Al axis. Homogenization annealing resulted in the formation of massive rod-shaped precipitates inside the grains. Note these T-phase precipitates are preferentially elongated with their longitudinal axes parallel to the 〈010〉 directions of the matrix.

A bright-field TEM of a typical T-phase particle is shown in Fig. 3a (taken with B = [001]Al). The longitudinal axis of the rod-shaped particle is identified to be parallel to the [010] direction of the Al matrix. Figure 3b is the HRTEM image of the interface between the T particle and the Al matrix. Since the embedded T particle does not span over the entire thickness of the foil, moiré fringes are extensively observed along the sides of T-phase. The lattice parameters of T-phase are determined to be a = 2.42 ± 0.02, and b = 1.25 ± 0.02 nm, exactly the same as previously reported in Ref. [12, 13]. The corresponding fast Fourier transformation (FFT) pattern is provided in Fig. 3c. It is clearly seen that the (200) and (010) planes of T-phase are parallel to the (200) and (020) planes of the Al matrix, respectively. T-phase has an orthorhombic lattice [8, 12], the parallel relation of (010)T//(020)Al can be also represented as [010]T//[010]Al. The longitudinal axis of the T particle is thus found along the [010]T direction, which agrees with previous observations [10, 11]. Eventually we are able to determine the first orientation relationship (OR) between the T-phase and the Al matrix as [010]T//[010]Al, (200)T//(200)Al (OR-I).

Given that T-phase remains uniformly elongated parallel to [010]T//[010]Al direction, the main focus of the following work is on the shape in projections perpendicular to its longitudinal axis. Two other new types of OR, besides OR-I, are thus detected between T-phase and the Al matrix.

Figure 4 shows a set of TEM and HRTEM images of a T-phase particle with a near-parallelogram cross-section perpendicular to the longitudinal axis of [010]T. The cross-section is featured with an acute angle of 72° and an obtuse angle of 108°. Figure 3a, b further indicate that the two major sides of the cross-section are constituted by two low-index planes of T-phase, namely (200)T and (101)T, respectively. At one side, the (200)T is closely parallel to the matrix \( (40\bar{3})_{\text{Al}} \) plane, while at the other side, the (101)T is closely parallel to the matrix (403)Al plane. This T-phase particle is evidently twin-free. To achieve the parallelism of (200)T//(200)Al in OR-I, this T particle must rotate anticlockwise through ~36° about the longitudinal axis of [010]T (//[010]Al). We thus are able to indentify this OR as a new type: \( [010]_{\text{T}} //[010]_{\text{Al}} ,(200)_{\text{T}} //(40\bar{3})_{\text{Al}} \) (OR-II).

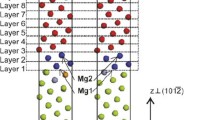

To our best knowledge, the atomic coordinates of T-phase (Al20Cu2Mn3) have not been fully determined yet. Even with the HRTEM images and the OR in Fig. 4, we are still unable to describe the detailed interfacial structure of T/Al at the atomic level. We noticed that the interplanar spacing of (001)T and (200)T closely matches with the thicknesses of four and six layers of (002)Al, respectively, as illustrated by red lines in Fig. 3c. This interplanar correlation might contribute positively to the preferred growth of T-phase with this particular OR, i.e., OR-II.

Figure 5 shows a set of TEM and HRTEM images of a rod-shaped T-phase particle with an isosceles trapezoid-like cross-section perpendicular to the longitudinal axis of [010]T. This cross-section is featured with an acute and a obtuse angle that are almost equal to those of the parallelogram in Fig. 4. This T-phase clearly shows a twinned structure. Figure 5a presents the HRTEM image of one twin component (on the right side) interfacing with the Al matrix. This T-twin component is oriented with its (200)T plane parallel to the (403)Al plane. The resulting OR, i.e., [010]T//[010]Al, (200)T//(403)Al, differs from OR-II only by a rotation of 180° about the [200]Al axis. We thus determine it as a variant of OR-II. Figure 5b presents the HRTEM image of the other T-twin component (on the left side) interfacing with the Al matrix. This twin component is oriented with its (200)T plane being parallel to the (200)Al plane, which apparently conforms to OR-I.

The twinning relationship between the two twin components is evident in Fig. 5c. The two sub-crystals are mirror related across a {101}T plane with a twinning angle of ~36° (35.72°), confirming that reflection is one twinning form of T-phase in Al matrix, in accordance with Ref. [25]. The other twinning form, i.e., glide reflection, can be also confirmed later in Fig. 6.

Figure 6 shows a T-phase with the more common shell-like shape viewed along [010]T//[010]Al. It consists of five well-faceted sectors (marked successively from I to V), with an angle of ~36° away from one another. The interfaces between the four sectors (I, II, III, and V) of T-phase and the Al matrix are displayed in Fig. 6a–d, respectively. All these interfaces are mainly composed of a {200}T plane.

As seen from Fig. 6a, b, sector I is oriented with its (200)T plane rotated anticlockwise by ~18° from the (200)Al, while sector II is clockwise rotated by the same amount. The stereographic projection by superimposing the plane poles of T-phase and the Al matrix reveals the (200)T planes of these two twin sectors nearly coincide with the \( (30\bar{1})_{\text{Al}} \) and (301)Al planes, respectively. These ORs with the Al matrix differ from OR-I and II, and shall be regarded as two variants of a new OR type, namely [010]T//[010]Al, (200)T//(301)Al (OR-III). Sector III in Fig. 6c is oriented with its (200)T plane rotated anticlockwise by ~36° from the (002)Al, while sector V is clockwise rotated by the same amount. These ORs with the Al matrix are determined to be [010]T//[010]Al, (200)T//(304)Al and \( [010]_{\text{T}} //[010]_{\text{Al}} ,(200)_{\text{T}} //(\bar{3}04)_{\text{Al}} , \) respectively, which, apparently, are two variants of OR-II. The OR between sector IV and the Al matrix cannot be easily identified, due to the presence of moiré fringes at the interface region. Figure 6e shows a HRTEM image at the center of this T-phase. It is clear that these sectors of T-phase are mutually related to one another by glide twinning, with a twin operator of m (101)|1/4〈101〉. Based on the twinning angle of 36°, the OR for sector IV can be deduced as [010]T//[010]Al, (200)T//(002)Al, which, obviously, is a variant of OR-I.

Careful inspection on about 100 T-phase particles reveals that OR-II widely exists in all T-phase precipitates (both twinned and twin-free) without an exception. OR-I exhibits only in twinned T-phases where OR-II already presents. OR-III is the least common OR, and occurs only in multiply twinned T-phases where both OR-I and II already present. These observations, combined with the above analyses on the crystallographic relation among the three ORs, allow us to deduce that OR-I and III form from the twinning of OR-II. In all observed T-phase, the habit planes for OR-II are determined as {403}Al. Using the formula in Ref. [29], the lattice misfits of the \( (200)_{\text{T}} /(40\bar{3})_{\text{Al}} \) and (101)T/(403)Al interfaces formed from OR-II (as seen in Figs. 4, 5) are calculated to be only 3.7 and 4.9 %, respectively. Considering the significant differences between the lattice parameters of T-phase and Al matrix, such low misfit values shall lead to minimal misfit strains during the formation of these interfaces in the Al matrix, which might help explain the origin of the {403}Al habit plane. A thorough understanding of the {403}Al habit plane might be achieved from crystallography by a so-called Δg method [30] based on the O-lattice theory [31], which will be our future research focus.

The orientation difference among these twin variants is very close to 36° which is a typical value for a tenfold symmetric structure. A successive twinning operation as shown in Fig. 6 can produce a complete set of tenfold twins. Decagonal-shaped tenfold T-twins featured with the 36° sector morphology have been observed in Al–Cu–Mg alloy in Ref. [32]. Here, we reported that the ten twin components in the decagonal-shaped T-twins can only possibly exhibits three different ORs (OR-I, OR-II, and OR-III), as seen in sectors I–V in Fig. 6. We further deduced that OR-I and III could be derived from the twinning of OR-II. Given the same volume, such a decagon shape always has a smaller surface area than a parallelogram-shaped one. Therefore, it can be expected from energetics that the shell-like shape T-phase in Fig. 6 shall outnumber the parallelogram-shaped one (in Fig. 4) in this alloy. This has been indeed confirmed by our observations on about 100 T-phase precipitates in the matrix.

Tenfold twins have a close connection to quasicrystals in some alloy systems. They exhibit very similar electron diffraction patterns, and can be hardly differentiated from each other using conventional electron diffraction analysis. It has been postulated that tenfold twins can transform from quasicrystals through a sequential decomposition process [33–35]. For example, an investigation on the ORs of decagonal-shaped quasicrystals and tenfold twins in a rapidly cooled Al–Fe alloy suggested that the observed tenfold twins (Al13Fe4) might be produced from the decomposition of the decagonal quasicrystal [36]. Similar results were also reported between tenfold T-twins and AlCuMn quasicrystals [32]. Figure 6 strongly suggests that tenfold twins could also form from the successive twinning of a single T crystal along the {101}T plane. Correspondingly, the cross-section of T-phase may transform from a parallelogram-like shape (in Fig. 4) into a shell-like shape (in Fig. 6).

Conclusions

We employed HRTEM to study the morphologies and ORs of T-phase and its twins in an as-homogenized Al–Cu–Mg–Mn alloy. The T-phase has a rod-like shape with its longitudinal axis ([010]T) parallel to the [010]Al direction. Three ORs have been identified as {200}T〈010〉T//{200}Al〈010〉Al (OR-I), {200}T〈010〉T//\( \{ 40\bar{3}\}_{\text{Al}} \)〈010〉Al (OR-II), and {200}T〈010〉T//{301}Al〈010〉Al (OR-III). OR-II is the most widely observed OR, while OR-I and III form from the twinning of OR-II. During twinning along a {101}T plane, the cross-section of T-phase may gradually transform from a parallelogram-like shape into a shell-like shape. Further analyses on the shell-like T-twins strongly suggest that tenfold twins could also form directly from the successive twinning of an individual T crystal, which can be regarded as a complementary mechanism to the widely accepted one that tenfold twins transform from quasicrystals through a sequential decomposition process.

References

Zhou MZ, Yi DQ, Liu HQ, Liu WJ, Zheng F (2010) Mater Sci Eng A 527:4070

Okayasu M, Sato K, Mizuno M (2008) J Mater Sci 43:2792. doi:10.1007/s10853-008-2544-y

Safarkhanian MA, Goodarzi M, Boutorabi SMA (2009) J Mater Sci 44:5452. doi:10.1007/s10853-009-3735-x

Rioja RJ, Liu J (2012) Metall Mater Trans A 43:3325

Xu Y, Gregson PJ, Sinclair I (2000) Mater Sci Forum 331:1525

Srivatsan TS, Champlin J, Zakrajsek J, Lam PC, Manoharan M (2001) J Mater Eng Perform 10:362

Malekjani S, Hodgson PD, Cizek P, Sabirov I, Hilditch TB (2011) Int J Fatigue 33:700

Liu J (2006) Mater Sci Forum 519–521:1233

Cai YH, Cui H, Zhang JS (2010) Mater Sci Technol 26:352

Liu Q, Chen CZ, Cui JZ (2005) Metall Mater Trans A 36:1389

Li CZ, Wang SC, Jin Y (1992) Acta Metall Sin 5:227

Robinson K (1952) Philos Mag 43:775

Wang SC, Li CZ, Yan MG (1989) Mater Res Bull 24:1267

Wang SC, Starink MJ (2005) Int Mater Rev 50:193

Mahon GJ, Howe JM, Vasudevan AK (1990) Acta Metall Mater 38:1503

Uygur I (2004) Iranian J Sci Technol Trans B 28:240

Kertz JE, Gouma PI, Buchheit RG (2001) Metall Mater Trans A 32:2561

Li Y, Liu ZY, Lin LH, Peng JT, Ning AL (2011) J Mater Sci 46:3708. doi:10.1007/s10853-010-5143-7

Feng WX, Lin FS, Starke EA Jr (1984) Metall Mater Trans A 15:1209

Castillo LD, Lavernia EJ (2000) Metall Mater Trans A 31:2287

Starke EA Jr, Lin FS (1982) Metall Mater Trans A 13:2259

Wang LM, Flower HM, Lindley TC (1999) Scripta Mater 41:391

Mukhopadhyay AK, Eggeler G, Skrotzki B (2001) Scripta Mater 44:545

Moy CKS, Weiss M, Xia JH, Sha G, Ringer SP, Ranzi G (2012) Mater Sci Eng A 552:48

Chen ZW, Chen P, Li SS (2012) Mater Sci Eng A 532:606

Zheng ZQ, Cai B, Zhai T, Li SC (2011) Mater Sci Eng A 528:2017

Nie JF (2008) Acta Mater 56:3169

Lee WM, Zikry MA (2011) Metall Mater Trans A 42:1215

Yang P, Engler O, Klaar HJ (1999) J Appl Cryst 32:1105

Zhang WZ, Weatherly GC (2005) Prog Mater Sci 50:181

Zhang WZ, Purdy GR (1993) Philos Mag 68:279

Li XZ, Kuo KH (1992) Philos Mag 66:117

Fung KK, Zou XD, Yang CY (1987) Philos Mag Lett 55:27

Tendeloo GV, Singh A, Ranganathan S (1991) Philos Mag 64:413

Xu L, Wang N, Lee ST (2000) Phys Rev B 62:3078

Zou XD, Fung KK, Ku KH (1987) Phys Rev B 35:4526

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant No. 51071177) and the Major State Basic Research Projections of China (Grant No. 2012CB619506). We also thank Dr. S.B. Wang for experimental assistance.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, Y.Q., Yi, D.Q., Jiang, Y. et al. Twinning and orientation relationships of T-phase precipitates in an Al matrix. J Mater Sci 48, 3225–3231 (2013). https://doi.org/10.1007/s10853-012-7102-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7102-y