Abstract

We have prepared two polysiloxane networks with different molecular structures and similar compositions as suitable precursors of silicon oxycarbide glasses (SiOC), in order to understand the influence of the molecular architecture of the polymeric networks on the structure of these glasses. The structural evolution from the polymeric precursor to glasses was followed by solid-state 29Si magic angle spinning nuclear magnetic resonance (29Si MAS NMR) and FTIR spectroscopies, X-ray diffraction, thermogravimetric analysis, and density measurements up to 1000 °C. The high- temperature behavior of SiOC glasses, up to 1600 °C, was studied by X-ray diffraction, and 29Si MAS NMR spectroscopy. The formation of carbosilane bridges in the polymeric networks during the hydrosilylation reaction contributed to the generation of a larger amount of carbidic sites in the final products. An increase in the pyrolysis temperature led to a distribution of silicon sites and crystallization profiles that depended on the molecular architecture of the polymeric precursors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

An impressive amount of research effort has been directed toward the synthesis of covalent ceramics from the pyrolysis of polymeric precursors [1–4]. This type of ceramics offers advantages such as applicability of polymer-processing techniques, homogeneity of precursors at the molecular level, lower processing temperatures as compared with conventional powder sintering methods, and possible synthesis of new compounds [5–7]. However, the main advantage of this approach is the possibility of building up polymers from molecular units and tailoring the molecular structure, so that the nano- and/or microstructure as well as the desired phases in the final glass or ceramic product can be dictated. Although the composition and the molecular structure of the polymeric network, the curing process, the pyrolysis cycle, and the atmosphere have been pointed out as variables that determine the properties of the product, and consequently their applications, it is still rather difficult to predict the appropriate polymeric architecture for the target glass or ceramic products under specific pyrolysis condition. The first paper dealing with a systematic structural characterization of silicon oxycarbide glasses (SiOC) regarding the above parameters was published by Babonneau et al. [8].

Control of the molecular architecture and knowledge about the structural evolution, through which the crosslinking and the polymer-to-ceramic transformation processes occur, are important parameters to consider if the performance of the material is to be improved. These parameters are particularly relevant in relation to the range of polymer-to-ceramic transformation temperatures and composition of the ceramic product.

Among some well-established methods for the processing of polymeric precursors is the hydrosilylation reaction, one of the most often employed routes in this area [9–13]. This reaction corresponds to the addition of a Si–H group to unsaturated moieties, usually in the presence of a catalyst [2, 10, 14, 15] or in a thermally-induced process [9, 16, 17]. Each reactive Si group gives rise to a Si–C x –Si site, where x = 1 or 2, with high selectivity toward the ethylene bridges, as represented below:

Due to the large number of different commercially available building blocks, including monomers, oligomers, and polymers, a wide variety of precursors can be employed in this strategy [12, 14]. Hydrosilylation is a versatile reaction that provides many benefits in relation to other crosslinking mechanisms: It can occur at room temperature in the presence of a catalyst, but it can also be accelerated by heat. As a result, the time spent on preparation is reduced, and no byproducts are formed. Furthermore, the shrinkage in the “green body”, the undesired feature usually observed in the sol–gel process, is minimized. However, the most important feature of the hydrosilylation reaction is the incorporation of carbosilane bridges (Si–C x –Si) in the polymeric network. The preparation of silicon oxycarbide with an O/Si ratio equal to 1 ratio is not straightforward, although this ratio can be found in a linear polydiorganosiloxane, such as poly(dimethylsiloxane) (PDMS), in which pyrolysis leads to 0 % residue [15, 18]. Carbosilane bridges allow for better control of the carbon content without decreasing the crosslinking density of the polysiloxane networks, thereby culminating in materials with controlled O/Si ratios. The presence of these bridges has also been pointed out as being responsible for the better incorporation of carbon in the oxycarbide glasses, as compared with those derived from alkoxysilanes containing Si–H and/or Si–CH3 groups by the sol–gel process [19–23]. In contrast to the hydrolysis-condensation reactions of alkoxysilanes commonly utilized during the sol–gel process, hydrosilylation reactions enables the formation of Si–C–C–Si or Si–C–Si bridges in the polymeric network, which contribute to the generation of a greater amount of SiC4 molecular sites in the final product.

The current study focuses on a comparative study of the structural evolution from two different polymeric networks based on polysiloxane structures prepared by hydrosilylation reaction; i.e., polymers bearing Si–CH2–CH2–Si bridges as cross-linked units. We obtained the polymeric networks CP1 and CP2 via a Pt-catalyzed hydrosilylation reaction between 1,3,5,7-tetramethyl-1,3,5,7-tetravinylcyclotetrasiloxane (D4Vi) and poly(hydromethylsiloxane) (PMHS) or 1,3,5,7-tetramethylcyclotetrasiloxane (D4H), respectively. We aimed to understand the influence of the molecular architecture on the structure of the final SiOC glasses. According to the previously published data [2, 9, 15, 18, 24–26], such kind of network is a promising ceramic precursor of SiOC glasses. We monitored the pyrolysis up to 1000 °C by thermal and spectroscopic techniques such as thermogravimetric analysis (TGA); Fourier transform infrared (FTIR) and 29Si and 13C magic angle spinning nuclear magnetic resonance (MAS NMR) spectroscopies; X-ray diffraction (XRD); and density measurements. We subjected the resulting silicon SiOC glasses to further pyrolysis at selected temperatures, up to 1600 °C, and evaluated their high temperature crystallization behavior by X-ray diffraction, and also by 29Si MAS NMR for the CP2-derived samples. We compared the results with respect to the different molecular architectures of the precursors and the final products.

Experimental procedure

Preparation of the samples

Polysiloxane networks were obtained from homogeneous mixtures of PMHS (\( \mathop {M_{n} }\limits^{\_\_} \) = 2300 g/mol) (Dow Corning, Midland, WI, USA) and 1,3,5,7-tetramethyl-1,3,5,7-tetravinylcyclotetrasiloxane (D4Vi) (Dow Corning, Midland, WI, USA), coded CP1, and from 1,3,5,7-tetramethylcyclotetrasiloxane (D4H) (Dow Corning, Midland, WI, USA) and D4Vi, labeled CP2. The preparation of these polysiloxane precursors involved a Pt-catalyzed hydrosilylation reaction having 2–3.5 % platinum divinyltetramethyldisiloxane in vinyl-terminated PDMS solution (ABCR GMBH Co., Kalsruhe, Germany) as catalyst, without the use of a solvent. The preparation is described in detail in refs. [2, 10, 26]. The PMHS/D4Vi and D4Vi/D4H weight ratios employed during the synthesis of the polymeric networks CP1 and CP2 were 50:50 and 59:41, respectively, in order to obtain the same number of Si–H/Si–Vi groups. After the curing procedure, the polymeric networks were subjected to pyrolysis under Ar atmosphere. Bulk pyrolysis experiments of the polymeric networks were carried out in a tube furnace (EDGcon 5P, EDG, SP, Brazil) equipped with an internal alumina tube and a temperature controller, under atmosphere of flowing argon (100 mL/min), up to 1000 °C. A typical heating cycle involved heating of the sample to 200 °C, at 5 °C/min; maintenance of the sample at 200 °C for 60 min; further heating of the sample to 400 °C, at 5 °C/min; maintenance of the sample at this plateau for 90 min; additional heating of the sample to 1000 °C, at 2 °C/min, followed by maintenance of the sample at this temperature for 120 min. Finally, the samples were cooled down to room temperature at 2 °C/min. Samples were also submitted to pyrolysis at final temperatures ranging between 1200 and 1600 °C. Pyrolysis was carried out in a Thermolyne F59340-CM instrument, in the same conditions described above.

Characterization techniques

The structural evolution from the polymeric network precursors to ceramic materials was investigated by FTIR using a transmission Fourier transform spectrometer (Bomem Hartmann & Braun, MB series, Quebec, Canada) operating between 4000 and 400 cm−1, at 4 cm−1 resolution, by means of the conventional KBr pellet method. 29Si and 13C solid-state nuclear magnetic resonance (NMR) experiments were carried out on a spectrometer (Bruker AC 300/P MHz, Karlsruhe, Germany) operating at 59.62 and 75.48 MHz, respectively. Spectra were recorded by applying magic angle spinning (MAS), with a 30° pulse of 7 μs and 60-s delay between pulses. On average, 1200 scans were necessary for a good signal-to-noise ratio to be achieved. 29Si MAS NMR spectra were adjusted using Gaussian fit multi-peaks available in Microcal Origin™ 7.0 software. Thermogravimetric analyses (TGA) were performed in a thermobalance (2950 Thermal Analysis Instrument, TA Instrument, New Castle, DE, USA). Analyses were conducted using ~10 mg of the polymer samples, in flowing nitrogen (100 mL/min), at a heating rate of 10 °C/min, up to 1000 °C. Density measurements were accomplished on a picnometer (Micromeritics 1305, Norcross, GA, USA). Samples were exhaustively purged with He before measurements. X-ray diffraction patterns (DRX) were recorded on a diffractometer (Shimadzu, model XRD-6000, Kyoto, Japan), using Cu Kα radiation. Carbon and hydrogen elemental analyses were carried out in an elemental analyzer (Perkin Elmer, model 2400) employing the procedure suggested in [27]. The accuracy was checked with reference samples, and the deviation was estimated to be around 5 %. The Si content in the ceramic products was evaluated by X-ray fluorescence in an X-ray equipment (Spectrace 5000, Tracor), using a cellulose filter. The oxygen content was estimated by difference.

Results and discussion

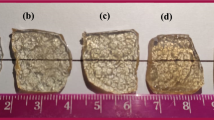

We prepared the polymeric networks CP1 and CP2 at room temperature via a Pt-catalyzed hydrosilylation reaction between D4Vi and PMHS or D4H, respectively. Figure 1 displays an idealized molecular structure for the precursors as well as for the networks CP1 and CP2. Both polymeric networks consist of shaped transparent rubbery samples. CP1 and CP2 have the same O/Si = 1 molar ratio, a C/Si molar ratio of ≈1.5, but distinct molecular architecture. CP1 is a traditional silicon network based on a linear polymeric chain cross-linked by D4Vi oligomers, whereas CP2 is a polycyclic silicon network similar to a “molecular sponge.” Indeed, small angle X-ray scaterring (SAXS) measurements of this network revealed a low fractal dimension value (D parameter from the power-law region), which implies an open structure that probably results from the great steric hindrance experienced by the precursors during formation of the the network as well as the free volume of the cycles [10].

The polymeric networks CP1 and CP2 exhibit similar thermogravimetric behavior (Fig. 2). Although the network of CP1 is slightly more stable than that of CP2, the maximum degradation temperature obtained for CP1 is 10 °C (from DTG curves not shown) higher than the one observed for CP2. However, both samples furnish the same ceramic yield at 1000 °C (86 wt %), which is a direct consequence of the crosslinking density in the preceramic precursors [15].

Figure 3 contains the FTIR spectra of CP1 and CP2 obtained at room temperature as well as the spectra of the resulting SiOC glasses obtained at 1000 °C. The spectra are similar and present the typical absorptions related to the C–H, Si–H, Si–O, C=C, and Si–CH3 bonds of D4Vi, PMHS, and D4H [10, 15, 23]. The absorptions in the ranges 2960–2800 cm−1 and 1402–1261 cm−1 are related to aliphatic C–H (CH3 and CH2 groups). The band at 1080 cm−1 corresponds to ν(Si–O–Si), and the one at 791 cm−1 can be assigned to ν(Si–C) and has contribution from Si–O–Si bonds. The most characteristic absorptions of the vinyl group in D4Vi are ν(C–H) and ν(C=C) at 3061 and 1595 cm−1, respectively. The strong band at 2160 cm−1 is typical of ν(Si–H) absorption, suggesting that part of both groups still remain in the cured network, due to incomplete reaction. The spectra of samples CP1 and CP2 submitted to pyrolysis at 1000 °C display only two broad bands centred at 1030 and 800 cm−1, which can be attributed to ν(Si–O–Si) and ν(Si–C–Si), respectively [2, 15, 26, 28, 29]. The relative intensity of the band ascribed to Si–C bonds is higher for CP2 than CP1, indicating that the total amount of sites containing Si–C is larger in CP2.

The structural evolution of the polymeric networks CP1 and CP2 as monitored by 29Si MAS NMR spectra can be found in Fig. 4. At 200 °C, the resonances at δ = −20 and −37 ppm for CP1 and δ = −19 and −33 ppm for CP2 can be assigned to D (C2SiO2) and DH [C(H)SiO2] or DV [C(C=C)SiO2] units, respectively [2, 9, 30–32]. At this temperature, 70 and 83 % of the functional groups of the precursor units are directly involved in the formation of the network (peaks at −20 and −19 ppm) in polymers CP1 and CP2, respectively. The remaining Si–H or Si–Vi groups (peaks at −37 and −33 ppm) were not able to participate in the hydrosilylation reaction. No residual Si–H or Si–C=C groups are detected for CP2 at 400 °C, whereas 20 and 12 % of these groups can be verified for CP1 at 400 and 600 °C, respectively. These results suggest that the organic-to-inorganic transformation is faster in CP2 compared with CP1. The more open structure of CP2 culminates in complete crosslinking at 400 °C, affording a structure with 100 % of SiC2O2 sites. Moreover, in the case of CP2, heating at 600 °C is enough to promote reorganization reactions of the siloxane sites, as demonstrated by two other additional broad resonances centered at δ 6 and −63 ppm, assigned to C3SiO and CSiO3 sites. In contrast, some functional groups can be inaccessible to the hydrosilylation reaction in CP1. In this polymeric network, the organic-to-inorganic conversion starts only at 615 °C. Following the structural evolution promoted by pyrolysis, the redistribution of the Si sites is similar for both CP1 and CP2 up to 800 °C, with increase in the relative intensity of the resonances at δ −10 and −106 ppm, attributed to SiC4 and SiO4, respectively [2, 9, 26, 31, 32]. At 1000 °C, the products display the characteristic silicon oxycarbide glass spectrum with random distribution of the SiO4, SiO3C, SiC2O2, and SiC4 sites for CP1 and CP2 [33]. The composition of each site is described in Table 1 for the samples obtained at 800 and 1000 °C. For both CP1 and CP2, the abundance of SiC4 sites is higher than those usually observed in glass products obtained from the pyrolysis of alkoxysilane gels, which consist primarily of SiO4, SiO3C, and SiC2O2 and contain a lower amount of or no SiC3O and SiC4 sites [21, 34]. In addition, the distribution of silicon sites in the CP1 and CP2-derived glasses is similar to the one observed in Blackglas™ [35].

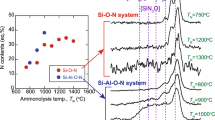

The densification processes up to 1000 °C undergone by CP1 and CP2 as a function of the temperature are similar. There is a higher increase in the density values from 600 to 800 °C, which is in agreement with the 29Si MAS NMR data. The density values of CP1 and CP2 at 1000 °C are 2.1 ± 0.2 and 2.2 ± 0.2 g/cm3, respectively. The XRD patterns of the CP1 and CP2 glass samples subjected to pyrolysis at 1000 °C are given in Fig. 5. The patterns are characteristic of amorphous materials, as expected for silicon oxycarbide glasses. At 1200 °C, the main diffractions associated with β-SiC can be observed as very broad peaks with low intensity. This suggests the beginning of the crystallization process, as a consequence of the continuous reorganization of the silicon sites. These diffractions become more intense with rising pyrolysis temperatures, up to 1600 °C. At this final temperature, the CP2-derived product has pattern typical of pure β-SiC, with peaks at 35.6°, 41.3°, 60.0°, and 72.0° (2θ). It was observed before that for SiOC samples with an excess of “free” carbon phase in the glass network are better stabilized, at least until 1500 °C, toward the formation of β-SiC [36]. Such behavior is quite similar to the one observed for CP2. The CP1-derived product presents less intense and broad peaks relative to β-SiC, in addition to a broad halo centered at 21.9° (2θ), assigned to α-cristobalite, suggesting that the amorphous phase is a near-silica-structure for the silicon oxycarbide network [36]. The XRD pattern of CP2 obtained between 1000 and 1400 °C contains a very low intense peak centered at 26.5° (2θ), assigned to a lamellar structure, such as graphitic carbon [24]. The mean size of the β-SiC crystals as estimated by the Scherrer equation is 40 and 140 Å for CP1 and CP2, respectively.

For the CP2-derived sample, we also monitored the structural evolution promoted by the further rise in the firing temperature by 29Si MAS NMR (Fig. 6). For the samples subjected to pyrolysis at 1200 and 1400 °C, there is an increase in the relative amounts of SiC4 and SiO4 sites. The redistribution reactions of silicon sites are essential steps for carbothermal reactions, as discussed by some authors [9, 28, 37, 38]. These reactions afford crystalline β-SiC, which is characterized by a narrow resonance peak at −16 ppm in the 29Si MAS NMR spectrum. For CP2, density growth depends on the pyrolysis temperature. At 1600 °C the density value is 3.21 g/cm3, which corresponds to pure SiC phase.

The 13C MAS NMR spectra recorded for the polymeric networks CP1 and CP2 submitted to pyrolysis at 1000 °C are illustrated in Fig. 7. The spectra of both samples are similar, with a broad signal centered at 133 ppm. This signal is assigned to unsaturated and probably conjugated species, such as aromatic carbons and carbon structure units with double or triple bonds, which may not be directly attached to silicon sites [28, 29]. In addition, another peak centered at 32 ppm may be ascribed to structures like –Si–CH2– units [28, 29]. The carbon phase is dispersed in the SiOC matrix, which is more significant in CP2. Consequently, at high temperatures, the carbothermal reduction of SiO2 can take place, thereby consuming the carbon phase [26]:

This reaction results in the evaporation of CO and SiO gaseous species. However, the above equation is only valid for low levels of free carbon in the material. In the presence of high carbon contents, SiC(s) and CO(g) are the major decomposition products, according to:

The above equations show that the SiO species plays an important role as intermediate species in the reduction of silica. For samples with high C amounts, the carbothermal reduction of SiO2 will preferentially produce SiC, as observed for CP2. The larger amount of total carbon in the CP2-derived glass is also supported by the chemical composition of the derived-glasses obtained at 1000 °C (Table 2) as well as by the more intense absorption band at ~800 cm−1 in the FTIR spectrum of CP1 (Fig. 3). Similar results have been observed before for samples derived from phenylsilsesquioxanes, which showed higher amount of total carbon, when compared to vinylsilsesquioxane [39].

Conclusions

We obtained polysiloxane networks with distinct molecular architectures and similar compositions by hydrosilylation reaction. These networks are suitable precursors of SiOC glasses. At 1000 °C, these polymers give rise to silicon oxycarbide glasses with higher amounts of SiC4 sites than similar ceramics usually prepared by hydrolysis-condensation reaction of alkoxysilanes. Our results indicated that the polysiloxane network prepared from polycyclic oligomers (CP2) has faster organic-to-inorganic transformation compared with the linear precursor (CP1). The higher amount of total carbon in the CP2-derived glass compared with the CP1-derived glass might be related to the molecular architectures of CP1 and CP2, which are strictly related to the crosslinking density observed during pyrolysis. The amount of free carbon is able to drive the synthesis toward a ceramic phase constituted exclusively by β-SiC, in good ceramic yield, as observed for CP2.

References

Richter R, Roewer G, Böhme U, Busch K, Babonneau F, Martin HP, Müllert E (1997) Appl Organomet Chem 11:71–106

Radovanovic E, Gozzi MF, Gonçalves MC, Yoshida IVP (1999) J Non Cryst Solids 248:37–48

Colombo P, Mera G, Riedel R, Soraru GD (2010) J Am Ceram Soc 93:1805–1837

Vakifahmetoglu C, Balliana M, Colombo P (2011) J Eur Ceram Soc 31:1481–1490

Riedel R (1996) In: Brook RJ (ed) Materials science and technology. A comprehensive treatment processing of ceramics. Part II, vol 17B. VCH Verlagsgesellschaft, Weinheim, pp 1–50

Li YL, Liang T, Su D, Du HB (2010) J Eur Ceram Soc 30:2677–2682

Ma Q, Xu T, Chen Z (2011) Mater Lett 65:1538–1541

Bréquel H, Parmentier J, Walter S, Badheka R, Trimmel G, Masse S, Latournerie J, Dempsey P, Turquat C, Desmartin-Chomel A, Le Neindre-Prum L, Jayasooriya UA, Hourlier D, Kleebe HJ, Sorarù GD, Enzo S, Babonneau F (2004) Chem Mater 16:2585–2598

Su D, Li YL, An HJ, Liu X, Hou F, Li JY, Fu X (2010) J Eur Ceram Soc 30:1503–1511

Redondo SUA, Radovanovic E, Gonçalvez MC, Yoshida IVP (2001) Polymer 42:1319–1327

Nyczyk A, Paluszkiewicz C, Pyda A, Hasik M (2011) Acta A 79:801–808

Schiavon MA, Ciuffi KJ, Yoshida IVP (2007) J Non Cryst Solids 35:32280–32288

Blum YD, MacQueen DB, Kleebe HJ (2005) J Eur Ceram Soc 25:143–149

Hecht W (1991) Silicones-Chemistry and Technology. Vulkan, Essen, pp 61–73

Schiavon MA, Redondo SAU, Pina SRO, Yoshida IVP (2002) J Non Cryst Solids 304:92–100

Gozzi MF, Yoshida IVP (1997) Eur. Polym. J. 33:1301–1307

Kleebe HJ, Blum YD (2008) J Eur Ceram Soc 28:1037–1042

Liu X, Li YL, Hou F (2009) J Am Ceram Soc 92:49–53

Sorarù GD, D’Andrea G, Campostrini R, Babonneau F, Marriotto G (1995) J Am Ceram Soc 78:379–387

Sorarù GD, Karakuscu A, Boissiere C, Babonneau F (2012) J Eur Ceram Soc 32:627–663

Dibandjo P, Diré S, Babonneau F, Soraru GD (2010) J Non Cryst Solids 356:132–140

Das G, Bettotti P, Ferraioli L, Raj R, Mariotto G, Pavesi L, Soraru GD (2007) Vib Spectrosc 45:61–68

Chomel AD, Dempsey P, Latournerie J, Bahloul DH, Jayasooriya UA (2005) Chem Mater 17:4468–4473

Segatelli MG, Pires ATN, Yoshida IVP (2008) J Eur Ceram Soc 28:2247–2257

Siqueira EJ, Yoshida IVP, Pardini LC, Schiavon MA (2009) Ceram Int 35:213–220

Schiavon MA, Radovanovic E, Yoshida IVP (2002) Powder Technol 123:232–242

Borda PP, Legzdin P (1980) Anal Chem 52:1777–1778

Téllez L, Rubio J, Rubio F, Morales E, Oteo JL (2003) J Mater Sci 38:1773. doi:10.1023A/:1023240129477

Brus J, Kolár F, Machovic V, Svítilová J (2001) J Non Cryst Solids 289:62–74

Kalfat R, Babonneau F, Gharbi N, Zarouk H (1996) J Mater Chem 6:1673–1678

Ionescu E, Papendorf B, Kleebe H, Poli F, Müller K, Riedel R (2010) J Am Ceram Soc 93:1774–1782

Ionescu E, Papendorf B, Kleebe H, Riedel R (2010) J Am Ceram Soc 93:1783–1789

Renlund GM, Prochazka S, Doremus RH (1991) J Mater Res 6:2723–2734

Pantano CG, Singh AK, Zhang H (1999) J Sol-Gel Sci Technol 14:7–25

Hurwitz FI, Meador MAB (1999) J Sol-Gel Sci Technol 14:75–86

Brequel H, Parmentier J, Sorarù GD, Schiffini L, Enzo S (1999) Nanostruct Mater 11(6):721–731

Belot V, Coriu RJP, Leclercq D, Mutin PH, Vioux A (1992) J Non Cryst Solids 147:52–55

Corriu RJP, Leclercq D, Mutin PH, Vioux A (1997) J Sol-Gel Sci Technol 8:327–330

Bujalski DR, Grigoras S, Lee W-LN, Wieber GM, Zank GA (1998) J Mater Chem 8(6):1427–1433

Acknowledgements

The authors kindly acknowledge CAPES, CNPq, FAPESP, and FAPEMIG for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sousa, B.F., Yoshida, I.V.P., Ferrari, J.L. et al. Silicon oxycarbide glasses derived from polymeric networks with different molecular architecture prepared by hydrosilylation reaction. J Mater Sci 48, 1911–1919 (2013). https://doi.org/10.1007/s10853-012-6955-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6955-4