Abstract

The electrochemical copolymerization of carbazole (CZ) and dibenzo-18-crown-6 (DBC) was successfully achieved in pure boron trifluoride diethyl etherate (BFEE) by direct anodic oxidation of the monomer mixtures on the platinum or stainless steel electrodes. The optimal feed ratio together with the suitable applied potential for their copolymerization was determined. The copolymer films, which were electrosynthesized with a feed ratio of CZ/DBC = 1:5, owned both the advantages of poly(dibenzo-18-crown-6) (PDBC) and polycarbazole (PCZ), such as nice electrochemical behavior, excellent fluorescence properties and good mechanical properties. Besides, the copolymers possessed better thermal stability and higher electrical conductivity than those of PDBC or PCZ. The structure of the copolymers was investigated by UV–vis and FT-IR spectroscopy. Fluorescent spectral studies revealed that the dedoped copolymer film was a good blue-light emitter with strong emission at 410 nm. With these advantageous properties, as-formed poly(CZ-co-DBC) films may be a good candidate for optoelectronic devices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

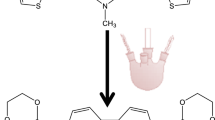

Inherently conducting polymers with π-conjugated electronic structures have been widely investigated since the late 1970s [1–3] due to their potential industrial applications based on their high electrical conductivity and good environmental stability. Among these polymers, polycarbazole (PCZ) and poly(dibenzo-18-crown-6) (PDBC) have been received considerable attention. PCZ and its derivatives (PCZs), have a structure of a pyrrole ring with two fused benzene rings, are well known to exhibit excellent electroactive and photoactive properties because of their high hole-transporting mobility of the charge carriers [4]. Moreover, PCZs, with the advantages of good environmental stability, photoconductivity, and electrochromic properties, have attracted great attention because of their wide fundamental interest and potential industrial applications in electroluminescent applications [5–7], light-emitting diodes [8, 9], electrochromic displays [10], organic transistors [11], rechargeable batteries [12], and so forth. However, it is hard to obtain freestanding films of PCZ.

Dibenzo-18-crown-6 (DBC) as one of dibenzo-crown ethers derivative, has several other advantages. Firstly, its polymer film is light-sensitive, the photocurrent of which can increase with increasing illumination intensity [13]. Secondly, its polymer constitutes a new family of electroactive polymers after other well-known ones like polyacetylene [14]. Thirdly, the band gap of CPs obtained from DBC will be decreased due to the fact that DBC has very low LUMO level [14]. Finally, high-quality free-standing PDBC films with favorable electrical and mechanical properties were just reported by us [26]. These properties facilitate future applications of PDBC films in membranes domain. Comparing with the advantages of both PCZ and PDBC, it would be interesting to copolymerize CZ with DBC.

The usage of boron trifluoride diethyl etherate (BFEE) as the solvent and the supporting electrolytes is mainly because catalytic effect [15]. With the use of BFEE, a wide variety of high-quality conducting polymers electrochemically from heterocyclic or fused ring aromatic monomers have been successfully achieved [16–22]. In this work, BFEE was chosen as the solvent and electrolyte for the electrochemical copolymerization of CZ and DBC, and high-quality free-standing poly(CZ-co-DBC) films can be easily electrodeposited by direct anodic oxidation of the monomer mixtures on the stainless steel electrodes. The electrochemical behavior, structural characterization, fluorescence properties and thermal stability of as-prepared poly(CZ-co-DBC) films were studied in detail.

Experimental

Materials

BFEE (Beijing Changyang Chemical Plant) was distilled and stored at 0 °C before use. CZ (Shanghai Chemical Reagent Plant) was purified by recrystallization from methanol. DBC (Alfa Aesar) was used as received without further purification. Tetrabutylammonium tetrafluoroborate (TBATFB, 95%; Acros Organics) was dried under vacuum at 60 °C for 24 h before use. Commercial HPLC grade acetonitrile (ACN; Tianjin Guangfu Fine Chemical Research Institute), tetrahydrofuran (THF, analytical grade; Shandong Laiyang Fine Chemical Corporation), sulfuric acid (98%; Ji’nan Chemical Reagent Company), and ammonia (25%; Ji’nan Chemical Reagent Company) were used directly. Other reagents were all analytical grade and used as received.

Electrochemical tests

Electrochemical synthesis and examination were performed in a one-compartment cell with a model 263 A potentiostat/galvanostat (EG&G Princeton Applied Research) under computer control at room temperature. The working and counter electrodes for the cyclic voltammetry experiments were platinum wire and stainless steel wire with diameter of 0.5 and 1 mm placed 0.5 cm apart. They were polished and cleaned with water and acetone successively before each examination. To obtain a sufficient amount of the polymer for characterization, stainless steel sheets with surface area of 10 and 12 cm2 were employed as the working and counter electrodes, respectively. The stainless steel electrodes were carefully polished with abrasive paper (1500 mesh) and then cleaned with water and acetone successively before each examination. All potentials were referred to a saturated calomel electrode and all solutions were deaerated by a dry argon stream and maintained at a slight argon overpressure during the experiments. The polymer films grew potentiostatically, and their thickness was controlled by the total charge passed through the cell that was read directly from the current–time (I–t) curves by computer. After polymerization, polymer films were washed repeatedly with anhydrous ACN to remove the electrolyte, monomer, and oligomer [22]. The polymer films were dedoped with 25% ammonia for 3 days and then washed with water and acetone successively. After that, they were dried under vacuum at 60 °C for 2 days.

Characterization

The conductivity of as-formed polymer films was measured by conventional four-probe technique. UV–vis spectra were taken with a Perkin Elmer Lambda 900 UV–vis/near-infrared spectrophotometer. FT-IR spectra were recorded with a Bruker Vertex 70 FT-IR spectrometer with KBr pellets. Fluorescence spectra were determined with a Hitachi F-4500 fluorescence spectrophotometer. The thermogravimetric analysis was performed with a Netzsch TG 209 thermal analyzer.

Results and discussion

Electrochemical copolymerization

In order to ensure the copolymerization of CZ and DBC in BFEE, the anodic oxidation of CZ and DBC was first examined. The anodic polarization curves were taken in BFEE solutions at a potential sweep rate of 50 mV s−1, as shown in Fig. 1.

The oxidation onset of CZ was initiated at 0.74 V (Fig. 1A) while the oxidation onset for DBC was at 1.05 V (Fig. 1E). The onset oxidation potential of DBC was much higher than that of CZ (∆E = 0.31 V). From this point, it seems that it is almost impossible to achieve the electrochemical copolymerization of CZ and DBC [23]. In order to realize the copolymerization successfully, the strategy of diffusion method established by Kuwabata et al. [24] was used. When a current potential curve was taken in BFEE containing 0.01 mol L−1 CZ + 0.005 mol L−1 DBC (Fig. 1B), 0.005 mol L−1 CZ + 0.025 mol L−1 DBC (Fig. 1C), 0.005 mol L−1 CZ + 0.05 mol L−1 DBC (Fig. 1D), curve B, C, and D was obtained, which can be regarded as the superposition of curves A and E. When the electrolytic solutions contained 0.005 mol L−1 CZ and 0.025 mol L−1 DBC, the anodic polarization curve C (Fig. 1C) was obtained. Curve C was quite different from curve A and E. It can be seen that the oxidation onset of this mixture was initiated at 0.85 V, which was intervenient between CZ and DBC. However, the superposition of curve A and E can not add up to curve E. This may be partly due to some changes of the electrochemical environment caused by successive deposition of two monomers during the anodic polarization, or partly due to the influence of the low electrical conductivity accompanied by the incorporation of CZ unit into the copolymer chain [23]. In addition, the oxidation potential of the mixture was between the values of two monomers, which indicated two monomers were oxidized together and the copolymer chains were composed of CZ and DBC units, also indicating the occurrence of copolymerization [25].

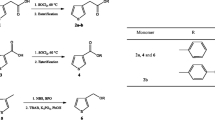

The successive cyclic voltammograms (CVs) of CZ, DBC, and the mixtures of the two monomers with various feed ratios in BFEE at a potential scanning rate of 100 mV s−1, were illustrated in Fig. 2. As the cyclic voltammetry scans continued, polymer films were also observed on the working electrode surface. The increase in the redox wave currents implied that the amount of the polymer on the electrode was increasing [26, 27]. CZ could be reduced and oxidized between 0.4 and 0.8 V (Fig. 2A). The CVs of DBC showed broad redox waves with the reduction and oxidation peaks at 0.67 and 1.1 V, respectively (Fig. 2E). The CVs of the mixtures with various feed ratios were also recorded to choose a suitable feed ratio for copolymerization. When CVs were taken in BFEE containing a CZ/DBC = 0.01/0.005 (Fig. 2B) mixture, their CV curves of the copolymers were similar to that of CZ (Fig. 2A), indicating the domination of CZ units in the copolymer (Fig. 2B). With an increase in the DBC concentration in solution, great changes could be easily observed. When the concentration of DBC was increased to 0.05 M, the CV curve of the copolymer was similar to that of PDBC, implying that more DBC units were incorporated into the copolymer film (Fig. 2D). Therefore, it can be reasonably deduced that when the feed ratios of CZ to DBC were more than 2:1 or less than 1:5, the copolymer was not formed because of the similarity of the CVs to those of pure PDBC and PCZ, respectively. Therefore, an appropriate feed ratio of CZ/DBC = 1:5 was chosen for the copolymerization of CZ and DBC.

Electrochemistry of the copolymer films

To further prove the occurrence of copolymerization, additional studies were carried out for PCZ, PDBC, and the copolymer films prepared with a feed ratio of CZ/DBC=1:5 under a constant applied potential of 1.1 V. The electrochemical behavior of these polymer films were characterized with CV in monomer-free BFEE solutions (Fig. 3) and concentrated H2SO4 (Fig. 4), respectively. From the experimental results, these polymer films could be cycled repeatedly between the conducting and insulating states without significant decomposition. Furthermore, the peak current densities were proportional to the potential scan rates (inset of Figs. 3, 4), indicating that reversible redox couples were fixed on the electrode. In BFEE, PCZ was oxidized and reduced from 0.98 to 0.62 V (Fig. 3A). For PDBC, higher potentials were needed to oxidize or reduce the film (from 1.11 to 0.63 V) (Fig. 3E). On the other hand, the CVs of the copolymer films (CZ/DBC = 1:5) had a new pair of anodic and catholic peaks located at 1.14 and 0.37 V (Fig. 3C), indicating that the two monomers were oxidized together and that the copolymer chain was composed of CZ and DBC units. Similar results were also observed in concentrated H2SO4. A detailed summary of the oxidization and reduction potentials of these polymers in different electrolytes is listed in Table 1.

CVs of A PCZ, B poly(CZ-co-DBC) = 2:1, C poly(CZ-co-DBC) = 1:5, D poly(CZ-co-DBC) = 1:10, and E PDBC recorded in BFEE at potential scanning rates of (a) 50, (b) 100, (c) 150, (d) 200, and (e) 250 mV s−1, which were electrodeposited at the same applied potential of 1.1 V (j = current densities j pa, j pc)

CVs of A PCZ, B poly(CZ-co-DBC) = 2:1, C poly(CZ-co-DBC) = 1:5, D poly(CZ-co-DBC) = 1:10, and E PDBC recorded in concentrated H2SO4 at potential scanning rates of (a) 50, (b) 100, (c) 150, (d) 200, and (e) 250 mV s−1, which were electrodeposited at the same applied potential of 1.1 V (j = current densities, j pa, j pc)

UV–vis and fluorescence spectra

All the copolymers obtained were metallic dark in the doped state, and changed little after dedoping. Therefore, the UV–vis spectra of PCZ, PDBC, and the copolymer dissolved in DMSO were shown in Fig. 5. The broadening of the absorbance of the copolymer in comparison with PCZ and PDBC implied the wide molar mass distribution of the as-prepared films. For the PCZ film (Fig. 5A), there was a maximum absorption peak at 334 nm with a tailor to about 400 nm. This absorption could be ascribed to the π–π* transition of carbazole monomer. At the same time, the very broader peaks around 734 nm can be attributed to the radical cation of carbazole units in the doped state [26]. The PDBC film (Fig. 5E) showed a maximum at 305 nm with a tailor to about 400 nm (π–π* transition). This absorption band could be attributed to the benzene ring in DBC units. This wide peak about 638 nm can be assigned to the absorption of conductive species (polaron or bipolarons) on the main backbone of PDBC in the doped state [27]. As seen from the figure, the spectrum of the copolymer (Fig. 5B–D) showed different characteristic absorptions of both PCZ and PDBC obviously. They showed maximum absorption at 396 nm (Fig. 5B), 310 nm (Fig. 5C) and 314 nm (Fig. 5D) with tailors to about 400 nm, respectively, in addition, they also showed different broader peaks at 756 nm (Fig. 5B), 768 nm (Fig. 5C) and 734 nm (Fig. 5D). Although the absorptions of copolymer were similar to the PCZ and PDBC, however, there was an obviously red shift of the main absorption of the copolymer films in comparison with that of PCZ due to the incorporation of DBC units, further confirming the occurrence of copolymerization. Moreover, there was a small increase in the absorption towards the visible region with the increase in the applied potential during copolymerization.

An important interest of conducting polymers was their unique and promising fluorescence properties. Figure 6 showed the fluorescence spectra of as-formed PCZ, PDBC and the copolymer films in DMSO. It was well known that PCZ was an ideal blue-light emitter polymer [26]. According to Fig. 6, an obvious peak of the emission spectra was found around 410 nm for PCZ and PDBC. Whereas the poly(CZ-co-DBC) = 1:5 (Fig. 6D) had the other peak at 430 nm. This might be due to the interaction between CZ units and DBC units in the copolymer. This indicated that the good blue-light emitter characteristics of PCZ was inherited by the copolymer of poly(CZ-co-DBC) = 1:5 and implied that poly(CZ-co-DBC) = 1:5 might have some potential applications in various fields, such as organic lasers.

Structural characterization

Infrared spectra can provide evidence for the occurrence of copolymerization, especially for those insoluble and infusible. The copolymers prepared potentiostatically from BFEE containing CZ and DBC at 1.1 V were analyzed with FT-IR spectroscopy as shown in Fig. 7, and the monomer of CZ and DBC were also investigated for comparison. From this figure, no apparent difference was found between the FT-IR spectra of the copolymer prepared from BFEE, indicating the similar structure of the polymer obtained with different feed ratio of CZ and DBC.

In Fig. 7B, the band at 734 cm−1 was assigned to the out-of plane vibration of –CH2–CH2–. The band at 1132–1060 cm−1 was assigned to the –CH2–O–CH2– stretching vibration of the monomer [27]. The peaks at 876 cm−1 in the spectra of polymer can be ascribed to the C–H wagging of benzene ring isolated hydrogen, which suggested that benzene ring on PDBC unit was 1, 2, 4, 5-tetrasubstitution. This result implied that the electro-polymerization of DBC was at the 4, 5-position of the benzene ring on DBC unit [27]. The peaks at 804 cm−1 was also assigned to the C–H wagging of benzene ring isolated hydrogen, indicating the occurrence of polymerization on the benzene ring of CZ unit [26]. The bands at 1235 cm−1 were related to the C–C deformation of CZ [26]. The bands in the region from 1440 to 1610 cm−1, which mostly consisted of the C=C and C–C stretching and shrinking modes, were selectively broadened. The peaks at 685 cm−1 were related to the C–C deformation of benzene ring. In Fig. 7C, D, these peaks can also be found. The broad peak at 3400 cm−1 (Fig. 7B) observed in the poly(CZ-co-DBC) = 2:1 spectrum was the characteristic absorption of N–H bond in the CZ unit, which was narrow in the spectrum of poly(CZ-co-DBC) (1:5) (Fig. 7C) and poly(CZ-co-DBC) = 1:10 (Fig. 7D) film. From Fig. 7C, D, the absorption peak at about 2900 and 1446 cm−1 was attributed to the –CH2 stretching of crown ethers of the monomer DBC, but in Fig. 7B the band at 2900 cm−1 was unconspicuous.

Some peaks differ apparently from the polymer of PCZ [26] and PDBC [27] in many regions. This may be due to the interaction between CZ units and DBC units in the copolymer and may be regarded as evidence of copolymerization. On the basis of the previous discussion, the characteristic peaks of CZ and DBC could be found in the spectrum of the copolymer (Fig. 7B). All these features implied that the copolymerization happened during the potentiostatic electro-polymerization of CZ and DBC, in well accordance with the results of CV.

Thermal analysis

The degradation behavior of conducting polymers is very important for their potential applications. Therefore, the thermal analysis of copolymers was tested by thermogravimetric analysis, as shown in Fig. 8. All thermal analyses were performed under a nitrogen stream in the temperature range of 300–1100 K with a heating rate of 10 K min−1. According to Fig. 8A, when the temperature reaches 324 K, the weight loss of the PCZ was about 1%. We can get the similar result in (Fig. 8B–E), But the PDBC has lost about 4%. This degradation can be ascribed to the water evaporation or other moisture trapped in the polymer, which is not necessarily associated with a change in polymer structure [23]. As shown in Fig. 8, prominent decomposition of PCZ was occurred at about 400 K (Fig. 8A). When the temperature reached 700 K, the decomposition was only up to 20% (Fig. 8A). This weight loss was attributed to the degradation of the skeletal PCZ backbone chain structure. And PDBC film started to lose weight when the temperature reached 450 K (Fig. 8E). The decomposition was up to 20% when the temperature reached 577 K (Fig. 8E). But the copolymer obtained at 1.1 V underwent degradation at about 400 K (Fig. 8B–D), and the decomposition was up to 20% when the temperature reached 690 K which was higher than that of PDBC, but lower than that of PCZ. The maximal decomposition rate of PCZ was located at 660 K (Fig. 8A). And the most prominent decomposition of PDBC happened at about 635 K (Fig. 8E). But the corresponding maximum decomposition rates occurred at 654, 673 and 670 K for poly(CZ-co-DBC) (Fig. 8B–D), respectively. When the temperature reached 860 K, the decomposition of PCZ was up to 29% (Fig. 8A), and poly(CZ-co-DBC) was up to 37, 43, and 39% (Fig. 8B–D). But at 860 K, the weight loss of the PDBC was about 80% (Fig. 8E). A detailed summary of the thermal analysis results were listed in Table 2. It could be concluded that PCZ films have better thermal stability compared with PDBC, and poly(CZ-co-DBC). On the other hand, because of the CZ units in the copolymers, the thermal properties of the obtained copolymers were similar to PCZ. All the aforementioned results implied that the incorporation of CZ units into the polymer contributed to the improvement of the thermal properties of PDBC.

Conductivity and morphology

The conductivity of the poly(CZ-co-DBC) = 1:5 film obtained from BFEE was measured to be 0.8 S cm−1, which was significantly higher than that of PCZ (7.5 × 10−3 S cm−1) obtained from BFEE [26], 5.0 × 10−4 S cm−1 obtained from ACN [28], and PDBC (4.1 × 10−2 S cm−1) obtained from BFEE [27], which was listed in Table 3. The poly(CZ-co-DBC) = 1:5 film deposited on the electrode surface was shiny, metallic, compact and smooth. Moreover, the polymer film was very flexible and had a fairly good mechanical property. It can be peeled off from the electrode surface as a free-standing film, as shown in Fig. 9. Another advantage was that much cheaper stainless steel sheet was used as the working electrode for large-area polymer film deposition. In addition, the shape and size can be adjusted by the shape and size of the working electrode.

Conclusions

In summary, high-quality free-standing poly(CZ-co-DBC) = 1:5 films with conductivity of 0.8 S cm−1 were electrochemically synthesized in pure BFEE containing 0.005 mol L−1 CZ and 0.025 mol L−1 DBC. As-formed poly(CZ-co-DBC) films showed good redox activity. TGA results indicated that the copolymer films with good thermal stability can be prepared from BFEE. The fluorescence spectra implied that the copolymer was a good blue light emitter. These copolymer properties could extend the applications of both PCZ and PDBC.

References

Skotheim TA (1986) Handbook of conducting polymers. Marcel Dekker, New York

Skotheim TA, Elsembaumer RL, Reynolds JR (1998) Handbook of conducting polymers, 2nd edn. Marcel Dekker, New York

Bernier P, Lefrant S, Bidan G (1999) Advances in synthetic metals: twenty years of progress in science and technology. Elsevier, New York

Cloutet E, Yammine P, Ades D, Siove A (1999) Synth Met 102:1302

Tirapattur S, Belletete M, Drolet N, Leclerc M, Durocher G (2003) Chem Phys Lett 370:799

Huang J, Niu YH, Yang W, Mo YQ, Yuan M, Cao Y (2002) Macromolecules 35:6080

Abe SY, Bernede JC, Delvalle MA, Tregouet Y, Ragot F, Diaz FR, Lefrant S (2002) Synth Met 126:1

Pandey PC, Prakash RJ (1998) Electrochem Soc 145:4103

Sarac AS, Sezer E, Ustamehmetoglu B (1997) Polym Adv Technol 8:556

Morin JF, Boudreault PL, Leclerc M (2002) Macromol Rapid Commun 23:1032

Huang J, Xu YS, Hou Q, Yang W, Yuan M, Cao Y (2002) Macromol Rapid Commun 23:709

Meng H, Chen ZK, Yu WL, Pei J, Liu XL, Lai YH, Huang W (1999) Synth Met 100:297

Qasrawi AF, Cihaner A, Onal AM (2004) Cryst Res Technol 39:56

Simonet J (1998) Pure Appl Chem 70:1253

Shi GQ, Jin S, Xue G, Li C (1995) Science 267:994

Chen W, Xue G (2005) Prog Polym Sci 30:783

Xu JK, Zhou WQ, Hou J, Pu SZ, Yan LS, Wang JW (2005) J Polym Sci Polym Chem 43:3986

Xu JK, Hou J, Zhang SS, Xiao Q, Zhang R, Pu SZ, Wei QL (2006) J Phys Chem B 110:2643

Ma ML, Liu HT, Xu JK, Li YZ, Wan YQ (2007) J Phys Chem C 111:6889

Liu HT, Xu JK, Pu SZ, Luo MB, Le ZG (2007) Mater Lett 61:1392

Lu BY, Xu JK, Fan CL, Jiang FX, Miao HM (2008) Electrochim Acta 54:334

Lu BY, Xu JK, Fan CL, Miao HM, Shen L (2009) J Phys Chem B 113:37

Nie GM, Xu JK, Zhang SS (2006) J Appl Polym Sci 102:1877

Kuwabata S, Ito S, Yoneyama H (1988) J Electrochem Soc 135:1691

Li L, Chen W, Xu N, Xiao ZG, Xue G (2004) J Mater Sci 39:2395. doi:10.1023/B:JMSC.0000020001.34413.e5s

Nie GM, Xu JK, Zhang SS, Han XJ (2006) J Appl Electrochem 36:937

Zhou WQ, Guo MP, Xu JK, Yuan XL (2008) Eur Polym J 44:656

Hosseini SH, Entezami A (1995) Eur Polym J 31:635

Acknowledgements

NSFC (50663001), the key scientific project from Ministry of Education, China (2007-207058), 2008 Jinggang Star Project of Jiangxi province, Jiangxi Provincial Department of Education (GJJ08369) are acknowledged for their financial supports.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, J., Lu, B., Liu, C. et al. Electrochemical copolymerization of dibenzo-18-crown-6 and carbazole and characterization of their copolymer. J Mater Sci 45, 5769–5777 (2010). https://doi.org/10.1007/s10853-010-4650-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4650-x