Abstract

In this study, we report a comparative study of the structural, morphological, and optical properties of the deposited ZnO thin films on Poly Propylene Carbonate (PPC) and glass substrates by direct current (DC) sputtering technique. X-ray diffraction (XRD) spectra of the films on PPC and glass substrates show mainly the ZnO (002) diffraction peaks at 2θ = 34.1 and 34.3o with full width at half maximum (FWHM) of 0.31 and 0.34o, respectively. Scanning electron microscopy (SEM) images show that both ZnO thin films have smooth surface. Photoluminescence (PL) spectra show two peaks, the first intense peak was found in the UV region. The second weak peak was observed in the visible region. The transmission and absorption spectra of the ZnO thin films deposited on both substrates showed that the films have good transmission in the visible region and a good absorption in the UV region. The optical energy gap (E g) values of the deposited ZnO thin films on PPC plastic and glass substrates were derived from absorption measurements and it found to be 3.38 and 3.40 eV, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

ZnO is an n-type II-VI semiconductor with a wide and direct band-gap (E g of 3.37 eV at room temperature). It has a wurtzite type crystal structure with a hexagonal symmetry with lattice constants a = 0.325 nm, c = 0.521 nm, melting point 2,248 K, and high exciton binding energy (60 meV). Pure ZnO is transparent in the wavelength range from 400 to 700 nm and is electrically conductive [1] which makes it a promising alternative material for several potential applications, such as gas sensor [2] and UV photodetector [3].

ZnO thin film properties could be influenced by several factors, for example preparation technique. ZnO films have been prepared on glass and flexible plastic substrates by many researchers using various techniques like pulsed laser deposition, DC-sputtering, sol–gel, thermal evaporation, chemical vapor deposition, radio-frequency (RF) magnetron sputtering, and spray pyrolysis [4–9].

Apart from preparation technique, type of substrate also plays an important role in influencing the properties of ZnO thin films. ZnO has been deposited on different substrates such as Si, glass, and plastic.

Plastic substrates have many advantages over glass-substrates based displays, such as more robust, light weight, and small volume. Moreover, the plastic substrates provide devices lighter in weight and more resistant to impact damage, flexibility, durability, and ease of to carry [5, 10]. Polycarbonate (PC), polyarylate (PAR), polyestersulfone (PES), polyimide (PI), polyethylene terephthalate (PET), polyolefin polytetrafluoroethylene (Teflon), and etc. are commonly used for above mentioned applications. However, from the literature, no other research groups using PPC plastic as a substrate for depositing ZnO thin films. We succeeded to deposit ZnO thin films by using this plastic as substrate [3]. The deposition of ZnO thin film on PPC plastic may open a new way for fabrication of cheap optical devices. PPC has been selected as a substrate in this study because it is not only cheap, but has low chemical reactivity. In addition, it also has a high dielectric strength over wide frequencies and high surface resistivity; these properties are attractive for PPC to serve as a good substrate for a variety of microelectronic applications [11].

In this study, we study and compare the properties of ZnO thin films deposited on PPC and glass substrates. The crystallinity, microstructure, surface morphology of ZnO thin films will be determined below by using XRD, SEM, and AFM. The optical properties such as PL, transmission, and absorption will also be presented below.

Experimental study

The ZnO thin films deposition process in this study has been reported elsewhere [3, 11]. Before the deposition, the plastic and glass substrates were cleaned thoroughly. The cleaning procedures started by immersing the plastic and glass sheets in the active cleaning liquid (DECON90) for 5 min, then rinsed with distilled water, after that they were dried by N2 gas.

Before the deposition process, the target was pre-sputtered for 20 min to remove any contamination from the target surface. After deposition, the thin films thickness was measured by using optical reflectometry system: Filmetric F20-VIS. The crystalline structure of the films was studied using high-resolution XRD diffractometer PANalytical X’pert with a Cu-Kα1 radiation source (λ = 1.5406 Å). The microstructure of the films was studied by imaging the morphology of the films surface using SEM and AFM. The photoluminescence spectra (PL) were recorded by using photoluminescence spectroscopy system: Jobin–Yvon HR 800 UV. The wavelength 325 nm of He–Cd laser with power of 20 mW was used with power of 20 mW is used to excite the sample. The absorption and transmission spectra of the sample were measured using a Hitachi U-2000 Double-beam spectrophotometer.

Results and discussion

The deposited ZnO thin films on PPC and glass substrates were found with thickness of 1 μm as determined by optical reflectometry system. Figure 1 shows XRD patterns of the deposited ZnO thin films on the two substrates which confirmed the formation of polycrystalline ZnO. Both of the films display mainly ZnO (002) diffraction peak at 2θ = 34.1 and 34.3o with FWHM of 0.31 and 0.34o as shown in the figure. This indicates that the films are preferentially grown along c-axis orientation, perpendicular to the substrates with the lattice parameters a = 3.2498 Å and c = 5.2066 Å.

The figure also shows another less intense peak at 2θ = 52.7o attributed to the plane (110) which is only observed in the ZnO thin film deposited on PPC substrate, which indicated that the thin film is polycrystalline. This result is in good agreement with most of the results reported in the literature, such as [12–14].

In order to obtain the detailed structure information, we calculated the grain size along the c-axis according to the Scherrer’s formula [15]:

where B is the full width at half maximum [)FWHM(in radians] of XRD, λ is the X-ray wavelength (Cu Kα = 0.154 nm), θ is the Bragg diffraction angle, and K is a correction factor which was taken as 0.9 [15].

The grain size was equal to 26.8 and 24.4 nm for the deposited ZnO on PPC and glass substrates, respectively. It shows that the grains are bigger in size on PPC substrate as compared to that in glass substrate. Table 1 shows the X-ray diffraction data summary of ZnO thin films on PPC and glass substrates.

From Table 1, we notice that ZnO/PPC plastic has much stronger peak intensity than ZnO/glass. This indicates that, under the same deposition conditions, the crystallite quality of the film deposited on PPC substrate is better than that on the glass substrate.

Figures 2 and 3 show the SEM images for the deposited ZnO thin films on PPC and glass substrates, respectively. It could be observed that both ZnO thin films on PPC and glass substrates possess smooth surface morphology, which are well connected to each other and strongly adheres to the substrate and has tightly bounded particles.

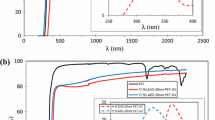

Figures 4 and 5 shows the AFM images of the deposited ZnO thin films surface on PPC plastic and glass substrates. The grain height is equal to 100 and 150 nm with root mean square (rms) 10.0 and 7.7 nm for ZnO thin film on PPC and glass, respectively, while the rms for the PPC plastic substrate was found equal to 11.3 nm. This reveals that the surface roughness of the deposited ZnO thin film on PPC plastic is higher than that on the glass substrate. From the AFM results, the ZnO/PPC shows slightly higher rms value as compared to ZnO/glass. This reveals that ZnO/PPC is rougher than ZnO/glass. The rougher surface morphology of the film surface may be useful by the absorption of the UV light when ZnO is used as UV detector active region. PL spectra of the ZnO thin films on PPC plastic and glass substrates are shown in Fig. 6. The inset in Fig. 6 shows the visible emission peak on both substrates. Two luminescence peaks can be observed in each of the PL spectrum; the first peak is the UV emission corresponding to the near band edge emission (NBE) because of the electronic transition from the near conduction band to the valence band [16].

The other peak is in the visible region which is because of the defects related to the deep level emission [17]. Table 2 summarizes the PL data of both samples. From the table, it can be seen that the UV emission peak is at 379.55 nm for ZnO thin film on PPC substrate; whereas, 382.82 is observed for ZnO thin film on the glass substrate. For the second luminescence peak, the deposited thin film on PPC substrate shows broad blue-green emission peaked at 490.67 nm. While, the deposited thin film on glass substrate shows green band peaked at 527.16 nm. The latter is consistent with the results reported by many researchers, such as [18–20].

However, the PL spectrum of the ZnO thin film on PPC plastic substrate shows higher UV emission peak and lower visible peak comparing to that deposited on glass substrate, indicated that the optical quality of the first film is superior than the second one because of the decrease of deep–emission peak which is attributed to the reduction of the film defects.

The transmission and absorption spectra of ZnO thin films on PPC plastic and glass substrates are shown in Fig. 7. The film on both substrates has demonstrated high optical transmittance which is over 70% in the visible range. This indicates that the films are highly transparent in the visible region (from 400 to 800 nm). From the figure, the transmission of ZnO/PPC was observed to be lower than the transmission of ZnO/glass, whereas for absorption ZnO/PPC was found to be higher.

These finding is consistent with AFM measurements in which ZnO/PPC was slightly rougher than ZnO/glass. Rough surface morphology might allow higher absorption of light and lower transmittance [21]. As a result, these larger and rougher surface areas are favorable to improve light absorbing and charge-harvesting efficiency and to absorb more dye for better photoelectric conversion efficiency and better applications, such as photocatalysis, sensors, etc. [22].

For thin film deposited on glass substrate, the absorption edge is shifted to the shorter wavelength because of some potential sources, such as the interface effect and surface defects, which are expected to strongly influence the electronic and optical properties of ZnO films [18]. This good agreement with PL results showed in the inset of Fig. 6.

Since ZnO is considered as a direct band gap semiconductor the well-known Tauc relation, equation below can be used for E g determination ([5, 23]):

where A is a constant, h is Planck’s constant, ν is the frequency of light, E g is the band gap energy, and n = ½ (for direct transition mode materials) ([23, 24]). Figure 8 shows the Tauc plot of (αhν)2 versus hν. Band gap could be derived by extrapolating the linear portion of the graphs to the hν axis. From the plot the E g were determined to be 3.38 and 3.40 eV for ZnO/PPC and ZnO/glass, respectively.

Conclusion

In summary, crystallinity, microstructure, and surface morphology of ZnO thin films have been investigated by XRD, SEM, AFM, and PL XRD spectra. The both films showed mainly the ZnO (002) diffraction peaks of hexagonal wurtzite type structure. SEM images revealed that the ZnO thin film deposited on both PPC and glass substrates have smooth surface. The PL spectra displayed two peaks; the first intense peak in the UV region and the second weak peak in the visible region were observed for both of the samples. Transmission and absorption spectra for both ZnO thin films exhibited that the films have good transmission in the visible region and a good absorption in the UV region. The optical band gap (E g) values of ZnO as determined from Tauc plot were found to be 3.38 and 3.40 eV on PPC plastic and glass substrates, respectively.

The results showed that the properties of the deposited ZnO thin films on PPC are better than those prepared on glass substrate. This indicates that PPC plastic can be potentially used as a cheap substrate for depositing ZnO thin films. This may open a new way for fabricating inexpensive optical devices.

References

Haško D, Bruncko J (2010) Vacuum 84:166

Roy S, Basu S (2002) Bull Mater Sci 25(6):513

Jandow NN, Yam FK, Thahab MS, Abu Hassan H, Ibrahim K (2010) Curr Appl Phys 10:1452

Shibata T, Ohnishi T, Sakaguchi I, Osada M, Takada K, Kogure T et al (2009) J Phys Chem C 113:19096

Banerjee NA, Ghosh KC, Chattopadhyay KK, Minoura H, Sarkar KA, Akiba A et al (2006) Thin Solid Films 496:112

Nishii A, Uehara T, Sakano T, Nabetani Y, Akitsu T, Kato T et al (2006) Phys Stat Sol (a) 203(11):1890

Huang HB, Shen P, Sh CY, Eur J (2008) J Eur Ceram Soc 28:2545

Matsubara K, Fons P, Iwata K, Yamada A, Niki Sh (2002) Thin Solid Films 422:176

Hunger R, Iwata K, Fons P, Yamada A, Matsubara K, Niki S, Nakahara K, Takasu H (2001) Mat Res Soc Symp Proc 668:H2.8.1

Mcalpine CM, Friedman SR, Jin S, Lin h K, Wang UW, Lieber MCh (2003) Nano Lett 3(11):1531

Jandow N, Yam FK, Thahab MS, Ibrahim K, Abu Hassan H (2010) Mater Lett 64:2366

Fujimura N, Nishihara T, Goto S, Xu J, Ito T (1993) J Cryst Growth 130:269

Lee J-H (2009) J Electroceram 23:512

Lin SS, Huang JL (2004) Surf Coat Technol 185:222

Ghosh T, Bandopadhyay S, Roy KK, Maiti KA, Goswami K (2009) Cryst Res Technol 44(8):879

Zhang HD, Wang PQ, Xue YZ (2003) Appl Surf Sci 207:20

Jandow NN, Ibrahim K, Abu Hassan H, Thahab MS, Hamad SO (2010) JED 7:225

Jin JB, Bae HS, Lee YS, Im S (2000) Mater Sci Eng B 71:301

Jandow NN, Ibrahim K, Abu Hassan H (2010) AIP Conf Proc 1250:424

Ghodsi EF, Absalan H (2010) Acta Phys Pol A11 8(4):659

Tejos M, Rolón GB, Río DR, Cabello G (2007) J Chil Chem Soc 52(3):1257

Hu A, Cheng C, Li X, Jiang J, Ding R, Zhu J et al (2011) Nanoscal Res Lett 6:91

Rusdi R, Abd Rahman A, Mohamed NS, Kamarudin N, Kamarulzaman N (2011) Powder Technol 210:18

Sze MS, Ng KK (2006) Physics of semiconductor devices, 3rd edn. Wiley, New York, p 52

Acknowledgements

This study was conducted under the grant no.: 100/PFIZIK/8/4010 support from Universiti Sains Malaysia is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jandow, N.N., Abu Hassan, H., Yam, F.K. et al. Comparative study of the properties of ZnO thin films deposited on poly propylene carbonate (PPC) and glass substrates. J Mater Sci 47, 1972–1976 (2012). https://doi.org/10.1007/s10853-011-5992-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5992-8