Abstract

Frequency and temperature dependence of dielectric constant (εr), dielectric loss (tanδ), ac conductivity (σac) and complex impedance spectroscopy studies on cured polyester matrix and sisal fibre-reinforced polyester composites (SFRPC) have been investigated in the frequency range from 180 Hz to 1 MHz and temperature range from room temperature to 200 °C. The experimental results showed that with the incorporation of sisal fibre, the values of εr, tanδ and σac are increased. It is also found that the values of εr and tanδ for both cured polyester matrix and SFRPC are decreased with increasing frequency, which indicates that the major contribution to the polarization may come from orientation polarization and interfacial polarization. The increasing value of εr with increasing temperature at a particular frequency is due to free motion of the dipole molecular chains within the cured polyester matrix and SFRPC at higher temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plastics are by nature very good insulators. These excellent insulation properties have made plastics as one of the most desirable materials for electrical applications. The use of plastics in electrical applications was limited to nonload bearing general-purpose applications. Fibre-reinforced plastic materials not only act as effective insulators but also provide mechanical support for field carrying conductors. In recent years, natural fibre-reinforced polymer composites have attracted more and more research interests owing to their potential as an alternative for synthetic fibre composites such as glass or carbon fibre composites [1–5]. The most interesting thing about the natural fibres is their environmental friendly nature, since they come from a natural resource, which is completely biodegradable. Natural fibre-reinforced composites are attractive due to their low cost, availability, low density, biodegradability, renewability and high degree of flexibility during processing [6]. Properties of natural fibre composites are influenced by many factors such as fibre loading, dispersion and fibre to matrix adhesion [5, 7–11]. Over the past decade, natural fibres have found use as potential resources for making low cost composite materials. Insulation resistance and dielectric strength of lignocellulosic fibres give an indication of their dielectric constant, current leakages at certain voltages, moisture content and stability under electric fields. Composites as a dielectric are becoming more popular and studies of electrical properties of natural fibre-reinforced polymer composites are therefore very important.The study of electrical properties of such materials also indicates their suitability as insulating materials for special applications such as suspension insulators, bushings, studs, sleeves, gaskets, spacer panels and switch boards [12, 13]. Chemical composition, properties of untreated and various treated sisal fibres along with their composites had been investigated by Li et al. [14]. Kulkarni et al. [7] studied the electrical properties like volume resistivity and dielectric strength of natural fibres. Electrical and mechanical properties of coconut coir fibre-reinforced polypropylene composite with references to the fibre loading and chemical treatment had been reported earlier [15]. The electrical properties of natural fibre were studied by Naik and Mishra [16]. Similar electrical properties of Banana fibre-reinforced phenol formaldehyde composites were also discussed [17]. The relationship between water absorption and dielectric behaviour on polyester matrix composite of glass and jute fibres were studied and it was observed that the dielectric constant of jute fibre composite was higher than that of glass fibre because of higher water uptake of jute fibre than glass [9].

Dutta et al. [18] studied on the mechanical and electrical anisotropy of pineapple fibres. They observed a sharp increase of dielectric constant and fall of loss factor along fibre direction compared with that of the transverse direction because of increase in crystallinity along the fibre direction. Electrical properties of pineapple fibre-reinforced polyethylene composites were investigated by Jayamol et al. [19]. They found an increase in the dielectric constant of composite with fibre loading due to increased orientation and interfacial polarization. Effect of sisal fibre orientation on electrical properties of sisal fibre-reinforced epoxy composites has been studied by Chand et al. [20]. They found that the composites show electrical anisotropic behaviour. The electrical properties of sisal and coir fibre-reinforced LDPE composites were studied by Paul and Thomas [21]. The authors found that dielectric constant values increased with fibre loading this was more predominant at low frequencies. The effect of chemical modification on the electrical properties of sisal fibre-reinforced LDPE composites was also studied by Paul et al. [8]. They found that the dielectric values decreased with chemical modification, because of the decrease in hydrophilicity of fibres. The moisture content in untreated sisal fibre has been reported to be 11.7%, which plays a crucial role in determining the electrical properties of fibre and its composite [22]. Although with the help of theoretical model one can roughly predict the dielectric properties of a material but the results were influenced by many other parameters which were not taken into account [23]. Therefore the experimental evaluations were needed to explore the dielectric properties of polyester and sisal fibre-reinforced polyester composites (SFRPC). Though there are many reports on the electrical properties of fibre-reinforced polymeric system, but the detail study of dielectric and complex impedance properties of SFRPC compared to cured polyester matrix has not been studied yet.

In the present work, the dielectric and complex impedance spectroscopy studies on cured polyester matrix and SFRPC have been investigated and compared in details.

Materials and methods

The sample of sisal fibre was obtained from the Sisal Research Station, Indian Council of Agricultural Research, Bamara, Orissa, India having a diameter of (170–300) μm. The density of the sisal fibre was nearly 1.45 g/cm3 [24]. Unsaturated isophthalic polyester resin having density 1.1 g/cm3 and elastic modulous 3.25 GPa was supplied by Ciba-Giegy Ltd., India.

The fibre under investigation was dewaxed according to the previously reported process, which shows that it attained a hohlraum character, i.e. material packed in layers with free spaces in between [25, 26]. After dewaxing and drying, the sample was designated as ‘air-dried sisal’ having diameter (200–350) μm.

Test sample preparation

Two percent cobalt nephthalate (as accelerator) is mixed thoroughly in isophthalic polyester resin and then 2% methyl-ethyl-ketone-peroxide (MEKP) as hardener is mixed in the resin prior to reinforcement. All these are mixed manually. The above mixture was then poured in 15 mm wax-coated glass tubes and left for curing at room temperature for 24 h. The samples were then called ‘cured polyester matrix’.

The randomly oriented composites were prepared using polyester resin and chopped sisal fibre of (2–4) mm length range. The weight fraction of sisal fibre and polyester resin was kept at 20–80 in the composite. The desired ratios of the resin, accelerator and catalyst were first mixed together. The resulting mixture was thoroughly mixed with the previously weighed sisal fibres until uniform mixture of fibre–resin was obtained and poured into wax-coated glass test tubes of 15 mm diameter to have a cylindrical specimen. Then the samples were cured at room temperature around 28 °C for 24 h. After curing all the samples of polyester and sisal fibre-reinforced composites were recovered by breaking the glass test tubes.

Electrical measurements

Disc shaped specimens of 2 mm thickness were used. Samples were prepared by cutting from the composite specimens using a die. The circular surfaces of the test samples were coated with conductive silver paint. The test samples were fixed between two electrodes and kept inside the sample holder.

The capacitance and dielectric loss measurements in this study were performed by using a computer interfaced LCR HITESTER (3532-50), Japan. Two sets of measurements were carried out: one is from room temperature around 28–220 °C at various frequencies with a heating rate of 2 °C/min and another is from 180 Hz to 1 MHz frequency at various temperatures for the evaluation of dielectric properties of cured polyester matrix and SFRPC.

The dielectric constant (εr) was calculated from the capacitance using the following equation:

where εr is the dielectric constant of the material, ε0 is the permittivity of air (8.85 × 10−12 F/m), C is the capacitance, A is the area of cross section of the sample and t is the thickness of the sample.

Results and discussions

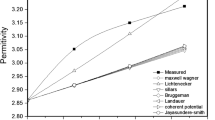

Figure 1 shows the room temperature frequency dependence of dielectric constant (εr) and dielectric loss (tanδ) of the cured polyester matrix. It is found that with increase in frequency the value of εr decreases. The change of εr at lower frequency region is higher than that of at very high frequency. The dielectric constant of a polymeric material depends on interfacial, dipole, electronic and atomic polarization. The atomic and electronic polarizations are instantaneous polarization components, the effect of which is seen only at high frequencies. The dipole or orientation polarization occurs due to the presence of polar groups in the material. The interfacial polarization arises due to heterogeneity, which is highest at lower frequency. Hence, the higher values of εr at low frequency can be explained in terms of interfacial polarization. The value of εr at 10 kHz frequency is found to be ~4.8. The behaviour of tanδ with frequency is very much similar to εr, i.e. with increase in frequency tanδ value also decreases. At lower frequency region the value of tanδ is maximum this may be again due to the presence of interfacial polarization.

The room temperature frequency dependence of dielectric constant (εr) and dielectric loss (tanδ) of the SFRPC is shown in Fig. 2. As in the case of cured polyester matrix, the value of εr was found to decrease with increase in frequency. The higher values of εr is obtained at lower frequency is again may be due to presence of interfacial polarization. Since composite is heterogeneous in nature and interfacial polarization occurs in between the fibre and matrix interface. The frequency dependence of εr is due to the fact that at lower frequencies complete orientation of the molecule is possible. But at medium frequencies there is only little time for orientation of the molecules. Orientation of molecule is not at all possible at very high frequencies. The frequency dependence of εr due to interfacial polarization is similar to those corresponding to dipole polarization. The values of εr and tanδ for SFRPC at 10 kHz frequency are found to be nearly 6.6 and 0.04, respectively.

As it is clear from Figs. 1 and 2 that with incorporation of fibre the value of εr and tanδ increases which may be attributed to the increase in polar groups, originated due to the incorporation of sisal fibre. The value of tanδ in both cured polyester matrix and SFRPC at low frequency region becomes very high due to free motion of dipoles within the material and is connected to ac conductivity relaxation.

The temperature variation of dielectric constant of cured polyester matrix at four different frequencies is shown in Fig. 3a. It is observed that with rise in temperature εr of cured polyester matrix increases. It is also seen from the same figure that an exothermic peak is observed at ~80 °C at 0.5 kHz frequency which confirms the presence of a relaxation process in the polyester matrix. This relaxation is named as α relaxation. Further with increase in frequency this relaxation was shifted towards higher temperature side. This relaxation is associated with glass-rubbery transition of the polymer. Above this transition temperature the mobility of the charges in the polymer increases thus gives rise to the conduction process. As a result of which both εr and tanδ value increases. This result is in agreement with the previously reported results [27]. The similar behaviour can also be observed from the temperature variation of tanδ which is shown in Fig. 3b.

The temperature variation of dielectric constant and loss of SFRPC at four different frequencies is shown in Fig. 4. It is observed that with rise in temperature εr of SFRPC also increases. However, fibre incorporation in polyester matrix did not lead to a detectable evolution of glass transition, hence in the α relaxation. This may be due to the lower cross linking density in the vicinity of fibre. The increase in the value of εr of both cured polyester matrix and SFRPC can be explained on the basis of the increase in segmental mobility of the dipoles at higher temperature. Higher values of εr in case of SFRPC in comparison to the cured polyester matrix may be due to the incorporation of fibre, presence of water and impurities.

The frequency dependence of ac conductivity (σac) in cured polyester matrix at different temperatures in wide range of frequencies is shown in Fig. 5. The ac conductivity (σac) was calculated using an empirical relation, i.e. σac = ωεrε0tanδ, where ε0 is the permittivity in free space, and ω is the angular frequency. The σac patterns show a frequency independent plateau in the low frequency region and exhibits dispersion at higher frequencies. This behaviour satisfies the universal power law σ(ω) = σ0 + Aωn, where σ0 is the dc conductivity (frequency independent plateau in the low frequency region), A is the pre-exponential factor and n is the fractional exponent, whose value lies in between 0 and 1. It is observed that σac of cured polyester matrix increases with the increase in temperature and that confirms the negative coefficient of resistance behaviour. This behaviour also suggests that the electrical conduction is increasing at the higher temperature which may be again due to the increase in the segmental mobility of the polymer molecules.

The frequency dependence of ac conductivity (σac) of SFRPC at different temperatures in wide range of frequencies is shown in Fig. 6. The behaviour of frequency dependence of ac conductivity (σac) of SFRPC is similar to cured polyester matrix, i.e. with increase in temperature σac increases and frequency independent plateau is observed at lower frequency. It is clear from the Figs. 5 and 6 that the σac of SFRPC is higher than the cured polyester matrix, and that may be due to the incorporation of more polar molecules because of hydroxyl groups present in the fibre. Again the addition of fibres enhances the flow of current through the amorphous region due to their ability to absorb moisture [15].

The complex impedance (CI) technique is used to analyze the electrical response of cured polyester matrix and SFRPC in a wide range of frequencies (180 Hz–1 MHz). CI analysis is one of the powerful tools, which has been effectively used for probing into dielectric materials. From this analysis one can resolve the contributions of various processes involved in the electrical conduction. The data in the complex plane can be represented in any of the four basic formalisms. The four formalisms are complex impedance (Z*), complex admittance (Y*), complex permittivity (ε*) and complex modulus (M*).

The imaginary part of impedance (Z″) with frequency at different temperature for cured polyester matrix is shown in Fig. 7. The curves show that the Z″ values reach a maxima peak (\(Z_{\max}^{\prime\prime}\)) for the temperature around 160 °C and the value of \(Z_{\max}^{\prime\prime}\) shifts towards higher frequencies with increasing temperature. The broadening of peaks in frequency explicit plots of Z″ suggests that there is a spread of relaxation times, i.e. the existence of a temperature dependent electrical relaxation phenomenon in the material. The merger of Z″ values in the higher frequency region may possibly be an indication of the accumulation of charges in the matrix. It is also seen that at higher temperature Z″ values decreases. The plot of Z″ versus frequency of SFRPC at different temperatures is shown in Fig. 8. The behaviour of SFRPC is similar to cured polyester matrix. In this case the Z″ values reach a maxima peak (\(Z_{\max}^{\prime\prime}\)) for the temperature around 200 °C which may be due to the incorporation of fibre.

The complex impedance spectrum (Z″ versus Z′) of cured polyester matrix is shown in Fig. 9. The impedance data are taken over the specified frequency range at several temperatures. It is observed that with the increase in temperature, the slope of the lines decreases and their nature bend towards real (Z′) axis. In case of cured polyester matrix semi-circle was observed around 160 °C. This indicates that the conductivity is increasing with the increase in temperature. The plot of Z″ versus Z′ of SFRPC is shown in Fig. 10. The behaviour is very much similar to cured polyester matrix. But in this case semi-circle was observed around 180 °C.

Figure 11a, b shows the frequency dependence of Z′ and Z″ of cured polyester matrix and SFRPC at 200 °C. As it is seen from these figures that with the rise in frequency Z″ increases and Z′ decreases. This trend continues up to a particular frequency, where Z″ occupies a maximum value and Z′ intersects it. Further increase in frequency leads to decrease in the value of both Z′ and Z″. Above 10 kHz both the values merge with the logarithmic frequency axis. This indicates that there exists relaxation behaviour in cured polyester matrix as well as in SFRPC.

Conclusion

In the present work, the dielectric ac conductivity and impedance properties of cured polyester matrix and SFRPC have been studied over the temperature range from room temperature to 200 °C and frequency range from 180 Hz to 1 MHz. The frequency dependence of Z′ and Z″ indicates the relaxation behaviour in SFRPC is like that of cured polyester matrix. The complex impedance spectrum (Z″ versus Z′) confirms that with the increase in temperature, the slopes of the lines decrease and bend towards Z′-axis, which further confirms the increase in ac conductivity in the composite samples. The results in this study indicates that the dielectric constant (εr), dielectric loss (tanδ) and ac conductivity (σac) were found to be increased with the incorporation of the sisal fibre. This property may help to retain the electric charges over a longer period of time and can be exploited for antistatic applications.

References

Joseph S, Sreekala MS, Oommen Z, Koshy P, Thomas S (2002) Compos Sci Technol 62:1824

Li T, Matuana LM (2003) J Appl Polym Sci 88:278

Lundquist L, Marque B, Hagstrand PO, Leterrier Y, Manson JAE (2003) Compos Sci Technol 63:137

Eichhorn SJ, Baillaie CA, Zafeiropoulos N, Mwaikambo LY, Ansell MP, Dufresne A, Kentwistle PJ, Herrera-Ffranco PJ, Escamilla GC, Groom J, Hughes M, Hull C, Rials TG, Wild PM (2001) J Mater Sci 36:2107. doi:10.1023/A:1017512029696

Bledzki AK, Gassan J (1999) J Prog Polym Sci 24:221

Devi LU, Bhagawan SS, Thomas S (1997) J Appl Polym Sci 64:1739

Kulkarni AG, Satyanarayana KG, Rohatgi PK (1983) J Mater Sci 18:2290. doi:10.1007/BF00541832

Paul A, Joseph K, Thomas S (1997) Compos Sci Technol 57:67

Reid JD, Lawrence WH, Buck RP (1986) J Appl Polym Sci 30:1771

Chand N, Verma S, Khazanchi AC (1989) J Mater Sci Lett 8:1307

Abdelmouleh M, Boufi S, Belgacem MN, Dufresne A, Gandini A (2007) Compos Sci 67:1627

Mukherjee PS, De AK, Battacharjee S (1978) J Mater Sci 13(8):1824. doi:10.1007/BF00548749

Datta AK, Mukherjee PS, Mitra GB (1980) J Mater Sci 15:1856. doi:10.1007/BF00550607

Li Y, Mai Y-W, Lin Y (2000) Compos Sci Technol 60:2037

Lai CY, Sapuan SM, Ahmad M, Yahya N, Dahlan KZHM (2005) Polym Plast Technol Eng 44:619

Naik JB, Mishra S (2005) Polym Plast Technol Eng 44:687

Joseph S, Thomas S (2008) J Appl Polym Sci 109:256

Dutta AK, Samantary BK, Bhattachderjee S (1984) J Mater Sci Lett 3:667

Jayamol G, Bhagawan SS, Thomas S (1997) J Polym Eng 17:5

Chand N, Jain D (2005) Composites A 36:594

Paul A, Thomas S (1997) J Appl Polym Sci 63:247

Sydenstricker THD, Sandro M, Sandro CA (2003) Polym Test 22:375

Yangyang S, Zhuqing Z, Wong CP (2005) Polymer 46:2297

Mohanty AK, Misra M, Hinrichsen G (2000) Macromol Mater Eng 276–277:1

Roy SC (1960) Textile Res J 30(b):451

Ratho T, Torasia S, Mohanty JC (1964) Indian J Phys 38(1):28

Amor IB, Rekik H, Kaddami H, Raihane M, Arous M, Kallel A (2009) J Electrostat 67:717

Acknowledgements

Profound appreciation and gratitude is extended to one and all the members of the department of physics, NIT Rourkela for their valuable suggestions during completion of the manuscript of this paper. No doubt, all kinds of cooperation that is rendered by the Director, NIT Rourkela to provide all infrastructural facilities during the progress of this piece of work and so our sincere gratitude is also indebted to him.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patra, A., Bisoyi, D.K. Dielectric and impedance spectroscopy studies on sisal fibre-reinforced polyester composite. J Mater Sci 45, 5742–5748 (2010). https://doi.org/10.1007/s10853-010-4644-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4644-8