Abstract

Chemiresistors based on palladium phthalocyanine (PdPc) thin films were investigated as humidity sensors. The samples were thermally evaporated onto gold electrodes with a thickness about 100 nm. Optical and electrical characteristics of PdPc thin films were investigated by scanning electron microscopy (SEM), X-ray diffraction (XRD), and electrical measurements. The SEM image demonstrates PdPc (30–60 nm) nanosized particles, and XRD pattern shows that thin films are in α-phase at room temperature. Electrical measurements also confirm that PdPc exhibit semiconducting and photoconducting behaviors, and thermal activation energies of thin films were calculated. After that, the sensitivity and reversibility of devices were investigated on exposure to 20–90% RH in various chemical environments at 293 and 323 K. The response time (35–45 s) and recovery time (75–105 s) of sensors were measured at 293 K with respect to different chemical environments. At last, the stability of devices versus different RH% and chemical environments were tested. The sensors show very good stability on exposure to RH for a period of 2 months but their stability has been reduced in ethanol, acetone, and ammonia environments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

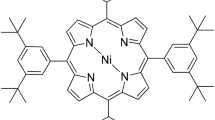

Humidity sensors are important devices in recent technology and life style; they can be used in automotive, medical, construction, semiconductor, meteorological, and food processing industries [1–4]. It is well known that a good humidity sensor should be focused on the improvement of the following requirements, such as linear response, high sensitivity, short response time, and long-term stability [5]. Different kind of materials such as organic semiconductors [6, 7], metal oxides [8–10], composites [11–13], and ceramics [14–16] are under intensive investigations to fabricate humidity sensors. Most of the metalophthalocyanines (MPcs) are p-type organic semiconductors, there is a growing interest in study of them based on their good thermal and chemical stabilities, low cost, simple, and versatile alternatives to fabricate thin film devices. Phthalocyanines include conjugated π-electron systems with 18 π-electrons in their skeletal structures, it enables the electrons to delocalize throughout the whole system, and thus many atoms may share them. The delocalized electrons may move around the whole system and become the charge carriers to make them conductive. As the result of their conductivity, MPcs are used as sensitive materials to fabricate chemical sensors. By contrast to other phthalocyanines, little studies have been carried out on Palladium Phthalocyanines. As shown in [17, 18], PdPc (C32H16N8Pd) thin films exhibit p-type conductivity with a hole mobility equal to 2.5 × 10−5cm2/(Vs) [17] and can be used as an active material to fabricate chemical sensors.

Phthalocyanine thin films have been proposed to be used for various applications including chemical and humidity sensors [19–24]. It is also known that structure, thickness, and morphology of phthalocyanines thin films can strongly influence their sensing characteristics. The researches of active materials behavior are carried out on several sensing methods such as piezoelectric crystal sensors [25], optical sensors (usually optical absorption measurements) [26], and electrical sensors (chemiresistors, diodes, and transistors) [27, 28].

Detection of humidity in different chemical environments and compounds of gases is a difficult task. Some analytes can influence on humidity sensing process and disturb it. In our laboratory, extensive studies were carried out on using of PdPc thin films as an active layer to fabricate humidity sensor. Device fabrication is based on chemiresistors as the most common type of sensors; chemiresistor consists of a planar interdigitated electrode coated with PdPc thin film. In this method, the change of electrical resistance is measured as the output, if a particular vapor is absorbed by the film and effect the resistance, so a simple ohmmeter or electrometer is enough to collect the data [20]. In present study, we are also studying the effect of ammonia, ethanol, and acetone vapors as chemical environments on sensitivity of devices versus humidity.

Experimental

Palladium Phthalocyanine in powder form (Merk-824462) was prepared to be used as sensitive material to fabricate humidity sensors. Interdigitated gold electrodes with a 50 μm gap were fabricated photolithographically on pre-cleaned polyborosilicate glass with a dimension of 8 mm × 8 mm as substrate. PdPc was thermally evaporated over the electrode arrays, the depositions were carried out using molybdenum boat in vacuum at a pressure of 10−5 mbar. The substrate temperature and deposition rate were controlled at 300 K and 0.5–1.0 Å/s, respectively. PdPc thin films were coated on interdigitated electrodes with a thickness about 100 nm, the thickness of thin films was monitored during deposition process by using a quartz crystal monitor. PdPc was deposited on glass in the same process of devices fabrication, and the surface morphology of PdPc thin films was studied. Crystalline structure of thin films was determined by X-ray diffraction (XRD) and surface morphology of PdPc thin films was characterized by scanning electron microscopy (SEM).

The electrical characteristics of the devices were studied by continuously recording current and resistance of samples at variable and constant potential. A stabilized DC power supply and an electrometer (Keithley 200) were used to record data at dark and light conditions. The electrical measurements were carried out as a function of relative humidity (RH%) in a specially designed chamber, a digital sensor (SHT 75, Sensirion) was used to measure the humidity and temperature [29]. The diluted vapor with high purity N2 was passed through the chamber at a flow rate of 500 mL/min and controlled by a mass flow controller. The sensitivity and reversibility of devices versus 20–90% RH were obtained and they were tested on exposure to different vapor environments. Further tests have been conducted to study the long-time stability of devices over 2 months. Some thin film samples were deposited on glass substrate and stored in atmospheric condition and the effect of environment vapors and humidity on surface morphology of thin films was investigated.

Results and discussion

Structural and electrical characteristics

The ratio of surface area (A) to volume (V) of active thin films is an important factor in chemical sensing. A film with higher ratio (r A/V ) makes analyte molecules diffuse and interact with the sensing layer more easily, which leads to a higher sensitivity and shorter response time [30]. The ratio can be measured by different methods such as optical confocal microscopy and nuclear magnetic resonance (NMR) technique [31]. The r A/V of samples was obtained about 14.3 ± 0.3 μm−1 by optical microscopy at room temperature. The ratio can be increased by using thinner films with smaller nanoparticles. The SEM image of PdPc thin films deposited on polyborosilicate substrate at 300 K is shown in Fig. 1a, the nanosized particles are spherical in shape with a grain size of 30–60 nm. Figure 1b shows the XRD pattern of PdPc thin film which thermally evaporated on glass substrate. The XRD pattern clearly shows that a single peak (2θ = 6.75°) which can be identified as (200) plane of tetragonal α-phase, was observed at room temperature and lattice spacing was obtained d = 13.1 Å. The lattice spacing obtained here is slightly larger than that reported in the literature [32].

Freshly evaporated devices were left to stabilize in vacuum at a fixed bias (5 V) for a period of 20 h. As shown in [33], surface electromigration due to a properly applied and sufficiently strong electric field can inhibit instabilities. A mixture of zero grade air and 20% oxygen was introduced to chamber and PdPc films were doped by O2. PdPc, similarly as CuPc or ZnPc, can be treated as a p-type semiconductor due to doping by oxygen [34]. The change of dark current was recorded over the period. As shown in Fig. 2, there is a rapid decrease in dark current during the first hour followed by slower increase which continues for the whole period. These results can be attributed to creation of surface traps by adsorbed oxygen. Appreciable oxygen adsorption does not occur until after cessation of this process and the slow conductivity change is then associated with different diffusion of oxygen into the thin films. Characterization of a thin film is an essential work in electrical studies. Figure 3a shows nonlinear I–V characteristic of the thin film devices at different temperatures, in zero grade air as the reference atmosphere. It can be seen that the device has very poor rectifying characteristics and the current, in reverse bias, does not show any trend of saturation or sharp breakdown and also the slope of curves is shown to be strongly temperature dependent. The I–V behavior of devices at zero grade air in semilogarithmic scale is shown in Fig. 3b for forward bias. All the results show that there are two district regions of conduction for each characteristic curve. It is found that at low voltages below a well-defined transition voltage (V T)—up to 3.5 V—devices have ohmic conduction, at higher voltages the space-charge limited conduction (SCLC) controlled by exponential trap dominates.

The results of the variation of current with temperature, at fixed voltage under forward bias are displayed in Fig. 4. An applied voltage (0.25 V) was chosen so that the devices were operating in ohmic region and measurements were carried out in the temperature range 290–420 K at zero grade air atmospheres. The I–T measurements were taken during cooling of thin films. The results show a linear dependence of ln(I) on the reciprocal absolute temperature (1/T). In this case, the situations are considered quantitatively on basis of existing theory, assuming that the dominant levels are the conduction and valence bands. The thermal activation energy of devices is calculated by using the conductivity relations:

where (E act = ΔE/2) is the thermal activation energy and k B is the Boltzmann’s constant. As shown in Fig. 4, there are two distinct regions, which correspond to two activation energies E 1 and E 2. The activation energies E 1 and E 2 were obtained at T < 375 K and T > 375 K, respectively. E 1 corresponds to extrinsic region, and E 2 corresponds to non-extrinsic region. The two different activation energy values can be interpreted as a transition from extrinsic to intrinsic (pseudo-intrinsic) conductivity [35, 36]. The activation energy corresponding to intrinsic generation is associated with resonance energy involved in a short-lived excited state, and that corresponding to impurity scattering is attributed to a short-lived charge transfer between impurity and the complex [37]. The thermal activation energies E 1 and E 2 were calculated about 0.085 ± 0.002 and 0.770 ± 0.018 eV, respectively.

In this study, one of the devices was lightened by a Quartz Tungsten Halogen (QTH) lamp (100 W, 12 V, Newport-6333 [38]), and illumination-dependent measurements were obtained by varying distance between lamp and device [4]. Figure 5 shows the change of current versus illumination (0 up to 1800 lux) for PdPc thin film devices at 293 and 323 K. It is obvious that the current increased with increase in illumination, so PdPc can be considered as photoconductive material and its thin films can be used as light sensors and photodetectors. Figure 5 also demonstrates that the current increased about 57 and 22% at 293 and 323 K, respectively, in illumination up to 1000 lux and beyond 1000 lux the devices have been reached a saturated state and current became almost constant. The charge carrier concentration may increase exponentially with the increase in the intensity of light due to band–band excitation [39] and increase the conductivity of thin films. Results also show the increase of photocurrent at 323 K is slower than device at 293 K, the probable reason for this effect is that the thermal energy can increase the hole concentration and fewer charge carrier can be activated by light.

Gas sensing measurements

To investigate the sensitivity of PdPc devices versus various environmental vapors, we have measured their electrical behavior by introducing humidity to ethanol, acetone, and ammonia (diluted with high purity N2) at room temperature. The samples were fixed in a specially designed chamber, after which vapors were separately introduced to chamber. After each experiment, chamber was purged by N2 at 380 K; the experimental sequence was indicated in legend table of Fig. 6 by numbers. Figure 6a shows the effect of vapors on I–V graphs of sensors at a variable range of voltages (0–10 V), the dashed line is I–V graph of device before exposure to analytes in zero grade air at room temperature and it is consumed as the base line. As shown in Fig. 6a, the conductivity of devices decreased after exposure to environmental vapors. PdPc is a p-type semiconductor and its conductivity decreases after exposure to reducing gases and vapors, for example, ammonia can react with PdPc molecules and produces NH4 + ions and reduces the hole concentration near the surface of thin films. The other probable reason is that the vapor molecules such as water molecules can swell on surface of thin films and penetrate inside them; these absorbed molecules can deform the sensors and reduce their sensitivity. After that, ethanol, acetone, and ammonia were mixed with humidity as second component of its mixture, and the sensitivity of devices versus humidity mixtures was measured. Figure 6b shows I–V graphs of sensors versus 33% RH and its mixtures with 100 ppm of ethanol, acetone, and ammonia at room temperature. Results show that the sensitivity of devices was optimum in ammonia environment and minimum in ethanol environment.

Figure 7 shows the change in sensitivity factor (S = R H/R a, where R H is the resistance in the present of humidity and R a is the resistance in zero grade air) on exposure to different RH% and its mixture with environmental vapors (to simulate the usual chemical environments). As shown in Fig. 7a, the resistance of devices has been increased on exposure to 22–91% RH in dry air and different chemical environments. Obtained results show that the sensitivity factor is variable and dependent on chemical environments. The sensitivity factor was obtained about 11 on exposure to 90% RH in dry air at 293 K, and in ethanol, acetone, and ammonia environments this factor is measured about 11.2, 13, and 14.6, respectively. As shown in Fig. 7b, the sensitivity factor decreased with increase of temperature. This phenomenon can be interpreted as the effect of temperature on adsorption/desorption equilibrium; temperature is able to influence both of the two steps. Adsorption always prefers low temperature and the increase of temperature will shift the equilibrium to desorption.

Hysteresis is a common issue with gas and humidity sensors. In a humidity sensing process, most of the adsorbed water molecules are desorbed after process, but some hysteresis is remained in sensors after long-time operation or short exposure to high humidity. Hysteresis can have effect on reversibility of sensors and reduces the stability of them. To study the effect of remained hysteresis on sensitivity and reversibility of thin film devices, the relative humidity was introduced to chamber with different percentages from 20 to 90 RH% (adsorption-indicated in the plots by solid line), and then cycled down to 20 RH% (desorption-dashed line). Figure 8 shows the humidity hysteresis characteristics of sensor at 293 K (Fig. 8a) and 323 K (Fig. 8b). As can be clearly seen from Fig. 8, the sensitivity of devices was reduced with increase of temperature. However, the response of the sensors became more reversible. The probable reason for this phenomenon is that the some remained hysteresis (water molecules which trapped on surface of thin films) can be removed more easily from surface of devices at higher temperatures. Obtained results show that the devices are more reversible in dry air and ethanol environment in comparison with other chemical environments. The average percentage of reversibility of devices in these environments is about 88% at 293 K and 95% at 323 K. The minimum of reversibility was observed in ammonia environment about 79% at 293 K and 91% at 323 K.

In present study, we also tried to determine the characteristics of sensors with respect to exposure 90% RH in different chemical environments at room temperature. After the devices were tested at N2 atmosphere (Fig. 9, till 75 s), diluted vapors with high purity N2 were introduced into the chamber for a period of time that devices reached saturated state. Then, analytes were switched off and the chamber was purged, this cycle was repeated several times. Obtained results show that the sensitivity field of devices was decreased after sensing process; this phenomenon can be interpreted as the effect of hysteresis (trapped water molecules) on surface of devices. Figure 9 shows the dynamic response of sensors toward various vapors. The details show that the thin film devices have good response and reversibility and can be used as humidity on/off switches. According to the response and recovery times calculated for sensors, it may be noted that the response and recovery time were estimated for the 63% step change (the baseline drift was taking into account). Obtained results show that the response times were calculated about 40 s in dry air and in ethanol, acetone, and ammonia environments were about 45, 35, and 40 s respectively, the recovery times were also measured, 75, 90, 95, and 105 s, respectively.

To study long-time stability and effect of humidity on sensitivity and surface morphology of PdPc thin films, the sensors were stored at atmospheric condition for a period of time. Figure 10a shows the change in resistance of sensors toward different RH% for a period of 2 months. All results confirm that there were a few changes (less than 10%) in resistance of thin films on exposure to different RH% after 2 months and devices show good long-time stability as humidity sensors. Figure 10b shows the effect of chemical environments on resistance and sensitivity of thin film devices. Obtained results show that various vapors can increase the resistance of thin film devices more than humidity, the change of resistance in ethanol, acetone, and ammonia environments were calculated about 21, 26, and 35%, respectively. It is thought that vapor molecules can swell on surface of thin films and interact chemically with PdPc molecules. Some surface reactions can take place between vapor and PdPc molecules, these reactions can produce new compounds and change the electrical and structural characteristics of sensitive thin films. After that, some samples were stored in dry air and vapor environments to study the effect of environment on surface morphology of PdPc thin films for a period about 1 year. Figure 11a shows the PdPc thin film as deposited at 300 K; Fig. 11b, c show PdPc thin films on exposure to dry air and 22% RH for 1 year, respectively. As shown in Fig. 11, the environmental gases such as carbon dioxide and humidity can be adsorbed on surface of thin films and change the surface morphology of them. As can be clearly seen from Fig. 11c, water molecules can swell on surface of thin films and penetrate inside them. Some of these absorbed molecules can be removed from the surface of films by heat and UV treatment but the others remain on the surface of films. At all, water molecules may deform the sensors and shorten life time of them.

Conclusions

PdPc thin films were deposited on interdigitated gold electrodes to fabricate chemiresistor humidity sensors. PdPc thin films were prepared by thermal evaporation technique with a thickness about 100 nm. Optical and electrical properties of PdPc thin films were investigated by SEM, XRD, and electrical measurements. The SEM image of thin films shows PdPc nanoparticles with an average size about 30–60 nm, crystalline structure of thin films has been identified as (200) plane of tetragonal α-phase by XRD method. Electrical measurements show that PdPc demonstrated semiconducting behavior with two district region of conduction (ohmic conduction followed by space-charge limited conduction) for each characteristic curve. PdPc also exhibited temperature-dependent characteristics and the thermal activation energies of PdPc thin film were calculated about 0.085 ± 0.002 eV (extrinsic region) and 0.770 ± 0.0.18 eV (intrinsic region) at T < 375 K and T > 375 K, respectively. Obtained results show that PdPc can be considered as photoconductive material and its thin films can be used as light sensors and photodetectors.

PdPc chemiresistors were used as humidity sensors in various chemical environments. Obtained results show that various vapors reduced the conductivity of PdPc films as a p-type semiconductor. After that, the sensitivity factor of devices was measured versus different RH% in chemical environments. All results show that the sensors demonstrated the highest sensitivity in ammonia environment and the lowest in dry air, and the sensitivity of sensors has been decreased with increase of temperature. However, the response of the PdPc sensors became more reversible. The response time (35–45 s) and recovery time (75–105 s) of sensors were measured at 293 K with respect to different chemical environments, and devices were relatively stable on exposure to different RH% after 2 months in dry air but the stability of devices was reduced in chemical environments. At last, PdPc thin films were stored in dry air and 22% RH for about 1 year to study the effect of environment on thin films. The SEM images show that water molecules can swell and penetrate inside thin films and deform the sensors.

References

Chang SP, Chang SJ, Lu CY, Li MJ, Hsu CL, Chiou YZ, Hsueh TJ, Chen IC (2010) Superlattices Microstruct 47:772

Vijayan A, Fuke M, Hawaldar R, Kulkarni M, Amalnerkar D, Aiyer RC (2008) Sensor Actuat B 129:106

Bosch P, Fernández A, Salvador EF, Corrales T, Catalina F, Peinado C (2005) Polymer 46:12200

Sayyad MH, Saleem M, Karimov KS, Yaseen M, Ali M, Cheong KY, Noor AFM (2010) Appl Phys A 98:103

Hao YW, Wang J, Chen ZY (2010) J Mater Sci 45:1361. doi:10.1007/s10853-009-4092-5

Virji S, Kaner RB, Weiller BH (2006) J Phys Chem B 110(44):22266

Geng W, Li N, Li X, Wang R, Tu J, Zhang T (2007) Sensor Actuat B 125:114

Kuang Q, Lao C, Wang ZL, Xie Z, Zheng L (2007) J Am Chem Soc 129(19):6070

Tai WP, Oh JH (2002) Thin Solid Films 422:220

Buvailo AI, Xing Y, Hines J, Dollahon N, Borguet E (2011) ACS Appl Mater Interfaces 3(2):528

Kleinfeld ER, Ferguson GS (1995) Chem Mater 7(12):2327

Li Y, Ying B, Hong L, Yang M (2010) Synthetic Metals 160:455

Pokhrel S, Jeyaraj B, Nagaraja KS (2003) Mater Lett 57:3543

Bayhan M, Kavasoğlu N (2006) Sensor Actuat B 117:261

Nitta T (1981) Ind Eng Chem Prod Res Dev 20:669

Lee NY, Hwang IS, Yoo HI (2001) Nucl Eng Des 205:23

Karl N, Kraft KH, Marktanner J, Münch M, Schatz F, Stehle R, Uhde HM (1999) J Vac Sci Technol A17:2318

Kim I, Haverinen HM, Li J, Jabbour GE (2010) Appl Phys Lett 97:203301

Karimov KS, Qazi I, Khan TA, Draper PH, Khalid FA, Mahroof-Tahir M (2008) Environ Monit Assess 141:323

Azim-Araghi ME, Jafari MJ (2010) Eur Phys J Appl Phys 52:10402

Azim-Araghi ME, Jafari MJ, Barhemat S, Karimi-Kerdabadi E (2011) Sensor Lett 9:1349

Azim-Araghi ME, Krier A (1997) Appl Surf Sci 119:260

Aziz F, Sayyad MH, Karimov KS, Saleem M, Ahmad Z, Khan SM (2010) J Semicond 31:114002

Belghachi A, Collins RA (1988) J Phys D 21:1647

Zellers ET, Han M (1996) Anal Chem 68:2409

Somani PR, Viswanath AK, Aiyer RC, Radhakrishnan S (2001) Org Electron 2:83

Joseph Y, Peić A, Chen X, Michl J, Vossmeyer T, Yasuda A (2007) J Phys Chem C 111:12855

Xiao SH, Xu HJ, Hu J, Jiang WF, Li XJ (2008) Thin Solid Films 517:929

Sohn JH, Atzeni M, Zeller L, Pioggia G (2008) Sensor Actuat B 131:230

Bai H, Shi G (2007) Sensors 7:267

Butler JP, Mair RW, Hoffmann D, Hrovat MI, Rogers RA, Topulos GP, Walsworth RL, Patz S (2002) J Phys 14:L297

Azim-Araghi ME, Karimi-Kerdabadi E, Jafari MJ (2011) Eur Phys J Appl Phys 55:30203

Sfyris GI, Gungor MR, Maroudas D (2010) J Appl Phys 108:093517

Signerski R, Jarosz G, Kościelska B (2009) J Non-Cryst Solid 355:1405

Soliman HS, El-Nahass MM, Farid AM, Farag AAM, El-Shazly AA (2003) Eur Phys J Appl Phys 21:187

Krier A, Azim-Araghi ME (1997) J Phys Chem Solids 58:711

Bekaroğlu Ö (2010) In: Mingos DMP (Series ed), Jiang J (Volume ed) Structure and bonding: functional phthalocyanine molecular materials, vol 135. Springer, Berlin

Newport, Quartz-Tungsten-Halogen Lamps Catalog. http://www.newport.com/Quartz-Tungsten-Halogen-Lamps/378263/1033/catalog.aspx

Saleem M, Sayyad MH, Karimov KS, Yaseen M, Ali M (2009) J Mater Sci 44:1192. doi:10.1007/s10853-008-3234-5

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jafari, M.J., Azim-Araghi, M.E. & Barhemat, S. Effect of chemical environments on palladium phthalocyanine thin film sensors for humidity analysis. J Mater Sci 47, 1992–1999 (2012). https://doi.org/10.1007/s10853-011-5996-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5996-4