Abstract

Temperature-dependent ferroelectric hysteresis properties of modified lead zirconate titanate ceramics have been investigated in a wide temperature range from 300 to 433 K. It is observed that remnant polarization, saturation polarization, and coercive field are increasing with an increase of the temperature in a low-field region and decreasing in a high-field region. Such behavior is explained by the competition between switching and backswitching mechanisms. A three-stage dependence of the logarithm of the hysteresis loop area on the logarithm of the electric field is identified. The temperature dependence of backswitching properties has been studied. The obtained results indicate that the temperature dependence of the polarization backswitching can be well described by the Arrhenius law. The activation energy for the domain switching determined from the fitting results exhibits decreasing tendency with the increase of the electric field.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lead oxide-based ferroelectrics, represented mostly by lead zirconate titanate (PZT) compositions, are the most widely used materials for piezoelectric actuators, sensors, and nonvolatile ferroelectric random access memories (FeRAM) [1] due to their excellent ferroelectric and piezoelectric properties. All these applications based on polarization switching characteristics are often subjected to strong electric fields and high temperatures. However, the ferroelectric polarization generally shows a bad retention at high temperatures, which affects the device commercialization [2]. Thus, a deep understanding of the temperature dependence of the polarization switching behavior represents an essential technical interest.

Up to date, a considerable progress has been made on the temperature-dependent electrical properties of ferroelectric thin films. The temperature dependences of ferroelectric and dielectric characteristics have been reported by Meng et al. [3] for PbZr0.5Ti0.5O3 ferroelectric thin films, Wu et al. [4] for Bi3.15Nd0.85Ti3O12 ferroelectric thin films, and Wang et al. [5] for Bi0.9La0.1FeO3 thin films. These measurements suggest that domain wall motion is an important factor in determining the electrical properties of the ferroelectric thin films. The study of the temperature dependence of the polarization switching is mostly focused on the ferroelectric thin films as mentioned above.

For the reason that hysteresis loop area 〈A〉 corresponds to the energy dissipation within one cycle of domain reversal, the key kinetic picture of nucleation, growth, and motion of the domain walls can be evaluated from the details of 〈A〉 scaling laws. Previous studies have reported the scaling of ferroelectric hysteresis loop area in thin films [6, 7], BaTiO3 single crystals [8], PZT ceramics, and (1 − x)BiScO3–xPbTiO3 ceramics [9–11]. In these studies, the electric field E and frequency f dependences of 〈A〉 have been considered. Furthermore, the initiative work on the scaling behavior of dynamic hysteresis loops in ceramics revealed that the scaling relations between 〈A〉 and E, f were different in two field ranges (low field and high field) [9, 10]. On the contrary, the experimental results concerning the temperature scaling behaviors of ferroelectric hysteresis loops in bulk ferroelectric ceramics are limited and scattered in literature [12–14]. It has been found that the polarization switching behavior was different in three different ranges of applied electric field, e.g., E < E c, E ≈ E c, and E > E c (where E c is coercive field) [15, 16]. It was proposed that three scaling relations with the different applied field may reflect three different polarization mechanisms. The room temperature relations between 〈A〉 and E, f have been reported by Yu [17]. The fitting results showed that linear dependencies existed between ln〈A〉 and lnE in the first and third field ranges. The slopes at the third range increase with the increase of the frequency, which could be attributed to the large dielectric loss at high frequencies. However, the results mentioned above were generally obtained at a fixed temperature and the scaling behavior at a wide temperature range is not known from the open literature. This fact guides our research to further understanding of the relation between 〈A〉 and E in the high-temperature region.

The polarization backswitching is a critical criterion for the FeRAM applications because polarization backswitching leads to a loss of the storage capability (retention) of ferroelectric films [18]. In previous study, Liu et al. [19, 20] have measured the polarization reversal and dynamics of backswitching in epitaxial BaTiO3 thin films at different temperatures by transient electro-optic (EO) response. The field dependence of relaxation time has been attributed to nucleation and growth of domains. Upon removal of the bias pulse, domain backswitching was observed, which is described by the Kohlrausch–Williams–Watts extended exponential function in time. The activation field and the activation energy were determined from the measured transient EO response.

Little is known about the temperature stability of the bulk ceramics which is often desirable for practical applications. Electrical devices may need to work at different temperatures, so it is necessary to evaluate the electrical behavior of the materials as a function of temperature. In fact, the temperature dependence of ferroelectric properties is one of the most important characteristics in view of not only engineering but also basic physics points. In this study, the temperature-dependent ferroelectric hysteresis characteristics of the modified PZT ceramics are studied, focusing on domain wall motion at low temperature. The evolution of the electric field-dependent scaling behavior in a broad temperature range is also studied.

Experimental

The polycrystalline ceramic disks from modified PZT composition Pb0.96Sr0.04(Mg1/3Nb2/3)0.275(Ni1/3Nb2/3)0.1Ti0.375Zr0.25O3 prepared via a solid-state reaction technique were used for all described experiments. Raw materials were reagent grade Pb3O4, SrCO3, MgCO3·Mg(OH)2·5H2O, Ni(CH3COO)2·4H2O, ZrO2, TiO2, and Nb2O5. In order to compensate the lead loss during high-temperature calcination/sintering processes, 1.5 wt% extra Pb3O4 was added. The ingredient oxide powders were mixed thoroughly in wet condition (alcohol) with yttria-stabilized zirconia balls for 6 h and calcined at 800 °C in a high-purity alumina crucible in air for 1 h. The calcined powders were subsequently ball-milled in the same media for 6 h, then dried and sieved again. The resulting fine milled powder was mixed with 3 wt% polyvinyl alcohol binder and then pressed into cylindrical pellets (15 mm in diameter and 1.2 mm in thickness) under a uniaxial pressure of 4 MPa. Following a binder burn-up at 450 °C, the pressed pellets were sintered in air at 1070 °C for 4 h using sealed alumina crucibles.

For electrical characterization, the samples were polished to form disks with a thickness of 1 mm, and silver-paste was painted on the flat polished surfaces to act as electrodes followed by firing at 600 °C for 20 min. The polarization hysteresis loops were measured using a Sawyer–Tower capacitive voltage divider in a computerized measuring system over a temperature range from 300 to 433 K. The electric field was supplied by a high-voltage power supply (Trek 609B, NY, USA) driven by a frequency generator (HP33220A, CA, USA) generating bipolar triangular voltage waveform with a frequency of 1 Hz. The hysteresis loop area 〈A〉 was calculated by integrating the area bounded by the hysteresis loop.

Results and discussion

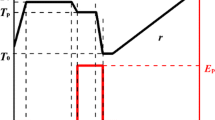

The hysteresis loops of the modified PZT ceramics measured with the amplitude of the applied electric field E = 2 and 0.5 kV/mm at various temperatures are shown, respectively, in Fig. 1a, b. In the high-electric field range (E = 2 kV/mm), both the saturation P s and the remanent polarizations P r decay with increasing temperature, while P s and P r increase with increasing temperature in the low-electric field range (E = 0.5 kV/mm). To illustrate the evolution of hysteresis loops, the P r and the coercive field E c at different temperatures as a function of electric field are presented, respectively, in Fig. 2a, b. It was observed that with the increase of the temperature, the P r increases in the low-field region and decreases in the high-field region, followed by the merging of all P r versus E curves in the high-field region. This result suggests that the switching behavior is different in the low- and the high-applied field ranges, which are similar with recently obtained results [21]. It has been reported [20] that both the polarization switching and backswitching are enhanced and accelerated with the increase of the temperature, thus, the temperature-dependent polarization switching is determined by the competition between the switching and the backswitching processes and the latter is dominant in the high-field range.

As the temperature increased from 300 to 433 K, the E c decreases quickly from 790 to 287 V/mm and the saturation of E c and P r shifts to lower field. Therefore, both the reduction of the polarization and increase of the coercivity indicate a freezing tendency of domains with the decrease of temperature. In addition, the polarization switching process is governed by the thermodynamic nucleation process in the low field and high-temperature range.

Temperature dependence of 〈A〉 obtained from the hysteresis loops are shown in Fig. 3. It was observed that the data can be clearly divided into two regimes [4, 5]. The hysteresis loops are saturated and the loop areas increase with decreasing temperature in the high field and high-temperature range, most of the domains are switched by the external field and polarization decays visibly, just as shown in Fig. 1a. While it decreases with decreasing temperature in the low field and low-temperature range, where the hysteresis loops are unsaturated. More and more domain switching could not be accomplished under a fixed field due to the larger coercive field at lower temperatures, resulting in the decreased 〈A〉. It has been reported that the loop area is related to irreversible domain wall motion, and larger loop area at lower temperature in the saturated regime imply the increase of difficulty for such domain wall motion with decreasing temperature [5].

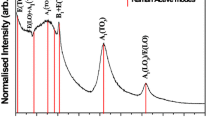

To investigate the hysteresis scaling behaviors between 〈A〉 and E, T, Kamel [16] divided the poling process into three regions according to the polarization current versus time curves from low to high fields: (1) Maxwell–Wagner polarization, (2) polarization switching, and (3) steady state. Based on these conclusions and our results, we assume that the polarization switching process in the bulk ceramics can also be divided into three regions. The relationship between 〈A〉 and E reflects the polarization reversal process [17]. Three different polarization mechanisms in different applied field ranges suggest that there may be three different scaling relations. In Fig. 4, the dependencies of ln〈A〉 and dln〈A〉/dlnE versus lnE are shown at T = 300 K. At the low-field range, ln〈A〉 shows only slight change and then increases rapidly at intermediate field range. At the high-field range, ln〈A〉 increases slowly with the increase of E. The curves between ln〈A〉 and lnE show similar profile at all temperatures. At the same time, the curves can be also divided into three parts with the increase of E from the changing tendency of differential curve dln〈A〉/dlnE.

The different behaviors observed in the three field ranges strongly suggests the different polarization mechanisms as discussed above. In the first range (low field), the Maxwell–Wagner polarization may be the main polarization mechanism [15, 16]. The Maxwell–Wagner polarization can be attributed to the accumulation and release of the mobile charge carriers that arise at the interface between grains [22]. Due to the low-electric field, domain switching cannot be activated in this field range. The Maxwell–Wagner polarization is followed by the domain switching mechanism in the intermediate field range. The domain switching in this range may be interpreted as the nucleation of new domains and the motion of domain walls. Generally speaking, at low field, the rate of nucleation is so low that the switching is primarily governed by the nucleation process. But at high field, the rate of nucleation is high and the switching time is primarily determined by the motion of the domain walls [23]. In the third range (high field), the nucleation of domains has been completed and the polarization reversal is governed by the motion of domain walls. It is well known that polarization switching is deemed to be governed by the field-driven motion of the domain wall, whose mobility is interface-controlled and rate-limited by nucleation at the wedge of the domain walls [24]. Our results confirm this viewpoint. In other words, the amount of newly activated domains by the increase of E decreases dramatically in this field range.

Figure 4 shows linear fits between ln〈A〉 and lnE for the first field range at different temperatures. As shown in Fig. 5, the temperature dependence of slope k (estimated from the linear fits) follows a simple exponential function shown in the Fig. 5. The increase of the slope with increasing temperature may be explained as follows: the accumulation and release of the mobile charge carriers were activated with increasing temperature. The Maxwell–Wagner polarization process, which is limited to short time only, is accomplished more easily. According to conventional thought, the energy at which the polarization switching occurs is a threshold that represents the intrinsic switching barrier [16]. When the applied field is a little lower than E c, a longer time is needed to overcome the threshold for the polarization switching. Considering that the high temperature can provide a strong driving force, the overcome of the coercivity occurs easily. And the nucleation of domain can finish at a lower field, which is in agreement with the results in Fig. 2a. So the first stage and the second stage occur at the same time with increase of the temperature. These experiment results further reflect that thermodynamic nucleation process can play an important role in domain switching.

In order to further explain the temperature dependence of P r, we must pay attention to the backswitched domains comprising a part of switched domains. Backswitched domains have no contribution to P r (when the value of electric field is zero). In general, the volume of switchable domains is related to the value of P s. And the volume of backswitched domain is proportional to the value of P s − P r. When a suitable voltage is applied to the ferroelectrics, the polarization reaches P s. After the applied voltage is removed, the polarization reaches a stable polarization of P r. During the relaxation process, the switched polarization is switching back partially [25]. Such a phenomenon is referred to as polarization backswitching, and the corresponding backswitching polarization P bc can be expressed as [26]

According to the classical theory of nucleation by random fluctuations, it can be seen that the nucleation rate ν increases with increasing T. So the temperature dependence of dynamic relaxation response for domain nucleation and growth was calculated by the following equation:

where U 0 is the energy barrier for domain nucleation and growth, k B is the Boltzmann constant, and T is the temperature. This suggests that an increase in temperature will result in a decrease in the switching time [20, 26]. The backswitching polarization also increases with the increase of temperature, as shown in Fig. 6. The backswitching polarization has a relaxation process when the applied field is removed, so we consider the relaxation process as similar to dynamic one for domain nucleation and growth.

The temperature dependence of P s − P r is plotted in Fig. 6. We selected the temperature range from 300 to 433 K, which is below the phase transition temperature. In the high-field ranges, the relationship between P s − P r and T obeys the Arrhenius law:

where E A is the average activation energy of trapped charge defect such as oxygen vacancy, and P 0 is a constant. The slope of ln(P s − P r) versus 1/T can be used to estimate the average activation energy of domain switching. In general, E A is dependent on the applied field [20]. Arrhenius plots for the samples at different temperatures are shown in Fig. 7. Whereas Fig. 8 shows the activation energy estimated from the slope of the linear fits. The field dependence of the activation energy for the modified PZT ceramics fits well to a simple exponential decay function given by the following equation:

Figure 8 indicates a zero field activation energy ~0.178 eV, which is typical for the mobility of singly ionized oxygen vacancy. The activation energy decays to 0.042 eV as the electric field increased. Kumar et al. [27] have reported an activation energy of 0.21 eV in the low-temperature regime for Pb(Zr0.52Ti0.48)0.5(Fe0.5Nb0.5)0.5O3 ceramics. It has been suggested that the lower value of the activation energy obtained at low temperatures is associated mainly with the creation of a large number of space charge carriers in oxidation–reduction processes.

Conclusion

The temperature-dependent switching characteristics of the modified PZT ceramics have been studied between 300 and 433 K. It is observed that the switching characteristics are different in the low- and high-applied field ranges, resulting from the competition between switching and backswitching processes. More interestingly, the fitting results showed two linear relations existed between ln〈A〉 and lnE in the low- and high-field ranges. In the second range (intermediate field), no linear relation existed due to polarization reversal. This three-stage behavior was distinct from the existing two-stage one. The increase of the slope in the low-field range with the increase of temperature can be attributed to both space charge polarization and nucleation of domain at high temperatures. Besides, the temperature dependence of backswitching kinetics of ferroelectric domains has been summarized. The results indicate that the relationship between polarization backswitching and temperature obeys the Arrhenius law. The activation energy of trapped charge defect is about 0.04–0.07 eV. The field dependence of the activation energy for the modified PZT ceramics fits well to a simple exponential decay function. These results are helpful to fully characterize the PZT ceramics for applications in which a broader temperature range is anticipated.

References

Scott JF (2007) Science 315:954

Kang BS, Yoon JG, Kim DJ, Noh TW, Song TK, Lee YK, Lee JK, Park YS (2003) Appl Phys Lett 82:2124

Meng XJ, Sun JL, Wang XG, Lin T, Ma JH, Guo SL, Chu JH (2002) Appl Phys Lett 81:4035

Wu D, Yuan GL, Li AD (2007) Appl Phys Lett 90:062902

Wang Y, Wang J (2009) J Appl Phys 106:094106

Liu JM, Li HP, Ong CK, Lim LC (1999) J Appl Phys 86:5198

Pan B, Yu H, Wu D, Zhou XH, Liu JM (2003) Appl Phys Lett 83:1406

Wongdamnern N, Ngamjarurojana A, Laosiritaworn Y, Ananta S, Rimnirun R (2009) J Appl Phys 105:044109

Yimnirun R, Laosiritaworn Y, Wongsaenmai S, Ananta S (2006) Appl Phys Lett 89:162901

Yimnirun R, Wongmaneerung R, Wongsaenmai S, Ngamjarurojana A, Ananta S, Laosiritaworn Y (2007) Appl Phys Lett 90:112908

Yu G, Dong XL, Wang GS, Cao F, Chen XF (2010) J Alloys Compd 500:56

Yimnirun R, Wongmaneerung R, Wongsaenmai S, Ngamjarurojana A, Ananta S, Laosiritaworn Y (2007) Appl Phys Lett 90:112906

Yimnirun R, Ngamjarurojana A, Wongmaneerung R, Wongsaenmai S, Ananta S, Laosiritaworn Y (2007) Appl Phys A 89:737

Chen XF, Dong XL, Zhang HL, Feng NB, Nie HC, Cao F, Wang GS, Gu Y, He HL (2009) J Appl Phys 105:096104

Viehland D, Li JF (2001) J Appl Phys 90:2995

Kamel TM, Kools FXNM, de With G (2007) J Euro Ceram Soc 27:2471

Yu G, Dong XL, Wang GS, Cao F, Chen XF, Nie HC (2010) J Appl Phys 107:106102

Fu DS, Suzuki K, Kato K, Suzuki H (2003) Appl Phys Lett 82:2130

Liu ZF, Meier AL, Wessels BW (2008) J Appl Phys 104:064115

Li JH, Lin PT, Wesselsa BW (2009) J Appl Phys 106:054113

So YW, Kim DJ, Noha TW, Yoon JG, Song TK (2005) Appl Phys Lett 86:092905

Waser R, Hagenbeck R (2000) Acta Mater 48:797

Chen XF, Dong XL, Zhang HL, Yu G, Cao F, Wang GS (2010) Solid State Commun 150:720

Merz WJ (1954) Phys Rev 95:690

Picinin A, Lente MH, Eiras JA, Rino JP (2004) Phys Rev B 69:064117

Zhang Y, Zhong XL, Chen ZH, Wang JB, Zhou YC (2011) J Appl Phys 110:014102

Kumar N, Ghosh A, Choudhary RNP (2011) Mater Chem Phys 130:381

Acknowledgements

This study was supported by the Ministry of Sciences and Technology of China through 973-Project under Grant No. 2009CB623306, National Natural Science Foundation of China (Grant Nos. 50672042, 51072016) and State Key Laboratory of New Ceramics and Fine Processing (KF1014). The authors also acknowledge enlightening discussions with Dr. Ivan Baturin.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wen, B., Zhang, Y., Liu, X. et al. Temperature-dependent ferroelectric hysteresis properties of modified lead zirconate titanate ceramics. J Mater Sci 47, 4299–4304 (2012). https://doi.org/10.1007/s10853-012-6280-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6280-y