Abstract

A superhydrophobic surface on an aluminum substrate was fabricated by one-step electrochemical machining using the sodium chloride (NaCl) aqueous solution containing fluoroalkylsilane as the electrolyte. The resulting superhydrophobic surfaces showed a static water contact angle of 166° and a tilting angle of about 1°. The morphological features and chemical compositions were characterized by scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS), electron probe micro-analyzer (EPMA), and Fourier-transform infrared spectrometer (FTIR). It shows that the binary micrometer–nanometer-scale rough structures and the low surface energy coating were present on the aluminum surfaces. The resulting surfaces have good properties of anti-adhesion and self-cleaning. The durability of the superhydrophobic surfaces on aluminum substrates was also investigated. This preparation method is advantageous as it does not require acid electrolyte or a separate process to lower the surface energy, uses simple steps, and is environmental friendly and highly efficient.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The lotus leaf is a typical plant with self-cleaning effect in nature, and held as a symbol of purity in many countries. Water droplets fell on the lotus leaf bead up and roll off freely by taking away dust and dirt. Barthlott, Neinhuis and Jiang [1–3] have revealed that the wettability of the lotus leaf is governed by both the binary rough geometric structures at the micro-and nanometer scales, and the paraffinic wax crystals with a low surface energy, which summarizes the two types of technology roadmap: (1) modification of an appropriate rough surface with the low surface energy molecules or coatings, and (2) creation of a micro-and nanostructure on the hydrophobic surface [4–9].

As the important metal engineering materials for the applications in aerospace, aircraft, national defense, and cooler air-conditioner, the fabrication of the superhydrophobic surfaces on aluminum and its alloys attract more and more attention from researchers around the world. The conventional electrochemical machining method is an effect process to prepare the superhydrophobic surfaces on aluminum substrates [10–14]. Nevertheless, the above techniques always involve a two-step process in which a surface is first roughened, and then modified to lower the surface energy. Moreover, the conventional electrochemical machining method requires acid corrosive liquid, such as sulfuric acid, oxalic acid, and phosphoric acid, as the electrolyte, also takes a long time (about several hours), and has a certain hazards to the environment and the health of the operator. In order to reduce the environmental pollution of the conventional electrochemical machining method, we have successfully fabricated superhydrophobic aluminum surfaces using a new electrochemical machining with the neutral NaNO3 electrolyte [15], but this method also involves conventional two steps, and the fluorination treating time needed is up to about 3 h (the processing time of rough structures requires only 60 min). So, if the superhydrophobic surfaces can be fabricated in just one step, the complexity and the processing time of two steps will be reduced greatly.

In the present study, a new electrochemical machining method using the neutral sodium chloride (NaCl) aqueous solution containing fluoroalkylsilane as the electrolyte has been developed to fabricate a superhydrophobic surface on aluminum substrates within 30 min. Comparing with the conventional electrochemical machining method, the one-step electrochemical machining method proposed has advantages of simple steps, non-toxicity, friendly environment, and high efficiency. Comparing with the NaNO3 electrolyte, the NaCl electrolyte is absolutely non-poisonous and its price is only half of the sodium nitrate.

Experimental

Materials

Aluminum plates (composition: 0.003% Si, 0.003% Fe, 0.005% Cu, with the balance being Al) with a size of 30 × 40 × 2 mm were procured from Dalian Aluminum Material Manufacturer, China. A cooper plate was purchased from Tianjin Kermel Chemical Reagent Co., China, Fluoroalkylsilane (tridecafluoroctyltrietho-xysilane (FAS), C8F13H4Si(OCH2CH3)3) was obtained from Degussa Co., Germany, and the other experiment drugs used were of analytical grade.

Sample preparation

A certain amount of fluoroalkylsilane was added into a beaker containing 0.2 mol/L sodium chloride aqueous solution. Then, the beaker was placed in an ultrasonic bath for 20 min to let the fluoroalkylsilane to hydrolyze completely. An aluminum plate was polished mechanically using abrasive paper of 1200# and 1500#, respectively, and washed ultrasonically using ethanol and distilled water successively for about 10 s. After drying, the anodic aluminum plate and cathodic copper plate were separated by a distance of 30 mm. Then, the aluminum plate was electrochemically machined in the 0.2 mol/L sodium chloride aqueous solution containing 1 wt% fluoroalkylsilane at a current density of 100 mA/cm2 for 30 min accompanied by ultrasonic vibration. The actual processing area of the aluminum plate was 30 × 30 mm, and the rest was used as a function of clamping and electric conduction. After machining, the substrates were rinsed using distilled water for several times, and finally dried at 80 °C for 15 min.

Surface characterization

The surface morphologies of the obtained samples were observed on a scanning electron microscope (SEM, JSM-6360LV, Japan). The chemical compositions were analyzed by energy dispersive X-ray spectroscopy (EDS, INCA Energy, Oxford Ins), electron probe micro-analyzer (EPMA-1610, Shimadzu), and Fourier-transform infrared spectrometer (FTIR, JACSCO, Japan). The surface roughness was measured by a 3D surface profiling (Talysurf CLI2000, UK). Water contact angles were measured using an optical contact angle meter (krüss, DSA100, Germany) at ambient temperature, and the tilting angles was measured by the conventional tilting plate method. Water droplets of 5 μL were dropped carefully onto the surfaces, and the average value of five measurements at different positions of the samples was used as the final contact angle. Advancing and receding contact angles were recorded while the water was added to and withdrawn from the drop, respectively. The flow rate of water was 0.2 μL/s.

Results and discussion

Morphological analysis of superhydrophobic surfaces

Figure 1 shows the SEM images of the sample prepared using the sodium chloride (NaCl) aqueous solution containing 1 wt% fluoroalkylsilane as the electrolyte with a current density of 100 mA/cm2 for 30 min. It can be seen from Fig. 1a that the surface is rather rough and covered by the irregular pits and protrusions. From Fig. 1b, we can clearly see that many rectangular-shaped plateaus with a size of a few microns are distributed homogeneously on the pits and protrusions. Large-scale SEM images (Fig. 1c, d) shows the randomly distributed step-like structures in the nanometer size range on the micrometer scale plateaus. Therefore, there exist the binary micrometer–nanometer-scale rough structures containing the micrometer scale plateaus and the nanometer scale step-like structures, which are similar to the microstructures of the lotus leaf. The surface roughness Ra of the aluminum after one-step electrochemical machining is about 3.66 μm.

Formation mechanism analysis of microstructures

The grain boundaries are often corroded and full of cracks and chinks because of the low applied current density or the inappropriate electrolyte composition or concentration in the electrochemical machining. This surface defect is called grain boundary corrosion, which is prone to take place in the electrochemical machining but need to avoid in the normal circumstances. The causes that lead to such binary micrometer–nanometer-scale rough structures are as follows:

A large number of grain boundaries and dislocations exist in the common crystalline metal [16, 17]. Grain boundary is a narrow region in crystal, where atoms arrange disorderly with a general scale running from several microns to tens of microns. Dislocations have a density of up to 1011 to 1012 per square centimeter in the general crystalline metal, so from a statistical point of view, the intervals of the dislocations are nano-scale. Grain boundaries have special composition and arrangement, they are prone to anodic dissolution and forming priority erosion of grain boundaries; similarly, from the view of potential energy, dislocations, especially in the special sites such as outcrops, are also conducive to electrochemical reaction and forming pits on the surface. Therefore, in proper condition, pits formed with the electrochemical reaction induced by the applied electric field, and the existing corresponding relationship between the grain boundary and dislocation can be employed to fabricate the irregular multi-scale micrometer–nanometer structures of the superhydrophobic surfaces.

The sodium chloride electrolyte was applied in here for the reason that the grain boundary corrosion is prone to take place using the NaCl electrolyte with the advantages of low-cost and environment friendly.

Wettability analysis of superhydrophobic surfaces

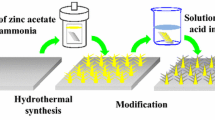

Fluoroalkylsilane containing the –CF3 group with a surface energy of 6.7 mJ/m2 and the –CF2 group with a surface energy of 18 mJ/m2 proves to have a very low surface energy and is often employed to reduce the free energy of the solid surface and render the solid surface hydrophobic. The self-assembly process of the fluoroalkylsilane is shown in Fig. 2. Firstly, silicon ethoxide (Si–OC2H5) as a functional group reacts with water to form silicon hydroxide (Si–OH) as a reactive group at the end of the molecule. Subsequently, in the silicon hydroxide causes dehydration–condensation reactions using the hydroxyl group to form a self-assembled film. Meanwhile, the surface also can induce vertical polymerization to form grafted polysiloxane [18–25].

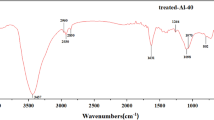

The chemical compositions of the superhydrophobic surfaces were analyzed using FTIR, EDS, and EPMA. Figure 3 shows the FTIR spectra of the aluminum surfaces treated by one-step electrochemical machining. We can see that the intense absorption bands between 1237 and 1120 cm−1 are assigned to C–F stretching of –CF3 and –CF2 groups of the fluoroalkylsilane molecules, indicating that the low surface energy –CF3 and –CF2 groups comprise the outermost surface contributing to superhydrophobic properties [26]. Figure 4 shows the EDS and EPMA spectra of the superhydrophobic surfaces. It can be seen that the superhydrophobic aluminum surfaces are mainly composed of element Al, C, Si, O, and F, which further confirm that the hydrophobic fluoroalkylsilane polymer film has been self-assembled on the aluminum surfaces [27]. However, these five elements could not be detected only by EDS or EPMA, because that the self-assembly of fluoroalkylsilane occurs simultaneously with the electrochemical corrosion, so the self-assembly time is short and the adsorption is less.

As a conclusion, the binary micrometer–nanometer-scale rough structures allow a large amount of air entrapment making it a heterogeneous surface composite of air and the surface where the air and the self-assembled film of fluoroalkylsilane contributes to low surface energy weakening its interaction with water and, therefore, enhancing the water contact angle [28]. Figure 3c shows an optical image of a 5 μL water droplet on the superhydrophobic aluminum surfaces with a water contact angle of 166° and a tilting angle of about 1°. The advancing and receding contact angles are 166.5° and 155.5°, respectively, and the contact angle hysteresis is about 1°.

Figure 5 shows the SEM images of the electrochemical machined aluminum surfaces using the sodium chloride electrolyte without fluoroalkylsilane with a current density of 100 mA/cm2 for 30 min. It can be seen that the surface structures have little difference with Fig. 1. Figure 6a shows the EDS spectra of the aluminum surfaces in Fig. 5, implying that the aluminum surfaces prepared are just composed of element Al. The surfaces in Fig. 5 also exhibit superhydrophilicity with a water contact angle of about 0°,as shown in Fig. 6b. This phenomenon conforms to the assumption proposed by Wenzel [29] that the rough surface structures could make the hydrophilic surface more hydrophilic. These findings indicate that the obtain of the binary micrometer–nanometer-scale rough structures in Fig. 1 have nothing to do with the presence of fluoroalkylsilane, and the main function of the fluoroalkylsilane is to reduce the surface energy of the aluminum surfaces.

Anti-adhesion analysis of superhydrophobic surfaces

Figure 7 shows the anti-adhesion behavior of water droplet on the superhydrophobic surfaces on aluminum substrates, and the directions of the arrow are the movements of the sample platform. The approach, contact, deformation, and departure processes of a 5 μL water droplet suspending on a syringe with respect to the superhydrophobic surfaces were carried out by the movement of the sample platform. It can be seen that water droplet may easily and completely depart from the surfaces even when the droplet was compressed with the sample, indicating good anti-adhesion ability.

Self-cleaning effect analysis of superhydrophobic surfaces

Figure 8 shows the self-cleaning effect of the superhydrophobic surfaces on aluminum substrates placed at a slope angle of 15.5°. Firstly, Graphite powder as dirt was deliberately spread on the surface, as shown in Fig. 8a. Subsequently, the water was dropped to the upper side of the surface by a plastic dropper, as shown in Fig. 8 b. It is clearly seen that water droplets fell on the superhydrophobic surfaces bead up and roll off freely by taking away graphite powder, as shown in Fig. 8c. This experiment indicates that the superhydrophobic aluminum surfaces obtained here has a similar self-cleaning effect of the lotus leaf.

Durability analysis of superhydrophobic surfaces

The durability of the superhydrophobic surfaces is a very important factor to apply our method to industrial applications. Here, the effects of the storage time, pH values, and soaking time in the 3.5 wt% NaCl aqueous solution on the wettability of the superhydrophobic surfaces were studied, respectively. Figure 9 shows the variation of the water contact angles with the storage time. It can be seen that the resulting superhydrophobic surfaces on aluminum substrates can maintain in air at least 180 days, and the values of the water contact angles vary little, indicating that the superhydrophobic surfaces have good long-term stability in air.

Figure 10 shows the relationship between pH values and the water contact angles of the superhydrophobic surfaces on aluminum substrates. There is no obvious fluctuation of the water contact angle values within the experimental errors at all the pH values. All the static water contact angles are in the range of about 166°–169°,with little difference coming from the experimental errors. This indicates that the aluminum surfaces obtained by one-step electrochemical machining have high hydrophobicity not only just for pure water but also for corrosive liquids, such as acidic and basic aqueous solutions [30]. These results are very important for the use of aluminum as engineering materials with the superhydrophobic surfaces in the corrosive liquids with a wide pH range.

Figure 11 shows the changes in the water contact angles as a function of the immersion time in the 3.5 wt% NaCl aqueous solution. We are surprised to find that the water contact angles do not decrease significantly with an increase in the immersion time, which is quite different from the previous literatures [30, 31]. The water contact angle of the superhydrophobic surfaces after immersion in the 3.5 wt% NaCl aqueous solution for 48 h is about 163°,indicating good superhydrophobicity. Figure 12 shows the variation of the water tilting angles with the immersion time. It can be seen that the water tilting angles increase slightly with the immersion time. But after 48 h immersion, the water tilting angles are still small, only 3°. From these results, it is speculated that the stability of the superhydrophobic surfaces on aluminum substrates in the 3.5 wt% NaCl aqueous solution is good. Moreover, further research of the duration of superhydrophobicity in the 3.5 wt% NaCl aqueous solution is needed and will be published elsewhere.

In conclusion, the as-fabricated superhydrophobic surfaces by our method show long-time stability in air and excellent resistance to corrosive liquids including acidic, basic, and salt solutions.

Conclusions

-

(1)

Superhydrophobic surfaces on aluminum substrates have been fabricated via a simple one-step electrochemical machining, simplifying the complexity of two different steps involved in the conventional electrochemical machining method, and reducing the processing steps and the processing time.

-

(2)

Neutral sodium chloride aqueous solution was used as the electrolyte. Comparing with acid corrosive liquid, the neutral electrolyte has advantages as follows: low-cost, environment friendly, and health safety.

-

(3)

SEM, FTIR, EDS, and EPMA images indicate that the binary micrometer–nanometer-scale rough structures with the low surface energy coating are present on the aluminum surfaces after processing. The micrometer–nanometer-scale rough structures are assumed to result from the preferential dissolution of grain boundaries and dislocations by an applied electric field, and the low surface energy coating is the self-assembled polymer film of the fluoroalkylsilane.

-

(4)

The resulting superhydrophobic surfaces on aluminum substrates with a water contact angle of 166° and a tilting angle of about 1° show good properties of anti-adhesion and self-clearing.

-

(5)

The resulting superhydrophobic surfaces on aluminum substrates also show a long-time stability in air. Moreover, these surfaces have the water contact angles of more than 166° in the solutions at pH ranging from 1 to 14, and the water contact and tilting angles do not change obviously with the immersion time in the NaCl aqueous solution, showing a high chemical stability.

References

Neinhuis C, Barthlott W (1997) Ann Bot 79:667

Barthlott W, Neinhuis C (1997) Planta 202:1

Feng L, Li SH, Li YS, Li HJ, Zhang LJ, Zhai J, Song YL, Liu BQ, Jiang L, Zhu DB (2002) Adv Mater 14:1857

Chen ZJ, Guo YB, Fang SM (2010) Surf Interface Anal 42:1

Sarkar DK, Saleema N (2010) Surf Coat Technol 204:2483

Huang Y, Sarkar DK, Chen XC (2010) Mater Lett 64:2722

Ryan AH, Jeffery RO, Stephanie AB, Rashelle SM, Hoon JL (2010) J Mater Sci 46:2503. doi:10.1016/S0955-2219(99)00100-4

Hoon JL (2009) J Mater Sci 44:4645. doi:10.1007/s10853-009-3711-5

Guo YG, Wang QH, Wang TM (2011) J Mater Sci 46:4079. doi:10.1007/s10853-011-5337-7

Tsujii K, Yamamoto T, Onda T, Shibuichi S (1997) Angew Chem Int Ed Engl 36:1011

Shibuichi S, Yamamoto T, Onda T, Tsujii K (1998) J Colloid Interf Sci 208:287

Wang H, Dai D, Wu XD (2008) Appl Surf Sci 254:5599

Wu WC, Wang XL, Wang DA, Chen M, Zhou F, Liu WM, Xue QJ (2009) Chem Commun 9:1043

Ohkubo YJ, Tsuji I, Onishi S (2010) J Mater Sci 45:4963. doi:10.1007/s10853-010-4362-2

Xu WJ, Song JL, Sun J, Dou QL, Fan XJ (2011) J Mater Sci 46:5925. doi:10.1007/s10853-011-5546-0

Henderson B (1972) Defects in crystalline solids. Edward Arnold Ltd, London

Hull D, Bacon DJ (2001) Introduction to dislocations. Butterworth-Heinemann, Oxford

Schondelmaier D, Cramm S, Klingeler R, Morenzin J, Zikens C, Eberhardt W (2002) Langmuir 18:6242

Onclin S, Ravoo BJ, Reinhoudt DN (2005) Angew Chem Int Ed 44:6282

Love JC, Estroff LA, Kriebel JK, Nuzzo RG, Whitesides GM (2005) Chem Rev 105:1103

Schwartz DK (2001) Annu Rev Phys Chem 52:107

Schreiber F (2000) Prog Surf Sci 65:151

Ulman A (1996) Chem Rev 96:1533

Sagiv J (1980) J Am Chem Soc 102:92

Song X, Zhai J, Wang Y, Jiang L (2005) J Phys Chem B 109:4048

Sarkar DK, Farzaneh M (2008) In: Mittal KL (ed) Contact angle, wettability and adhesion. Brill Academic Publishers, Toronto, pp 271–278

Li SM, Zhou SZ, Liu JH (2009) Acta Physico-Chimica Sinica 25:2581

Sarkar DK, Farzaneh M, Paynter RW (2010) Appl Surf Sci 256:3698

Wenzel RN (1936) Ind Eng Chem 28:988

Ishizaki T, Saito N (2010) Langmuir 26:9749

Yin YS, Chen SG, Liu T, Cheng S (2008) Appl Surf Sci 255:2978

Acknowledgements

The authors thank the National Science Foundation of China (No. 90923022) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, J., Xu, W. & Lu, Y. One-step electrochemical machining of superhydrophobic surfaces on aluminum substrates. J Mater Sci 47, 162–168 (2012). https://doi.org/10.1007/s10853-011-5783-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5783-2